In the realm of high-pressure cleaning equipment, having a clear understanding of how various elements are organized is crucial for both maintenance and troubleshooting. Whether you’re a professional or a DIY enthusiast, familiarity with the arrangement of internal mechanisms can enhance your ability to keep your device running smoothly. A well-structured overview of these components aids in identifying parts and understanding their functions.

Detailed schematics serve as essential tools, offering insights into the intricate relationships between different sections of the machine. By exploring these layouts, users can easily locate specific items, enabling efficient repairs and replacements. Furthermore, a comprehensive visual guide can simplify the learning curve for those new to handling such equipment.

As you delve into the specifics of component arrangements, it becomes clear that each part plays a vital role in the overall performance of the system. This knowledge not only fosters confidence in addressing issues but also empowers users to extend the lifespan of their devices through informed care and maintenance practices.

Dewalt DXPW3625 Overview

This section provides a comprehensive look at a powerful pressure cleaning device designed for efficiency and ease of use. Built to tackle various cleaning tasks, it stands out in the market due to its robust construction and versatile features.

Key Features

- High-performance motor for effective cleaning

- Multiple nozzle options for different surfaces

- Ergonomic design for user comfort

- Durable frame to withstand heavy use

Applications

- Cleaning vehicles and outdoor furniture

- Removing grime from patios and driveways

- Restoring surfaces like decks and fences

Key Features of the Pressure Washer

When considering a high-performance cleaning device, several attributes set it apart from others in the market. These features enhance its usability, effectiveness, and durability, making it an essential tool for various cleaning tasks.

- Powerful Motor: A robust motor ensures efficient water flow and pressure, allowing for quick and thorough cleaning.

- Adjustable Pressure Settings: The ability to modify pressure levels offers versatility, making it suitable for different surfaces, from delicate materials to tough grime.

- Durable Construction: High-quality materials contribute to longevity and reliability, even under heavy use.

- Mobility Features: Equipped with wheels and a lightweight design, the unit can be easily transported and maneuvered around various job sites.

- Variety of Nozzles: Different nozzle attachments enable customization for specific tasks, enhancing cleaning effectiveness.

- Built-in Detergent Tank: A dedicated tank allows for easy application of cleaning agents, increasing efficiency in tackling tough stains.

These features combine to provide an exceptional cleaning experience, ensuring that users achieve optimal results with minimal effort.

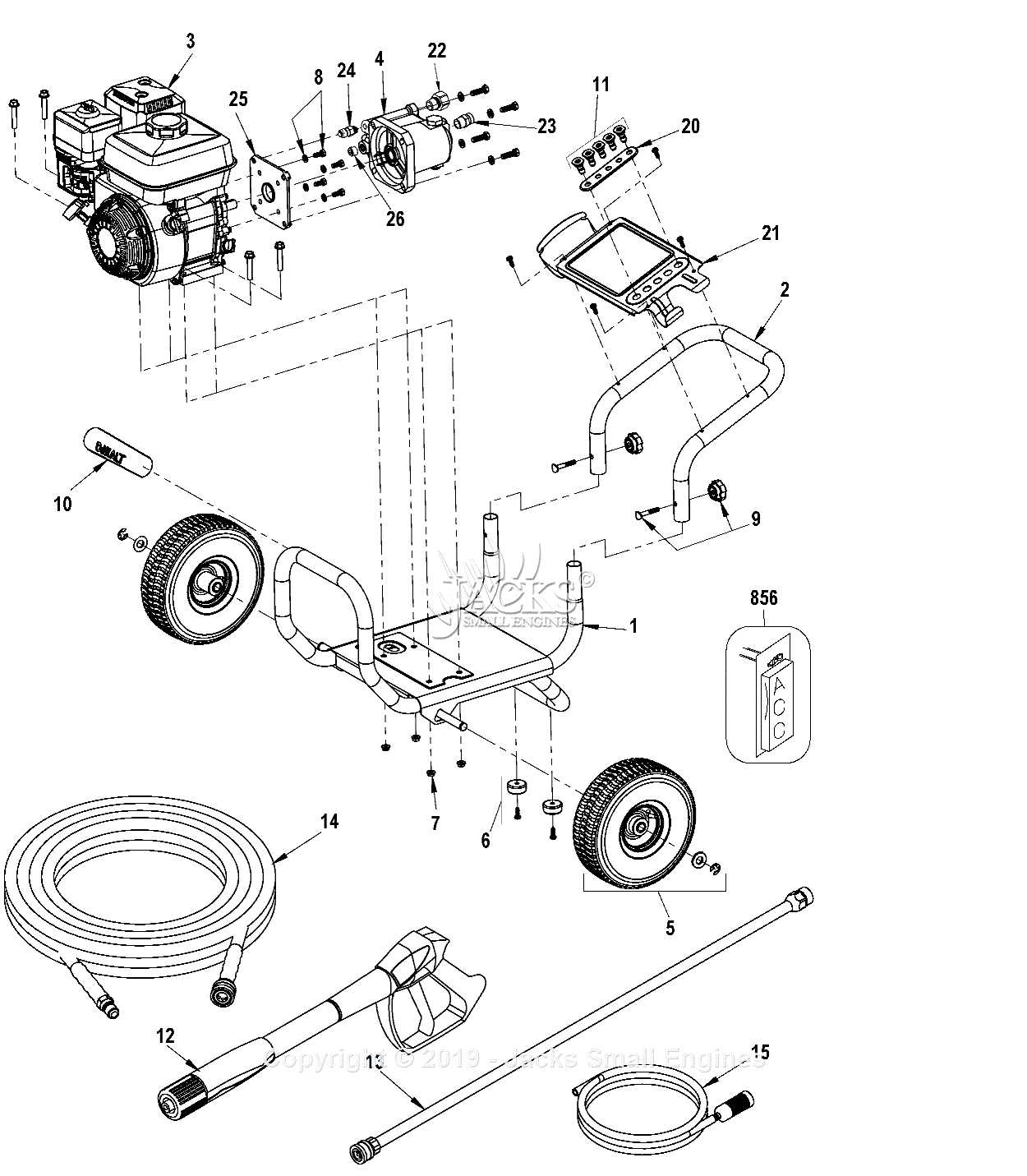

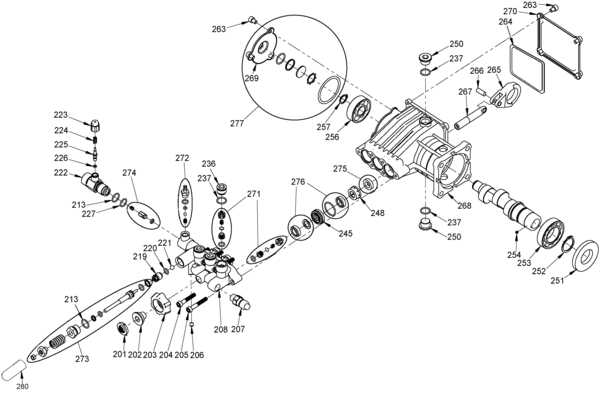

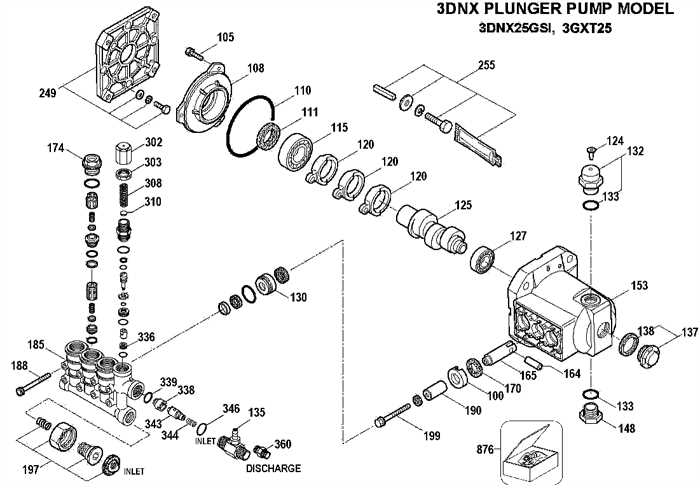

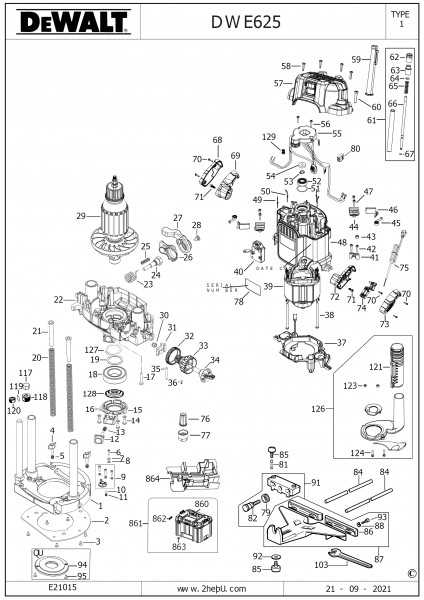

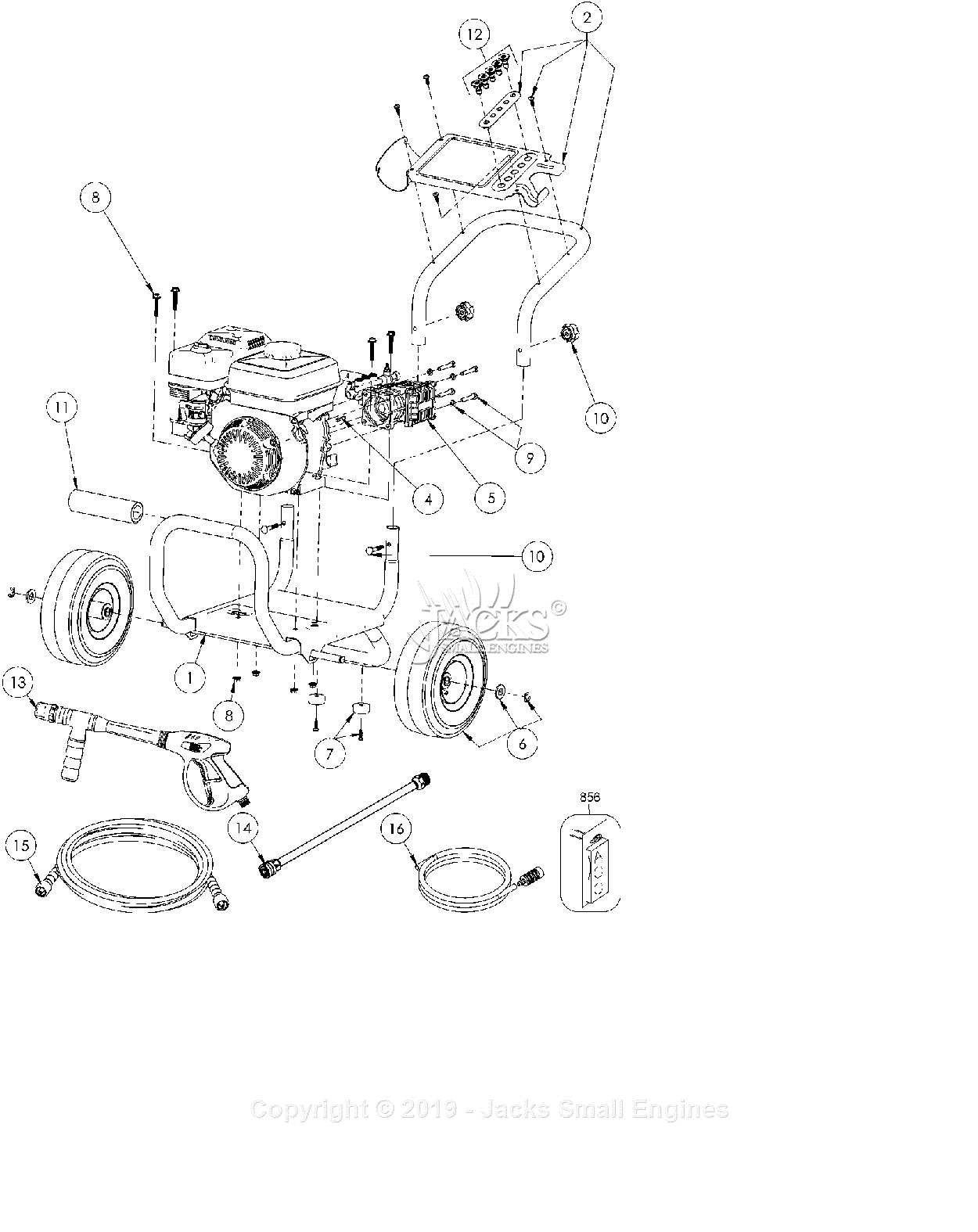

Understanding the Parts Diagram

Grasping the visual representation of components is essential for effective maintenance and repair. This illustration serves as a guide, outlining the essential elements and their interrelations, allowing users to navigate through the complexities of the machinery with ease.

Benefits of Component Visualization

A comprehensive illustration facilitates quick identification of individual pieces, streamlining the troubleshooting process. By having a clear reference, users can pinpoint issues, order necessary replacements, and ensure proper assembly, ultimately enhancing the longevity of the equipment.

Utilizing the Illustration for Repairs

When performing repairs, referring to the visual reference allows for a systematic approach. Each part’s placement and connection are depicted clearly, ensuring that users can delve into repairs with confidence and precision, minimizing the risk of errors.

Essential Components Explained

Understanding the fundamental elements of any pressure machine is crucial for effective operation and maintenance. Each component plays a vital role in ensuring the equipment runs smoothly and efficiently, contributing to overall performance and longevity. This section delves into the primary parts that constitute a typical high-pressure system, highlighting their functions and importance.

Key Elements Overview

In a high-pressure system, several core components work in unison. These elements include the motor, pump, and various valves, each serving a specific purpose. A clear grasp of these components can facilitate troubleshooting and enhance user experience.

| Component | Function |

|---|---|

| Motor | Powers the pump to generate high pressure. |

| Pump | Increases the water pressure for effective cleaning. |

| High-Pressure Hose | Transmits the pressurized water to the nozzle. |

| Nozzle | Controls the spray pattern and intensity of water. |

| Valves | Regulate water flow and pressure within the system. |

Importance of Regular Maintenance

To ensure optimal performance, regular upkeep of these essential components is necessary. Neglecting any part can lead to reduced efficiency or even failure of the equipment. Understanding each component’s role allows users to identify potential issues early, ensuring a reliable and effective high-pressure experience.

Common Issues and Solutions

This section explores frequent problems encountered with high-performance equipment and their corresponding solutions. Understanding these common issues can help ensure optimal functionality and longevity of the machinery.

| Issue | Possible Cause | Solution |

|---|---|---|

| Overheating | Clogged filters | Clean or replace the filters regularly. |

| Weak pressure | Worn pump seals | Inspect and replace seals as necessary. |

| Noisy operation | Lack of lubrication | Apply appropriate lubricant to moving parts. |

| Difficulty starting | Faulty ignition system | Check and repair the ignition components. |

| Leaking fluid | Deteriorated hoses | Replace damaged hoses immediately. |

Maintenance Tips for Longevity

Proper upkeep is essential to ensure the durability and optimal performance of your equipment. Regular attention not only enhances functionality but also prolongs the lifespan of your tools, preventing unnecessary repairs and replacements.

Start with routine inspections to identify any signs of wear or damage. Cleaning your equipment after each use removes debris that can cause corrosion and affect performance. Ensure all moving parts are adequately lubricated to minimize friction and enhance efficiency.

Store your tools in a dry, protected environment to avoid moisture-related issues. Keep an eye on electrical components for fraying or damage, as these can lead to serious malfunctions. Lastly, refer to the manufacturer’s guidelines for specific maintenance recommendations tailored to your model.

Where to Find Replacement Parts

Locating components for your equipment can seem challenging, but several resources can help streamline the process. Whether you’re dealing with a malfunction or planning maintenance, knowing where to search is essential.

- Manufacturer’s Website: Often, the official site provides an extensive catalog of items along with detailed descriptions.

- Authorized Retailers: Check local or online stores that specialize in tools; they usually carry a range of accessories and components.

- Online Marketplaces: Websites like Amazon or eBay often have listings from various sellers, making it easier to compare prices.

- Repair Shops: Local repair centers may have spare parts or can guide you on sourcing them.

- Forums and Community Groups: Engaging with user communities can provide leads on where to find specific items.

Utilizing these resources can ultimately enhance your chances of obtaining the necessary components efficiently.

Comparing OEM vs. Aftermarket Parts

The choice between original equipment and alternative components often hinges on performance, cost, and reliability. Understanding the differences can help users make informed decisions based on their specific needs.

Benefits of OEM Components

- Designed specifically for the original model.

- Typically offer superior quality and reliability.

- Often come with warranties and customer support.

Advantages of Aftermarket Options

- Usually more affordable than original parts.

- Wide variety available, offering customization options.

- Can be easier to source from multiple suppliers.

Ultimately, the decision should consider budget constraints, performance requirements, and availability.

Assembly Instructions for Beginners

When embarking on a new project, understanding how to properly assemble various components is crucial for success. This guide aims to simplify the process, providing clear steps to help novices navigate through the intricacies of putting parts together. Following these instructions will ensure a smoother assembly experience and help avoid common pitfalls.

Before you begin, make sure you have all necessary components and tools at hand. A well-organized workspace can significantly enhance your efficiency and focus.

| Step | Action | Tips |

|---|---|---|

| 1 | Lay out all pieces in a logical order. | Check the manual for reference. |

| 2 | Identify the primary components and their functions. | Group similar parts together. |

| 3 | Begin with the base assembly. | Ensure everything is aligned correctly. |

| 4 | Gradually add subsequent parts. | Double-check connections as you go. |

| 5 | Secure all connections firmly. | Use the appropriate tools for tightness. |

| 6 | Review your work for any missed steps. | Refer back to your layout for accuracy. |

By following these basic guidelines, beginners can build confidence in their assembly skills and ensure a successful outcome in their projects.

Tools Required for Repair

When undertaking maintenance or repairs on equipment, having the right tools is essential for ensuring efficiency and effectiveness. A well-equipped toolkit not only simplifies the process but also enhances safety and precision. Below is a list of necessary instruments that can facilitate a successful repair.

- Screwdrivers: A variety of screwdrivers, including both flathead and Phillips, will be needed to remove and secure screws.

- Wrenches: Adjustable and socket wrenches are vital for loosening or tightening bolts.

- Pliers: Needle-nose and slip-joint pliers can help grip, twist, and cut wires or other materials.

- Socket Set: A comprehensive socket set will allow for better access to tight spaces and provide more torque.

- Utility Knife: A sharp utility knife is useful for cutting various materials safely and accurately.

In addition to the basic tools, consider the following specialized equipment that may be beneficial:

- Torque Wrench: Essential for applying a specific amount of torque to fasteners.

- Multimeter: Useful for diagnosing electrical issues by measuring voltage, current, and resistance.

- Inspection Mirror: Helps to view hard-to-reach areas and identify potential problems.

- Work Light: Adequate lighting is crucial for seeing small components and details during repair.

Having these tools at hand will not only aid in executing repairs but also contribute to a smoother and more organized workflow. Always ensure that your tools are in good condition before starting any maintenance tasks.

Safety Precautions During Repairs

Ensuring safety while performing maintenance tasks is essential for both personal well-being and effective operation of equipment. Proper precautions minimize risks and prevent accidents, creating a secure environment for repairs.

General Safety Measures

- Wear appropriate personal protective equipment (PPE) such as gloves and goggles.

- Work in a well-ventilated area to avoid inhaling harmful fumes.

- Keep the workspace organized to prevent tripping hazards.

- Disconnect power sources before starting any repairs.

Handling Tools Safely

- Inspect tools for damage before use.

- Use the right tool for each job to avoid unnecessary strain.

- Store tools properly when not in use to prevent accidents.

- Never bypass safety features on tools and equipment.

Upgrading Your Dewalt Pressure Washer

Enhancing your pressure cleaning equipment can significantly improve its performance and extend its lifespan. By investing in quality components and accessories, you can achieve better efficiency and effectiveness during your cleaning tasks. This section will explore various upgrades to consider for your machine.

Essential Accessories

One of the simplest ways to boost functionality is by adding essential accessories. A high-quality nozzle set allows for versatile cleaning options, enabling you to switch between different spray patterns depending on the task at hand. Furthermore, incorporating a longer hose can provide greater reach, making it easier to tackle larger areas without moving the unit frequently.

Performance Enhancements

Upgrading the internal components can yield remarkable results. Consider replacing the standard pump with a more efficient model that offers increased pressure output. Additionally, enhancing the motor can lead to better reliability and performance under heavy use. Regular maintenance and timely upgrades not only improve your equipment’s functionality but also ensure it operates smoothly for years to come.