Maintaining expansive outdoor spaces requires efficient machinery designed for durability and performance. Understanding the inner workings and essential elements of this type of equipment is crucial for optimal operation and longevity. A comprehensive exploration of these components will illuminate their functions and interrelations, ensuring users can effectively manage their devices.

Identifying individual elements of such machinery is essential for troubleshooting and repairs. Each segment plays a vital role in the overall functionality, contributing to seamless operation. By delving into the specifics of these components, one can enhance their knowledge and ability to care for their equipment, ultimately leading to improved performance and satisfaction.

Visual aids that illustrate the various sections can serve as valuable references, making it easier to comprehend the assembly and interactions among different parts. This understanding can empower users to undertake maintenance tasks with confidence, ensuring their devices remain in excellent condition throughout their lifecycle.

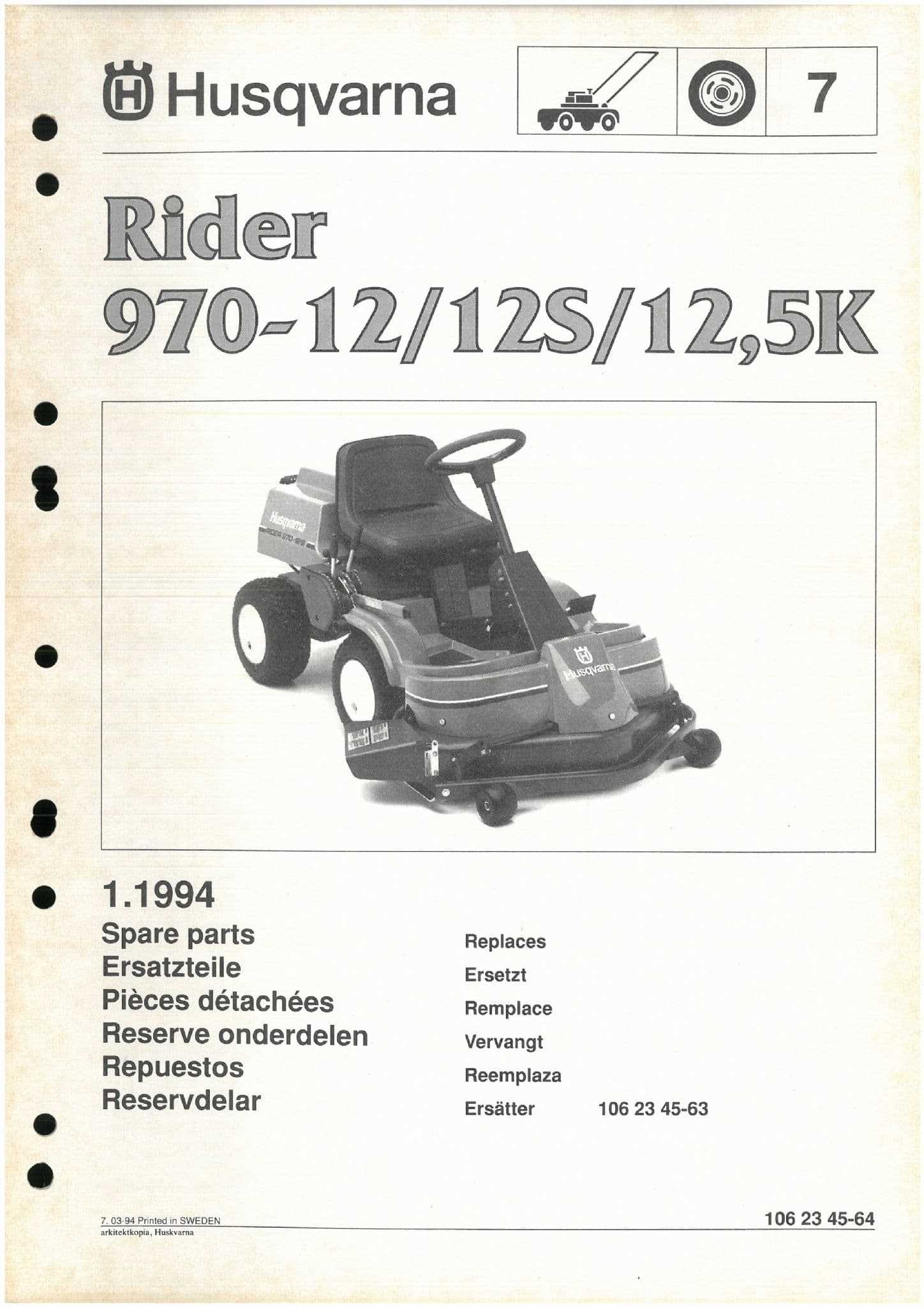

Overview of Husqvarna Riding Lawn Mowers

This section provides a comprehensive understanding of a popular type of outdoor equipment designed for efficient grass maintenance. These machines are renowned for their durability, innovative features, and ease of use, making them a favorite among homeowners and professionals alike.

Key Features

- Ergonomic design for comfortable operation

- Powerful engines for optimal performance

- Advanced cutting technology for a precise finish

- Variety of attachments for enhanced functionality

Maintenance Tips

- Regularly check and change the oil for engine longevity.

- Sharpen blades to ensure clean and efficient cutting.

- Inspect belts and cables for wear and tear.

- Keep the machine clean to prevent rust and damage.

Essential Components of Lawn Mowers

The efficiency of a grass-cutting machine is greatly influenced by its critical elements, each playing a vital role in its overall functionality. Understanding these key components not only enhances the performance of the equipment but also aids in effective maintenance and troubleshooting. Familiarity with the fundamental structures allows operators to optimize usage and extend the lifespan of their machinery.

Cutting Mechanism

The cutting mechanism is the heart of any grass-trimming device, designed to provide precise and clean cuts. This system typically includes sharp blades that rotate at high speeds, efficiently slicing through grass. Proper alignment and maintenance of these blades are essential for achieving an even and manicured appearance on the turf.

Power Source

The power source is another essential element that drives the entire operation. Whether it’s a gasoline engine or an electric motor, the choice of power significantly affects performance, efficiency, and environmental impact. Regular inspection and upkeep of this component ensure reliable operation, preventing disruptions during use.

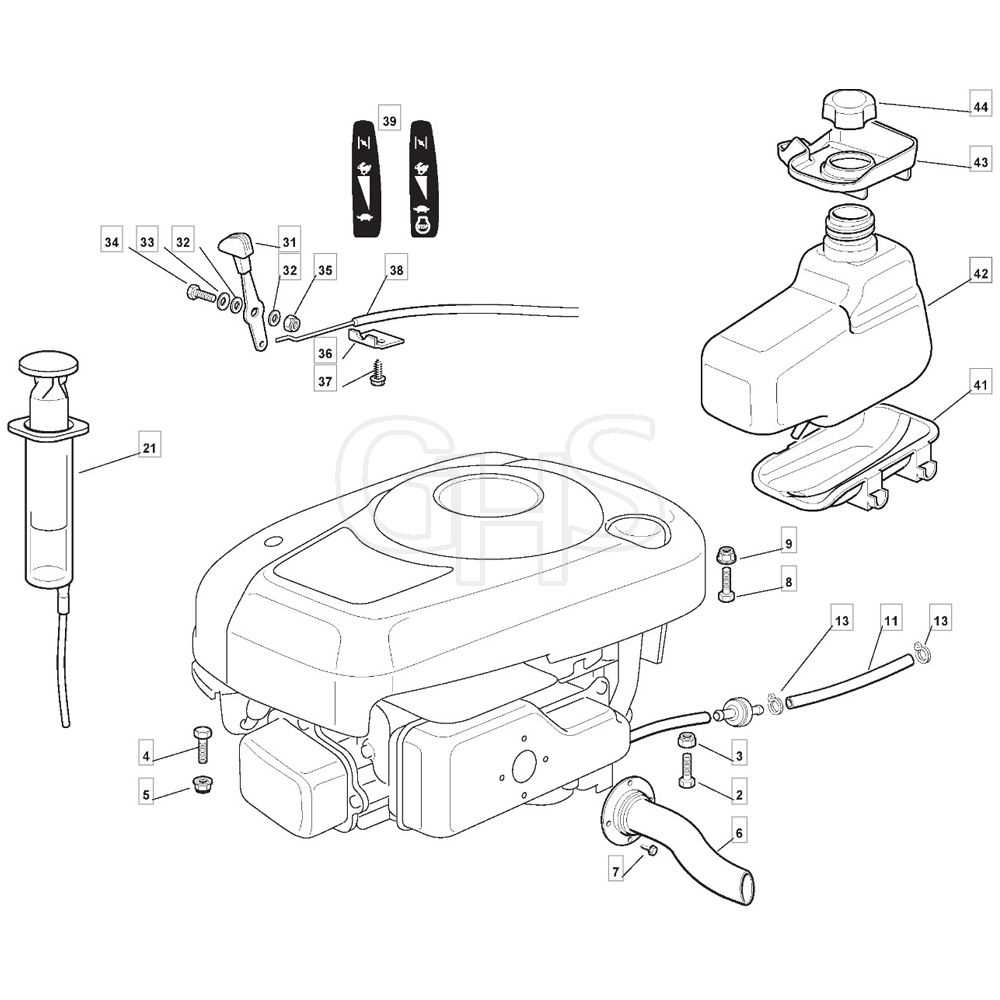

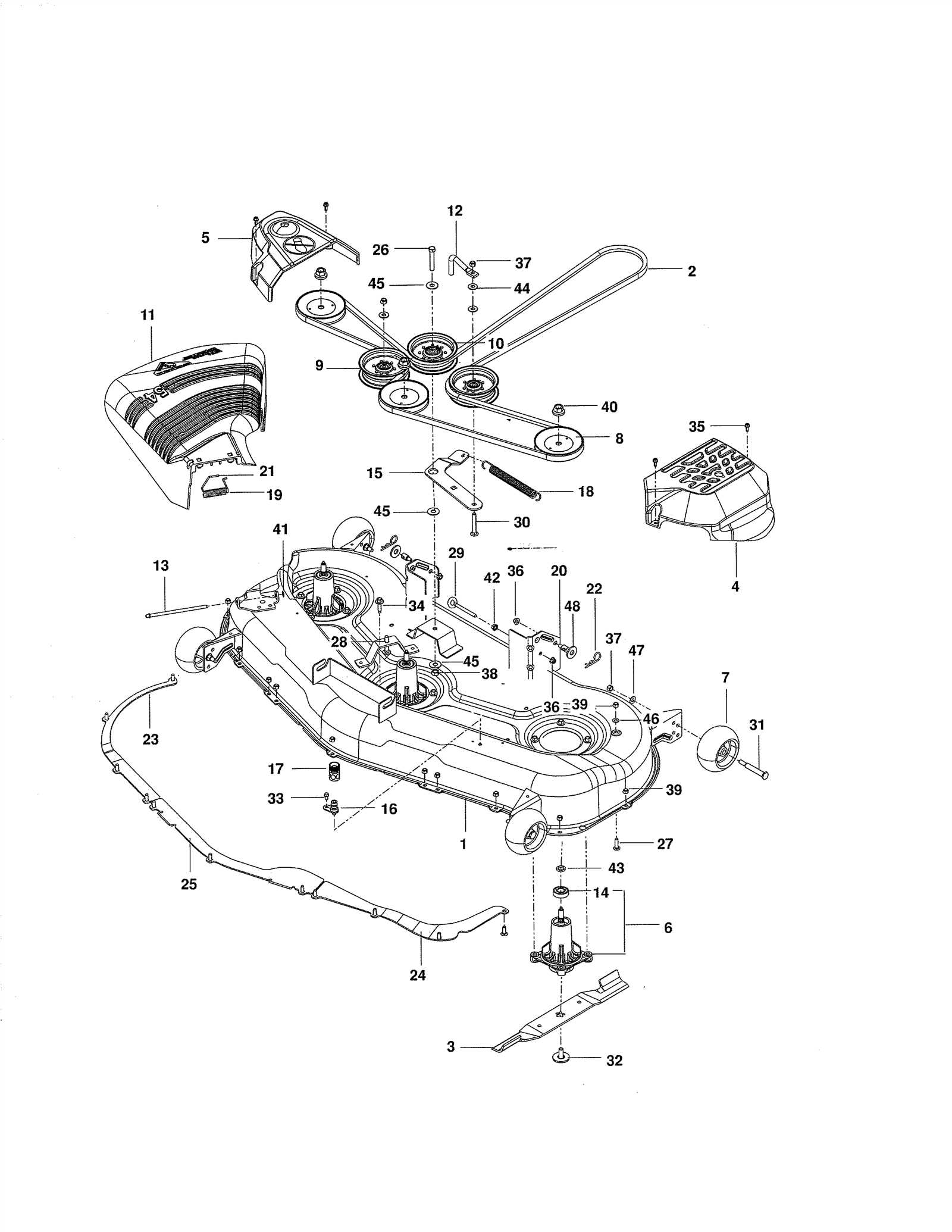

Understanding Lawn Mower Parts Diagrams

Visual representations of equipment components play a crucial role in maintenance and repair tasks. These illustrations provide an organized overview, helping users identify individual elements and their relationships within the machinery.

Familiarity with these visuals enables operators to:

- Quickly locate specific components.

- Understand the assembly and disassembly processes.

- Identify compatible replacements or upgrades.

- Enhance troubleshooting by pinpointing potential issues.

Effective comprehension of these visuals requires attention to detail. Users should consider:

- The labels and numbering of each element.

- The connections and interactions between different components.

- The overall layout, which often indicates the sequence of assembly.

By mastering these representations, individuals can improve their efficiency in maintaining their equipment, ensuring longevity and optimal performance.

Identifying Key Replacement Parts

Understanding the essential components of your equipment is crucial for effective maintenance and repair. Recognizing the various elements that may require attention can significantly enhance the longevity and performance of your machine. This section focuses on the primary components that are commonly replaced, ensuring your device operates at its best.

Common Components to Monitor

Key elements that often need replacement include the engine, transmission, and cutting blade. The engine is the heart of the machinery, providing the necessary power for operation. Regular inspection of the engine can prevent performance issues. The transmission is responsible for transferring power to the wheels, and wear in this component can lead to operational difficulties. Lastly, the cutting blade is vital for achieving a clean cut; it must be sharp and free of damage to ensure optimal functionality.

Signs of Wear and Tear

Identifying signs of deterioration is essential for timely replacements. Listen for unusual noises, check for vibrations, and observe any irregularities in operation. Increased resistance during use or leaking fluids can indicate that a component requires immediate attention. Regularly inspecting these areas will help maintain your equipment’s efficiency and reliability.

Maintenance Tips for Lawn Mower Parts

Proper upkeep of your equipment is essential for ensuring its longevity and optimal performance. Regular attention to its various components can prevent costly repairs and enhance efficiency. By implementing a few simple practices, you can significantly extend the life of your machinery.

1. Regular Cleaning: Keeping the exterior and interior free from debris is crucial. Grass clippings, dirt, and dust can accumulate and lead to overheating or mechanical issues. Use a brush or compressed air to clean these areas after each use.

2. Lubrication: Ensuring that moving parts are well-lubricated reduces friction and wear. Use appropriate oils or greases as specified in the user manual, focusing on bearings and pivot points.

3. Inspection: Routinely inspect components for signs of wear or damage. Look for cracks, rust, or loose connections that could impact functionality. Addressing minor issues early can prevent more significant problems later.

4. Blade Maintenance: Sharpening the cutting blades regularly is vital for achieving a clean cut. Dull blades can cause uneven trimming and stress the engine. Consider replacing them if they are excessively worn.

5. Fuel Management: Use fresh fuel to prevent clogs and starting difficulties. Consider using fuel stabilizers if the equipment will sit unused for an extended period, as they help maintain fuel quality.

By adhering to these maintenance practices, you can ensure that your equipment remains efficient and reliable throughout its service life.

Common Issues with Lawn Mower Components

Understanding the frequent problems that can arise with various components of a grass-cutting machine is essential for maintenance and efficiency. By recognizing these issues early, users can ensure optimal performance and extend the lifespan of their equipment.

Here are some typical challenges encountered with different elements:

- Engine Problems:

- Hard starting or stalling can indicate fuel delivery issues or air filter blockages.

- Excessive vibration may result from loose or damaged engine mounts.

- Cutting Mechanism:

- Uneven cutting can stem from dull blades or incorrect blade height adjustment.

- Clumping of grass under the deck often points to poor airflow or blade wear.

- Transmission Issues:

- Slipping gears may occur due to low fluid levels or worn belts.

- No movement or sluggish response can suggest a clogged transmission filter.

- Electrical Failures:

- Dead batteries or faulty wiring can prevent starting.

- Malfunctioning safety switches may lead to unexpected shut-offs.

Regular inspections and timely repairs can mitigate these issues, ensuring a reliable and efficient operation for any grass-cutting equipment.

Tools Needed for Repairs

Proper maintenance and repairs require a set of essential implements to ensure efficiency and effectiveness. Having the right tools not only facilitates the process but also helps in achieving precise results while minimizing the risk of damage to the equipment.

Basic hand tools are fundamental for most tasks. A selection of wrenches, screwdrivers, and pliers will cover a wide range of adjustments and replacements. These tools allow for the easy removal and installation of various components.

In addition to hand tools, power tools can significantly speed up repair work. A cordless drill or impact wrench is particularly useful for loosening stubborn fasteners and streamlining the assembly process. Furthermore, having access to a socket set will provide the versatility needed for different sizes of nuts and bolts.

Safety equipment is also critical. Protective goggles and gloves should be worn to prevent injuries during repair tasks. Ensuring a safe working environment is paramount for effective maintenance.

Lastly, a repair manual or guide can be invaluable. It provides detailed instructions and diagrams, ensuring that repairs are executed accurately. Combining the right tools with proper guidance can enhance the repair experience and prolong the lifespan of the machinery.

How to Access Parts Diagrams Online

Finding visual references for machinery components can greatly enhance your understanding and repair capabilities. Accessing these resources online has become increasingly convenient, enabling users to efficiently locate essential information.

To begin, you can visit official websites or reputable third-party platforms that specialize in equipment documentation. Utilize the search functionality to enter the model number or relevant specifications of your equipment. This method typically leads you directly to the necessary resources.

Additionally, online forums and community groups can be invaluable. Engaging with fellow enthusiasts allows you to share insights and gain access to diagrams that may not be readily available elsewhere. These platforms often have a wealth of shared knowledge and resources.

For further assistance, consider utilizing online retailers that offer comprehensive catalogs. These sites frequently include exploded views and detailed descriptions, making it easier to identify individual components and their respective functions.

Finally, bookmark useful websites for quick future reference. This practice ensures that you can swiftly access crucial diagrams whenever needed, streamlining your maintenance and repair tasks.

Comparing Different Models of Husqvarna Mowers

When evaluating various models of outdoor equipment, it’s essential to consider their unique features and specifications. Each variant offers distinct advantages that cater to different needs, whether for residential or commercial use. Understanding these differences can help users select the most suitable machine for their tasks.

Key Features to Consider

Several important factors should be taken into account when comparing models. These include engine power, cutting width, fuel efficiency, and comfort features. Below is a comparison of selected models based on these criteria.

| Model | Engine Power (HP) | Cutting Width (inches) | Fuel Efficiency (MPG) | Comfort Features |

|---|---|---|---|---|

| Model A | 20 | 42 | 5 | Adjustable seat, cup holder |

| Model B | 22 | 48 | 6 | Ergonomic controls, extra legroom |

| Model C | 24 | 54 | 5.5 | High-back seat, premium dashboard |

Choosing the Right Model

Selecting the appropriate variant depends on individual preferences and requirements. Users should evaluate their specific needs, such as the size of the area to maintain and desired features, to make an informed decision. By comparing specifications and features, one can determine the ideal equipment for their landscaping projects.

Benefits of Genuine Replacement Parts

Using authentic components for your machinery ensures optimal performance and longevity. These high-quality alternatives are specifically designed to meet the exact specifications required for efficient operation. As a result, investing in genuine replacements can lead to fewer repairs and lower overall maintenance costs.

Enhanced Reliability

Authenticity in components significantly contributes to the reliability of your equipment. Genuine items undergo rigorous testing and quality control, guaranteeing that they function seamlessly with your machinery. This reliability minimizes the risk of breakdowns, ensuring that your equipment remains operational when you need it the most.

Improved Performance

Utilizing original components can enhance the overall functionality of your machinery. These parts are engineered to work harmoniously with existing systems, allowing for better efficiency and performance. By choosing authentic replacements, you ensure that your equipment operates at its peak, leading to better results and increased productivity.

Safety Precautions During Repairs

Ensuring safety while performing maintenance or repairs is crucial for both personal well-being and the longevity of the equipment. Taking the necessary precautions can prevent accidents and injuries, making the repair process smoother and more efficient. Understanding the potential hazards involved and preparing accordingly is key to a successful repair experience.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is essential during any repair task. This includes safety goggles to protect your eyes from debris, gloves to shield your hands from sharp objects and chemicals, and sturdy footwear to guard against potential foot injuries. Additionally, consider using ear protection if working with loud machinery to prevent hearing damage.

Work Environment Safety

Maintaining a clean and organized workspace is vital for safe repairs. Ensure that the area is free of clutter and potential trip hazards. Proper lighting is also important, as it allows for better visibility of small parts and tools. If working outdoors, be mindful of weather conditions that could affect your safety, such as rain or extreme heat.

Resources for Lawn Mower Troubleshooting

When facing issues with your grass cutting equipment, it’s essential to have access to reliable resources that can assist in diagnosing and resolving problems. Understanding common complications and knowing where to find helpful information can significantly improve the maintenance experience, ensuring that your machine remains efficient and functional.

Online Forums and Communities

Joining online platforms dedicated to equipment enthusiasts can provide valuable insights. Users often share their experiences and solutions to common issues. Participating in these communities allows for the exchange of knowledge and can lead to quicker resolutions.

Manufacturer Manuals and Guides

Consulting the official manuals and troubleshooting guides from the manufacturer can be incredibly beneficial. These documents typically outline common problems and their respective fixes, along with maintenance tips that can prolong the lifespan of your device.

| Resource Type | Description | Examples |

|---|---|---|

| Online Forums | Community-driven platforms for advice and shared experiences. | Reddit, GardenWeb |

| Manufacturer Websites | Official resources providing manuals and troubleshooting tips. | Manufacturer’s official site |

| Video Tutorials | Visual guides that demonstrate repair and maintenance techniques. | YouTube, Vimeo |

| Repair Shops | Professional services that can provide expert assistance and repairs. | Local repair shops |