When maintaining outdoor machinery, a clear understanding of its elements is crucial for effective repairs and improvements. Each piece plays a vital role in ensuring optimal performance and longevity. By familiarizing yourself with these components, you can enhance your machine’s functionality and troubleshoot issues more efficiently.

In this section, we will explore the various elements that constitute your device, highlighting their functions and interrelationships. Whether you are an experienced technician or a novice user, comprehending these parts will empower you to make informed decisions regarding maintenance and repairs.

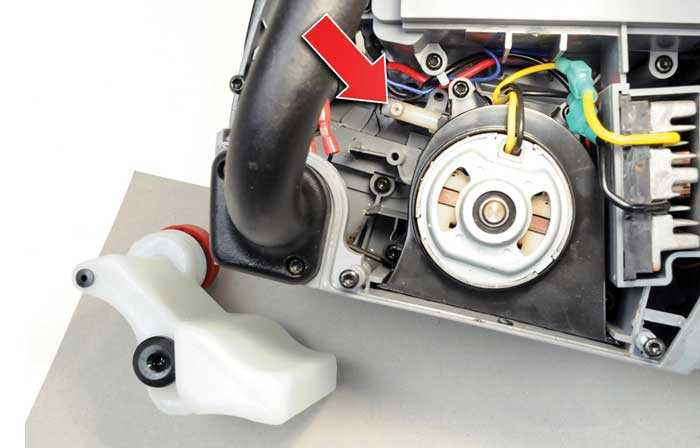

Additionally, having access to a comprehensive visual representation can simplify the process of identifying and replacing components. This resource will serve as a guide, allowing you to navigate through the intricacies of your machine and ensuring that you can confidently address any challenges that may arise.

Understanding the Oregon CS1500 Structure

The design of this electric saw emphasizes efficiency and durability, making it a popular choice for both amateur and professional users. Its components work in unison to provide optimal performance, ensuring that users can tackle various cutting tasks with ease.

At the core of this tool is a powerful motor that delivers robust energy, enabling swift cutting through different types of wood. The blade assembly is engineered for precision, featuring sharp teeth that enhance the tool’s cutting capacity while minimizing the effort required from the user.

The frame of the device is constructed from high-quality materials, providing a sturdy foundation that withstands rigorous use. Additionally, the ergonomic handle design ensures comfort during operation, allowing users to maintain control over extended periods.

Safety features are also integrated into the structure, such as protective guards and automatic shut-off mechanisms, which help prevent accidents while operating the saw. These elements reflect the thoughtful engineering that goes into creating a reliable and user-friendly cutting tool.

In summary, the architecture of this electric saw is a testament to its functional design, balancing power, precision, and safety. Understanding its structure enables users to appreciate how each component contributes to the overall effectiveness of the tool.

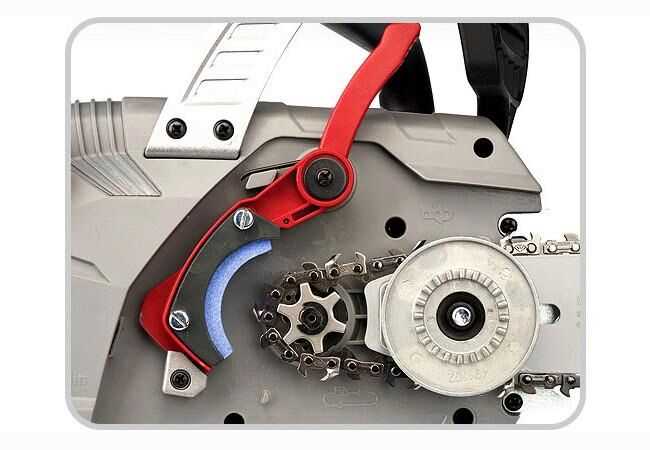

Key Components of Oregon CS1500

The efficient operation of a specific electric chainsaw relies on several vital elements that work harmoniously to ensure its performance and longevity. Understanding these fundamental components is essential for users seeking to maintain and optimize their equipment.

One of the primary components is the motor, which provides the necessary power for cutting through various materials. A robust motor significantly influences the saw’s overall performance, allowing for smooth and effective operation.

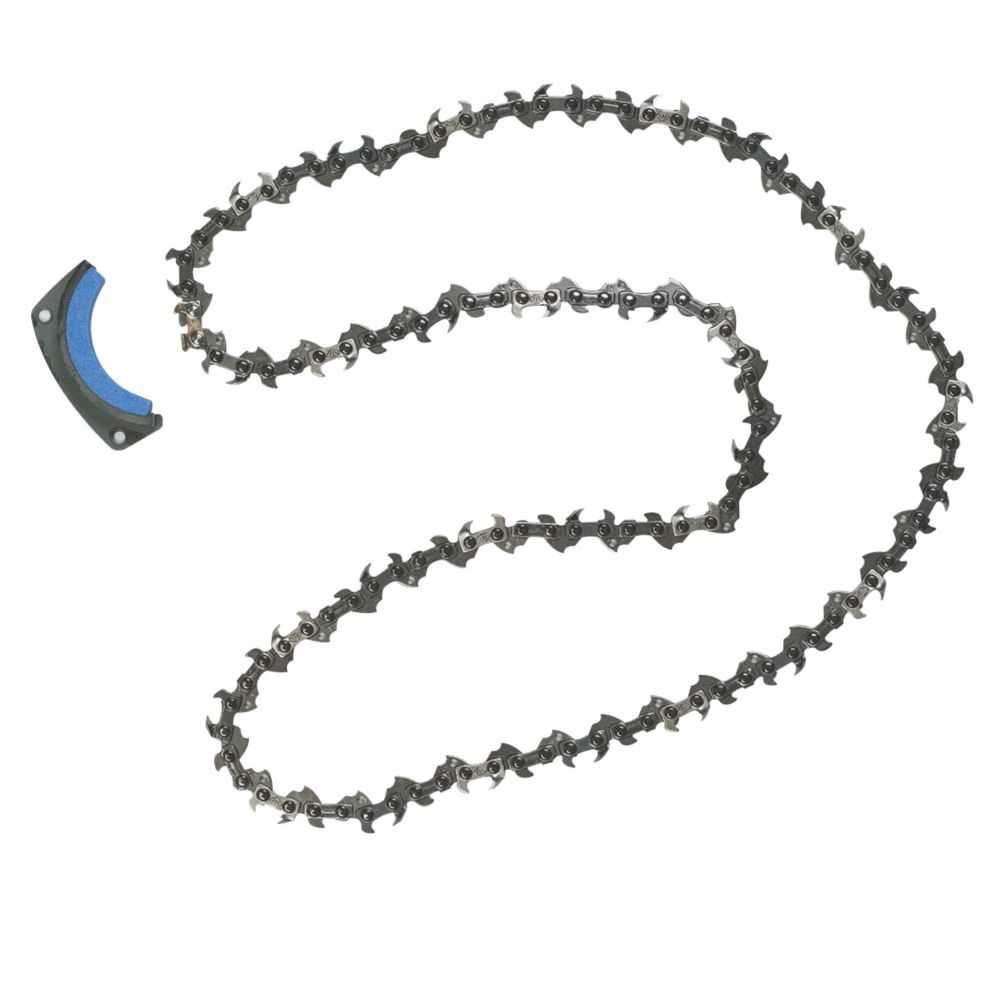

Another critical part is the chain. It is designed to handle tough jobs, ensuring sharpness and durability. The quality of the chain directly affects the cutting speed and precision, making it crucial for efficient wood processing.

The guide bar serves as a support structure for the chain, guiding it during operation. A high-quality guide bar enhances the stability of the cutting process, leading to better results and reduced wear on the saw.

Moreover, the oil reservoir is essential for maintaining the chain’s lubrication. Proper lubrication minimizes friction, which helps prevent overheating and prolongs the lifespan of both the chain and guide bar.

Lastly, a reliable safety switch is an important feature that protects the user by preventing accidental activation. This component ensures safe operation, providing peace of mind while using the tool.

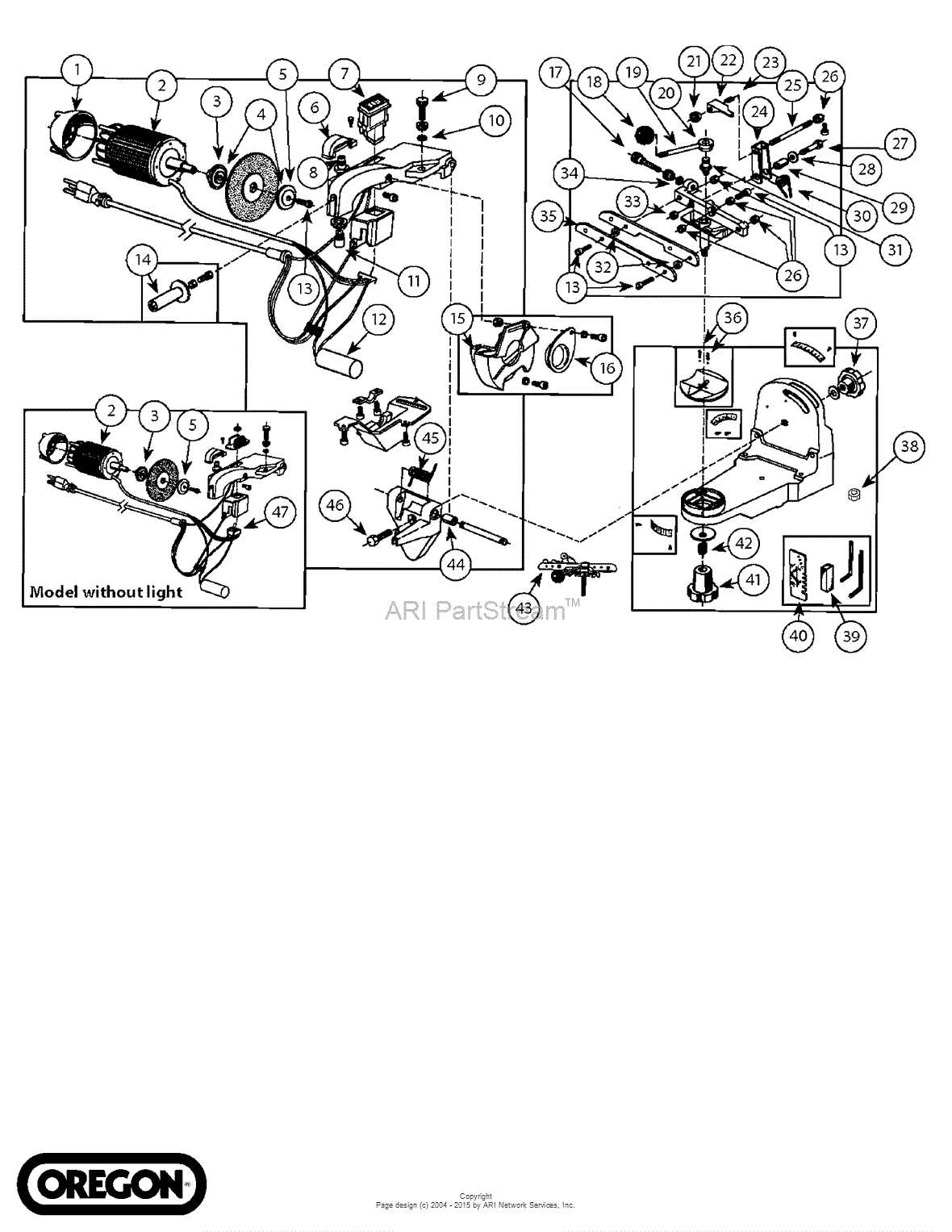

Importance of Parts Diagrams

Understanding the components of a machine is crucial for effective maintenance and repair. Visual representations serve as valuable tools that illustrate the relationships between various elements, enabling users to grasp complex systems more easily. These visual aids facilitate a smoother troubleshooting process and ensure that each part functions harmoniously within the overall assembly.

Clarity and Efficiency are key benefits of utilizing visual representations. They provide clear guidance for users, helping them identify specific components quickly. This clarity minimizes confusion during repairs or replacements, allowing for efficient and accurate work. Additionally, it saves time by reducing the likelihood of errors that may arise from misidentification.

Enhanced Learning is another advantage of visual aids. For individuals unfamiliar with machinery, these representations serve as educational resources, helping them learn about the structure and function of each element. As a result, users can develop a deeper understanding of their equipment, which can lead to more informed decision-making and improved performance over time.

In summary, employing visual representations in the context of machine maintenance is essential. They not only improve efficiency and clarity but also foster a greater understanding of the equipment, ultimately leading to better care and longevity of the machine.

Common Issues and Solutions

When operating a power tool, users may encounter various challenges that can hinder performance. Understanding these common problems and their corresponding solutions can greatly enhance the efficiency and longevity of the equipment. Below are some frequently observed issues and effective remedies.

Motor Overheating

One of the prevalent issues is motor overheating, which can occur due to prolonged use or inadequate ventilation. To resolve this, ensure the tool is operated within the recommended duty cycle. Allow the motor to cool down between uses and check for any blockages in the airflow that might restrict cooling.

Chain Stalling

Chain stalling can lead to frustration and inefficiency. This typically happens when the chain becomes dull or improperly tensioned. Regularly inspect the cutting chain for wear and sharpen it as necessary. Additionally, ensure proper tension by following the manufacturer’s guidelines to maintain optimal performance.

Maintenance Tips for Oregon CS1500

Regular upkeep is essential for ensuring the longevity and optimal performance of your electric saw. By adhering to a few simple practices, you can enhance the efficiency and safety of your tool, prolonging its lifespan and maintaining cutting performance.

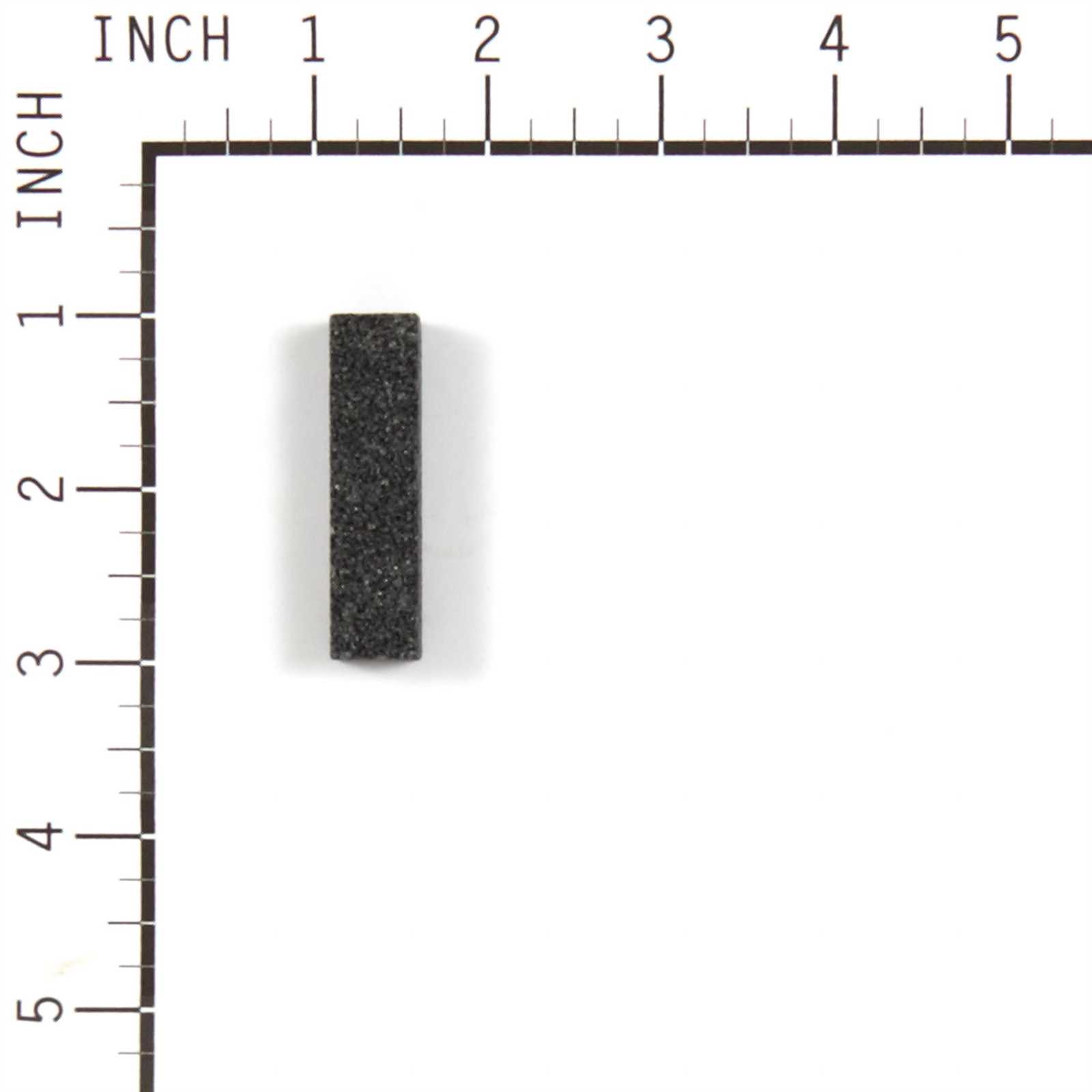

1. Keep the Blade Sharp: A sharp cutting edge is crucial for effective operation. Regularly inspect the blade for dullness or damage. Sharpen it as needed to ensure clean cuts and reduce strain on the motor.

2. Clean After Use: Debris accumulation can hinder performance and lead to wear. After each use, remove sawdust and other materials from the body and blade. Use a soft brush or cloth for a thorough cleaning.

3. Lubricate Moving Parts: Regular lubrication of moving components will prevent friction and prolong the life of the tool. Follow the manufacturer’s recommendations for the appropriate lubricants and intervals.

4. Check Electrical Connections: Inspect the power cord and connections for any signs of wear or damage. Ensuring that all electrical components are in good condition is vital for safe operation.

5. Store Properly: When not in use, store your equipment in a clean, dry place, away from moisture and extreme temperatures. Proper storage helps prevent corrosion and damage to sensitive parts.

6. Follow Operating Guidelines: Always refer to the user manual for specific operating instructions and safety precautions. Adhering to these guidelines ensures proper handling and minimizes risks during use.

By following these essential maintenance tips, you can significantly enhance the performance and durability of your electric saw, ensuring it remains a reliable tool for all your cutting tasks.

How to Identify Parts Easily

Recognizing components of your equipment can significantly enhance your maintenance and repair efficiency. Understanding how to locate and identify each element ensures you can address issues promptly and accurately, extending the life of your machine.

Here are some effective strategies to help you recognize components effortlessly:

- Consult the Manual: The user manual provides detailed information on the equipment, including descriptions and illustrations of individual elements.

- Utilize Online Resources: Various online platforms offer exploded views and detailed descriptions, aiding in visual identification.

- Labeling: Once you identify a component, consider labeling it for future reference. This practice simplifies future repairs and reduces confusion.

- Take Photos: Capturing images of components during disassembly can help you remember their arrangement and function when reassembling.

- Ask for Assistance: Engaging with forums or communities dedicated to your equipment type can provide insights and experiences from other users.

By applying these techniques, you can enhance your understanding and management of your equipment’s essential elements, leading to more effective usage and maintenance.

Ordering Replacement Parts Guide

When maintaining your equipment, acquiring the right components is crucial for ensuring optimal performance and longevity. This guide provides essential information to assist you in procuring the necessary items efficiently. By following these steps, you can streamline the ordering process and avoid common pitfalls.

Identifying the Correct Components

Before placing an order, it’s important to accurately identify the required components. Consult your user manual or online resources to locate the specific names and numbers associated with the items you need. Take note of any identifying characteristics to ensure compatibility with your equipment.

Where to Order

Replacement components can be sourced from various outlets, including local retailers and online platforms. Consider reputable suppliers who specialize in equipment maintenance for reliable service. Check for customer reviews and ratings to gauge the quality of the vendor. Ensure that the retailer offers a clear return policy, in case you receive incorrect or defective items.

By taking the time to research and select the right components, you can maintain your equipment effectively and prolong its operational life.

Comparison with Other Chainsaws

When evaluating different models in the chainsaw market, it’s essential to consider various features, performance metrics, and user experiences. Each saw offers unique advantages tailored to specific tasks, whether for light yard work or heavy-duty lumberjack duties. Analyzing these differences can help potential buyers make informed decisions based on their needs and preferences.

Power and Performance

Power output is a crucial factor that sets models apart. Some saws are designed with high-capacity motors that deliver exceptional torque, making them ideal for cutting through dense wood. In contrast, other units may focus on lightweight construction, offering ease of maneuverability for casual trimming tasks. Understanding the balance between power and usability can significantly impact the efficiency of any cutting job.

Ergonomics and Design

Comfort and usability are paramount when selecting a chainsaw. Models vary in weight, handle design, and vibration dampening features. A well-balanced tool with ergonomic handles can minimize fatigue during extended use, while those with superior anti-vibration systems provide a smoother experience. Additionally, ease of maintenance and accessibility of controls can influence user satisfaction and overall performance.

Tools Required for Assembly

When assembling equipment, having the right tools is crucial for ensuring a smooth and efficient process. Proper tools not only facilitate the construction but also contribute to the overall safety and functionality of the final product. This section outlines the essential implements needed to effectively assemble the components.

Essential Hand Tools

To begin, a selection of hand tools is fundamental. These typically include a screwdriver set, which is vital for tightening screws, and a wrench for securing nuts and bolts. Additionally, pliers are useful for gripping and manipulating smaller parts, while a utility knife can aid in cutting materials or trimming excess components. Having a reliable measuring tape ensures accuracy in dimensions during assembly.

Power Tools and Safety Equipment

Incorporating power tools can significantly enhance efficiency, especially for larger assemblies. A drill is essential for creating holes and fastening parts quickly. Moreover, a sander may be beneficial for smoothing edges and ensuring a professional finish. It is also important to prioritize safety by utilizing protective gear such as gloves and safety glasses to minimize the risk of injury during the assembly process.

Safety Features of Oregon CS1500

When it comes to outdoor power equipment, ensuring user safety is paramount. Advanced machines are designed with various protective elements to mitigate risks and enhance user experience. The incorporation of innovative safety mechanisms can significantly reduce the likelihood of accidents while operating cutting tools.

Key Safety Mechanisms

Modern tools come equipped with several safety features that provide both convenience and peace of mind. These elements include automatic shutoff systems, protective guards, and enhanced stability during use. Each component plays a crucial role in safeguarding the operator and maintaining control during operation.

Importance of Protective Gear

In addition to the built-in safety features, utilizing appropriate personal protective equipment (PPE) is essential. Wearing gloves, goggles, and sturdy footwear can further reduce the risk of injury. These precautions, combined with the machine’s safety enhancements, create a comprehensive safety strategy for effective and secure operation.

| Safety Feature | Description |

|---|---|

| Automatic Shutoff | Stops the motor immediately when the trigger is released to prevent accidental activation. |

| Chain Brake | Instantly halts the chain movement in case of kickback, protecting the user from injury. |

| Safety Guard | Prevents accidental contact with the cutting chain while operating. |

| Low Kickback Chain | Designed to minimize kickback and enhance control during cutting. |