In the realm of gardening and land cultivation, having a comprehensive grasp of the essential elements that contribute to the efficiency of soil preparation is vital. Various mechanical units are designed to enhance productivity and simplify the process of turning over earth, aerating soil, and managing weeds. Each of these machines consists of specific components, each playing a crucial role in their overall functionality.

Identifying the individual components is essential for anyone looking to maintain or repair their cultivation equipment. By understanding how these elements interact, operators can ensure optimal performance and longevity of their machinery. This section provides valuable insights into the configuration and roles of the various parts, assisting users in troubleshooting and enhancing their equipment’s capabilities.

Effective management of such devices not only contributes to improved agricultural practices but also enhances the user’s experience, making gardening tasks less labor-intensive. Familiarity with the structure of these machines empowers operators to execute necessary repairs and replacements, thereby maximizing their utility in diverse gardening applications.

This section provides a comprehensive examination of a specific type of agricultural machinery known for its efficiency in soil cultivation. Understanding the fundamental components and their functions is essential for maintaining optimal performance and ensuring longevity. Each element plays a crucial role in the overall operation, making it vital for users to familiarize themselves with the machinery’s inner workings.

Key Components and Their Functions

Every machine consists of various integral parts that contribute to its functionality. Identifying these components and understanding their roles can significantly enhance the user experience. Below is a summary of the primary elements that are crucial to the operation of this machinery:

| Component | Function |

|---|---|

| Engine | Powers the entire system, enabling it to perform various tasks efficiently. |

| Transmission | Transfers power from the engine to the wheels, controlling speed and torque. |

| Handlebars | Provides control and maneuverability, allowing the operator to steer the machine. |

| Blade Assembly | Engages with the soil, breaking it up for better aeration and preparation. |

| Fuel Tank | Holds the necessary fuel to power the engine during operation. |

Maintenance Tips

To ensure the machine remains in peak condition, regular maintenance is essential. Routine checks of each component can prevent breakdowns and extend the machinery’s lifespan. Key practices include cleaning the engine, checking oil levels, and inspecting the blade assembly for wear. Following these guidelines can help maintain performance and efficiency.

Key Components of the Tiller

The efficiency and functionality of agricultural machinery are largely determined by its essential elements. Understanding these core components helps users maintain and operate the equipment effectively, ensuring optimal performance in various tasks.

Core Elements

- Engine: Provides the necessary power to drive the machinery.

- Transmission: Transmits power from the engine to the working components.

- Frame: The structural backbone that supports all other elements.

- Handlebars: Allow the operator to steer and control the device.

- Wheels: Facilitate movement across different terrains.

Working Components

- Blades: Cut into the soil for tilling and aerating.

- Clutch: Engages or disengages the engine from the transmission.

- Fuel Tank: Stores the fuel needed for operation.

- Cooling System: Maintains optimal operating temperatures to prevent overheating.

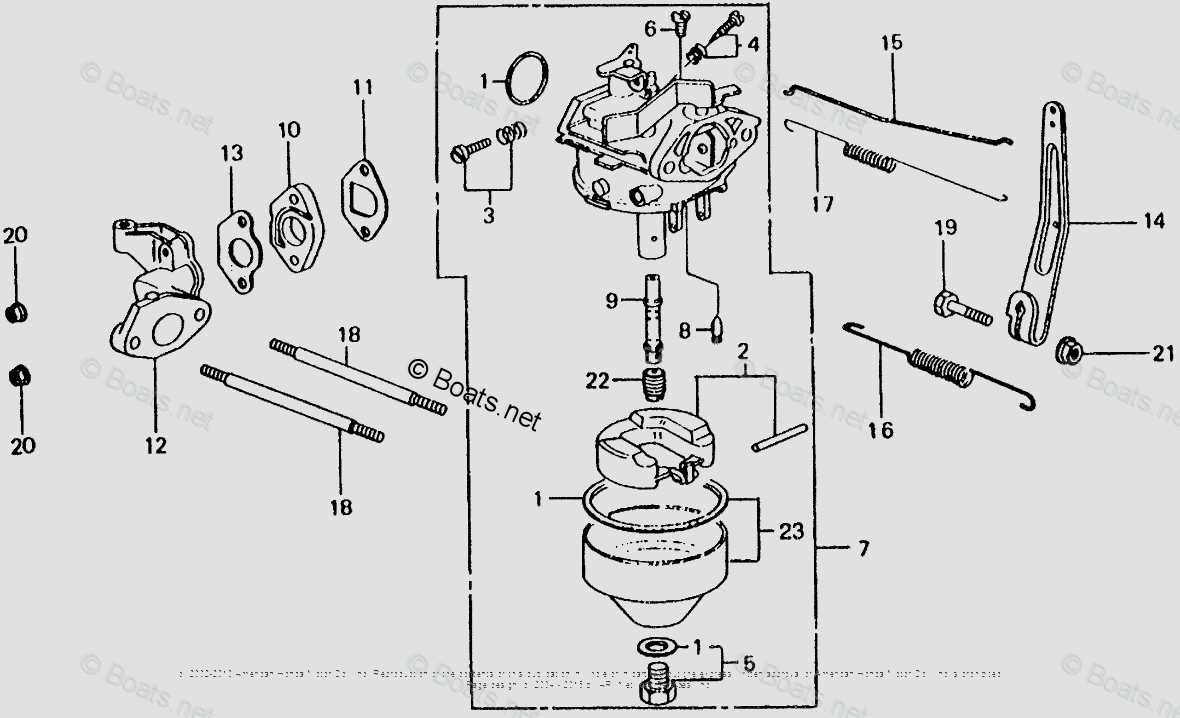

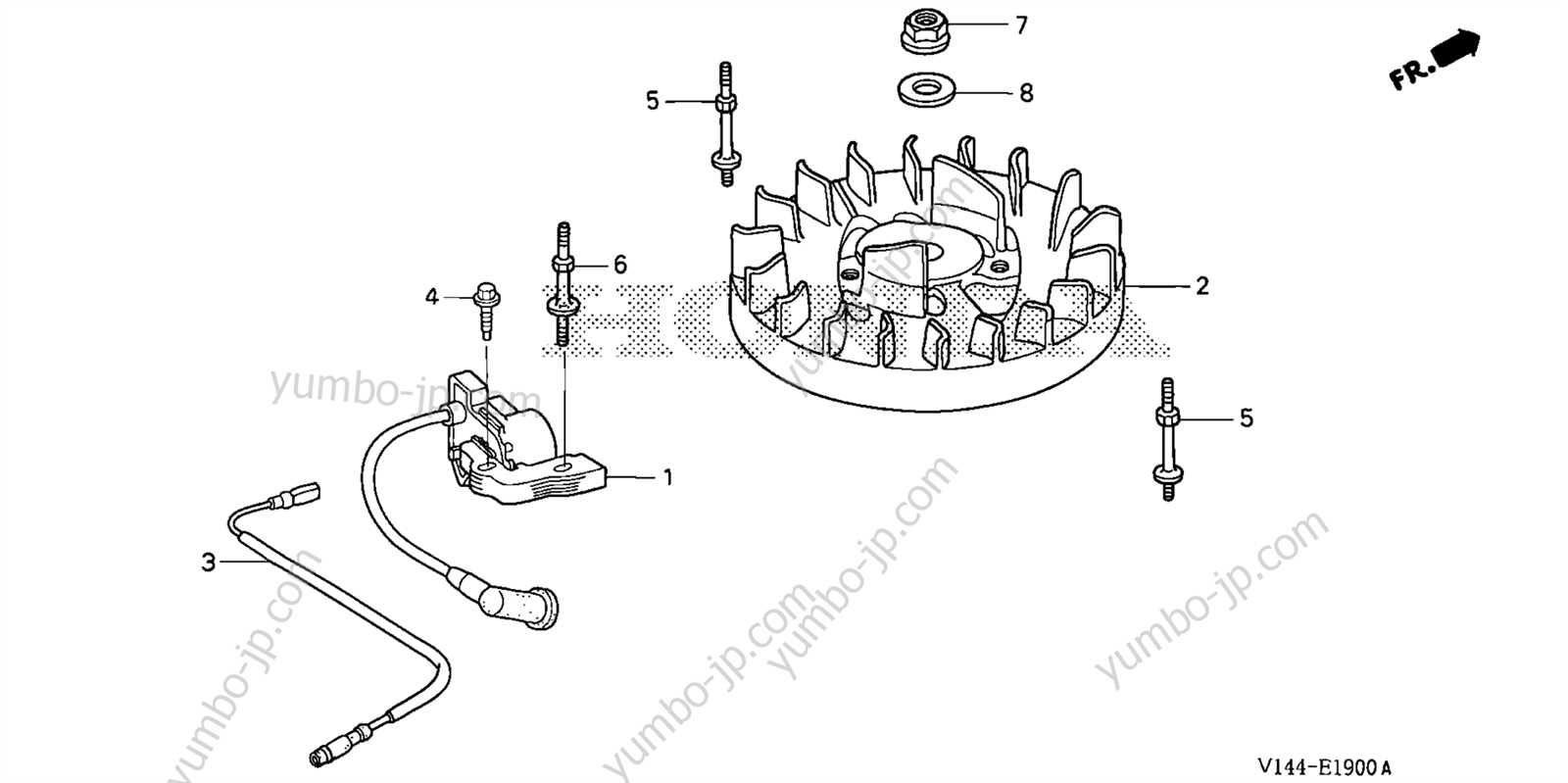

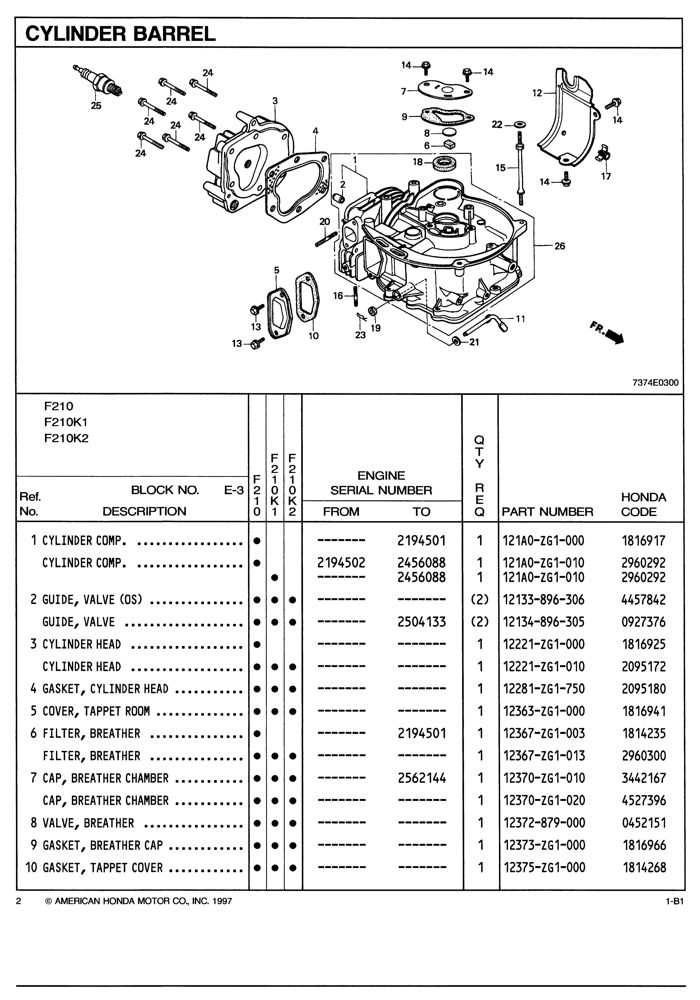

Understanding the Parts Diagram

The visual representation of components serves as a crucial tool for comprehending the assembly and functionality of machinery. By examining these illustrations, users can gain insights into how various elements interact and contribute to the overall performance. This understanding is essential for effective maintenance and troubleshooting, allowing operators to identify issues and perform necessary repairs efficiently.

Components Overview

Each element within the illustration plays a specific role, often categorized into functional groups. Recognizing these categories aids in grasping the purpose of each piece, whether it be for propulsion, power transmission, or control. Understanding the relationships between these components is vital for ensuring the proper operation of the entire system.

Maintenance and Troubleshooting

A clear grasp of the visual representation enables users to conduct regular upkeep and promptly address any malfunctions. By pinpointing specific components within the illustration, operators can focus their efforts on the most relevant areas, facilitating a more efficient repair process. This proactive approach not only enhances the longevity of the equipment but also improves overall performance.

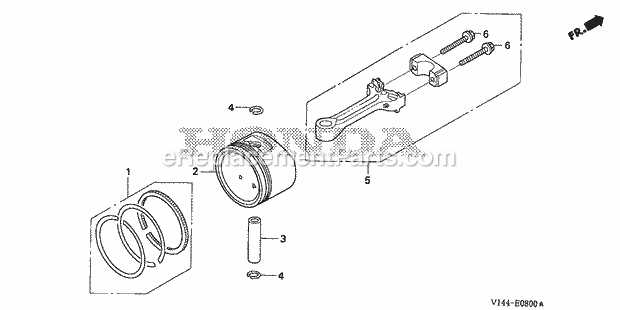

Identifying Engine Parts

Understanding the various components of a motor is crucial for maintenance and effective operation. Each element plays a specific role, contributing to the overall functionality of the engine. Familiarity with these components aids in troubleshooting issues and ensuring optimal performance.

Key components of a motor include the combustion chamber, where fuel and air mix and ignite, and the crankshaft, which converts the linear motion of the pistons into rotational force. Additionally, the cylinder head houses critical elements such as valves and spark plugs, playing a vital role in the engine’s efficiency.

Other significant parts encompass the intake and exhaust systems, which manage airflow and emissions, respectively. The cooling system is also essential, preventing overheating and ensuring the engine operates smoothly. By recognizing these individual components, users can better comprehend their roles and address any maintenance needs that arise.

Transmission System Breakdown

The transmission system is a vital component in agricultural machinery, responsible for converting engine power into usable mechanical energy for various functions. This section delves into the essential elements that make up the transmission mechanism, highlighting their roles and interactions in ensuring efficient operation.

Understanding the breakdown of the transmission system allows operators to maintain optimal performance and address potential issues proactively. The following table outlines the key components involved in the transmission process, their functions, and their significance in the overall system.

| Component | Function | Importance |

|---|---|---|

| Gear Assembly | Transfers rotational force from the engine to the wheels | Essential for power transmission and speed control |

| Clutch Mechanism | Engages and disengages power flow | Allows for smooth operation and stopping |

| Drive Belt | Transfers power between components | Critical for efficiency and performance |

| Transmission Housing | Encases and protects internal components | Provides structural integrity and durability |

| Fluid System | Lubricates and cools components | Ensures longevity and optimal operation |

Proper maintenance of these components is crucial for enhancing the longevity and performance of the machinery. Regular checks and timely replacements can significantly reduce downtime and improve operational efficiency.

Handle Assembly Components Explained

The handle assembly is a crucial element of any cultivating machine, providing the user with control and maneuverability. Understanding the components that make up this assembly can enhance maintenance practices and improve overall performance.

Main Components of the Handle Assembly

- Grip: This is the part where the operator holds the machine, designed for comfort and ease of use.

- Support Bracket: This component secures the handle to the main body, ensuring stability during operation.

- Control Levers: These levers allow the operator to engage and disengage various functions, facilitating smooth operation.

- Adjustment Mechanism: This feature enables users to modify the height or angle of the handle for optimal comfort and control.

Importance of Each Component

Each part of the handle assembly plays a vital role in ensuring efficient functionality. A well-designed grip reduces fatigue, while a sturdy support bracket enhances safety. Control levers must be positioned conveniently for quick access, and an effective adjustment mechanism allows for personalized setup, accommodating various user preferences.

Maintenance and Replacement Parts

Regular upkeep and timely replacement of components are essential for ensuring optimal performance and longevity of your machine. Consistent care helps prevent breakdowns and reduces the need for major repairs, ultimately extending the lifespan of the equipment.

When conducting routine maintenance, focus on inspecting key areas that are prone to wear over time. Proper lubrication, cleaning, and adjustment of mechanical elements will keep your equipment running smoothly.

- Inspect belts and pulleys for signs of wear or fraying.

- Ensure proper tension and alignment of drive mechanisms.

- Check oil levels and replace it according to the manufacturer’s recommendations.

- Examine filters and replace them regularly to maintain engine efficiency.

- Replace any damaged or corroded fasteners to ensure stability.

By following these basic guidelines, you will minimize the chances of unexpected failures and maintain the operational efficiency of your equipment for years to come.

Wheels and Tread Features

The design of wheels and the characteristics of their tread play a crucial role in ensuring smooth operation across various terrains. By providing the necessary traction and stability, these elements significantly impact the overall functionality and handling of outdoor machinery.

Wheels are often equipped with materials that enhance durability and allow for better maneuverability. This makes it easier to navigate over uneven surfaces, whether on grass, soil, or rocky ground. Properly designed wheels reduce wear and ensure a longer lifespan of the equipment.

The tread patterns on the wheels are equally important, as they determine how well the machine grips the ground. Deep, aggressive treads can provide superior traction in muddy or soft conditions, while shallower patterns are

Electrical System Overview

The electrical system is crucial for powering and ensuring the smooth operation of various components. It plays a key role in distributing energy efficiently across the machine, providing consistent performance. Proper maintenance and understanding of the system are essential for achieving reliability and longevity in usage.

This system consists of multiple interconnected elements, each contributing to the overall functionality. Wires, connectors, and control modules form the backbone, allowing seamless communication between different sections. Regular inspection of these parts ensures the avoidance of potential issues related to wear or malfunction.

Key areas of focus include energy flow management and protection mechanisms. Fuses and relays safeguard the system from overloads, while switches and regulators control the output. Understanding these components helps in troubleshooting and maintaining optimal functionality.

Choosing Quality Replacement Parts

When it comes to maintaining any equipment, ensuring the longevity and performance of your machine depends largely on the choice of suitable components. Opting for high-quality replacements can prevent future issues and improve the overall efficiency of the tool. Understanding the importance of durability and compatibility is key when selecting new elements.

Key Factors to Consider

- Material Quality: Choose components made from durable and resilient materials to extend the lifespan of your equipment.

- Fit and Compatibility: Ensure that the new parts align perfectly with your model, preventing malfunctions and unnecessary wear.

- Supplier Reputation: Purchase from reliable suppliers with a track record of providing high-quality, authentic components.

Benefits

Common Issues and Solutions

When using outdoor machinery, various operational challenges can arise over time. Whether it’s related to performance efficiency or mechanical breakdowns, understanding common problems and their practical solutions helps maintain smooth functionality and extend the equipment’s lifespan.

Engine Performance Problems

One of the most frequent issues users encounter is inconsistent engine operation. This can manifest as difficulty starting, stalling, or loss of power. To resolve these problems, it’s essential to check the fuel quality, clean the air filter, and inspect the spark plug for wear.

| Issue | Cause | Solution |

|---|---|---|

| Poor engine startup | Clogged air filter or old fuel |

Helpful Resources for OwnersMaintaining your equipment properly is crucial for ensuring its longevity and efficiency. Whether you’re looking for detailed maintenance advice or troubleshooting guides, various resources are available to assist you in keeping your machinery in top condition. These materials provide step-by-step instructions, expert recommendations, and helpful tips tailored to your needs. Online Guides: Many websites offer comprehensive manuals and detailed instructions for maintaining and repairing your machine. These guides often include visual aids to help you navigate more complex tasks. Video Tutorials: For visual learners, video tutorials can be an excellent resource. These step-by-step videos demonstrate repair techniques and regular maintenance procedures, making them easy to follow and understand. Community Forums: Joining an online community of fellow owners can provide invaluable support. These forums allow you to ask questions, share experiences, and receive advice |