In the realm of heavy machinery, grasping the intricate relationships between various elements is essential for optimal performance. Each component plays a pivotal role in ensuring seamless operation, making it crucial for operators and technicians to comprehend these connections.

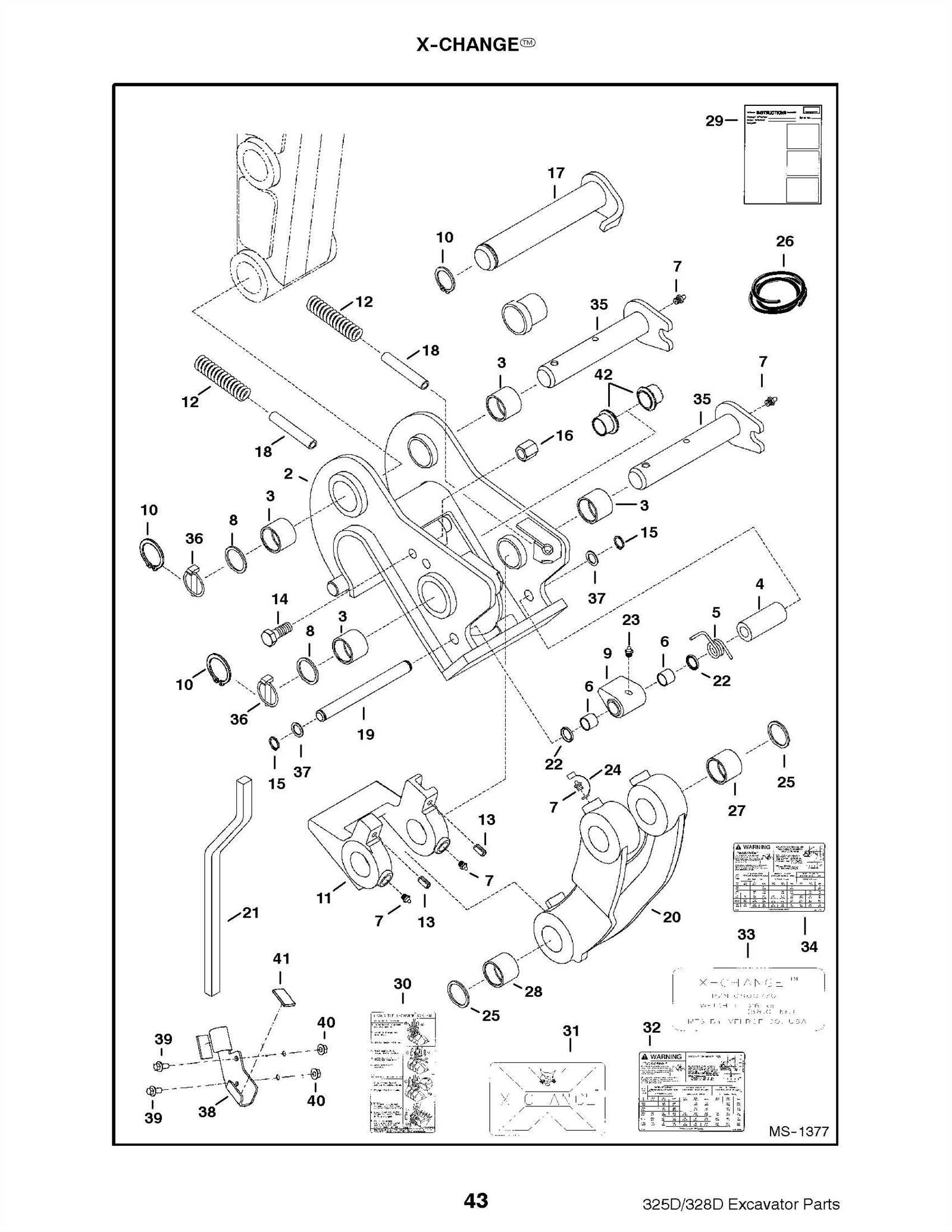

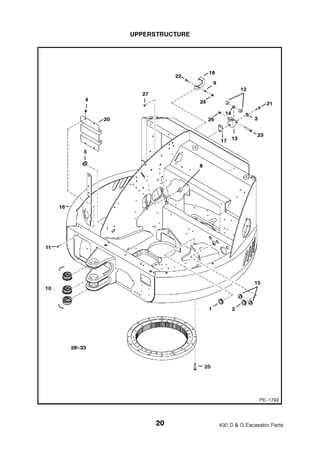

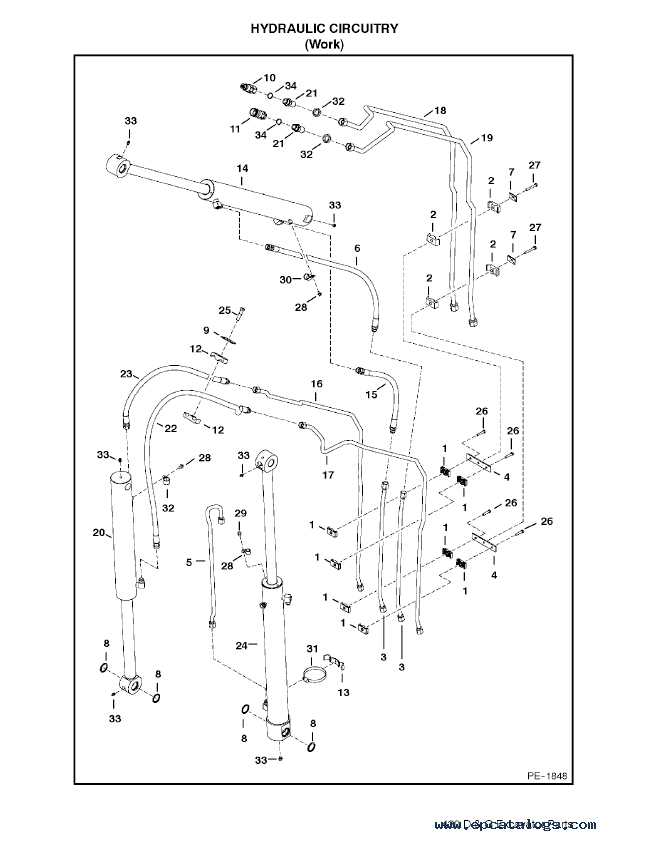

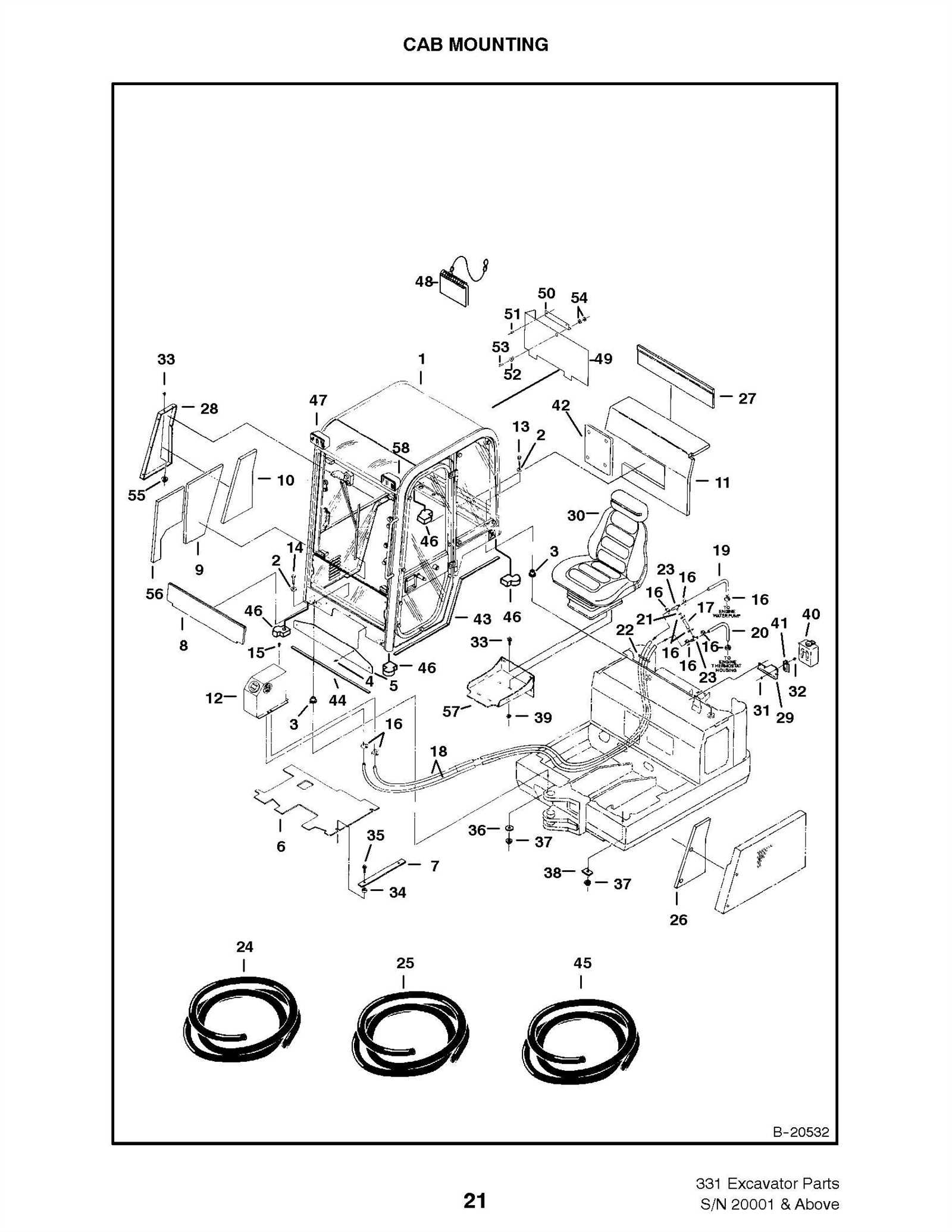

Visual representations serve as invaluable tools in this learning process. They allow users to identify and locate specific mechanisms, promoting a deeper understanding of how each piece contributes to the overall functionality.

Through careful examination of these illustrations, one can delve into the intricacies of machine assembly. This exploration ultimately leads to improved maintenance practices, enhancing both efficiency and longevity in demanding environments.

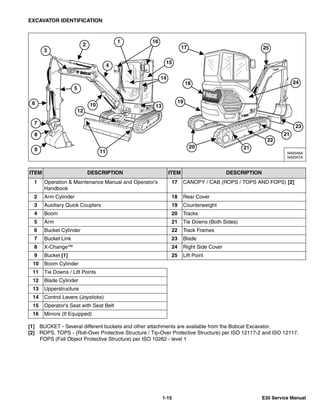

Understanding Bobcat Excavator Components

In the realm of heavy machinery, a thorough comprehension of individual elements is essential for optimal functionality and maintenance. Each component plays a vital role in ensuring that the machinery operates efficiently and effectively, contributing to overall performance.

Power Systems are crucial for delivering the necessary energy to drive various operations. This section includes engines and hydraulic systems, which are fundamental for mobility and lifting capabilities.

Structural Elements provide the framework and support for operations. These include the chassis and boom, designed to withstand rigorous tasks while maintaining stability.

Operational Accessories, such as buckets and attachments, enhance versatility, allowing the machine to tackle a variety of tasks. Understanding how these components interact is key to maximizing productivity.

Lastly, Control Mechanisms facilitate operator input, translating commands into precise movements. Familiarity with these systems is essential for safe and efficient machine operation.

Importance of Excavator Parts Diagrams

Understanding the various components of heavy machinery is crucial for efficient maintenance and repair. Clear visual representations help operators and technicians identify specific elements, facilitating timely interventions and ensuring optimal functionality.

Enhanced Maintenance Procedures

Visual aids provide a straightforward approach to maintenance tasks. When individuals can easily locate and recognize parts, they can perform inspections and replacements more efficiently. This reduces downtime and improves productivity on site.

Improved Troubleshooting Capabilities

When issues arise, having a reference that outlines component relationships and functions is invaluable. Quick access to this information allows for rapid diagnostics and resolution, minimizing the impact of mechanical failures.

| Benefits | Description |

|---|---|

| Time-Saving | Faster identification and resolution of issues. |

| Reduced Errors | Clear visuals help prevent mistakes during repairs. |

| Increased Safety | Understanding components promotes safer handling and operations. |

| Training Aid | Useful resource for training new personnel on machinery. |

Key Parts of Bobcat Excavators

This section explores the essential components that contribute to the functionality and efficiency of these powerful machines. Understanding these elements is crucial for effective operation and maintenance.

Core Components

- Hydraulic System

- Bucket and Attachments

- Tracks and Undercarriage

- Engine and Transmission

Operational Features

- Control Panel

- Stabilizers

- Counterweight

Familiarity with these critical elements ensures optimal performance and longevity of the machinery.

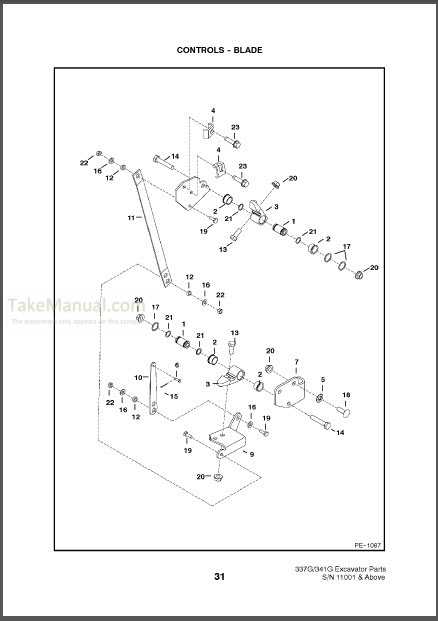

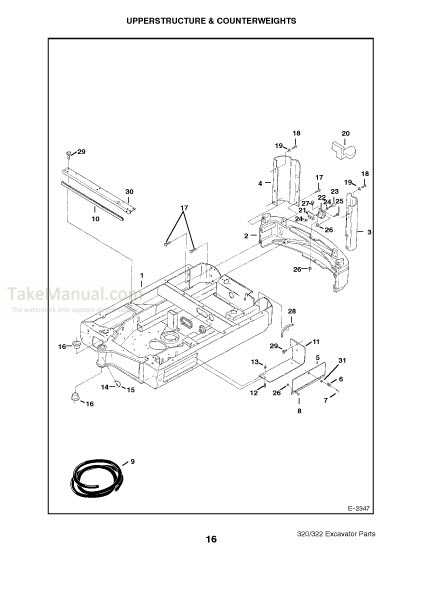

How to Read a Parts Diagram

Understanding a schematic representation of components can significantly enhance your ability to identify and locate specific elements within a machine. This skill is essential for maintenance and repair tasks, as it allows you to visualize how each item fits into the overall structure.

Typically, these illustrations include various symbols and annotations that correspond to the components of the equipment. Familiarizing yourself with these elements can simplify troubleshooting and ordering replacement items.

| Element | Description |

|---|---|

| Legend | A key that explains symbols used in the illustration. |

| Numbering | Unique identifiers assigned to each item, aiding in precise reference. |

| Arrows | Indicate relationships or connections between components. |

| Scale | Provides a sense of size and proportion in relation to the entire assembly. |

By mastering these aspects, you’ll be better equipped to navigate the complexities of machinery and ensure efficient repairs or replacements.

Common Issues with Excavator Parts

Heavy machinery often faces a variety of challenges that can hinder performance and efficiency. Understanding these common problems can help in maintaining optimal functionality and extending the lifespan of the equipment. Regular checks and prompt attention to these issues are crucial for effective operation.

| Issue | Description | Potential Solutions |

|---|---|---|

| Hydraulic leaks | Fluid loss can lead to reduced power and control. | Inspect seals and hoses; replace as needed. |

| Electrical failures | Malfunctions in the electrical system can disrupt operation. | Check wiring connections and battery health. |

| Wear and tear | Components can deteriorate over time, affecting performance. | Conduct regular inspections; replace worn parts. |

| Overheating | Excessive heat can damage critical systems. | Monitor coolant levels; clean radiators. |

Maintenance Tips for Bobcat Excavators

Regular upkeep is essential for ensuring optimal performance and longevity of heavy machinery. By adhering to a structured maintenance schedule, operators can prevent costly repairs and enhance efficiency. This section outlines key practices to keep your equipment running smoothly.

First, routinely check fluid levels, including hydraulic, engine oil, and coolant. Maintaining appropriate levels helps avoid overheating and ensures proper operation. Additionally, inspect filters and replace them as needed to ensure clean fluids circulate through the system.

Next, pay attention to the tracks or wheels. Regularly inspect for wear and adjust tension to prevent unnecessary strain on components. Cleaning debris from the undercarriage also helps avoid buildup that can hinder mobility.

Don’t overlook the importance of inspecting the electrical system. Ensure that all connections are secure, and check the battery for corrosion. A well-maintained electrical system is crucial for reliable performance.

Lastly, create a log of maintenance activities. Keeping detailed records not only helps track service intervals but also aids in identifying potential issues before they escalate into serious problems.

Ordering Replacement Parts Effectively

When it comes to maintaining machinery, acquiring the right components is crucial for ensuring optimal performance and longevity. Effectively ordering these elements can save both time and resources. Here are some strategies to enhance the process.

- Identify the Specific Component: Before making a purchase, ensure you know exactly which item you need. Check the manual or consult with a professional if necessary.

- Use Accurate Descriptions: When searching online or in catalogs, use precise terminology to narrow down your options. Keywords and model numbers can make a significant difference.

- Verify Compatibility: Confirm that the chosen element is compatible with your equipment model. Cross-reference with manufacturer specifications to avoid mismatches.

- Compare Suppliers: Explore multiple vendors to find the best price and availability. Consider both local and online retailers for a comprehensive view.

- Check for Quality: Opt for reputable brands or OEM alternatives. Quality components can prevent future issues and ensure better performance.

By following these guidelines, you can streamline the ordering process and minimize downtime, keeping your machinery running smoothly.

Identifying Model-Specific Components

Understanding the unique elements of various machinery is crucial for effective maintenance and repairs. Each model features distinct components that contribute to its functionality and performance. Familiarity with these individual parts can streamline the process of identifying issues and implementing solutions, ensuring that the equipment operates efficiently.

Recognizing Key Features

Different models exhibit specific characteristics that can help in pinpointing their components. Dimensions, shapes, and connection types often vary, making it essential to refer to the right resources when examining individual machinery. Utilizing manufacturer resources or technical manuals can provide valuable insights into these features.

Using Serial Numbers

Another effective method for identifying components is through the use of serial numbers. These identifiers can reveal the exact model and its specifications, allowing for a more precise selection of replacement items. Always ensure that the correct serial number is referenced when sourcing parts to avoid compatibility issues.

Differences Between Excavator Models

Understanding the variations among different machinery models is essential for making informed decisions in construction and earth-moving tasks. Each model is designed with specific features that cater to various operational needs, affecting efficiency, capability, and adaptability in different environments.

Size and Capacity

The first significant difference lies in size and operational capacity. Compact units are ideal for confined spaces, while larger machines offer greater power and reach for extensive projects. Choosing the right size can optimize performance and reduce costs.

Technology and Features

Modern machinery often comes equipped with advanced technology. Some models include enhanced hydraulics, intuitive controls, and improved fuel efficiency, while others may focus on durability and ease of maintenance. Assessing these features can lead to the ultimate choice for specific tasks.

Safety Considerations When Repairing

Ensuring safety during maintenance and repair tasks is crucial for preventing accidents and injuries. Proper precautions not only protect the individual performing the work but also safeguard the equipment and surroundings. Here are key considerations to keep in mind.

Personal Protective Equipment (PPE)

Utilizing appropriate gear is essential. This includes:

- Hard hats to protect against falling objects.

- Safety goggles to shield eyes from debris.

- Gloves to prevent cuts and abrasions.

- Steel-toed boots to safeguard feet from heavy components.

- Hearing protection in loud environments.

Work Area Safety

Creating a secure workspace can significantly reduce hazards. Follow these guidelines:

- Ensure the area is well-lit to identify potential risks.

- Keep the workspace organized to prevent trips and falls.

- Verify that all tools are in good condition and stored properly.

- Establish clear access routes for emergency exits.

- Regularly inspect the environment for potential hazards.

By adhering to these safety considerations, individuals can enhance their protection and ensure a more efficient repair process.

Where to Find Parts Diagrams Online

Accessing detailed illustrations of machinery components can greatly enhance maintenance and repair efforts. Fortunately, numerous resources are available on the internet to help users locate these valuable references.

- Manufacturer Websites: Official sites often provide comprehensive resources, including manuals and breakdowns of their equipment.

- Online Marketplaces: Platforms dedicated to machinery sales frequently host schematics and detailed listings of various models.

- Forums and Community Groups: Enthusiast communities and forums can be a treasure trove of shared knowledge, including links to useful visuals.

- Repair Manuals: Numerous websites specialize in hosting downloadable manuals that feature extensive visuals of machinery parts.

- YouTube Tutorials: Video guides often include screen captures of parts breakdowns, providing both visual and auditory learning opportunities.

By utilizing these resources, users can efficiently locate the information they need to ensure their equipment remains in optimal condition.

Upgrades and Modifications for Performance

Enhancing machinery efficiency can significantly improve productivity and operational effectiveness. By implementing strategic upgrades and modifications, users can achieve optimal performance, ensuring that the equipment meets the demands of various tasks.

Consider the following enhancements for improved functionality:

- Hydraulic System Optimization: Upgrading the hydraulic components can lead to increased lifting capacity and faster cycle times.

- Engine Performance Enhancements: Tuning the engine or installing performance kits can improve power output and fuel efficiency.

- Track and Tire Upgrades: Switching to specialized tracks or tires can enhance traction and stability in different terrains.

In addition to these improvements, regular maintenance and monitoring can prevent issues and extend the lifespan of the equipment. Consider integrating technology such as telematics systems for real-time performance data, which can help in making informed decisions about necessary upgrades.

Ultimately, customizing your machinery not only boosts its capabilities but also ensures a competitive edge in demanding environments.

Expert Advice on Excavator Maintenance

Maintaining heavy machinery is crucial for ensuring optimal performance and longevity. Proper upkeep not only enhances efficiency but also prevents unexpected breakdowns, which can lead to costly downtime. Understanding the key components and their functions can significantly improve maintenance practices.

Regular inspections are essential. Checking fluid levels, filters, and hydraulic systems can help identify potential issues before they escalate. Keeping an eye on wear and tear of components allows for timely replacements, thus avoiding major repairs.

Lubrication plays a vital role in the smooth operation of machinery. Ensuring all moving parts are adequately greased reduces friction and prolongs life expectancy. Implementing a consistent lubrication schedule can make a significant difference in performance.

Training operators on best practices is equally important. Knowledgeable users can spot anomalies and respond appropriately, reducing the likelihood of damage. Furthermore, adhering to the manufacturer’s maintenance guidelines is critical for warranty compliance and operational safety.

Finally, investing in quality replacement components is a wise decision. Cheap alternatives may save money initially but often result in increased repair costs and reduced efficiency over time. Prioritizing durability and reliability ensures that machinery remains operational for longer periods.