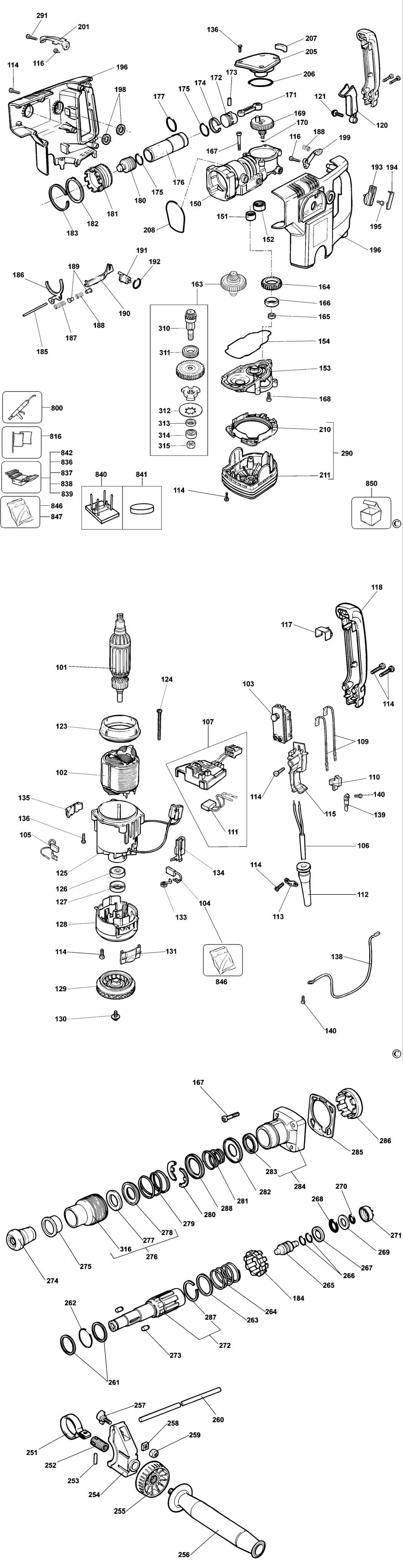

Understanding the configuration and placement of essential elements in outdoor equipment is crucial for maintaining and optimizing performance. Having a clear visualization of how each mechanism works together can make repairs and replacements easier, ensuring that all parts function harmoniously. A well-organized schematic can be an invaluable resource in identifying issues and locating the correct replacement pieces.

Each tool relies on a series of interconnected systems that contribute to its overall efficiency. By familiarizing yourself with the positioning and function of these vital parts, you can extend the lifespan of your equipment and enhance its operational capabilities. Whether you are performing routine maintenance or troubleshooting

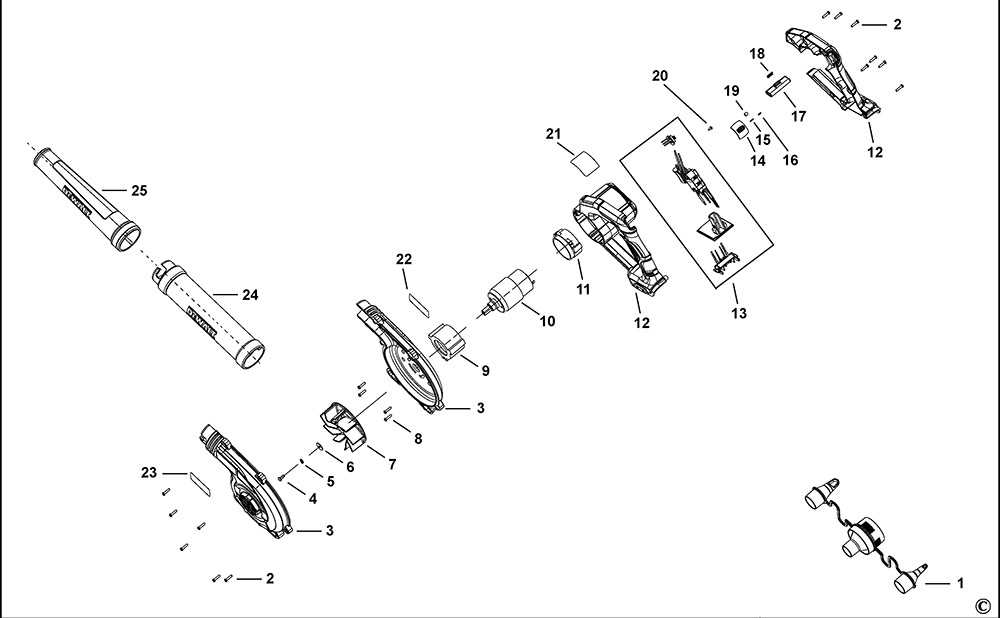

Essential Components Overview

In this section, we will explore the primary elements that make up this outdoor trimming tool. Each component plays a crucial role in ensuring optimal performance and smooth operation during yard maintenance. Understanding the different sections and how they function together can help in troubleshooting and maintaining your equipment effectively.

Main Structural Elements

- Motor Housing: Protects the engine and ensures the tool operates efficiently.

- Handle: Provides grip and control

Main Components and Their Functions

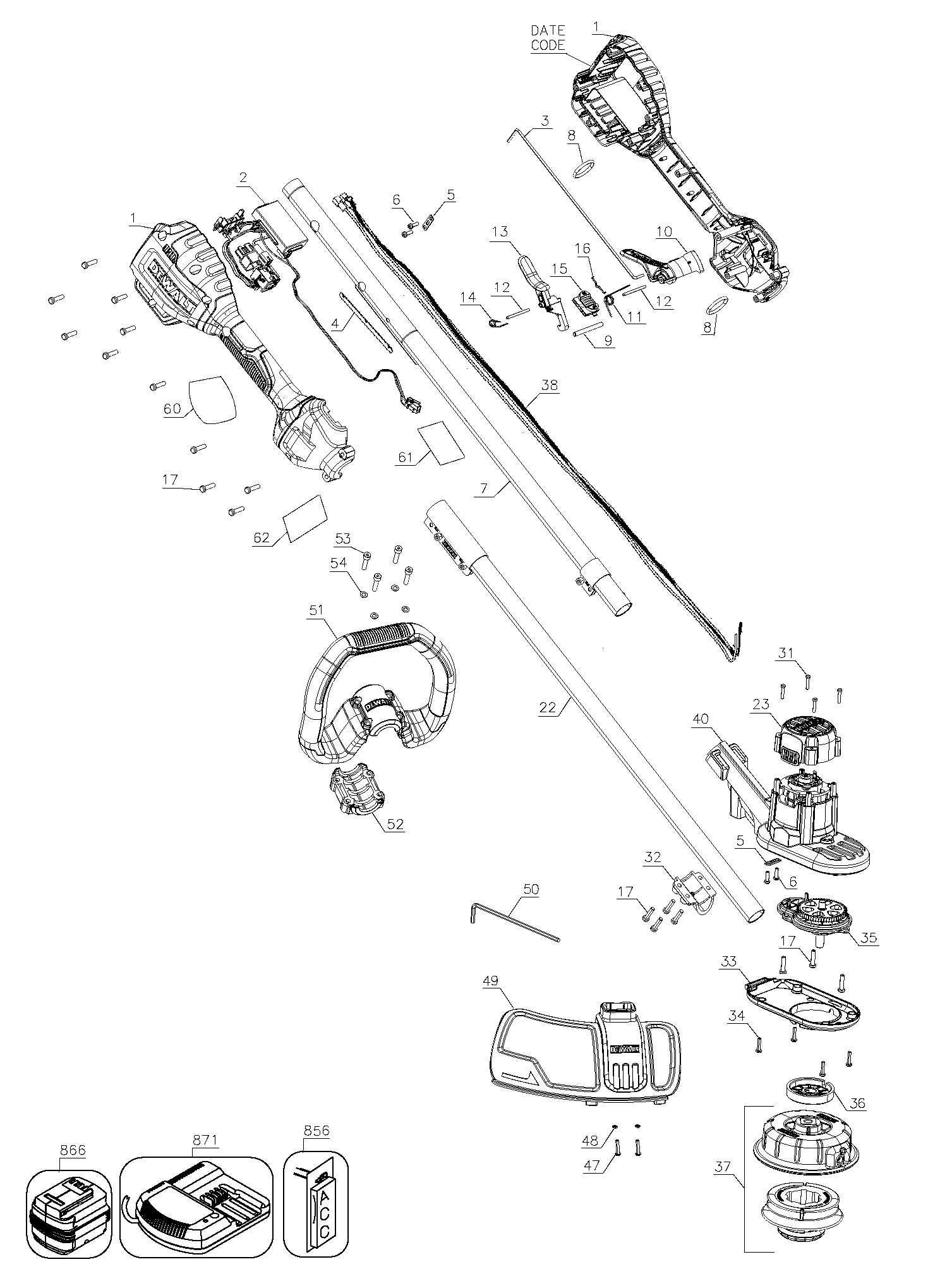

Understanding the key elements of this type of device is crucial for ensuring optimal performance and longevity. Each section plays a specific role in maintaining the overall functionality, contributing to the efficiency and ease of use during operation.

Power Source: The main energy supplier, responsible for providing the necessary force to drive the mechanism. It ensures that the device operates smoothly, allowing it to handle various tasks.

Drive Shaft: This component transmits power from the source to the cutting mechanism. Its structure is

Identifying Essential Parts for Repair

When maintaining outdoor equipment, it is crucial to understand which components are most likely to require replacement over time. Familiarity with the individual elements of the tool allows for more efficient troubleshooting and ensures that the correct items are chosen during repairs. Recognizing these critical pieces can help extend the lifespan of the device and improve overall performance.

Key elements such as the power source, motor, and cutting mechanism are commonly subject to wear and tear. Proper identification of these parts enables users to address issues promptly, reducing downtime and preventing further damage. It’s important to inspect these components regularly and ensure that replacements a

Understanding the Motor Assembly

The motor assembly is the core component responsible for powering the entire system. By converting electrical energy into mechanical movement, this unit drives the functionality of the device, ensuring optimal performance. A thorough understanding of how the motor functions and interacts with other elements is crucial for both maintenance and troubleshooting.

Main Components of the Motor

At the heart of the motor assembly are several key components, including the rotor, stator, and drive shaft. These parts work in unison to generate rotational force, which is then transmitted to other areas

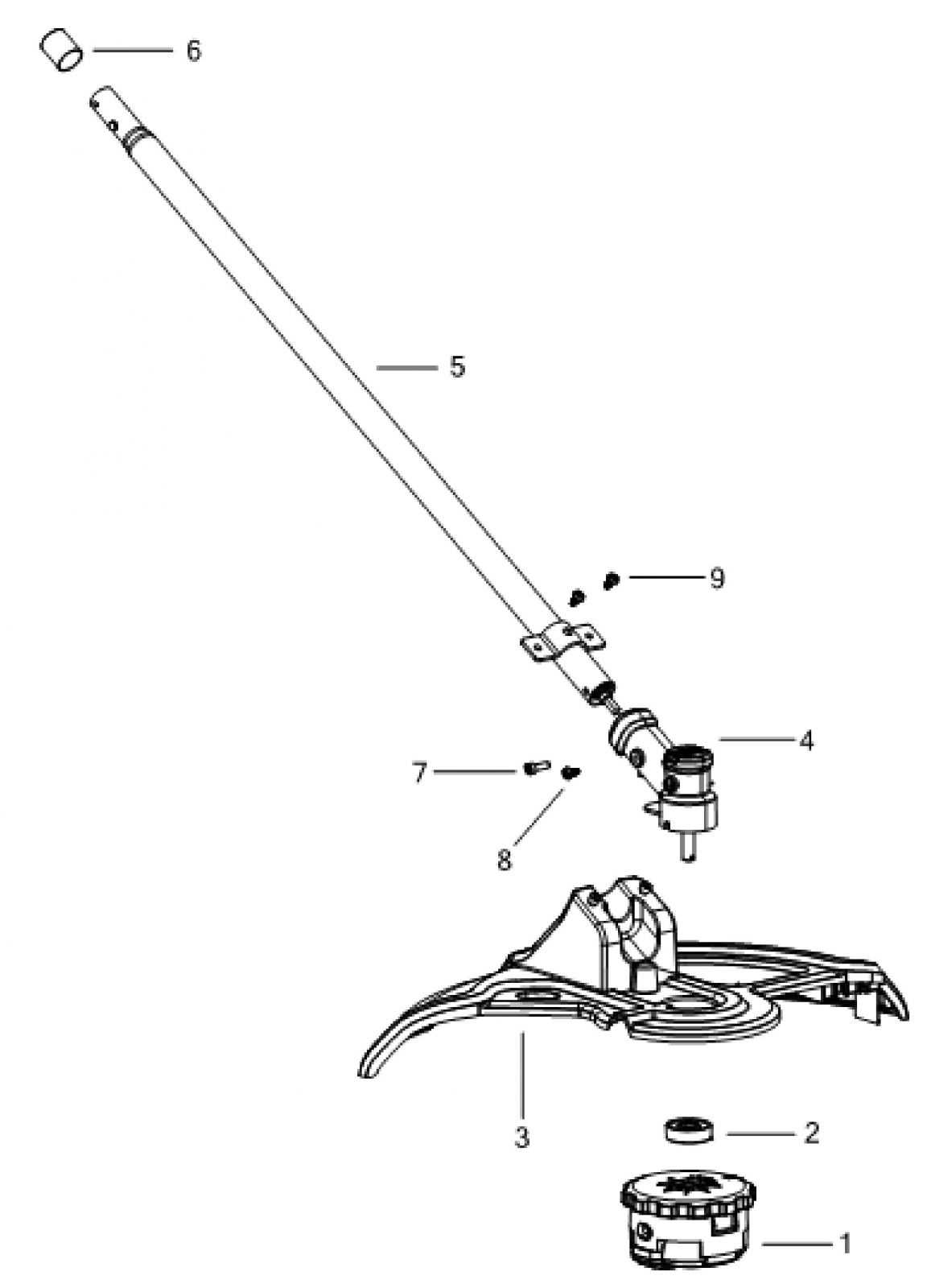

Guide to the Trimmer Head Assembly

The trimmer head is a crucial component responsible for the cutting mechanism, allowing the tool to maintain an efficient trimming process. This section will provide a step-by-step guide on assembling the key parts of the head to ensure optimal performance during operation.

Step 1: Preparing the Components

Before beginning the assembly, ensure all necessary parts are laid out and in proper working condition. This includes the line spool, housing, and any securing bolts or caps required for the assembly.Step 2: Installing the Line Spool

Insert the spool into the designatedHow the Driveshaft Works

The driveshaft is a crucial component that transmits power from the engine to various mechanisms, allowing for efficient operation of the equipment. It plays a vital role in ensuring that energy is effectively transferred to the working parts, enabling smooth functionality.

This component typically consists of a long, rotating shaft that connects the engine to the cutting or working mechanisms. As the engine operates, it generates rotational energy, which is then conveyed through the driveshaft. This energy transfer is essential for the device to perform its intended tasks, such as trimming or cutting.

Moreover, the driveshaft is designed to absorb vibrations and handle torque, which helps maintain stability during operation. Its construction often includes flexible joints or couplings that accommodate movement and reduce wear over time. Overall, understanding the mechanics of the driveshaft can enhance the user’s ability to maintain and troubleshoot the equipment effectively.

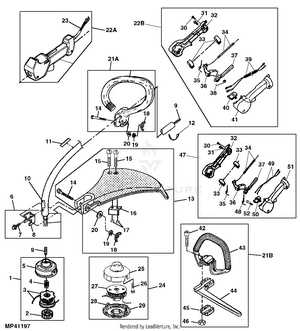

Exploring the Handle and Controls

Understanding the handle and controls of your outdoor power equipment is essential for effective operation and comfort during use. These components are designed to provide ease of handling, allowing the user to maneuver the device with precision. A well-structured handle can significantly enhance the overall experience, reducing fatigue and improving control.

The grip of the handle is typically designed for ergonomics, offering a comfortable surface that minimizes strain on the hands. Many models feature adjustable handles that can be modified to suit the user’s height and preferred operating position. This adaptability ensures that users can find a suitable stance, promoting better posture and reducing the risk of injury.

Control mechanisms are strategically placed for intuitive access, allowing for quick adjustments while operating the equipment. Common features include trigger switches, throttle controls, and safety locks, each contributing to a seamless and safe experience. Understanding these controls is vital for efficient usage, enabling the operator to manage speed and power with ease.

Regular inspection and maintenance of the handle and control components are crucial for ensuring safety and performance. Keeping these areas free from debris and ensuring that all parts are functioning correctly can prevent operational issues and enhance longevity. By paying attention to these details, users can enjoy a more effective and enjoyable experience with their outdoor tools.

Differences in Cutting Attachments

When it comes to outdoor maintenance tools, the choice of cutting accessories can significantly impact performance and efficiency. Various designs and configurations are available, each tailored to specific tasks and conditions. Understanding these distinctions helps users select the most suitable option for their gardening and landscaping needs.

Types of Cutting Attachments

Attachment Type Usage Benefits String Trimmer Head Grass and light weeds Flexible and easy to use, ideal for precision cutting. Metal Blade Thick vegetation Durable and effective for tackling tougher materials. Edger Blade Landscaping edges Provides a clean and defined border along paths and flowerbeds. Factors to Consider

Choosing the right cutting attachment depends on several factors, including the type of vegetation, the terrain, and the desired outcome. Compatibility with the tool and ease of attachment are also crucial considerations. By evaluating these elements, users can enhance their efficiency and achieve the best results in their outdoor tasks.

Maintenance Tips for Longevity

Proper upkeep of your outdoor equipment is essential for ensuring optimal performance and extending its lifespan. Regular maintenance can prevent unnecessary wear and tear, keeping your device functioning efficiently over the years.

Regular Cleaning

- After each use, remove debris and dirt from the exterior.

- Inspect the cutting mechanism for any buildup that could hinder performance.

- Use a soft brush or cloth to wipe down components to prevent rust and corrosion.

Check and Replace Consumables

- Regularly inspect and replace worn-out components, such as lines and filters.

- Ensure that all moving parts are adequately lubricated to reduce friction.

- Store equipment in a dry place to prevent moisture-related damage.

Replacing Worn-Out Parts

Maintaining optimal performance in your garden tool often requires the replacement of aged components. Over time, frequent use can lead to wear and tear, resulting in diminished efficiency and effectiveness. Addressing these issues promptly can restore functionality and prolong the lifespan of the equipment.

Identifying Components for Replacement

Before initiating the replacement process, it’s crucial to identify which elements have become worn or damaged. Common indicators include unusual noises, reduced power, or difficulty in operation. Conducting a thorough inspection will help pinpoint the specific components that need attention.

Steps for Effective Replacement

Once the necessary components are identified, follow these steps for a successful replacement:

- Gather Tools: Ensure you have the right tools, such as screwdrivers and pliers, ready for the task.

- Follow Manufacturer Guidelines: Refer to the provided instructions for the correct procedure and safety measures.

- Install New Components: Carefully remove the old items and replace them with new ones, ensuring they fit securely.

- Test Functionality: After replacing the components, run a test to confirm that the equipment operates smoothly.

By following these steps, you can effectively address any issues related to worn components, ensuring your tool remains reliable and efficient in your gardening tasks.

Accessories to Enhance Performance

Improving the efficiency and functionality of outdoor equipment can be significantly achieved through various supplementary tools and attachments. These enhancements not only optimize performance but also extend the lifespan of the machinery, ensuring a smoother and more effective operation.

Types of Enhancements

Investing in high-quality accessories can elevate the user experience. For instance, specialized cutting tools can provide sharper and more precise results, while additional handles or grips can improve control and comfort during usage. Moreover, power boosters can increase the overall efficiency, enabling the machine to handle tougher tasks effortlessly.

Maintenance and Care Tools

Incorporating maintenance accessories is equally essential. Items such as lubricants, cleaning kits, and protective covers can greatly contribute to the longevity and upkeep of the equipment. Regular maintenance not only ensures optimal functionality but also minimizes the risk of breakdowns, allowing users to achieve their gardening goals without interruptions. Overall, the right accessories can make a significant difference in performance and satisfaction.