Maintaining a healthy and beautiful outdoor space requires not only regular upkeep but also an understanding of the machinery used in the process. Familiarity with the components of your grass-cutting tool can significantly enhance its performance and longevity. Whether you’re a seasoned gardener or a novice, knowing the essential elements of your equipment will empower you to tackle any challenge that arises.

Each piece of machinery is composed of various sections that work together seamlessly. Grasping the function and interrelation of these components can make a notable difference in how effectively you manage your green areas. This knowledge allows for more informed decisions regarding maintenance, repairs, and upgrades.

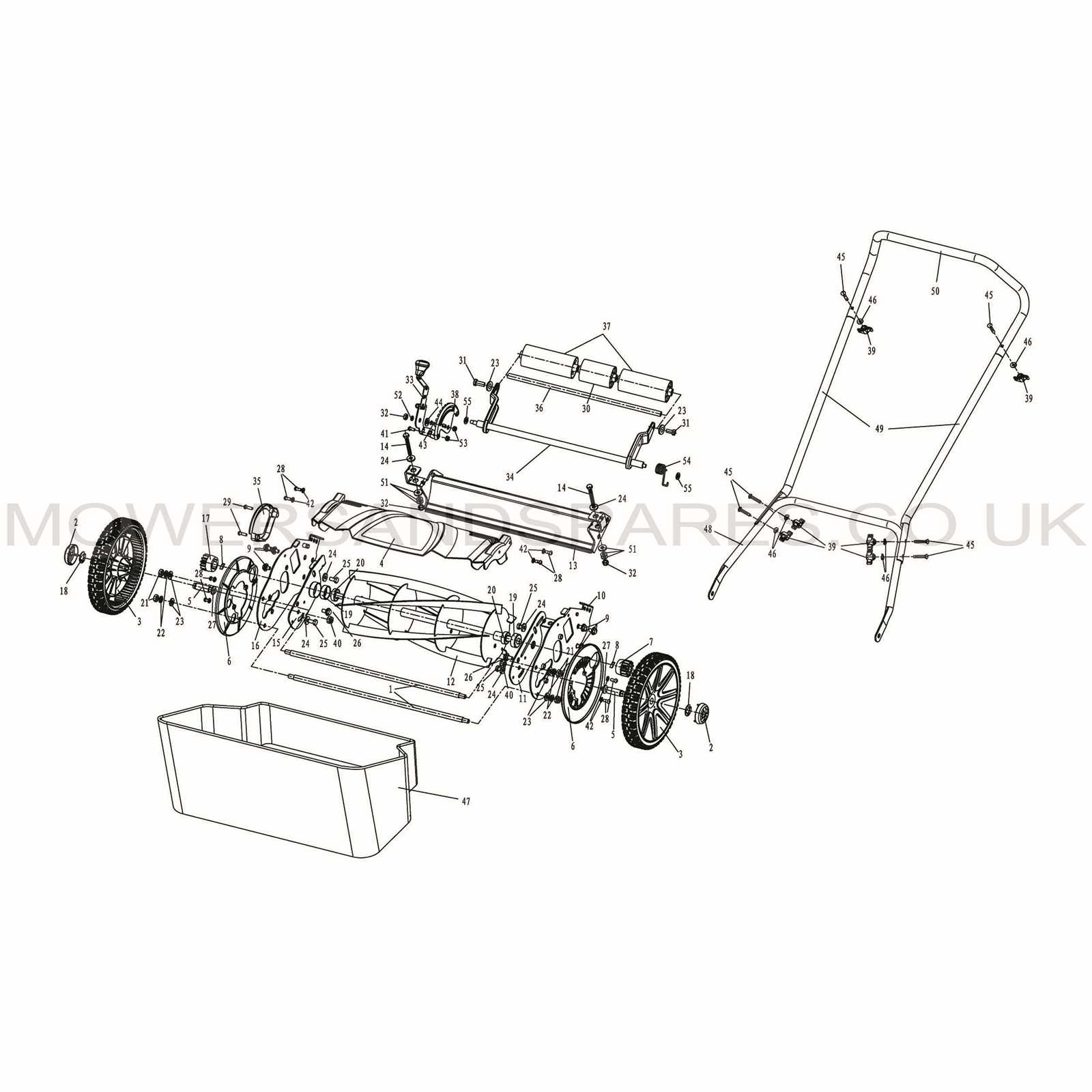

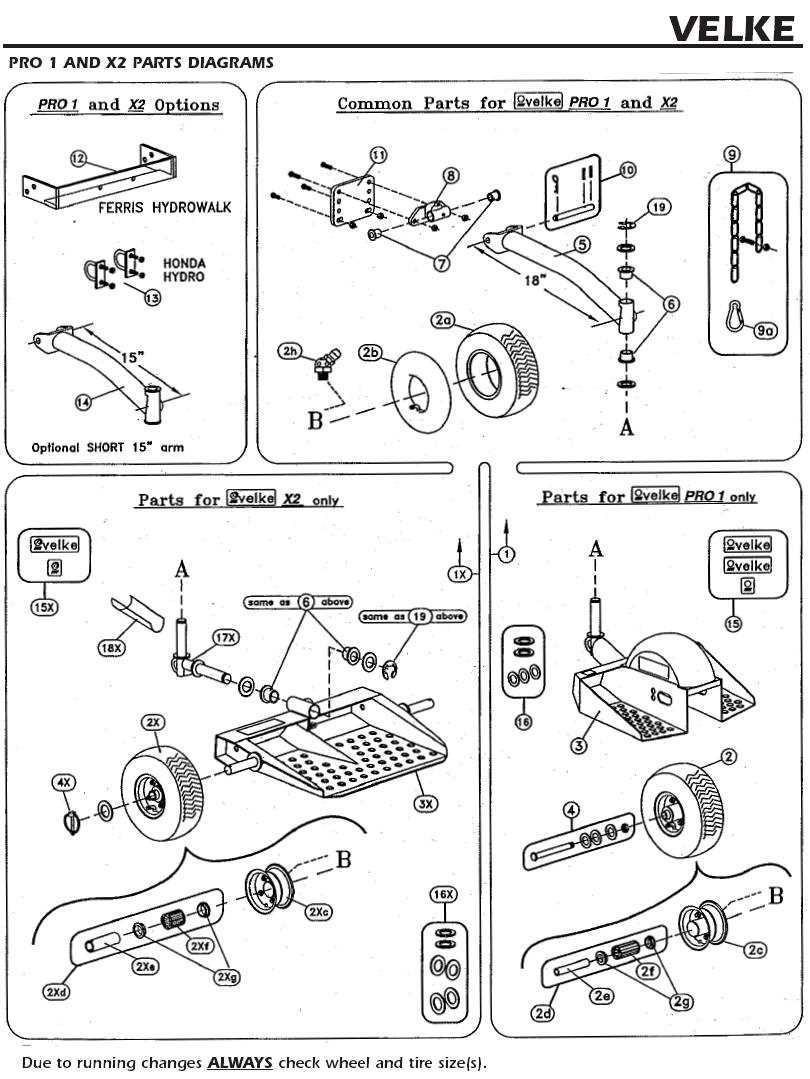

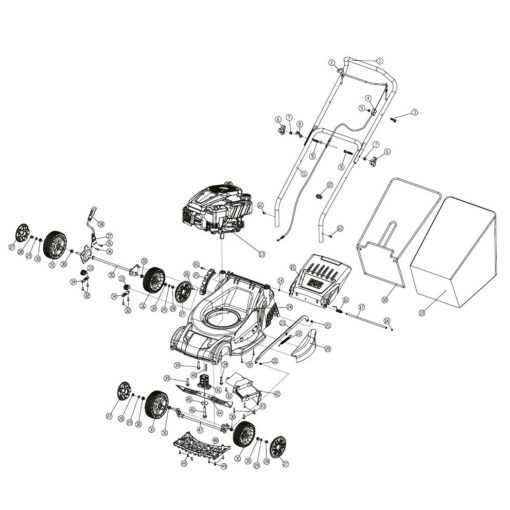

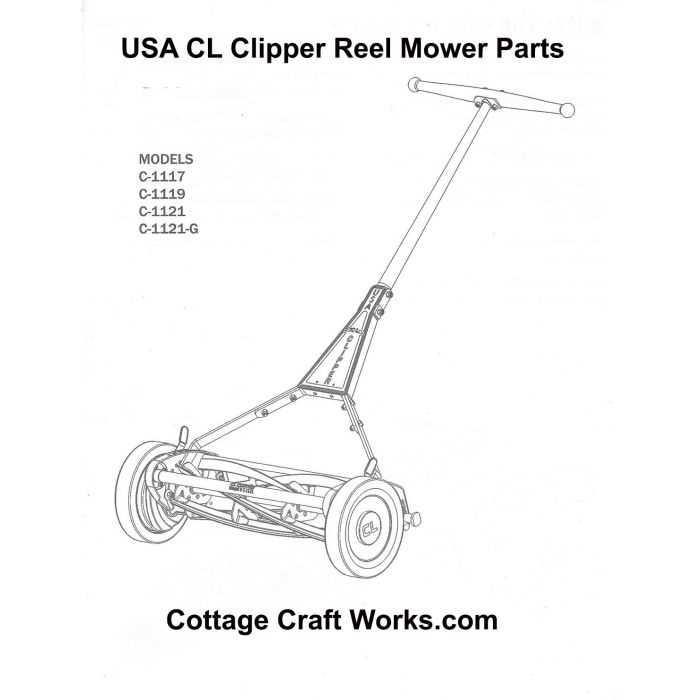

Moreover, visual aids can be invaluable for both troubleshooting and understanding the construction of your equipment. By exploring detailed representations, you can quickly identify areas that may need attention or replacement. Thus, gaining insight into the inner workings of your grass-cutting equipment not only simplifies upkeep but also fosters a deeper appreciation for the technology at play.

Understanding Push Lawn Mower Basics

This section explores essential components and their functions, offering insights into how these machines operate efficiently. Understanding the mechanics is crucial for effective maintenance and optimal performance.

| Component | Function |

|---|---|

| Engine | Powers the device for movement and cutting. |

| Blade | Responsible for cutting grass to the desired length. |

| Handle | Provides control and maneuverability during use. |

| Deck | Houses the blade and protects internal components. |

| Wheels | Facilitate movement across different terrains. |

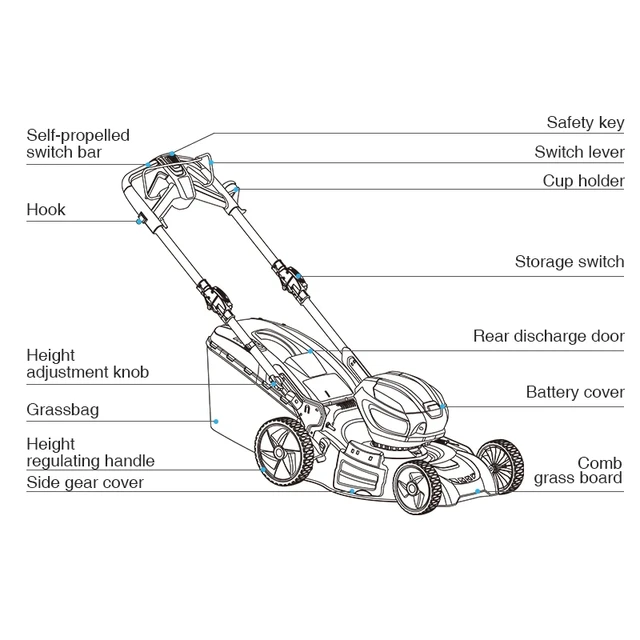

Essential Components of a Push Mower

Understanding the vital elements that comprise a cutting device is crucial for effective maintenance and operation. Each component plays a significant role in ensuring the functionality and efficiency of the machine, allowing for a smooth experience during use. Familiarity with these elements can enhance performance and prolong the lifespan of your equipment.

Key Elements to Know

At the heart of the apparatus lies the blade, responsible for achieving a clean cut. The quality and sharpness of the blade directly impact the overall effectiveness of the tool. Adjacent to it is the deck, which houses the blade and protects surrounding areas. This casing is designed to withstand wear and tear while providing optimal airflow for better cutting results.

Supporting Components

Other essential features include the handle, which allows for maneuverability, and the wheels, crucial for mobility across various terrains. The engine or motor provides the necessary power to drive the blade, while the fuel system ensures efficient operation. Lastly, the control levers enable the user to manage speed and cutting height, adding convenience to the overall experience.

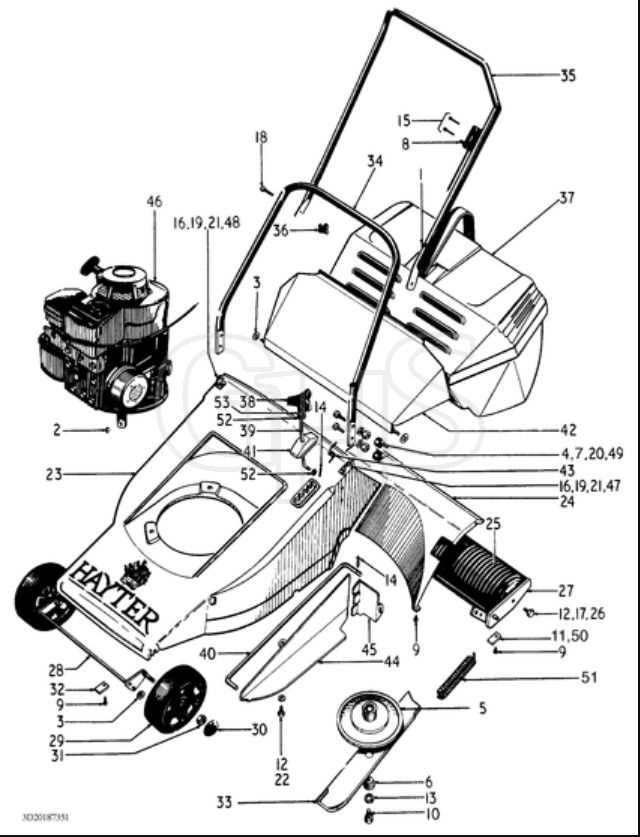

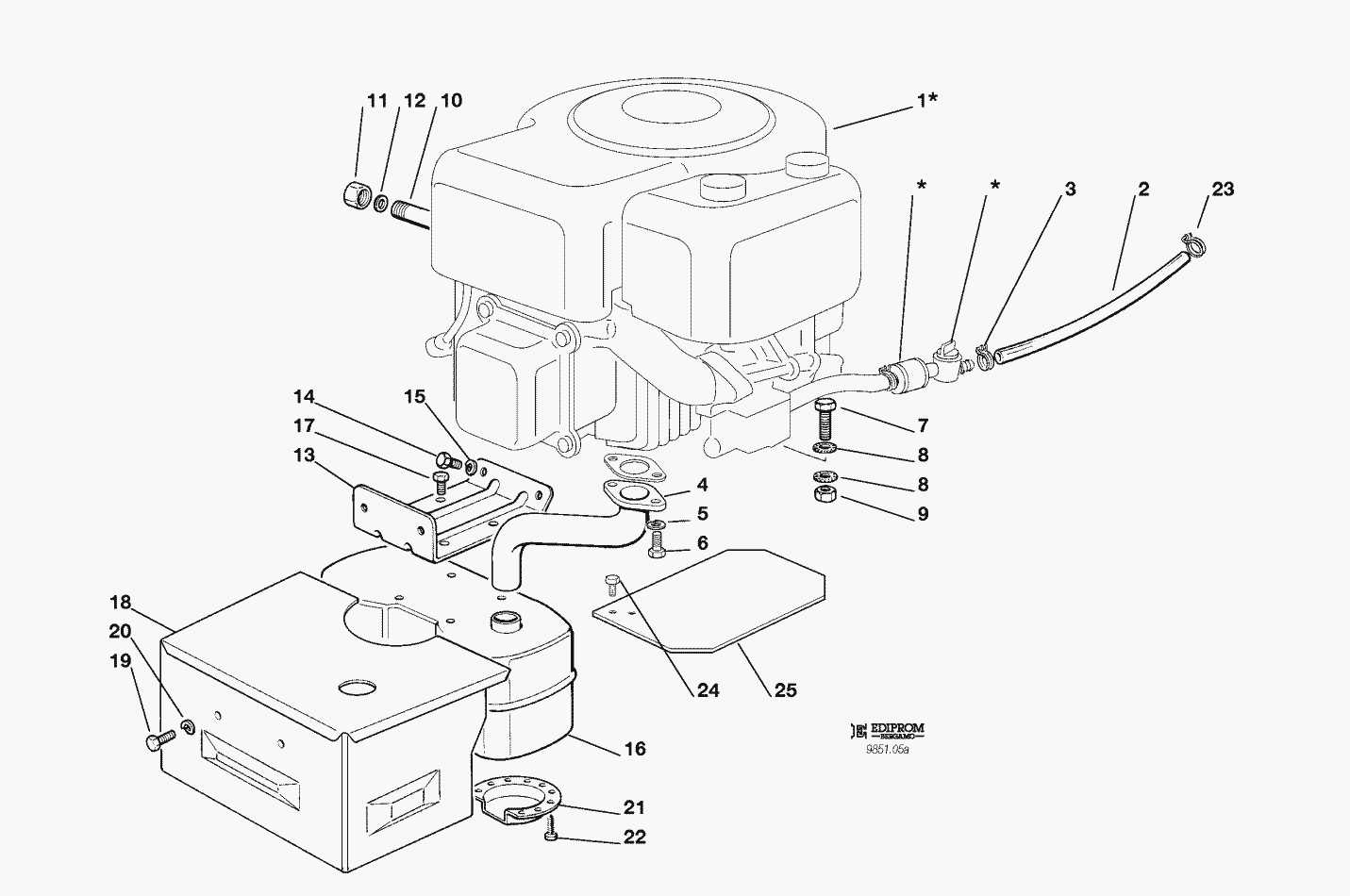

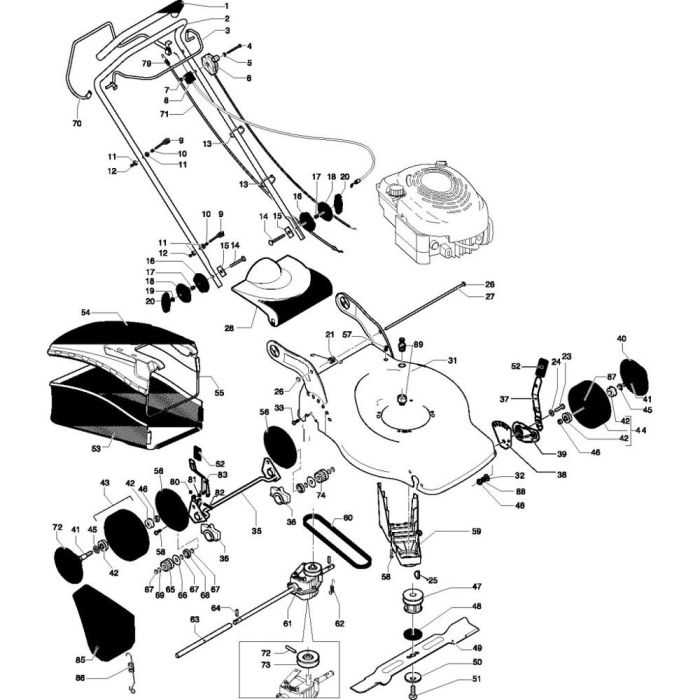

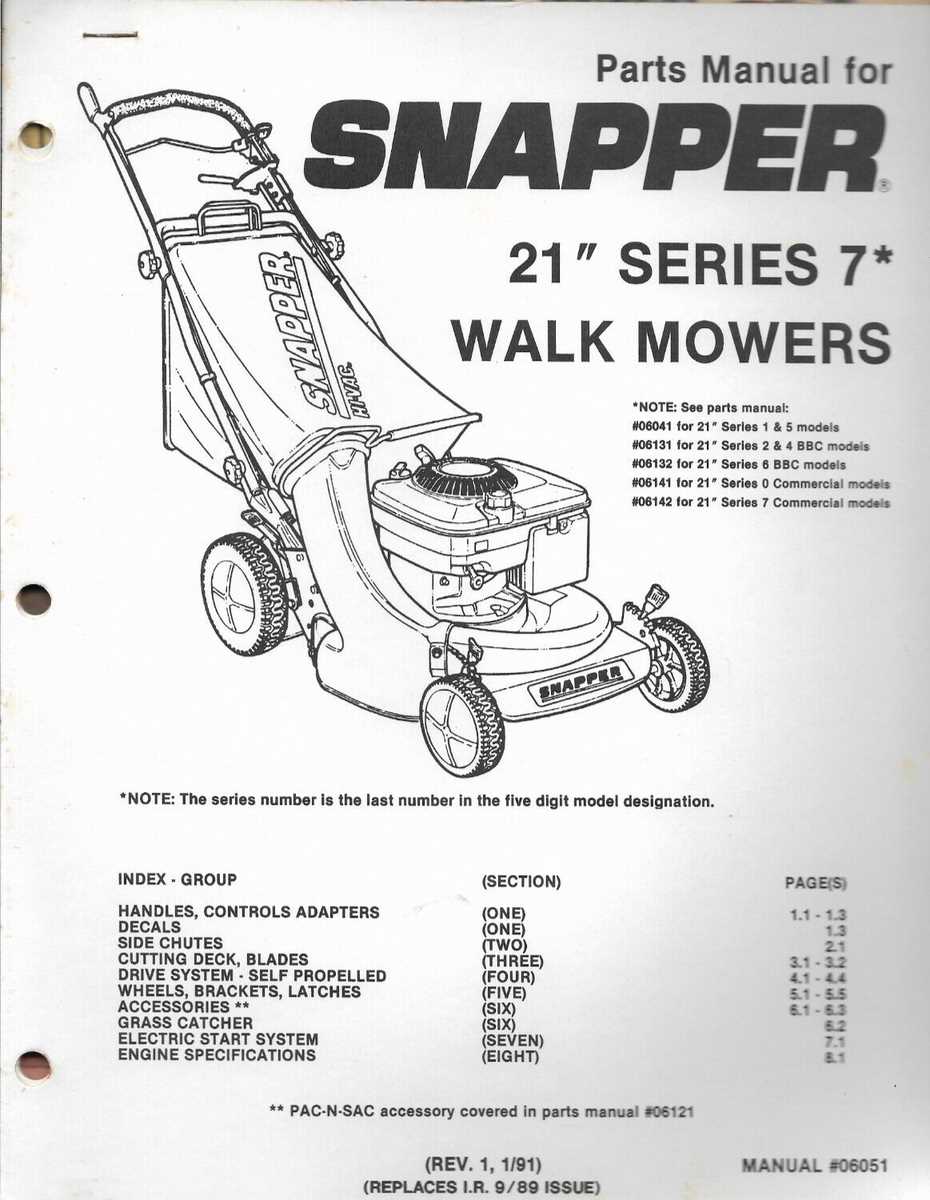

How to Read Parts Diagrams

Understanding technical illustrations is essential for anyone looking to maintain or repair equipment effectively. These visuals provide a clear representation of various components, their arrangement, and how they interact with one another. By familiarizing yourself with these depictions, you can enhance your comprehension of the machinery and streamline the repair process.

Start by identifying the legend or key that often accompanies the illustration. This section typically explains the symbols used, making it easier to recognize different elements. Next, observe how the pieces are labeled, which will guide you in locating specific items when ordering replacements or making adjustments.

Pay attention to the arrangement of components. Many illustrations depict the assembly in a logical order, helping you understand the sequence of disassembly or reassembly. Additionally, look for any notes or instructions that may highlight particular concerns or tips related to specific parts.

Lastly, practice reading these visuals regularly. With experience, you will become more adept at quickly deciphering the information presented, leading to more efficient maintenance and repairs. By mastering the art of interpreting these illustrations, you will empower yourself to handle equipment challenges with confidence.

Common Problems and Solutions

Maintaining garden equipment can often lead to various challenges that affect performance and efficiency. Understanding the frequent issues that arise, along with their remedies, is essential for any enthusiast. This section outlines some typical difficulties encountered during operation and practical solutions to resolve them.

1. Engine Won’t Start: One of the most frustrating problems is when the engine fails to ignite. This can be caused by several factors, such as an empty fuel tank or a clogged air filter. Ensure that the fuel is fresh and check for any blockages in the air intake. Additionally, inspecting the spark plug for wear or dirt can significantly improve starting performance.

2. Uneven Cutting: If your equipment is not providing a consistent cut, it could be due to dull blades or improper height settings. Regularly sharpening the blades and adjusting the cutting height can help achieve a uniform appearance across your yard. Also, ensure that the wheels are properly aligned, as this can affect cutting precision.

3. Excessive Vibration: Unusual vibrations during operation may indicate loose components or imbalanced blades. Check all screws and bolts to ensure they are securely fastened. If the blades are damaged or unevenly worn, consider replacing them to restore balance and smooth operation.

4. Stalling or Hesitation: If the machine stalls frequently or hesitates during use, this could point to fuel delivery issues. Inspect the fuel lines for cracks or blockages, and ensure the fuel filter is clean. Additionally, check for any air leaks around the carburetor that could disrupt the flow.

5. Overheating: Overheating can be a significant concern and may result from clogged cooling fins or low oil levels. Regularly clean the cooling system and ensure that oil levels are maintained within the recommended range. Monitoring these aspects can prevent overheating and extend the life of your equipment.

By being aware of these common challenges and their solutions, you can ensure a smoother and more efficient experience with your outdoor tools.

Maintenance Tips for Longevity

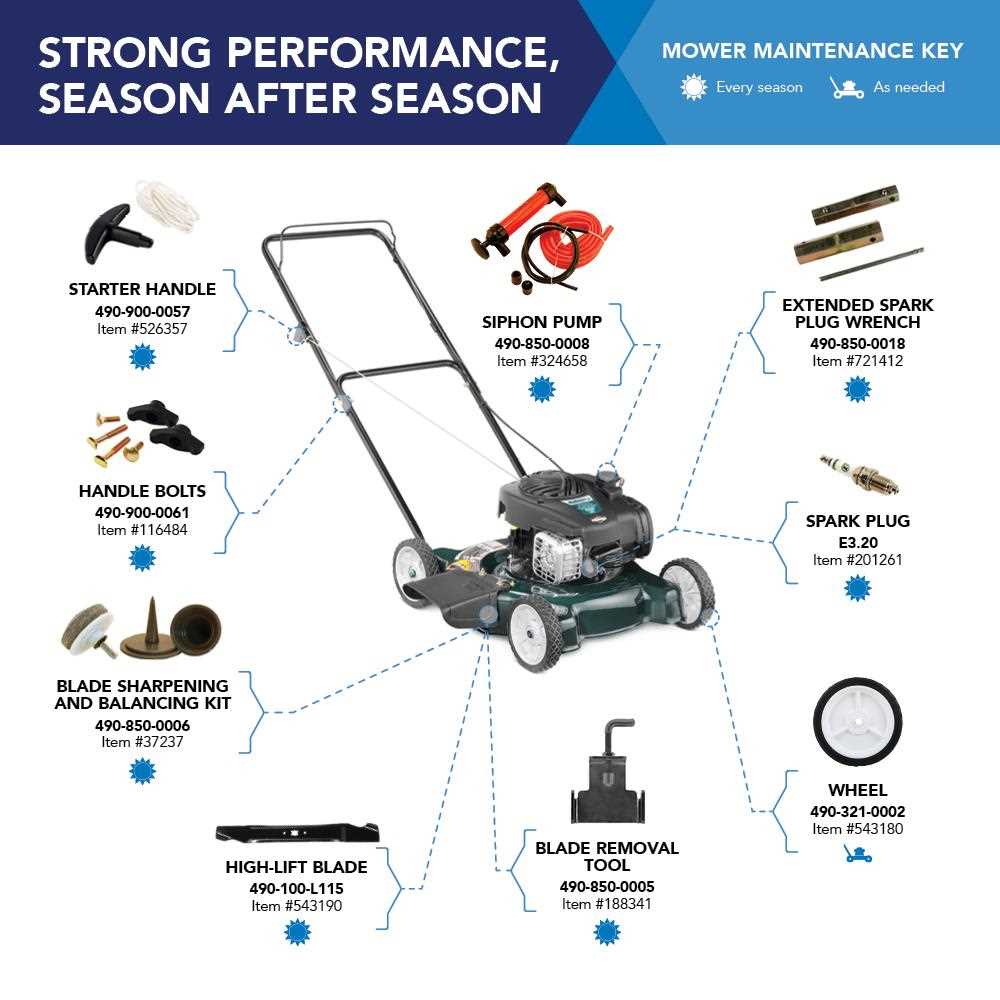

Proper upkeep is essential for extending the lifespan of your equipment. By following a few key practices, you can ensure optimal performance and reliability over time.

Regular Cleaning: Keeping your machinery free of debris and dirt not only enhances efficiency but also prevents rust and damage. Regularly wipe down surfaces and remove clippings.

Routine Inspections: Frequently examine components for wear and tear. Early detection of issues can save you time and money on repairs.

Lubrication: Apply appropriate oils to moving parts to reduce friction and wear. This practice is crucial for smooth operation and longevity.

Storage Considerations: Protect your equipment from harsh weather by storing it in a dry, sheltered space. This simple step can significantly reduce the risk of deterioration.

Sharpening Blades: Keeping cutting edges sharp ensures efficient performance and minimizes strain on the engine. Regularly sharpen and replace them as needed.

Fuel Maintenance: Use high-quality fuel and consider adding stabilizers to prevent degradation. This practice ensures reliable starts and smooth operation.

Identifying Worn-Out Parts

Recognizing components that have lost their functionality is essential for maintaining optimal performance. Understanding the signs of deterioration can prevent further damage and ensure efficiency. Regular inspections play a crucial role in this process, allowing users to catch issues early.

Common indicators of wear include unusual noises, reduced effectiveness, and visible damage such as cracks or corrosion. For instance, a component may show signs of excessive rust or become misaligned, impacting the overall operation. Checking for these symptoms regularly can help identify when a replacement is necessary.

It’s also beneficial to consult a reference guide to match symptoms with specific components. Familiarizing oneself with the expected lifespan of each item can aid in proactive maintenance, ensuring longevity and optimal functionality.

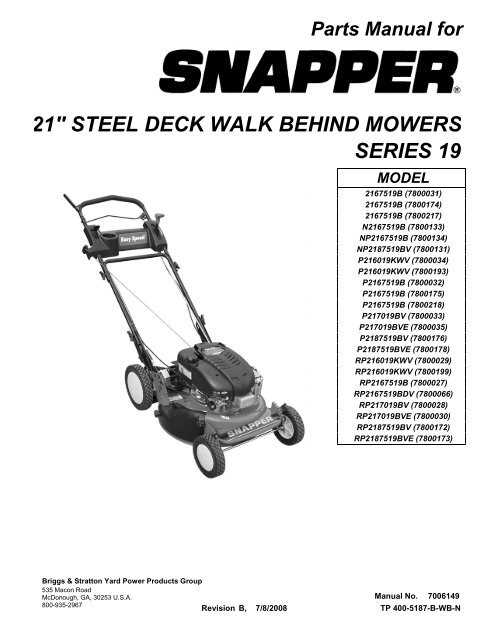

Comparing Different Mower Models

When selecting a cutting machine, understanding the distinctions between various designs is essential. Each type offers unique features, performance capabilities, and ease of use, which cater to different user needs and preferences.

Key Features

| Model | Engine Power | Cutting Width | Weight |

|---|---|---|---|

| Model A | 150cc | 21 inches | 70 lbs |

| Model B | 160cc | 22 inches | 75 lbs |

| Model C | 140cc | 20 inches | 65 lbs |

Performance Comparison

Assessing the performance of these models reveals how factors such as power and cutting width impact efficiency and user experience. Users should consider terrain type and frequency of use to choose the most suitable option for their needs.

Where to Find Replacement Parts

When seeking components for your outdoor equipment, there are various reliable sources to explore. Identifying the right supplier can significantly impact the quality and efficiency of your maintenance tasks.

| Source | Description |

|---|---|

| Manufacturer’s Website | Directly access the official site for authentic components tailored to your model. |

| Local Retailers | Visit nearby stores that specialize in gardening tools; they often carry essential items. |

| Online Marketplaces | Platforms like Amazon or eBay can offer a wide selection and competitive prices. |

| Repair Shops | Local repair facilities may have spare components or can order them for you. |

Tools Needed for Repairs

Maintaining and fixing outdoor equipment requires specific instruments to ensure efficiency and safety. Having the right tools on hand can significantly streamline the repair process and enhance the overall performance of the machinery.

Essential Instruments

- Wrenches

- Screwdrivers

- Pliers

- Socket set

- Hex keys

Additional Supplies

- Lubricants

- Cleaning solutions

- Replacement components

- Safety gear

Equipping yourself with these essentials allows for a more effective approach to maintenance tasks, ensuring the ultimate performance of your equipment.

Step-by-Step Repair Guide

This section provides a comprehensive approach to fixing your equipment, ensuring efficient performance and longevity. By following a systematic method, you can tackle any issue that arises.

- Identify the Problem:

Start by observing the symptoms and noting any unusual sounds or behaviors.

- Gather Necessary Tools:

Collect all essential tools and replacement components before beginning the repair process.

- Disassemble with Care:

Follow a methodical disassembly procedure to prevent loss of components. Keep track of screws and small parts.

- Inspect Each Component:

Examine every piece for wear, damage, or debris buildup. Note which parts need replacing.

- Replace Damaged Components:

Install new parts as needed, ensuring they are compatible and securely fitted.

- Reassemble:

Carefully put everything back together, reversing the disassembly steps. Double-check alignment.

- Test Functionality:

Once reassembled, test the equipment to confirm that the issue has been resolved.

Following this guide will help ensure that your machine operates at its ultimate efficiency.

Upgrading Your Mower Efficiently

Enhancing the performance of your grass cutting equipment can significantly improve its efficiency and longevity. By focusing on strategic upgrades, you can transform a standard machine into a highly effective tool, ensuring a pristine outdoor space with minimal effort.

Choosing the Right Enhancements

Start by assessing the current state of your equipment. Identify components that may need replacement or improvement, such as the blade or the motor. Investing in high-quality materials will lead to better results. For example, opting for sharper blades can enhance cutting precision and reduce the effort required during use.

Maintenance Tips for Optimal Performance

Regular maintenance is crucial for maximizing the benefits of any upgrades. Clean and inspect your machine frequently to prevent wear and tear. Proper lubrication of moving parts can also contribute to smoother operation, extending the life of your equipment and ensuring it runs efficiently.

Safety Tips for Lawn Mower Use

Using outdoor equipment requires attention to safety to prevent accidents and ensure an efficient experience. By following essential precautions, you can create a secure environment while maintaining your garden.

1. Wear Appropriate Gear: Always use protective eyewear, sturdy shoes, and long pants to shield yourself from debris and potential injuries.

2. Check Equipment Before Use: Inspect your machine for any damage, loose parts, or obstructions before starting. This simple step can prevent malfunction during operation.

3. Keep Children and Pets Away: Ensure that children and animals are at a safe distance while you operate machinery. Accidents can occur quickly if they are nearby.

4. Stay Alert: Avoid distractions and remain focused on your task. Sudden movements or inattentiveness can lead to serious mishaps.

5. Follow Manufacturer Instructions: Familiarize yourself with the operating manual to understand specific safety features and recommendations for your equipment.

6. Use Caution on Slopes: When navigating uneven terrain, proceed slowly and maintain a stable footing to avoid losing balance.

7. Turn Off Equipment When Not in Use: Always shut down your machine when making adjustments or clearing debris to minimize risks.

8. Store Properly: After use, store your equipment in a dry, secure area to prevent unauthorized access and maintain its condition.