When it comes to efficient machinery, having a clear understanding of individual elements and their configuration is essential. This knowledge not only aids in maintenance but also enhances overall performance. Familiarity with the specific parts and their relationships can lead to better troubleshooting and repairs, ensuring longevity and reliability of equipment.

In this section, we will explore the intricacies of the components involved in a particular model of compact machinery. By examining how each piece interacts with others, users can gain valuable insights into optimal usage and care. This understanding serves as a foundation for effective operation and upkeep, promoting a more seamless experience.

Through a detailed overview of the component layout, readers will find guidance on identifying critical parts and their functions. This resource will be particularly beneficial for those looking to enhance their mechanical knowledge or engage in hands-on maintenance. Whether you are a seasoned operator or a novice, mastering this information will empower you to make informed decisions regarding your machinery.

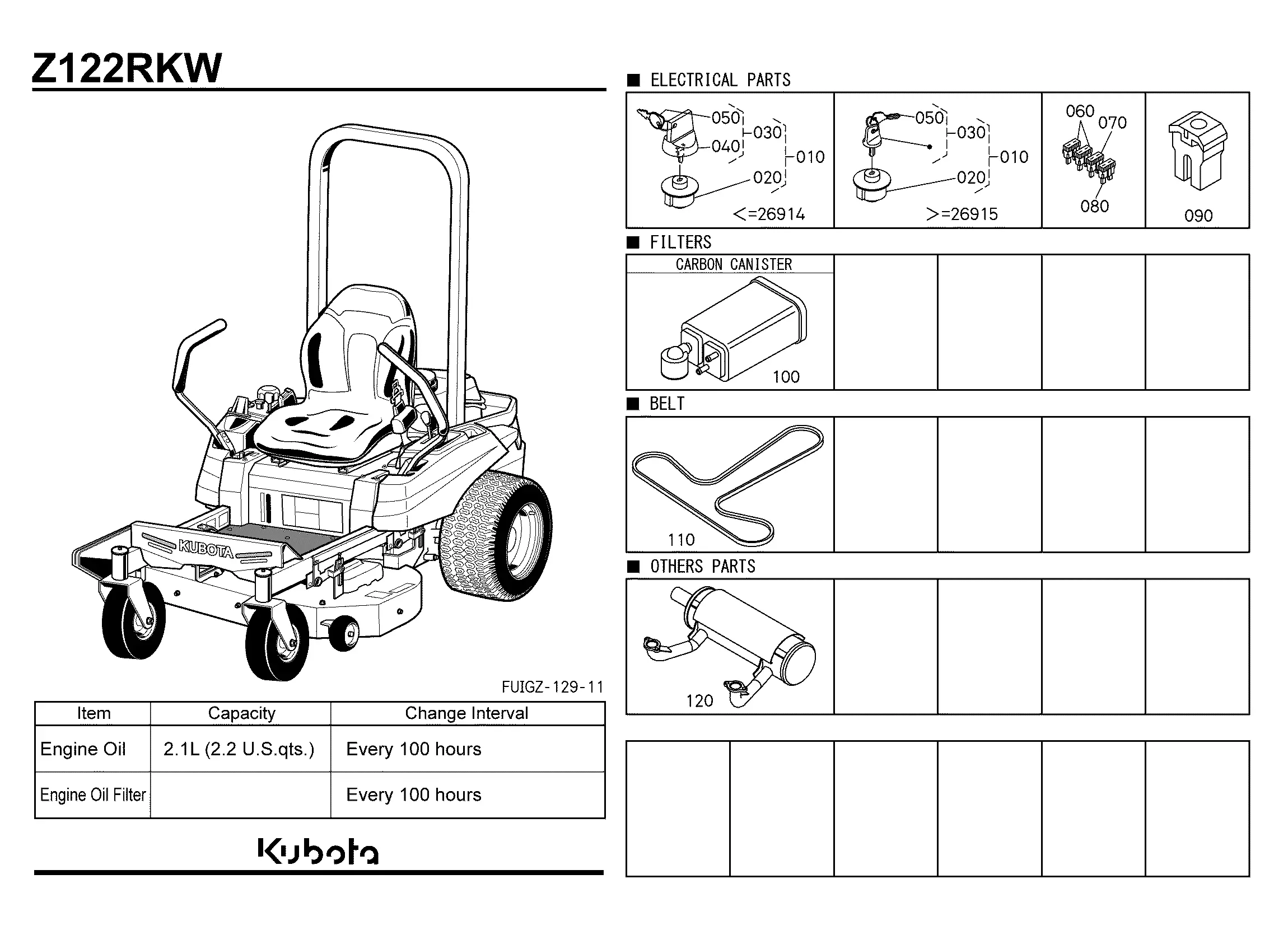

Kubota Z122RKW-42 Overview

This section provides a comprehensive look at a popular model in the compact mower category, known for its efficiency and versatility. Designed for both residential and commercial use, this machine combines powerful performance with user-friendly features, making it an ideal choice for maintaining lawns and landscapes.

Its innovative design includes a robust engine and maneuverable chassis, allowing for easy navigation in tight spaces. The mower is equipped with advanced cutting technology, ensuring a clean and precise cut. Furthermore, the comfortable operator station enhances the user experience during extended periods of operation.

Durability and reliability are hallmarks of this model, built to withstand various conditions and deliver consistent results. Maintenance is straightforward, which contributes to its long-term value for users seeking efficiency without sacrificing quality.

Key Features of Z122RKW-42

This section explores the remarkable characteristics that distinguish this specific model in the realm of compact machinery. Its innovative design and superior performance make it a top choice for users seeking efficiency and reliability in their tasks.

Performance and Efficiency

The machine is engineered for optimal functionality, ensuring effective operation across various terrains. Its powerful engine provides robust power while maintaining fuel efficiency, making it a cost-effective solution for lawn care and landscaping.

User-Friendly Design

Designed with the operator in mind, the layout offers enhanced accessibility and comfort. Intuitive controls simplify operation, allowing users to focus on their work without unnecessary distractions.

| Feature | Description |

|---|---|

| Engine Power | Robust engine delivering exceptional torque. |

| Cutting Width | Wide cutting deck for efficient mowing. |

| Durability | Sturdy construction for long-lasting performance. |

| Comfort | Ergonomically designed seat and controls. |

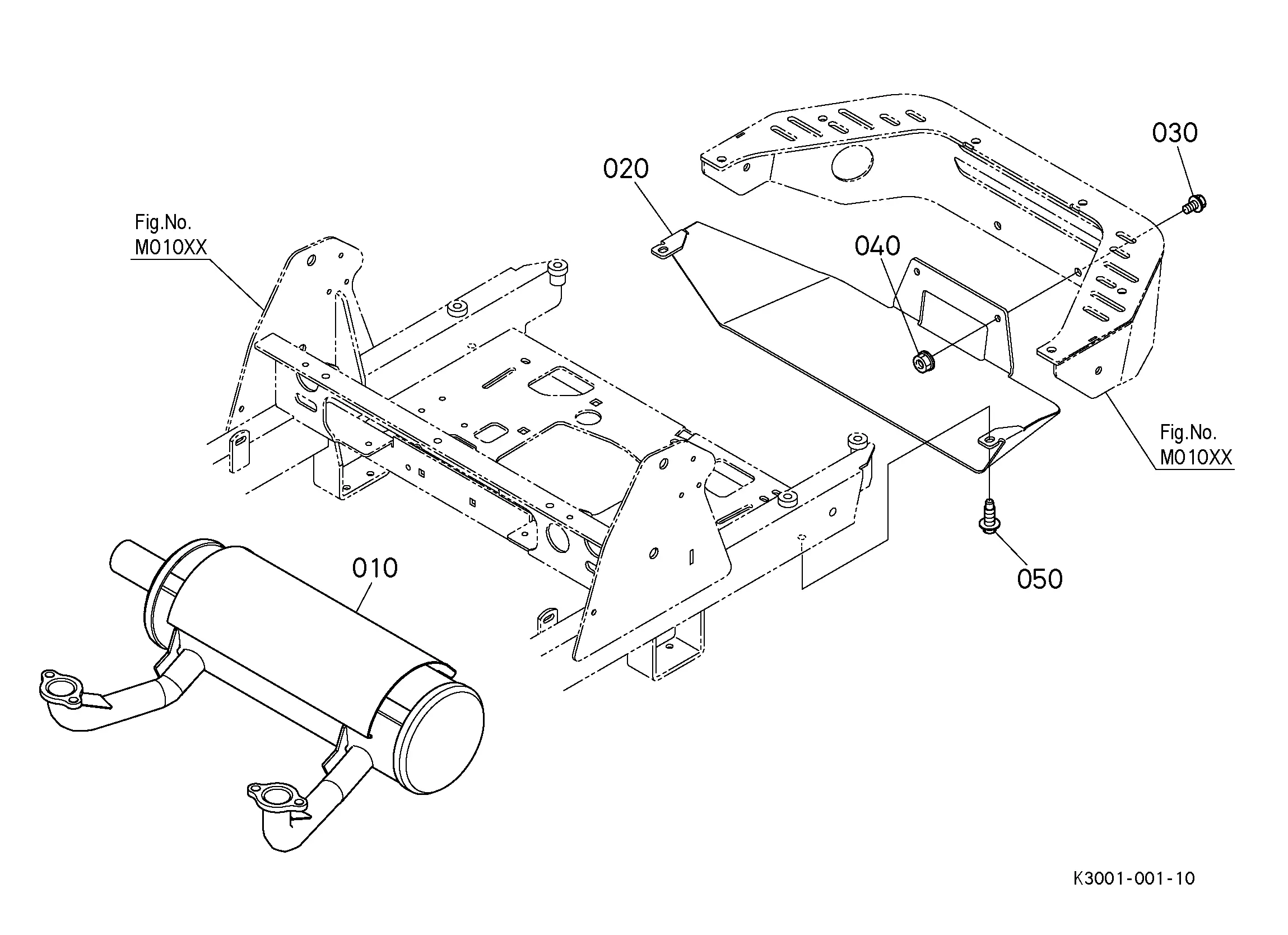

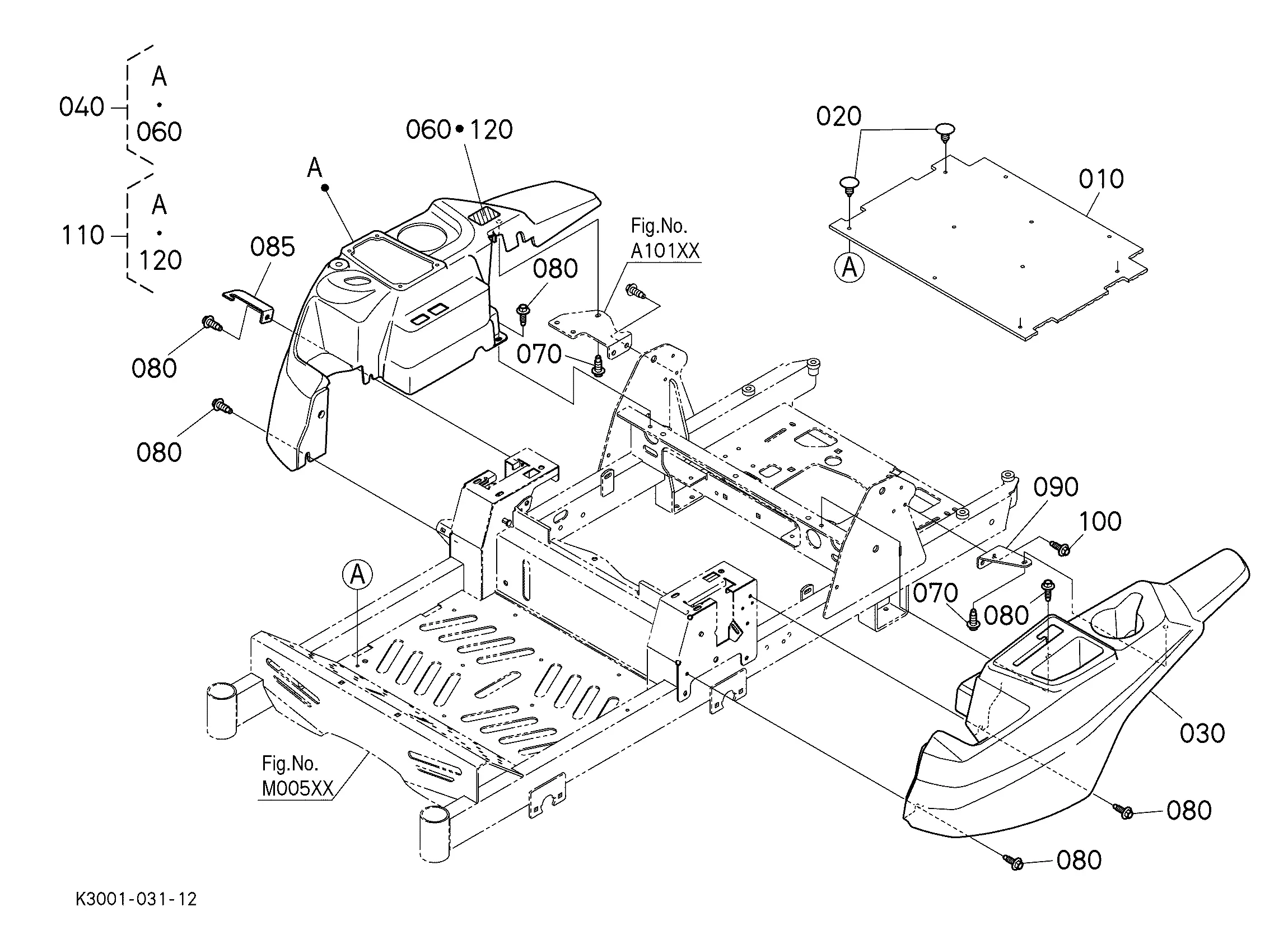

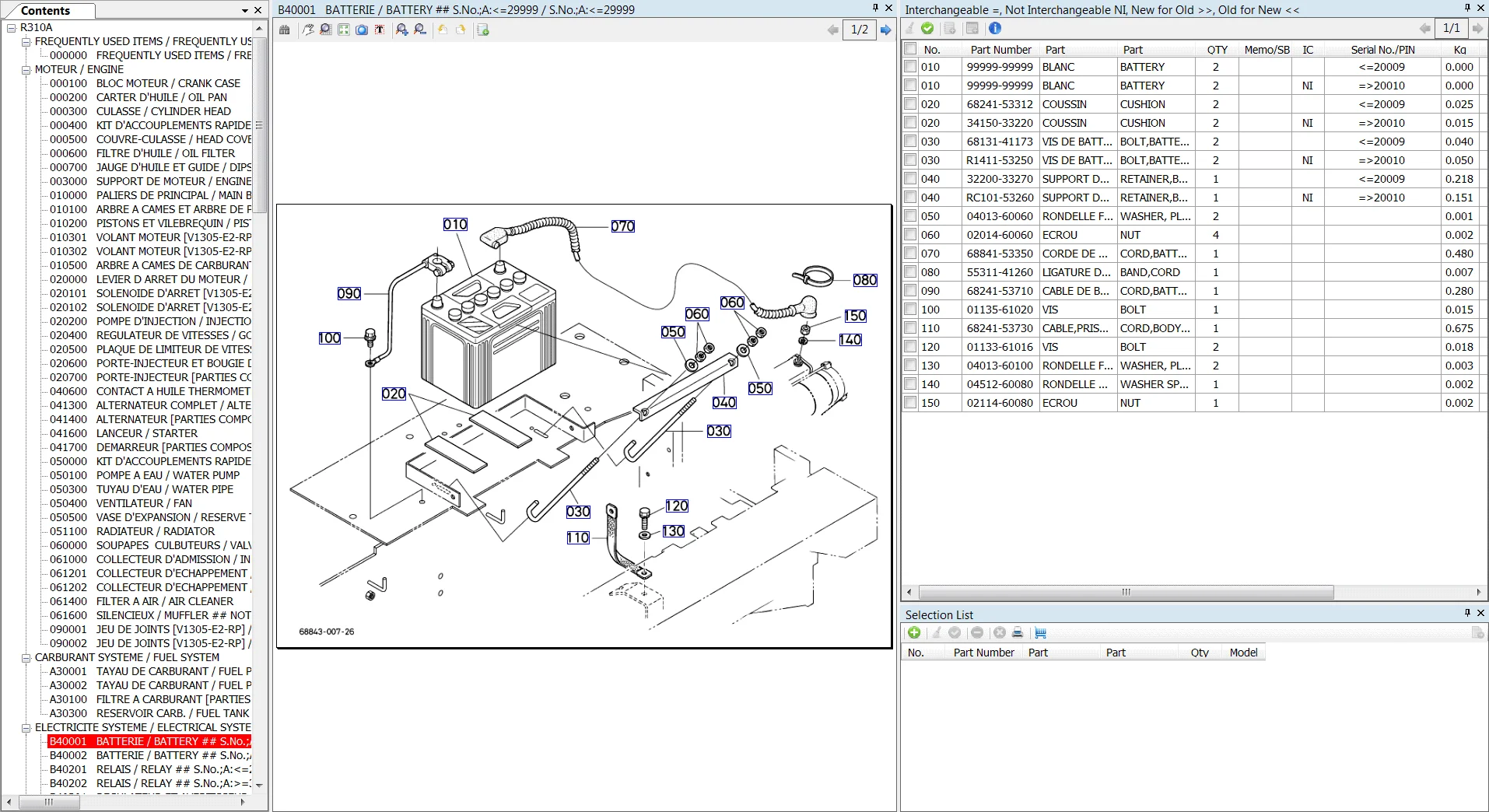

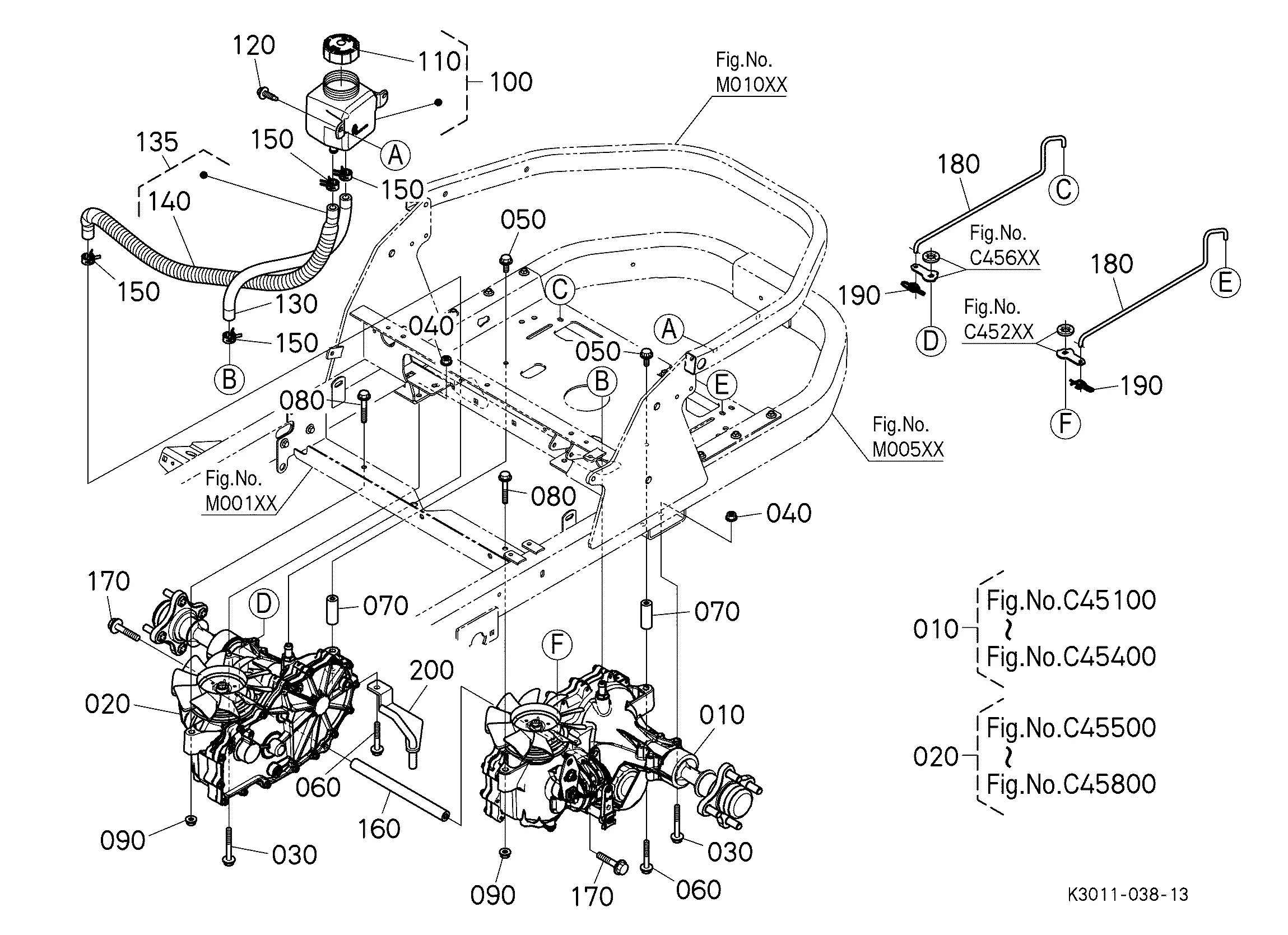

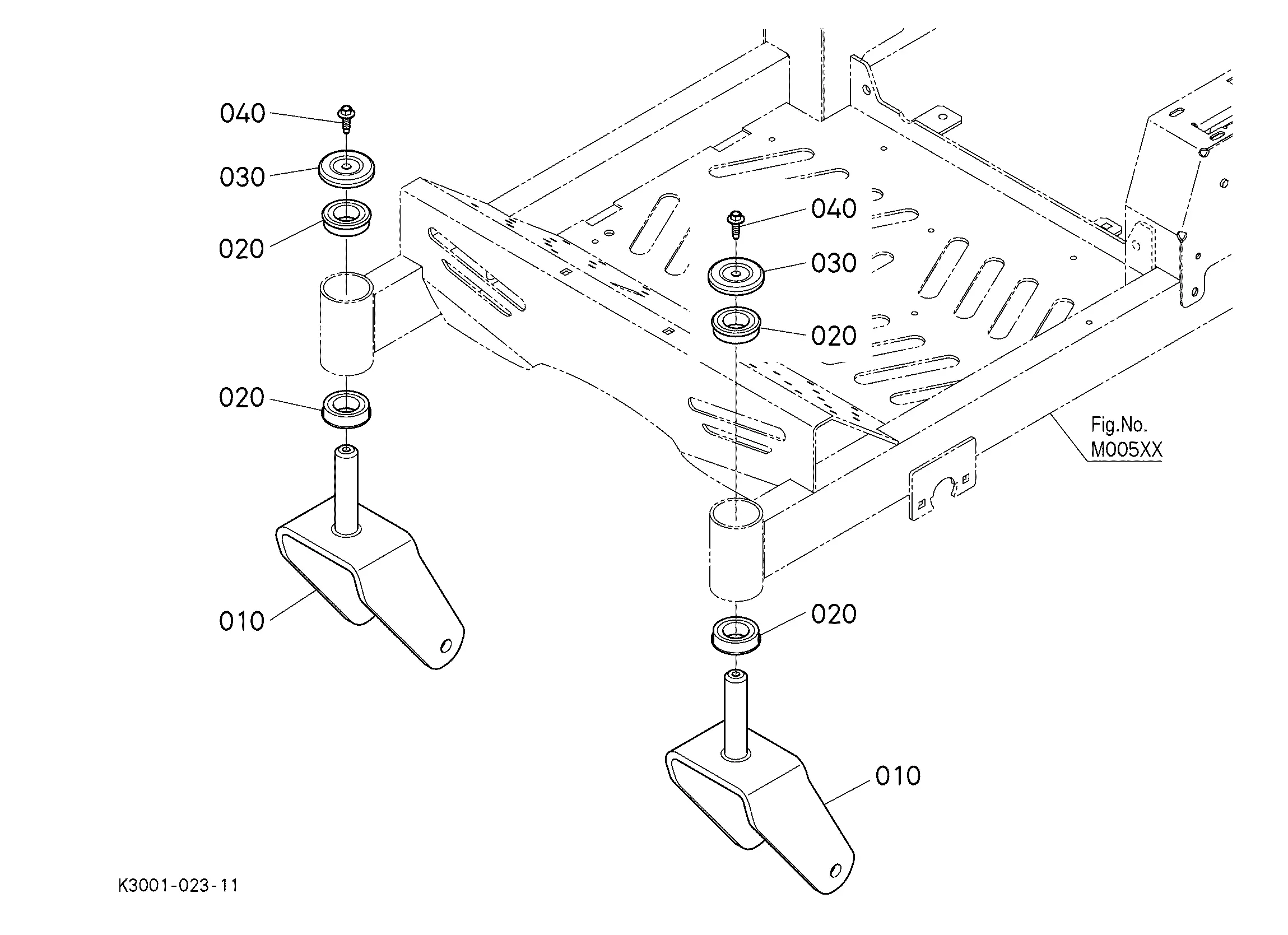

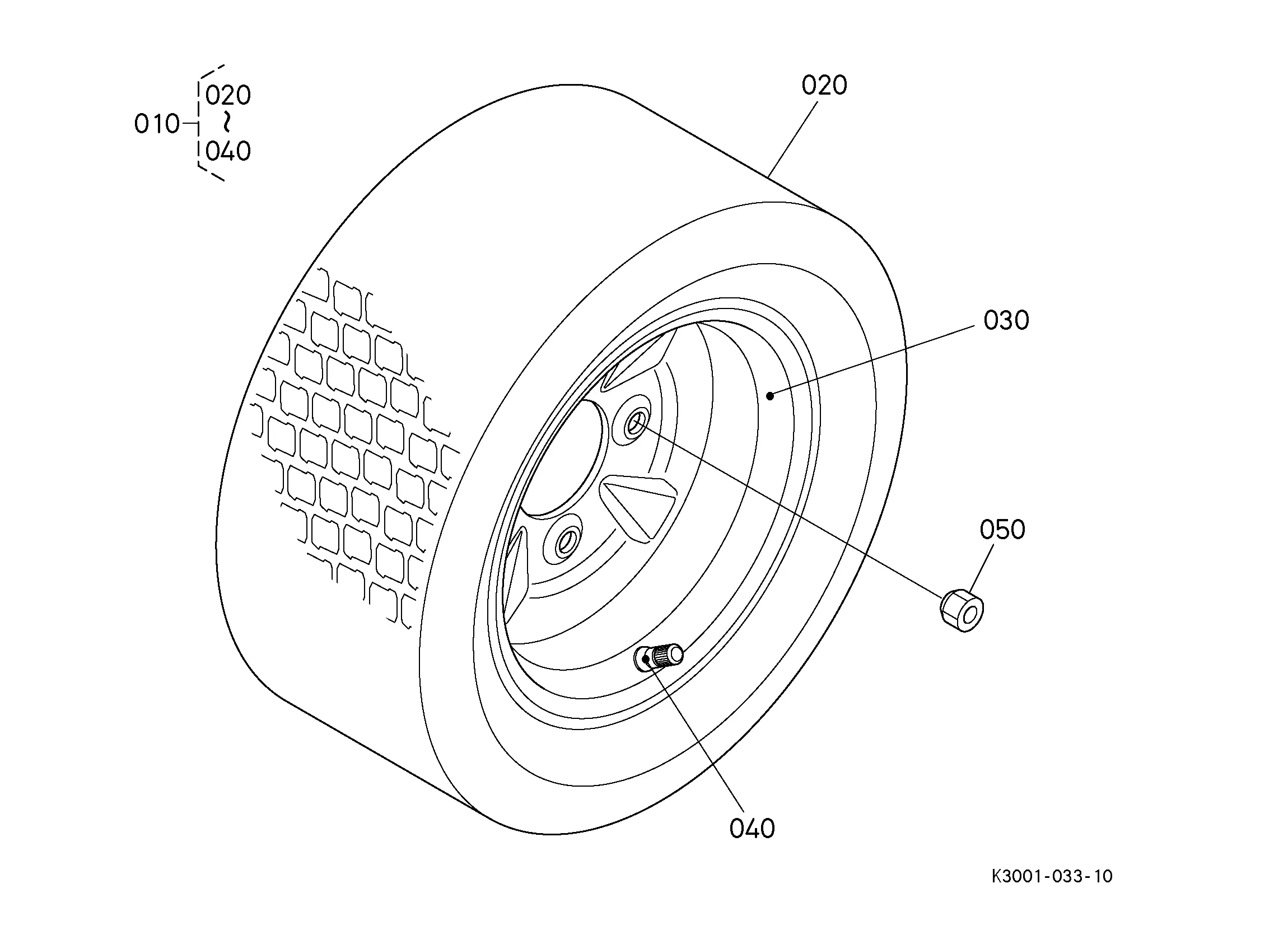

Understanding Parts Diagrams

Grasping the layout of components within machinery is crucial for effective maintenance and repairs. Visual representations of various elements provide a clear guide to understanding how each part interacts with others, facilitating smoother troubleshooting and restoration processes. These illustrations serve as essential tools for both professionals and enthusiasts, ensuring that everyone can navigate complex assemblies with confidence.

Importance of Visual Aids

Visual aids simplify the identification of components, allowing users to quickly locate and assess specific elements. By breaking down intricate systems into manageable sections, these graphics enhance comprehension and minimize errors during assembly or disassembly. Users benefit from a structured approach, leading to increased efficiency in tasks that may otherwise seem daunting.

Interpreting Illustrations Effectively

Understanding these visuals requires familiarity with symbols and terminology. Recognizing standard notations and labels used in such representations is key to accurately interpreting information. By familiarizing oneself with these aspects, users can enhance their ability to follow instructions, making repairs more straightforward and reducing the risk of missteps.

Importance of Accurate Diagrams

Precise illustrations are crucial in any technical field, serving as essential tools for understanding complex systems. They provide clarity and facilitate effective communication among users, engineers, and technicians. Accurate visual representations can significantly enhance efficiency and reduce errors during assembly, maintenance, or repairs.

| Benefits | Description |

|---|---|

| Enhanced Clarity | Clear visuals help users grasp intricate details quickly. |

| Reduced Errors | Minimized chances of mistakes during installation or service. |

| Improved Efficiency | Streamlined processes lead to faster task completion. |

| Effective Training | Supports onboarding and skill development for new users. |

Common Components of Z122RKW-42

The design of this mower incorporates various essential elements that contribute to its efficiency and performance. Understanding these components helps users maintain and troubleshoot their equipment effectively.

Engine: The heart of the machine, providing the necessary power for operation. A reliable engine ensures optimal performance in various conditions.

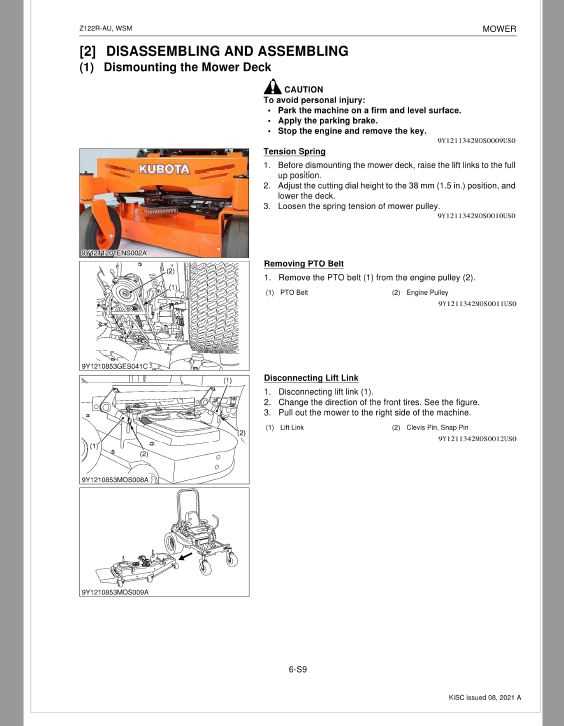

Deck: This part houses the cutting blades and is crucial for achieving a clean cut. The design and material of the deck affect both durability and performance.

Transmission: This system transfers power from the engine to the wheels, facilitating smooth movement and maneuverability. A well-maintained transmission is vital for responsiveness.

Wheels: Designed for stability and traction, the wheels enhance the mower’s ability to navigate different terrains. Their size and tread pattern play a significant role in performance.

Blades: Sharp and efficient, these components are essential for effective cutting. Regular inspection and sharpening of the blades are necessary for maintaining cutting quality.

Controls: User-friendly interfaces allow for precise operation. Familiarity with the controls enables operators to maximize the machine’s capabilities.

Identifying Wear and Tear Parts

Recognizing components that exhibit signs of deterioration is crucial for maintaining optimal performance and longevity of equipment. Understanding which elements are susceptible to wear allows for timely replacements, reducing the risk of malfunction and ensuring smooth operation. This section aims to guide you through the identification process of such elements, highlighting common indicators of damage and their implications for functionality.

| Component | Signs of Wear | Potential Impact |

|---|---|---|

| Belts | Cracks, fraying, or stretching | Reduced efficiency and power transfer |

| Blades | Dulling, chipping, or bending | Poor cutting performance and increased strain |

| Filters | Clogging or discoloration | Impaired airflow and reduced system performance |

| Tires | Uneven wear or cracks | Stability issues and compromised traction |

| Hoses | Leaking or bulging | Fluid loss and potential system failure |

How to Read Parts Diagrams

Understanding visual representations of components can significantly enhance maintenance and repair efforts. These illustrations provide crucial information on each element’s function and placement within a larger assembly.

Key Elements to Focus On

- Labels: Identify the marked sections and their corresponding numbers or letters.

- Symbols: Familiarize yourself with common icons that represent various types of components.

- Connections: Pay attention to how parts are linked, indicating assembly and disassembly order.

Steps for Effective Interpretation

- Start by reviewing the entire illustration to get a general layout.

- Locate the legend or key that explains the symbols and terminology used.

- Cross-reference the numbers with the accompanying list for detailed descriptions.

- Take notes on specific components that need replacement or attention.

Maintenance Tips for Z122RKW-42

Regular upkeep is essential for ensuring the longevity and optimal performance of your equipment. By implementing a few straightforward practices, you can keep your machine running smoothly and efficiently. Proper maintenance not only enhances functionality but also prevents costly repairs in the future.

1. Check Fluid Levels: Regularly inspect and replenish essential fluids, including oil and fuel, to maintain peak performance.

2. Clean Air Filters: Keeping air filters clean ensures that the engine receives adequate airflow, improving efficiency and performance.

3. Inspect Belts and Hoses: Routine checks for wear and tear on belts and hoses can prevent unexpected breakdowns and ensure reliable operation.

4. Sharpen Blades: Maintaining sharp blades is crucial for effective cutting and overall performance, reducing strain on the engine.

5. Store Properly: When not in use, ensure the machine is stored in a dry, sheltered environment to protect it from the elements.

By incorporating these practices into your routine, you can significantly enhance the reliability and efficiency of your machinery.

Where to Find Replacement Parts

When seeking components for machinery, it’s crucial to know where to look for quality and reliable options. Various sources offer a range of alternatives, ensuring that your equipment remains in optimal working condition.

Online Retailers

The internet is a valuable resource for locating necessary items. Many specialized websites provide detailed catalogs and competitive pricing.

- Manufacturer’s official site

- Third-party retailers

- E-commerce platforms

Local Dealers and Distributors

Visiting local suppliers can be beneficial. They often carry essential stock and can provide expert advice.

- Authorized dealerships

- Independent distributors

- Repair shops

Cost Considerations for Parts

When evaluating the expenses associated with machinery components, it’s essential to consider various factors that influence pricing. Understanding these elements can lead to informed decisions and potentially significant savings.

| Factor | Description |

|---|---|

| Brand Reputation | Renowned manufacturers often charge a premium for their reliability and quality assurance. |

| Material Quality | High-grade materials may incur higher costs but can enhance durability and performance. |

| Availability | Scarcity can drive up prices; commonly stocked items tend to be more affordable. |

| Compatibility | Specialized components designed for specific models might be more expensive than universal alternatives. |

| Supplier Markup | Different suppliers may have varying pricing strategies, affecting overall costs. |

By delving into these considerations, users can make the ultimate choice that balances quality with affordability, ensuring efficient operation without overspending.

Upgrades and Accessories Available

Enhancing the functionality and efficiency of your equipment can significantly improve performance and user experience. Various enhancements and supplementary items are available to tailor your machine to your specific needs, ensuring optimal operation for different tasks.

- Performance Enhancements:

- Powerful engine upgrades for increased horsepower.

- Advanced transmission options for smoother operation.

- Attachment Options:

- Various mowing decks for different cutting heights and styles.

- Snow plows and blowers for winter maintenance.

- Comfort Features:

- Ergonomic seat upgrades for improved comfort during extended use.

- Enhanced control systems for easier operation.

- Safety Equipment:

- Rollover protective structures to enhance safety.

- Lights and reflectors for better visibility in low-light conditions.

- Storage Solutions:

- Toolboxes and racks for organized storage of essential equipment.

- Bagging systems for efficient grass collection.

Exploring these options can provide greater versatility, ensuring your machine meets the demands of any job, whether in residential or commercial settings.

Comparing Z122RKW-42 to Similar Models

When evaluating compact mowing equipment, understanding the differences among similar units can provide valuable insights. Each model presents unique features, performance metrics, and user experiences that can influence the ultimate choice for consumers.

Performance: While some models offer superior speed and maneuverability, others excel in cutting precision and efficiency. Identifying which performance attributes matter most to the user is crucial.

Features: Variations in design, such as deck size and engine power, can significantly affect usability. Certain machines come equipped with advanced technology that enhances the overall mowing experience.

Durability: Comparing the build quality and materials used in construction can reveal long-term reliability. Users should consider warranties and customer reviews as indicators of durability.

Ultimately, by delving into these aspects, potential buyers can make informed decisions that best suit their mowing needs and preferences.