In the realm of firearm enthusiasts, the intricate design and functionality of weaponry are paramount. Knowledge of various elements that contribute to a firearm’s operation can significantly enhance one’s appreciation and expertise. This section delves into the essential components that play a critical role in the performance and reliability of these sophisticated tools.

Each element serves a specific purpose, working in unison to ensure optimal functionality. By exploring the arrangement and relationship between these components, one gains insight into how they influence overall performance. This understanding is not only beneficial for maintenance but also fosters a deeper connection with the equipment itself.

As we navigate through the intricacies of these mechanisms, it becomes evident that mastery over their configuration can elevate a user’s experience. Whether for competitive shooting or recreational use, comprehending these fundamental aspects is crucial for anyone seeking to enhance their proficiency and enjoyment in handling such devices.

Overview of Benelli Shotgun Components

This section provides a comprehensive look at the various elements that make up a renowned firearm, focusing on their functions and interactions. Understanding these components is essential for enthusiasts and users alike, as it enhances familiarity with the weapon’s mechanics and operational efficiency.

Key Elements of the Firearm

- Receiver: The central hub where all major components are housed, playing a crucial role in housing the trigger mechanism.

- Barrel: This elongated tube directs the projectile, significantly influencing accuracy and range.

- Stock: The rear portion that provides stability during aiming and shooting, crucial for overall control.

- Forend: Located at the front, it helps in gripping the firearm securely and supports the shooter’s technique.

Additional Components

- Chamber: The area where the ammunition is loaded before firing.

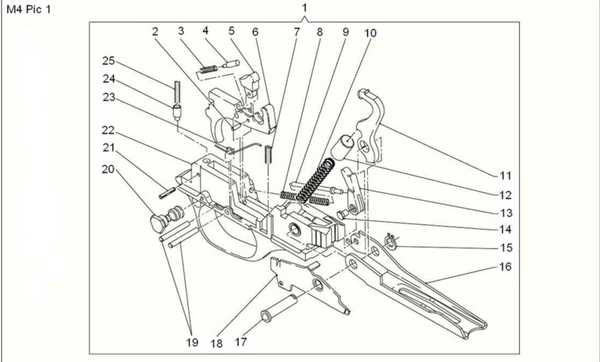

- Trigger Group: This assembly facilitates the firing process, consisting of mechanisms that engage when the trigger is pulled.

- Sights: Essential for aiming, these components assist the user in aligning the firearm accurately with the target.

- Action: The mechanism responsible for loading, firing, and ejecting cartridges, integral to the firearm’s operation.

Understanding Shotgun Mechanisms

The intricate workings of firearms showcase a remarkable blend of engineering and design. These mechanisms are crafted to ensure reliability and efficiency, providing users with the necessary tools for a variety of applications. Understanding the fundamental principles behind these systems can enhance one’s appreciation for their functionality and performance.

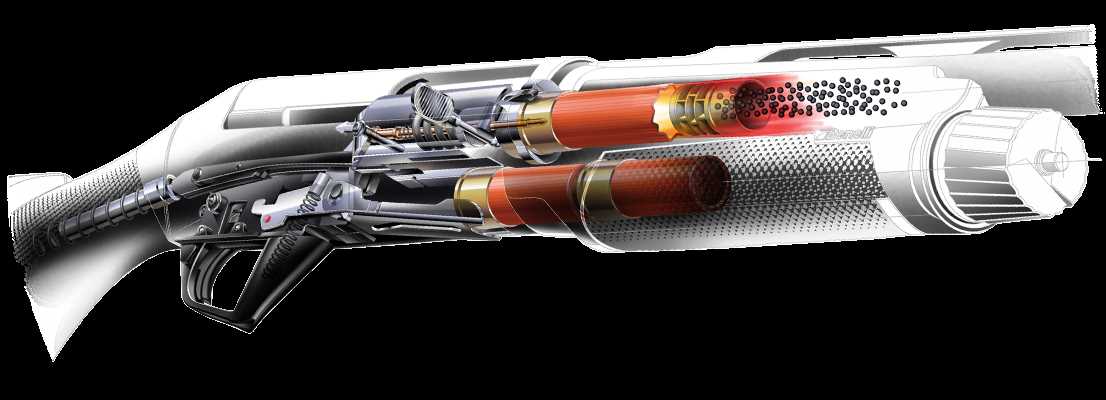

At the heart of these devices lies a series of components that interact seamlessly. The mechanism typically includes a trigger system, firing pin, and an ejector, each playing a crucial role in the overall operation. The trigger initiates the process, releasing energy that propels a projectile. The firing pin then strikes the primer, igniting the propellant, while the ejector ensures spent casings are expelled, making way for new rounds.

Moreover, the design can vary significantly, influenced by intended use and user preferences. Whether a single-shot configuration or a more complex multi-chamber setup, each variant offers unique advantages. Familiarity with these mechanisms not only aids in effective usage but also facilitates better maintenance and troubleshooting, ensuring optimal performance over time.

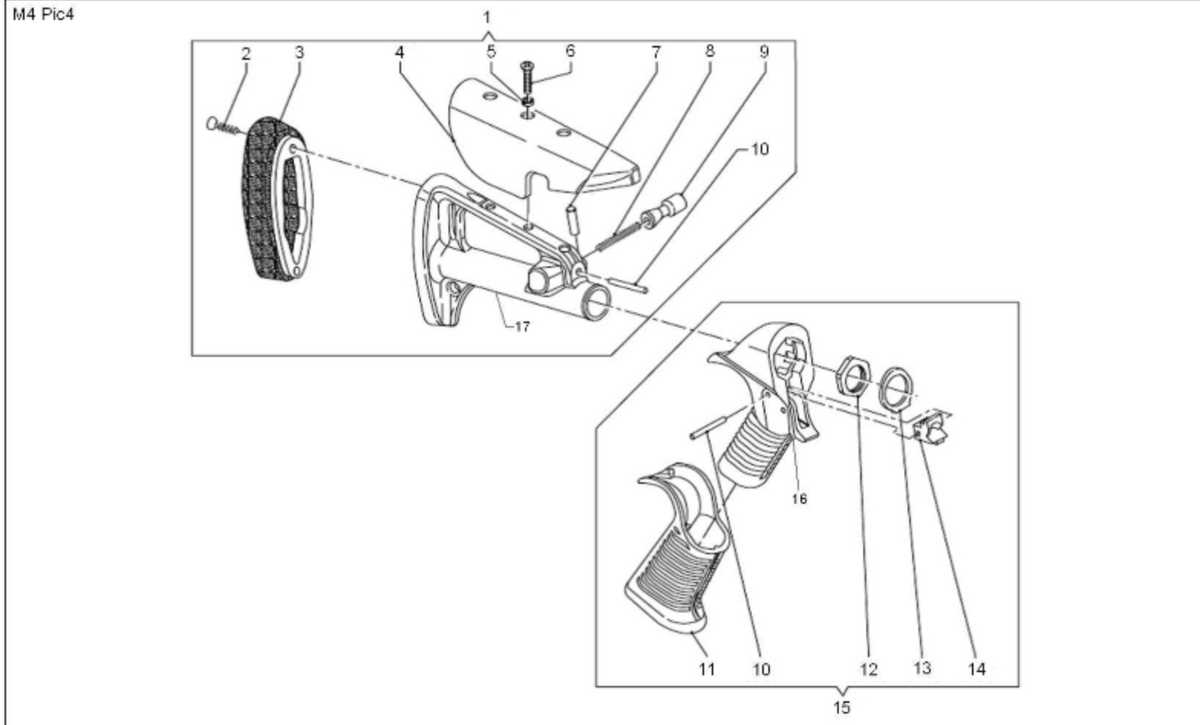

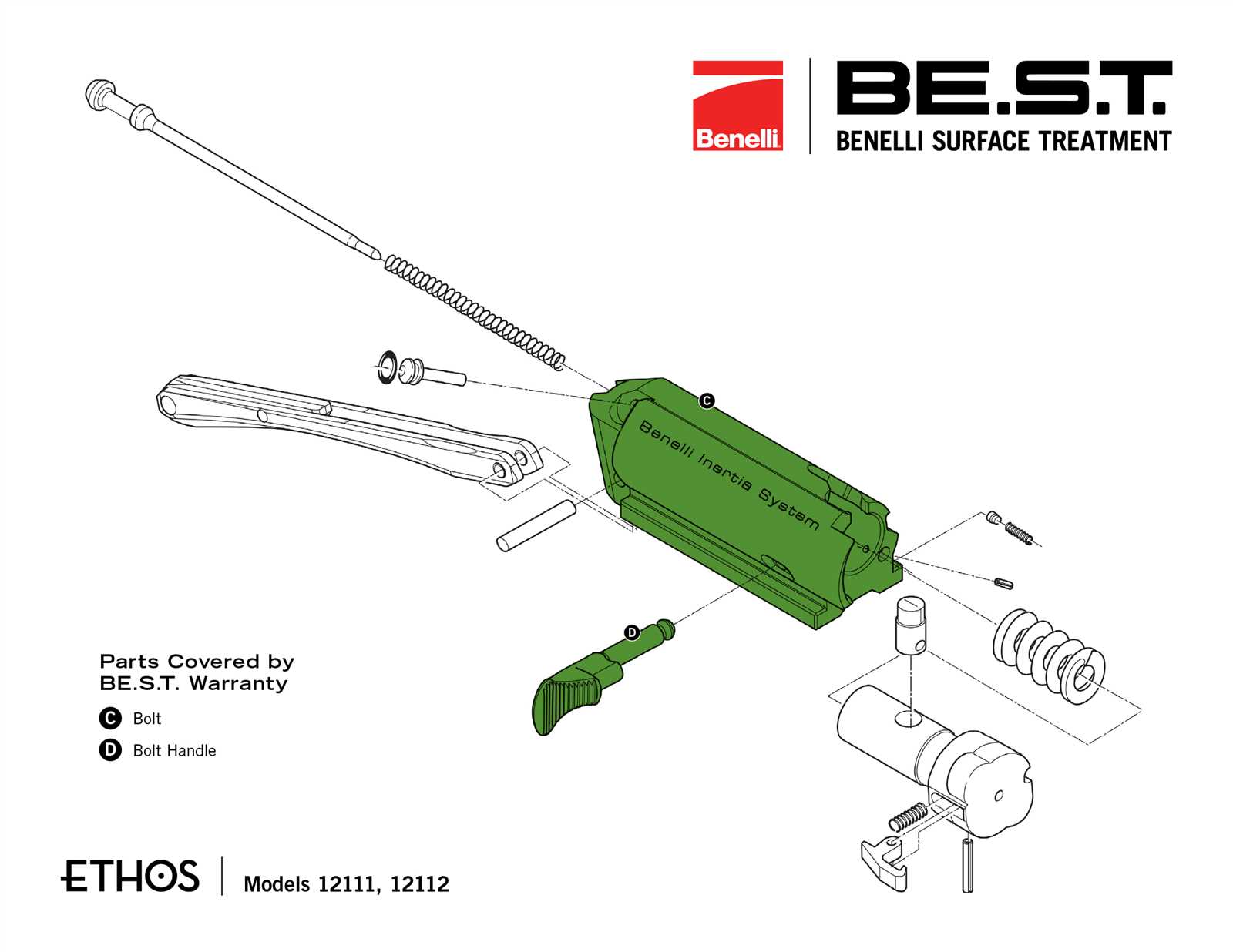

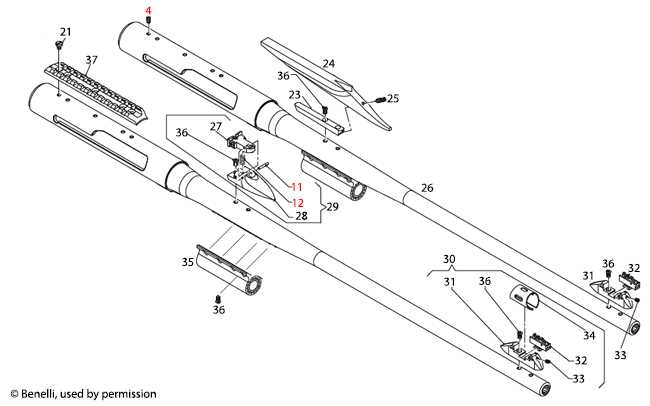

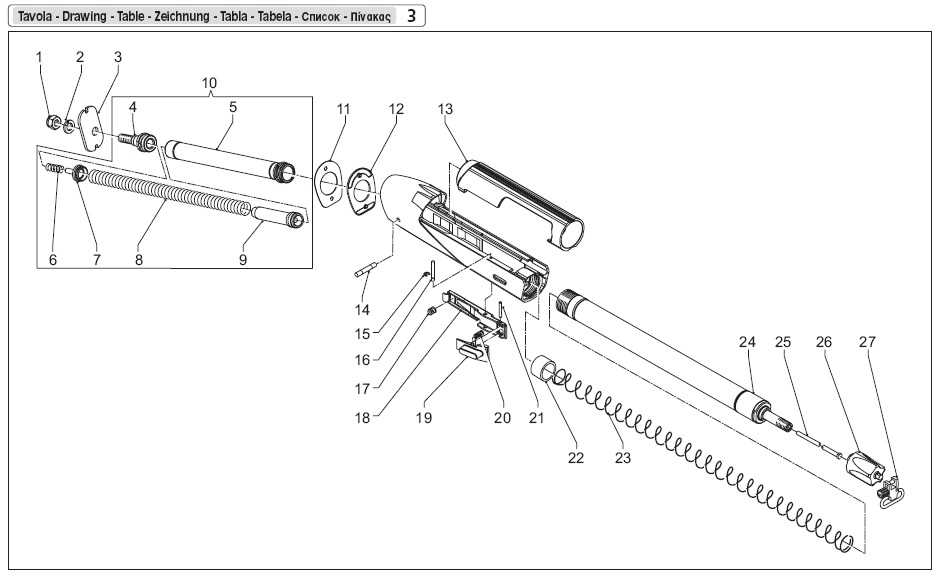

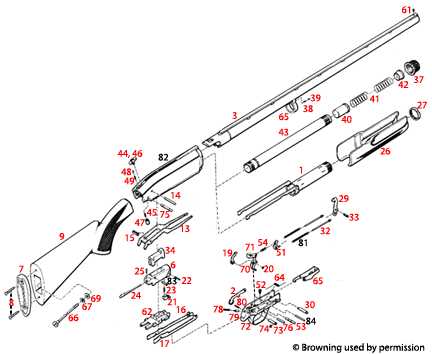

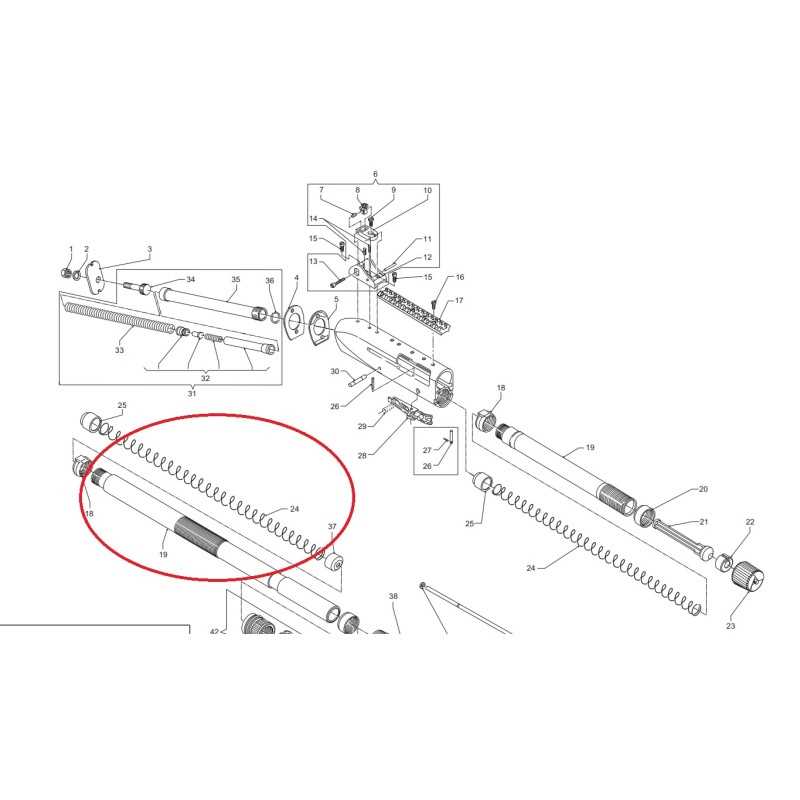

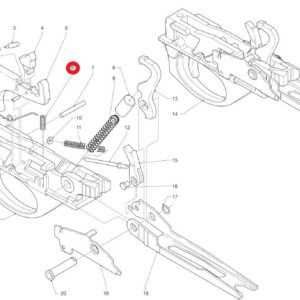

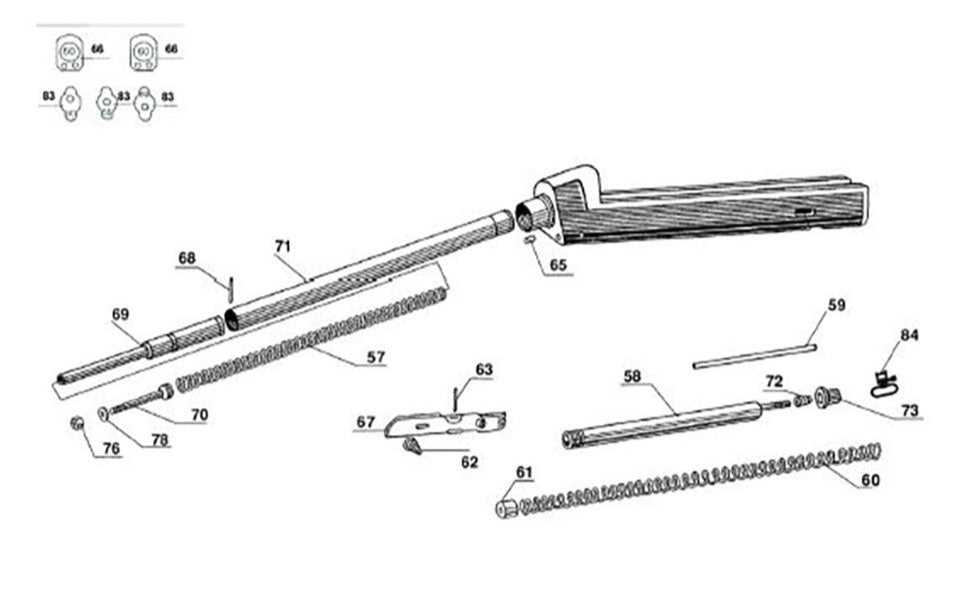

Identifying Key Parts in Diagrams

Understanding the components illustrated in technical visuals is essential for effective assembly and maintenance. Each element plays a crucial role, contributing to the overall functionality of the system. Recognizing these pieces can simplify the process of troubleshooting and enhance user knowledge.

When examining the visuals, it is beneficial to categorize the elements based on their functions. This approach aids in visualizing the relationships between various components. Below is a table that outlines common elements and their purposes:

| Component | Description |

|---|---|

| Receiver | Holds and aligns the inner mechanisms for smooth operation. |

| Barrel | Directs the projectile’s path and influences accuracy. |

| Trigger Mechanism | Initiates the firing process when engaged. |

| Sights | Assist in aiming by providing a visual reference. |

By familiarizing yourself with these components, you can enhance your understanding of the system’s operation and improve your skills in handling it effectively.

Maintenance Tips for Shotgun Parts

Proper upkeep of your firearm components is crucial for optimal performance and longevity. Regular care not only enhances functionality but also ensures safety during usage. Implementing a few simple practices can significantly improve the reliability of your equipment.

Cleaning and Lubrication

Regular cleaning is essential. After each use, wipe down surfaces to remove residues and moisture. Utilize appropriate cleaning solutions to avoid damage. Lubrication is equally important; apply suitable oils to moving elements to prevent rust and ensure smooth operation. Be mindful not to over-lubricate, as excess can attract debris.

Inspection and Replacement

Routine inspections help identify wear or damage early. Check for cracks, corrosion, or loose connections. If you notice any issues, address them promptly to maintain safety and functionality. Replace worn or damaged items with high-quality alternatives to ensure reliability and enhance the overall performance of your equipment.

Common Issues with Benelli Shotguns

Firearms enthusiasts may encounter a variety of challenges when using their favorite models. Understanding these common concerns can enhance reliability and performance during use. Below are some frequent issues that owners might face, along with potential solutions.

- Feeding Problems: Inconsistent feeding of ammunition can lead to malfunctions. Ensure that the magazine is clean and free of debris.

- Extraction Failures: Occasionally, spent cartridges may not eject properly. This can be resolved by inspecting the extractor for wear or damage.

- Firing Pin Issues: If the firearm fails to ignite rounds, the firing pin may be stuck or broken. Regular maintenance is essential to prevent this.

- Gas System Malfunctions: For models relying on gas operation, blockages can occur. Cleaning the gas ports regularly can help maintain proper function.

Addressing these concerns promptly can significantly improve performance and extend the lifespan of the firearm.

Upgrading Components for Performance

Enhancing the efficiency of a firearm can significantly improve its functionality and user experience. By focusing on specific elements, enthusiasts can achieve better accuracy, reduced recoil, and overall superior handling. Understanding the various components available for modification is crucial for anyone looking to elevate their shooting experience.

Several key areas can be addressed to enhance performance:

- Trigger Mechanism: Upgrading the trigger can lead to smoother pulls and quicker resets, improving shooting precision.

- Barrel Quality: A high-quality barrel can enhance bullet stability and overall accuracy, allowing for tighter groupings.

- Stock Material: Switching to a lighter or more ergonomic stock can improve balance and handling, making the firearm easier to control.

- Sights and Optics: Investing in better sight systems can increase target acquisition speed and enhance overall accuracy.

- Recoil Management: Adding recoil pads or upgrading to a muzzle brake can help mitigate felt recoil, allowing for quicker follow-up shots.

When considering upgrades, it is essential to select components that complement each other and suit individual shooting styles. Researching various brands and materials can provide insights into the best options available on the market.

Finally, consulting with experienced users or professionals can offer valuable advice on which modifications will yield the most significant improvements. Each enhancement contributes to a more enjoyable and effective shooting experience.

Safety Features of Innovative Shotguns

Modern firearms are equipped with advanced safety mechanisms designed to enhance user protection and operational security. These features play a critical role in preventing accidental discharges and ensuring safe handling during use. Understanding the safety components integrated into these firearms provides insight into their reliability and user-friendly design.

1. Trigger Safety Mechanism

- A crucial safety feature is the trigger mechanism, which includes mechanisms like safeties and mechanisms to protect against or restrict gun from

Comparing Models: Which is Best?

When choosing between different models, it is essential to consider the unique features and performance capabilities that each option offers. Each version caters to specific needs, from ease of handling to advanced technical elements, making the decision dependent on personal preferences and usage scenarios.

Performance and Handling

One of the main factors that sets models apart is how they perform in various conditions. Some are optimized for accuracy and smooth operation, while others focus on power and durability. Depending on the intended use, it’s important to evaluate how each option handles under different situations.

- Lightweight designs may offer greater maneuverability.

- More robust builds can provide better stability for precision.

- Adjustable features allow customization for different users.

Technical Features

Each model comes with its own set of technical specifications. These can range from simplified mechanisms for ease of maintenance to more complex systems that enhance performance. Understanding how these features affect the overall experience is key to selecting the best fit for your needs.

- Look for enhancements that improve speed and reliability.

- Consider options with adaptable settings for various conditions.

- Evaluate any additional elements that may enhance user experience.

Cleaning and Care for Shotgun Parts

Proper maintenance of your equipment is essential to ensure its longevity and performance. Regular cleaning and upkeep not only enhance functionality but also prevent potential malfunctions. By adopting a consistent care routine, you can significantly extend the life of the components and maintain their precision over time.

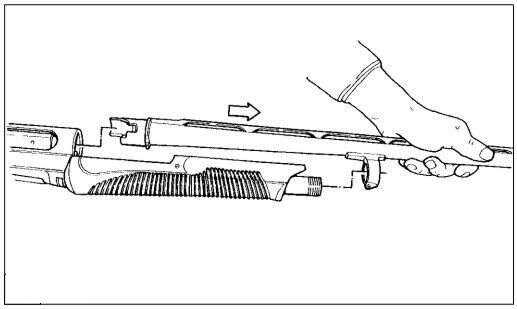

Disassembly and Inspection

Before beginning the cleaning process, carefully disassemble your tool, paying close attention to each section. Inspect each part for signs of wear, corrosion, or debris buildup. Early detection of issues allows for timely intervention and helps avoid more significant problems in the future.

Cleaning Techniques and Lubrication

For thorough cleaning, use a soft brush or cloth to gently remove dirt and residue from the surfaces. Pay special attention to areas prone to carbon buildup. Once cleaned, apply a light coat of oil or specialized lubricant to protect the surfaces from moisture and rust. Avoid over-lubrication, as excess can attract more debris, leading to reduced efficiency.

Tools Needed for Repairs

When performing maintenance or repairs on any mechanical device, having the correct set of tools is essential. A well-equipped workspace ensures that tasks can be completed efficiently and with precision. Below is a guide to some of the most commonly used tools for disassembling, cleaning, and reassembling such devices.

Screwdrivers are fundamental for loosening and tightening various screws and bolts. Both flathead and Phillips types are typically required, depending on the fasteners involved.

Punches are necessary for driving pins out of small, precise components. These are used when pins are difficult to remove by hand or require careful alignment during reassembly.

For tasks requiring extra grip, pliers and needle-nose pliers can be invaluable. They allow for handling small parts or gripping items tightly, especially when fingers cannot apply sufficient force.

Cleaning kits, including brushes and solvents, are vital for ensuring all mechanical parts are free from debris and properly lubricated. Maintaining cleanliness during repair can prevent unnecessary wear.

A bench vise or clamps can hold the device securely in place, allowing for more control during delicate tasks. Stability is crucial for avoiding damage to sensitive components.

In more complex repairs, specialized wrenches and torque tools may be required to apply specific levels of pressure without over-tightening or damaging parts.

History of Benelli Shotgun Design

The evolution of this iconic firearm reflects a blend of innovation and craftsmanship that has reshaped modern shooting technology. Rooted in engineering excellence, its development journey showcases the drive for performance, reliability, and cutting-edge features, continually pushing the boundaries of what a firearm can achieve.

In the early stages, the company focused on creating a streamlined, efficient weapon that combined durability with ease of use. Early models were designed with simplicity and ergonomics in mind, ensuring that they were not only effective but also comfortable for users of all levels. Over time, the mechanisms became more refined, incorporating advancements that improved speed and accuracy.

- The initial designs emphasized mechanical efficiency and ease of maintenance.

- Later versions incorporated recoil reduction systems to enhance stability during firing.

- Materials evolved, with lightweight alloys and advanced polymers improving both durability and maneuverability.

The refinement of these weapons also followed trends in modern firearm technology. Engineers introduced semi-automatic actions that allowed for faster follow-up shots without compromising on control. As the design matured, the focus on precision and reliability remained central, resulting in a product that catered to professionals and enthusiasts alike.

Aftermarket Parts: Pros and Cons

Choosing to upgrade or replace components with alternatives from third-party manufacturers can offer a range of benefits and challenges. Many enthusiasts turn to these options for various reasons, from improving performance to enhancing aesthetics, but it’s important to weigh the potential advantages and disadvantages before making a decision.

Pros

One of the biggest advantages of using third-party components is the wider selection available. These alternatives often provide more affordable pricing, making them a cost-effective choice for those looking to customize or upgrade their gear. Additionally, aftermarket options can sometimes surpass the original in terms of durability or functionality, offering specialized features that cater to specific needs or preferences.

Cons

On the other hand, there are potential downsides to using third-party alternatives. Compatibility issues can arise, as some items may not fit perfectly or function as intended with the original setup. Quality can also vary significantly, with some products failing to meet the standards of the original manufacturer. Lastly, using non-original components can sometimes void warranties or affect long-term reliability, which may be a crucial consideration for many users.

Resources for Further Learning

Exploring mechanical assemblies and their components often requires a deep understanding of technical documentation and engineering principles. To enhance your knowledge, it’s beneficial to consult various learning materials that cover not only the technical aspects but also the practical applications and maintenance tips for different systems.

Technical Manuals and Guides

Detailed manuals provide in-depth instructions on how various components work together, including troubleshooting methods. These resources often include exploded views, specifications, and step-by-step processes that are invaluable for anyone looking to master the assembly and care of complex mechanisms.

Community Forums and Expert Tutorials

Online communities and expert-driven tutorials are excellent places to gain insights from those with hands-on experience. Whether you’re a beginner or have advanced knowledge, these platforms offer discussions, tips, and video demonstrations that make learning more interactive and practical.