When it comes to maintaining and enhancing the efficiency of machinery, a clear visual representation of its individual elements is invaluable. Such illustrations serve as essential guides, allowing users to grasp the intricate relationships between each segment and how they contribute to overall functionality.

Detailed breakdowns provide insights that empower users to identify, replace, or upgrade various sections with confidence. By delving into these representations, one can discover the ultimate configuration needed for optimal operation.

Furthermore, having access to such information aids in troubleshooting, ensuring that any issues can be addressed swiftly and effectively. Understanding each component’s role not only simplifies repairs but also enhances the lifespan and reliability of the equipment.

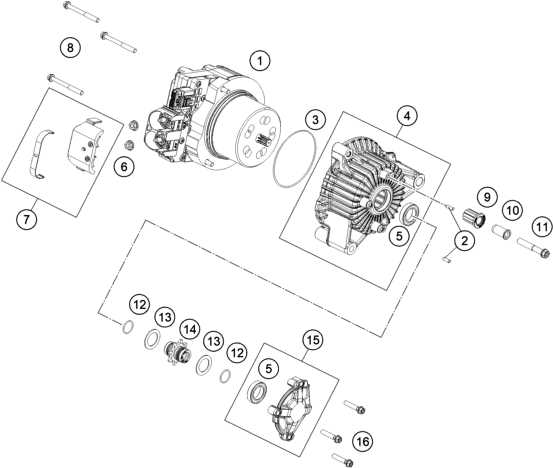

Understanding the Ms250c Parts Diagram

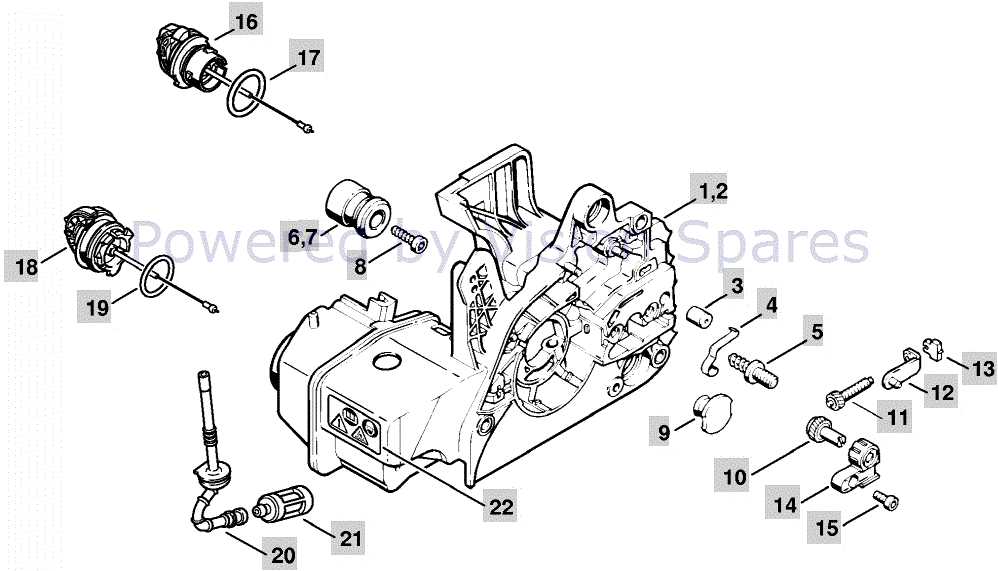

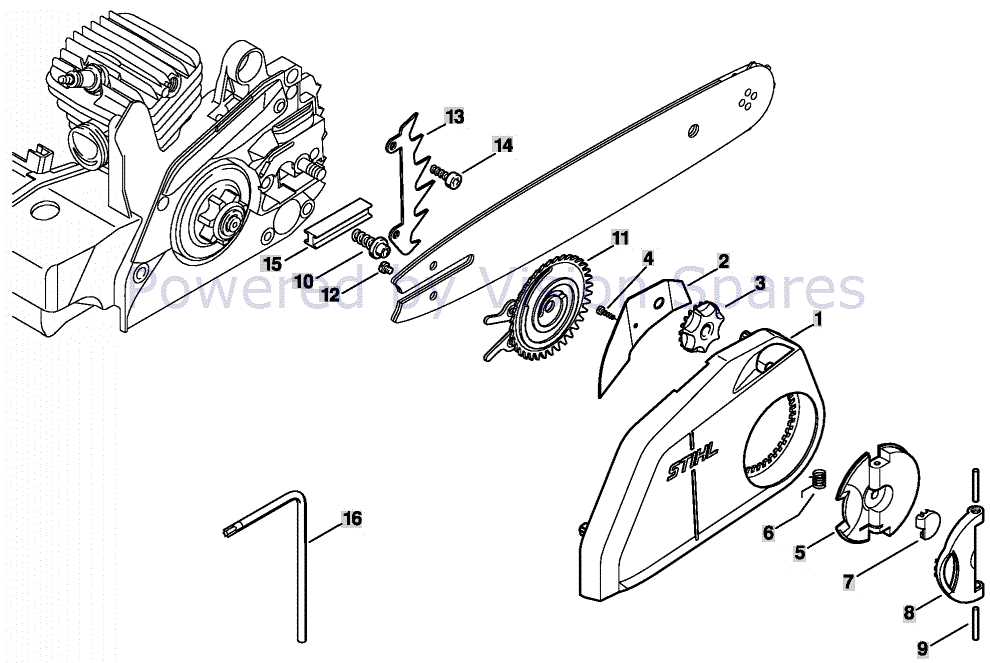

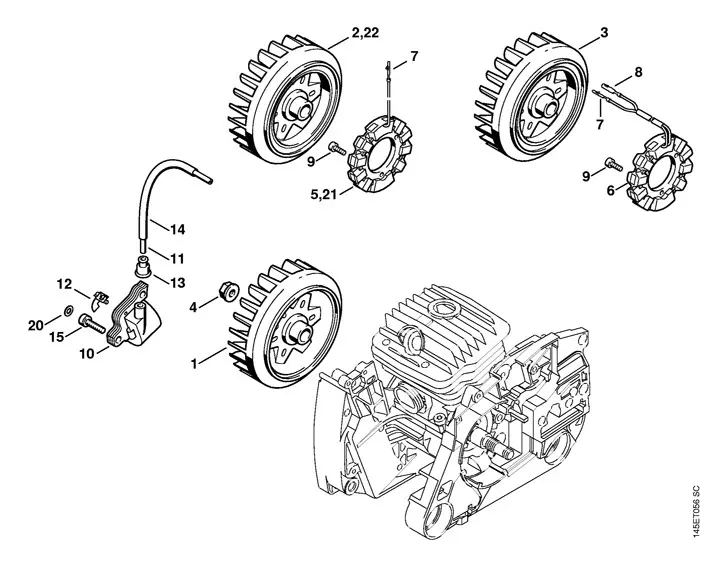

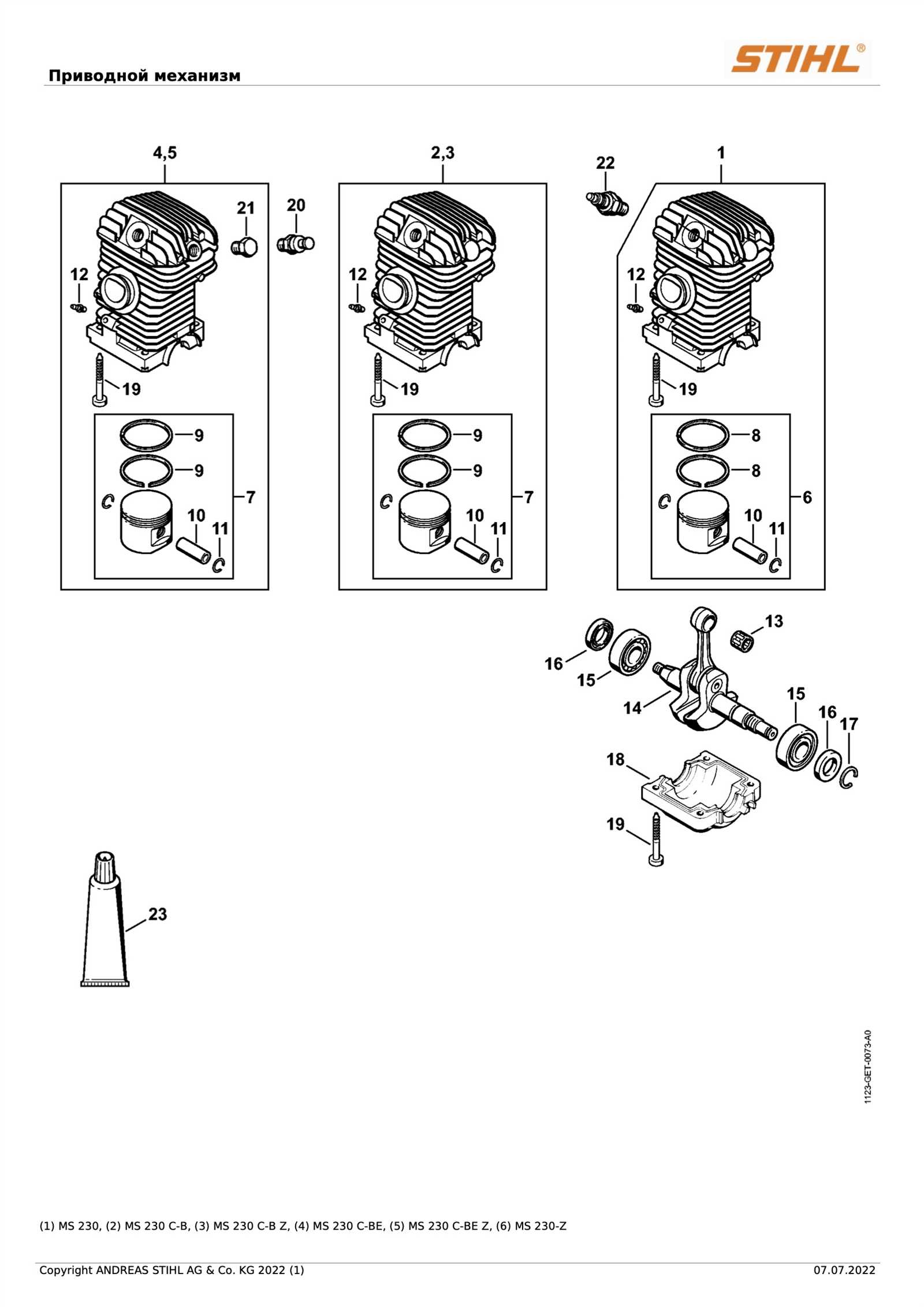

Comprehending the assembly layout of a specific tool is crucial for efficient maintenance and repair. This knowledge allows users to identify components and understand their functions, facilitating easier troubleshooting and parts replacement. A well-structured overview provides insights into the relationships between different elements, enhancing overall proficiency in handling the equipment.

Key Components and Their Functions

Each element in the schematic serves a unique purpose, contributing to the overall operation. Familiarity with these parts can greatly improve user experience and prolong the lifespan of the equipment. Below is a summary of essential components:

| Component | Description |

|---|---|

| Engine | Drives the entire system, providing the necessary power for operation. |

| Fuel Tank | Holds the fuel required for the engine to function efficiently. |

| Air Filter | Prevents debris from entering the engine, ensuring smooth operation. |

| Chain Brake | Enhances safety by stopping the chain quickly in case of kickback. |

| Guide Bar | Supports the cutting chain and directs its movement during operation. |

Importance of Familiarity with the Layout

Understanding the arrangement of these components is vital for troubleshooting and maintenance tasks. A clear grasp of how each part interacts enables users to perform repairs effectively, minimizing downtime. Moreover, recognizing the layout assists in identifying potential issues before they escalate, ensuring optimal performance and reliability.

Key Components of Ms250c Model

Understanding the essential elements of this model is crucial for effective maintenance and operation. Each component plays a specific role in ensuring optimal performance and longevity, contributing to the overall efficiency of the machinery.

Core Mechanisms

Among the primary mechanisms are the engine assembly and fuel system, which work in unison to provide power and efficiency. Engine performance is influenced by factors such as air intake and exhaust systems, which are designed to maximize output while minimizing emissions.

Support Structures

Support elements, including the chassis and handlebar, provide stability and ease of use. Ergonomic design enhances user experience, allowing for better control and maneuverability during operation. Understanding these components is vital for achieving the ultimate functionality of the machine.

Importance of Accurate Diagrams

Precision in visual representations is crucial for effective maintenance and assembly tasks. These illustrations serve as essential tools, providing clear guidance that can significantly impact the efficiency and success of repair work.

- Enhances understanding of complex systems

- Reduces the likelihood of errors during assembly

- Saves time by streamlining the repair process

- Facilitates communication among technicians

Accurate visuals not only clarify instructions but also ensure that all components are properly identified and utilized. This ultimately leads to more reliable and durable outcomes.

How to Read Parts Diagrams

Understanding visual representations of components can significantly enhance your ability to identify and replace specific items in various machines. These illustrations provide a systematic approach to understanding the arrangement and function of individual elements within a larger assembly. By familiarizing yourself with the layout and notation used, you can navigate through complex structures with ease.

Begin by examining the overall layout, which often groups related items together. This organization can help you recognize patterns and relationships between different parts. Look for a legend or key that explains symbols and numbering conventions, as this will clarify the meaning behind each illustration.

Pay close attention to the numbering system; it typically corresponds to a list or catalog that details specifications, dimensions, and materials. This cross-reference is essential for sourcing replacements or understanding the characteristics of each component. Additionally, note any directional arrows or connection points, as these indicate how items fit together and their intended orientation.

Practice makes perfect. The more you engage with these visual tools, the more proficient you will become at interpreting them quickly and accurately. Whether for maintenance, repair, or assembly, mastering this skill can lead to improved efficiency and success in your projects.

Common Issues with Ms250c Parts

Many users encounter various challenges with their equipment, often linked to wear and tear or improper maintenance. Understanding these common difficulties can help in effective troubleshooting and maintenance practices.

Frequent Problems

- Inconsistent performance due to clogged components.

- Difficulty starting, often resulting from fuel system issues.

- Excessive vibration during operation, signaling potential alignment problems.

- Overheating, commonly caused by inadequate cooling or lubrication.

Maintenance Tips

- Regularly clean filters and air intakes.

- Check fuel lines for leaks or blockages.

- Ensure all screws and bolts are properly tightened.

- Use recommended lubricants to prevent overheating.

Replacement Parts Availability and Sources

Finding suitable components for maintenance and repair can be crucial for ensuring optimal performance and longevity of equipment. Knowing where to source these items can save time and enhance efficiency. Various options exist, ranging from original manufacturers to aftermarket suppliers, each with its unique advantages and considerations.

Original Manufacturer Options

Obtaining components directly from the original manufacturer guarantees compatibility and quality. They often provide the latest versions of items, ensuring they meet current standards. Additionally, this option usually comes with warranties, offering peace of mind for buyers.

Aftermarket Suppliers

Aftermarket suppliers can provide a broader range of choices at competitive prices. While quality may vary, many reputable sellers offer reliable alternatives that can perform just as well as original components. Researching suppliers and reading reviews can help identify trustworthy options.

| Source Type | Pros | Cons |

|---|---|---|

| Original Manufacturer | High quality, warranty | Typically more expensive |

| Aftermarket Supplier | Lower prices, variety | Variable quality, less support |

Maintenance Tips for Ms250c Users

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. Following specific guidelines can help you maintain efficiency, reduce wear and tear, and enhance safety during operation.

| Task | Frequency | Tips |

|---|---|---|

| Clean the air filter | Every 10 hours | Remove and wash with soap and water; allow to dry completely. |

| Check the spark plug | Every 25 hours | Replace if damaged or fouled; ensure proper gap settings. |

| Inspect the chain | Before each use | Look for wear; adjust tension and lubricate as needed. |

| Sharpen the blade | After every 5 hours of use | Use a file or sharpener; maintain proper angle for effective cutting. |

| Fuel system maintenance | Seasonally | Use fresh fuel and stabilizer; clean the fuel filter regularly. |

By adhering to these practices, users can ensure their tools remain in excellent working condition, thereby maximizing performance and efficiency.

Comparing Ms250c with Similar Models

This section explores the similarities and differences among various models in the same category, focusing on performance, features, and usability. By analyzing these aspects, users can make informed decisions based on their specific needs and preferences.

Performance Analysis

When evaluating the efficiency of these machines, it is essential to consider engine power and cutting capabilities. Many comparable models offer similar horsepower, yet variations in design can influence overall performance during prolonged use. Weight also plays a significant role in maneuverability, impacting user comfort.

Features and Usability

Distinctive characteristics, such as ease of starting and maintenance, greatly enhance user experience. Some alternatives provide advanced features like vibration reduction and ergonomic handles, making them appealing for extended tasks. Ultimately, understanding these features will help users select the most suitable option for their requirements.

Identifying Genuine vs. Aftermarket Parts

Understanding the differences between authentic components and their substitutes is essential for ensuring optimal performance and longevity of your equipment. Distinguishing between these options can significantly impact maintenance and functionality.

Quality and Durability

Authentic components are typically manufactured to higher standards, offering superior durability and reliability. In contrast, substitutes may vary widely in quality, which can lead to premature wear or failure.

Cost Considerations

While substitutes often come at a lower price, this can be misleading. Investing in genuine components might be more economical in the long run, as they tend to last longer and perform better, reducing the need for frequent replacements.

Step-by-Step Repair Guide

This guide aims to provide a comprehensive approach to addressing common issues encountered with your equipment. By following a systematic procedure, you can ensure effective troubleshooting and restoration, ultimately enhancing the performance and longevity of your device.

Step 1: Begin by gathering the necessary tools and materials. Make sure you have everything you need at hand to avoid interruptions during the repair process.

Step 2: Carefully disassemble the unit, taking note of each component’s placement. This will help you maintain organization and make reassembly easier later on.

Step 3: Inspect all elements for wear or damage. Identifying any issues early on will allow you to address them effectively.

Step 4: Clean the parts thoroughly to remove debris and buildup. This step is crucial for optimal performance.

Step 5: Replace any faulty components with new ones, ensuring they are compatible. Proper installation is vital for the successful operation of your device.

Step 6: Reassemble the unit, following the notes you took during disassembly. Make sure everything is securely fastened.

Step 7: Conduct a thorough test to verify that the repairs were successful. Pay attention to any unusual sounds or performance issues.

Step 8: Finally, maintain regular checks and cleaning to keep your equipment in peak condition for future use.

Tools Needed for Ms250c Repairs

When undertaking maintenance or repair tasks, having the right equipment is essential for efficiency and effectiveness. This ensures that all components are addressed properly, minimizing the risk of damage and enhancing overall performance.

Essential Hand Tools

Basic hand tools are fundamental for any repair job. A screwdriver set is crucial for loosening and tightening various fasteners. Additionally, a wrench set is needed to handle nuts and bolts securely. Other handy items include pliers and a utility knife, which can assist in various applications.

Specialized Equipment

For more intricate tasks, certain specialized tools become necessary. A torque wrench ensures that components are tightened to the manufacturer’s specifications, preventing over-tightening. Furthermore, a multimeter is invaluable for diagnosing electrical issues, providing insights into performance anomalies.

FAQs about Ms250c Parts and Maintenance

This section addresses common inquiries related to components and upkeep of the chainsaw model in question. Understanding the essentials of maintenance can greatly enhance the performance and longevity of your equipment. Here, we provide concise answers to frequently asked questions, helping users navigate the necessary care and replacement procedures.

What is the recommended maintenance schedule for my chainsaw?

Regular maintenance should be performed after every use, including checking the chain tension and lubrication levels. Additionally, a thorough inspection and cleaning of air filters and spark plugs should be conducted every few months or after heavy usage.

How can I tell if I need to replace a component?

Signs of wear include difficulty in starting, unusual noises, or decreased cutting efficiency. If you notice any of these issues, inspect the relevant components for damage or excessive wear.

Where can I find quality replacement components?

It’s advisable to purchase replacements from authorized dealers or trusted online retailers to ensure compatibility and reliability. Always check for original or high-quality aftermarket options.

How do I properly clean the air filter?

Remove the air filter from its housing and use a soft brush or compressed air to remove dust and debris. For a deeper clean, wash it with soapy water, rinse, and allow it to dry completely before reinstallation.

What are the signs of a dull cutting chain?

A dull chain may cause the saw to bind or stall during use. Additionally, you might notice excessive smoke or a burning smell while cutting. Regular sharpening is essential to maintain optimal performance.

Can I perform maintenance myself?

Many basic maintenance tasks, such as cleaning and chain adjustment, can be performed by the user. However, for more complex repairs, it’s recommended to consult a professional or authorized service center.