Maintaining and optimizing your gardening machinery can significantly enhance its performance and longevity. A thorough comprehension of its components is essential for effective care and repair. This section delves into the intricate details that form the backbone of your equipment, offering valuable insights for enthusiasts and professionals alike.

By exploring the arrangement and function of each element, users can gain the ultimate advantage in troubleshooting issues. Whether you are a seasoned gardener or a novice, familiarizing yourself with these mechanical intricacies will ensure that your tools operate at their best.

In this guide, we will uncover the essential elements that contribute to the overall efficiency of your gardening devices. Understanding these components not only facilitates better upkeep but also empowers users to make informed decisions when addressing any mechanical challenges.

Kobalt Lawn Mower Parts Overview

This section provides a comprehensive look at the essential components of a popular outdoor equipment model, highlighting their functions and importance in maintaining optimal performance. Understanding these elements is crucial for effective operation and troubleshooting.

Key Components

Each unit consists of various integral sections that work in harmony to ensure efficiency. Familiarity with these components will enhance user experience and facilitate easier repairs when necessary.

| Component | Description |

|---|---|

| Engine | The power source that drives the entire machine. |

| Blade | The cutting tool responsible for trimming grass and other vegetation. |

| Chassis | The frame that holds all components together and provides stability. |

| Wheels | Elements that allow for mobility across various terrains. |

Maintenance Tips

Regular inspection and servicing of these vital sections will prolong the lifespan of the equipment and enhance its efficiency. Users should familiarize themselves with the assembly for more effective maintenance practices.

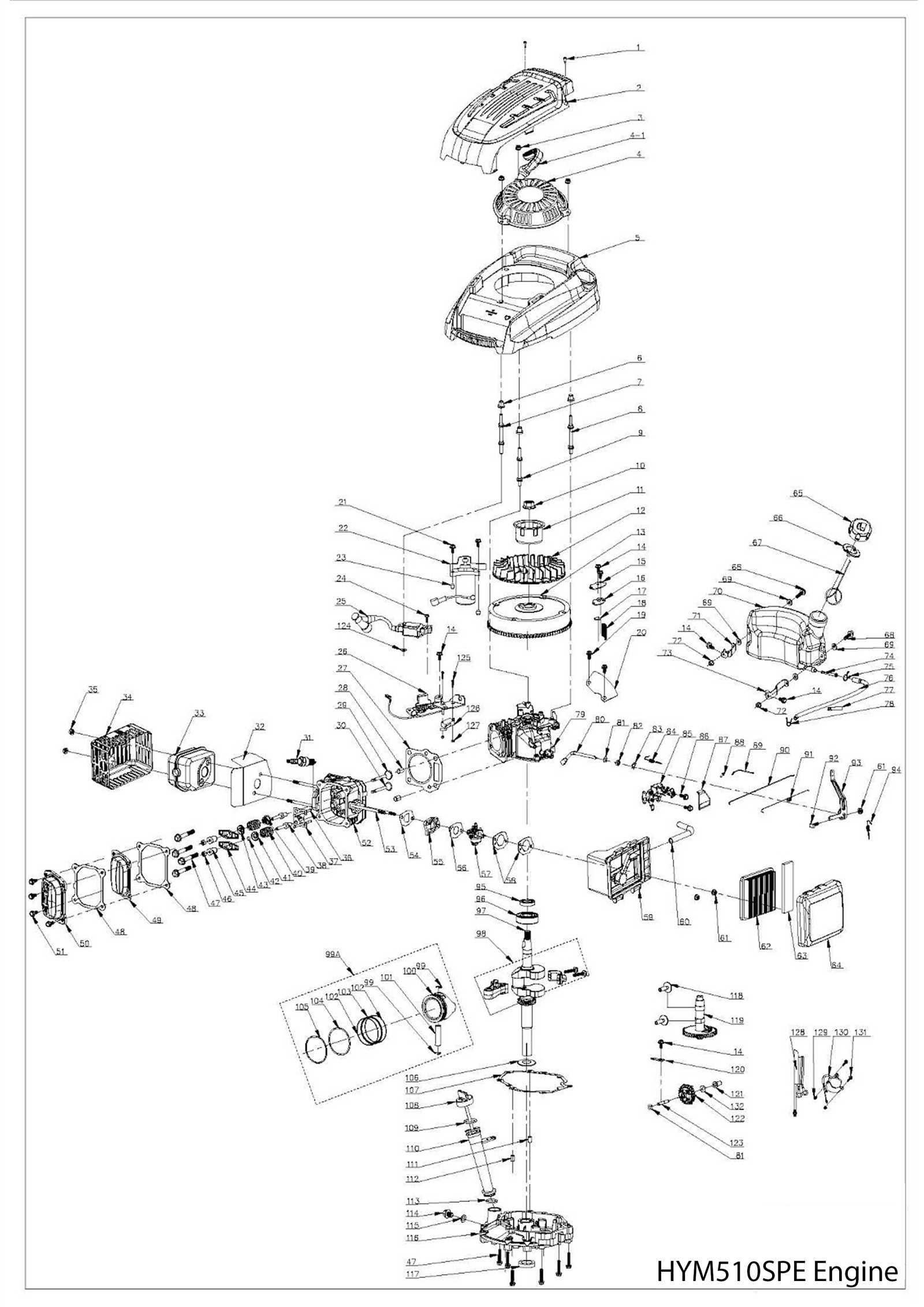

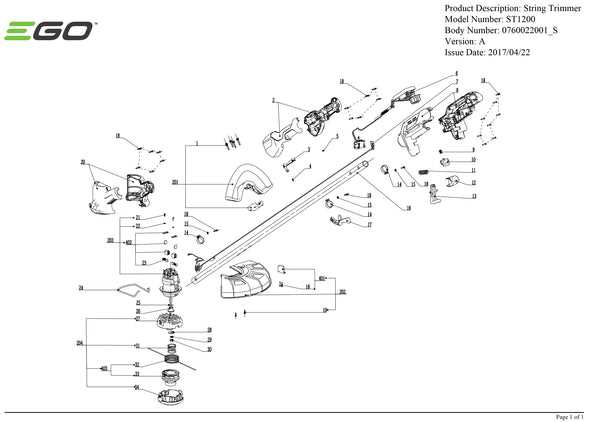

Understanding Lawn Mower Components

Grasping the various elements of outdoor cutting equipment is essential for effective maintenance and operation. Each component plays a crucial role in ensuring the machinery functions smoothly, contributing to the overall efficiency and longevity of the device. By familiarizing oneself with these elements, users can enhance their care and troubleshooting skills.

Main Elements

The core components typically include the engine, cutting blade, and drive system. The engine serves as the powerhouse, while the blade performs the essential task of trimming grass. The drive system connects these elements, allowing for seamless movement across the terrain.

Additional tools and accessories can significantly improve performance. Items such as grass collectors, mulching kits, and various attachments enhance versatility, making it easier to manage different types of vegetation and yard conditions.

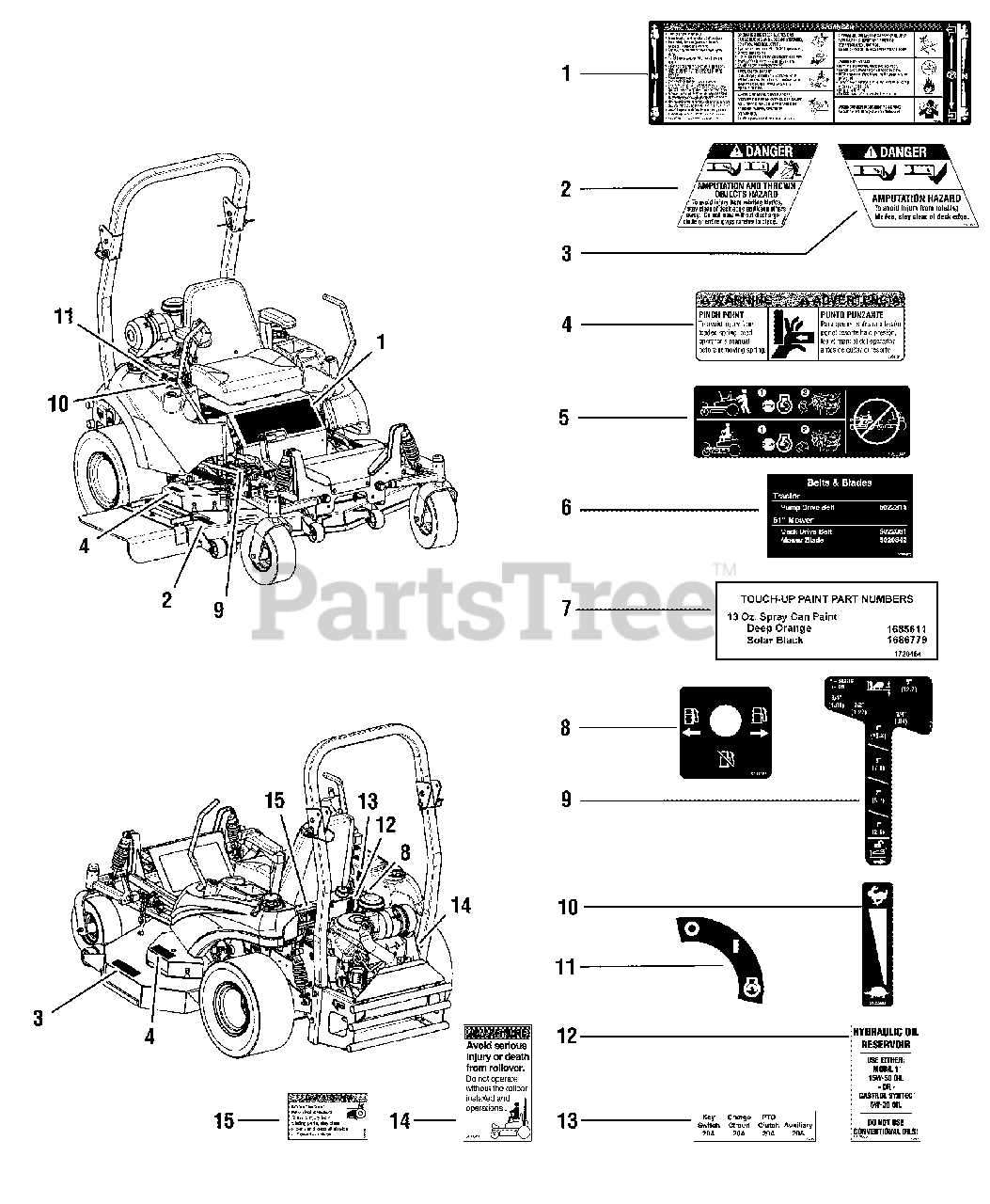

Importance of Parts Diagrams

Understanding the intricacies of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools that simplify the identification and assembly of various components. They enhance clarity, making it easier for users to navigate complex structures.

These illustrations not only provide insight into the arrangement of elements but also facilitate troubleshooting. By delving into the layout, individuals can quickly pinpoint issues, ensuring a more efficient repair process. Ultimately, these resources empower users to maintain their equipment with confidence.

Moreover, familiarity with such visual guides fosters a deeper appreciation of the mechanics involved. This knowledge can enhance decision-making when it comes to upgrades or replacements, ensuring optimal performance over time.

Common Kobalt Mower Issues

Many users encounter various challenges with their outdoor equipment, which can affect performance and efficiency. Understanding these common problems can help in effective troubleshooting and maintenance.

1. Engine Difficulties: One frequent concern is the engine failing to start. This may stem from fuel issues, spark plug malfunctions, or air filter blockages. Regular checks can prevent these complications.

2. Cutting Quality: Inconsistent cutting results can arise from dull blades or improper height settings. Ensuring blades are sharpened and correctly adjusted is essential for optimal performance.

3. Overheating: Equipment overheating can lead to severe damage. This often occurs due to debris buildup or insufficient oil levels. Regular cleaning and maintenance can mitigate this risk.

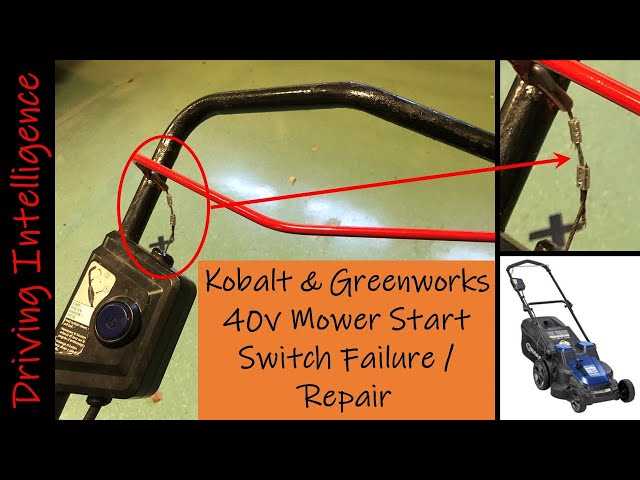

4. Electrical Issues: Problems with the ignition system or battery can disrupt operation. Checking connections and replacing worn-out components is crucial for reliability.

5. Wheel and Drive Problems: Difficulty in maneuvering may indicate wheel or drive issues. Inspecting wheels for damage and ensuring proper lubrication can enhance mobility.

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. These visual guides offer insights into the structure and assembly of devices, helping users identify individual elements and their functions.

Key Elements of the Representation

- Labels: Each component typically has a unique identifier, which can be alphanumeric.

- Connections: Lines or arrows indicate how different pieces interact with each other.

- Views: Diagrams may present multiple angles or sections to provide clarity on complex assemblies.

Steps to Interpret the Schematic

- Start by identifying the main assembly and its corresponding components.

- Check the labels to understand what each part is and its specific role.

- Follow the connection lines to visualize how components fit together.

- Refer to any accompanying notes or legends for additional context.

Essential Tools for Repairs

Having the right instruments at your disposal is crucial for effective maintenance and restoration tasks. These essential tools not only facilitate the repair process but also enhance efficiency and precision, ensuring that each job is completed to the highest standard.

Basic Hand Tools: A good set of hand tools, including wrenches, screwdrivers, and pliers, forms the foundation of any repair toolkit. These tools are vital for accessing and adjusting various components with ease.

Power Tools: Incorporating power tools such as drills and saws can significantly speed up the repair process. They allow for more complex tasks that hand tools might struggle with, providing the ultimate advantage in efficiency.

Safety Gear: Protecting yourself while working is paramount. Investing in safety glasses, gloves, and ear protection can prevent accidents and ensure a safer working environment.

Organizational Tools: Keeping your workspace tidy with organizers or toolboxes can greatly improve workflow. It helps you locate tools quickly and minimizes distractions during repairs.

Replacing Blades: A Step-by-Step Guide

Maintaining the sharpness and effectiveness of your cutting tool is essential for optimal performance. Over time, the blades can become dull or damaged, necessitating their replacement. This guide outlines the essential steps to ensure a smooth and safe process.

Step 1: Gather Necessary Tools

Before beginning, ensure you have the right tools at hand, including a wrench, safety gloves, and a protective eyewear. This will facilitate a hassle-free experience.

Step 2: Disconnect Power Source

For safety, always disconnect the power source before attempting any maintenance. This prevents accidental starts during the process.

Step 3: Remove Old Blades

Using the wrench, carefully unscrew the bolts securing the blades. Keep these bolts in a safe place for future use. Gently detach the old blades from their mounting.

Step 4: Clean the Area

Before installing the new blades, clean the mounting area to remove any debris or grass buildup. This ensures a secure fit and optimal function.

Step 5: Install New Blades

Align the new blades with the mounting holes and secure them with the bolts. Ensure they are tightened properly to avoid any movement during operation.

Step 6: Reconnect Power Source

Once everything is in place, reconnect the power source. Double-check the installation to ensure everything is secure.

Step 7: Test Functionality

Finally, perform a test run to ensure that the new blades are functioning correctly. This step verifies that your tool is ready for efficient use.

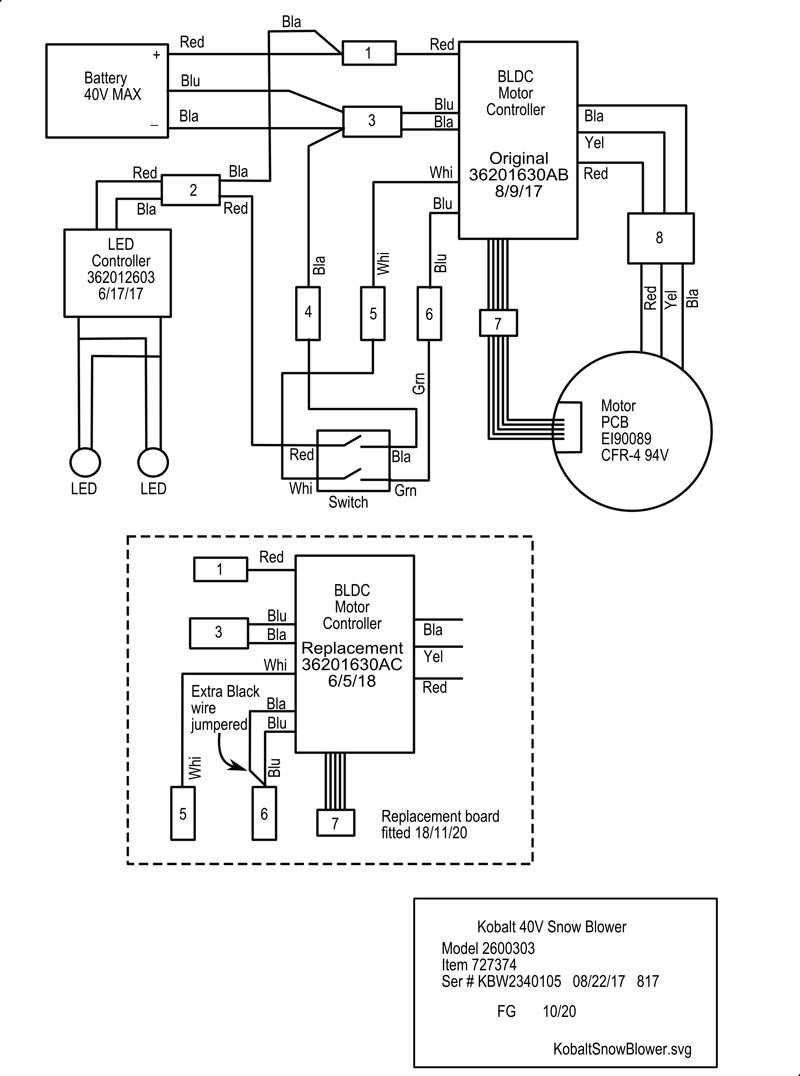

Electrical Components and Their Functions

This section explores the essential electrical elements found in outdoor machinery, highlighting their roles in ensuring optimal performance. Understanding these components is crucial for effective maintenance and troubleshooting, as each plays a significant part in the overall operation.

The battery serves as the primary power source, supplying the necessary energy for starting and running the equipment. The motor acts as the driving force, converting electrical energy into mechanical power to enable movement. Control switches manage the operation of the device, allowing the user to turn it on or off with ease.

Wiring harnesses facilitate the connection between various components, ensuring efficient transmission of power and signals. Fuses protect the electrical system from overloads, safeguarding against potential damage. Lastly, the ignition system is responsible for initiating the operation, providing the spark needed for efficient functioning.

Maintenance Tips for Longevity

Ensuring the durability of your outdoor equipment requires regular care and attention. Adopting a proactive approach to upkeep not only enhances performance but also extends the life of your machinery. Here are some essential practices to follow for optimal maintenance.

Regular Cleaning

- Remove debris and grass clippings after each use.

- Wipe down surfaces with a damp cloth to prevent rust.

- Inspect and clean the undercarriage to avoid buildup that can affect functionality.

Routine Checks and Lubrication

- Examine belts and cables for wear and tear.

- Check oil levels and change it according to the manufacturer’s recommendations.

- Lubricate moving parts regularly to minimize friction and wear.

By implementing these practices, you can ensure that your equipment remains in top condition, ready to tackle any task efficiently and effectively.

Where to Find Replacement Parts

Finding the right components for your equipment can enhance its performance and longevity. Whether you need to replace a specific item or perform maintenance, knowing where to look is essential.

Authorized Dealers are often the best source for high-quality components. They provide genuine items that ensure compatibility and durability.

Online Retailers offer a vast selection, making it easy to compare prices and read reviews. Websites dedicated to equipment supplies can be particularly helpful.

Local Repair Shops may stock various items or can order them for you. Establishing a relationship with a nearby shop can also provide valuable advice on maintenance and repairs.

Community Forums can be a treasure trove of information. Enthusiasts often share tips on sourcing components and troubleshooting issues.

By exploring these avenues, you can ensure your equipment remains in optimal condition and ready for use.

Upgrading Your Mower’s Performance

Enhancing the efficiency and effectiveness of your grass cutting equipment can significantly improve its operation and longevity. Whether you are looking to achieve a cleaner cut, increase power, or ensure smoother functionality, several strategies can be employed to elevate performance. By focusing on key components and modifications, you can transform your device into a more reliable tool for maintaining your outdoor spaces.

Essential Upgrades to Consider

When contemplating improvements, consider the following components that can impact overall performance:

| Component | Benefit |

|---|---|

| High-Performance Blades | Provides a sharper, cleaner cut, reducing wear and tear on the engine. |

| Air Filters | Enhances airflow, improving combustion and overall efficiency. |

| Spark Plug | Ensures a reliable ignition, promoting smoother operation. |

| Oil Type | Using the recommended oil improves lubrication and reduces friction. |

Maintenance Practices

Regular upkeep plays a vital role in maintaining optimal functionality. Performing routine checks and replacements on crucial components can prevent potential issues and extend the lifespan of your equipment. Consider implementing a seasonal maintenance schedule to ensure that all systems are operating at peak performance.

Safety Precautions During Repairs

Ensuring a secure environment while performing maintenance is crucial for avoiding accidents and injuries. Adhering to specific guidelines can significantly enhance safety and efficiency during the repair process.

- Always disconnect power sources before starting any work.

- Wear appropriate personal protective equipment, such as gloves and goggles.

- Work in a well-ventilated area to minimize inhalation of harmful fumes.

Prioritize the organization of your workspace:

- Keep tools and materials within easy reach to avoid unnecessary movement.

- Clear away any clutter to prevent tripping hazards.

Finally, follow the manufacturer’s instructions closely to ensure all safety measures are respected.

FAQs About Kobalt Mowers

This section aims to address common inquiries regarding a popular brand of outdoor power tools, focusing on their functionality, maintenance, and user experiences. Here, we explore various aspects that users frequently seek clarification on.

What are the benefits of using this brand’s equipment? The tools are known for their durability and efficiency, making them suitable for both residential and commercial use.

How do I maintain my equipment? Regular cleaning, blade sharpening, and following the manufacturer’s guidelines are essential for optimal performance.

Where can I find replacement components? Replacement items are typically available through authorized dealers and various online retailers.

What should I do if my tool isn’t starting? First, check the battery and connections; if problems persist, consulting the user manual or a professional may be necessary.