For those involved in the maintenance and operation of outdoor machinery, a comprehensive overview of the various elements that contribute to their functionality is essential. Recognizing how these components work together ensures optimal performance and longevity. Whether you are a seasoned professional or a weekend warrior, grasping the intricacies of each segment is crucial.

In this section, we will delve into the intricate web of machinery, exploring the essential mechanisms and their respective roles. By familiarizing yourself with these vital components, you can effectively troubleshoot issues and perform necessary repairs with confidence. The ability to visualize how each piece fits into the larger assembly allows for a deeper understanding of the overall system.

Equipped with this knowledge, operators can make informed decisions regarding maintenance and repairs, ultimately enhancing their equipment’s efficiency. With a clear picture of each individual section, managing your outdoor machinery becomes a more straightforward and satisfying endeavor.

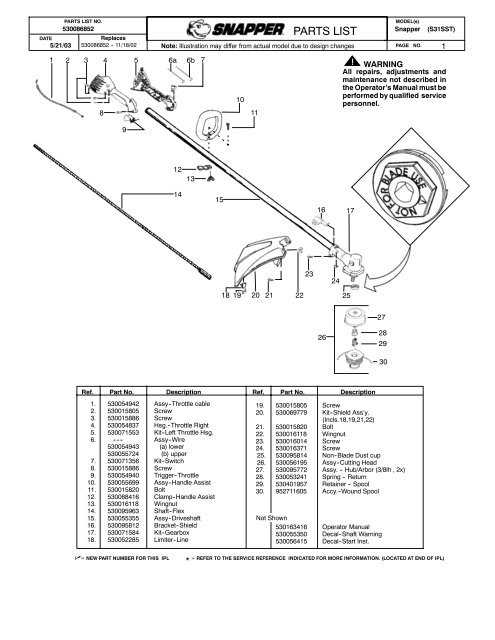

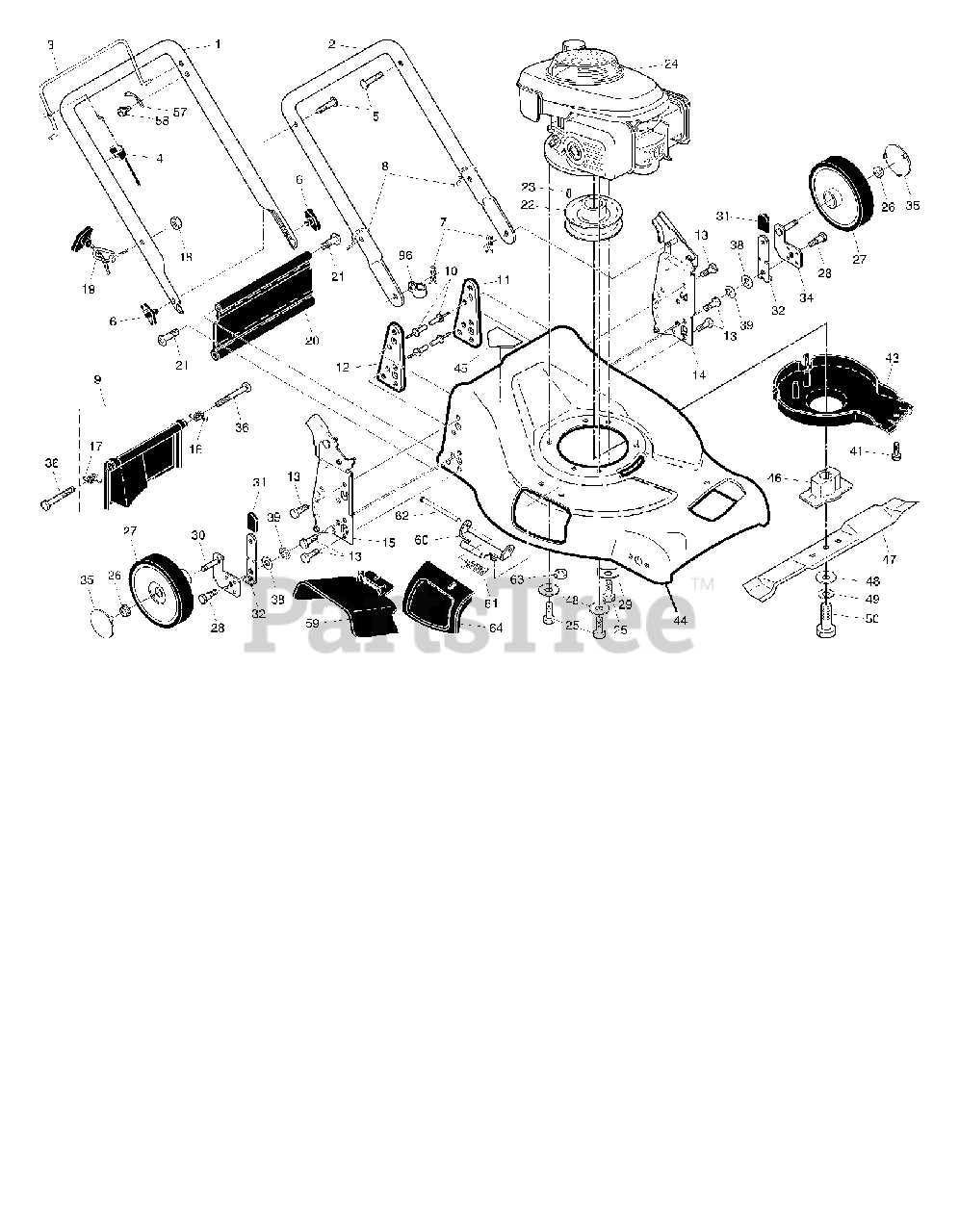

Poulan Riding Mower Parts Diagram

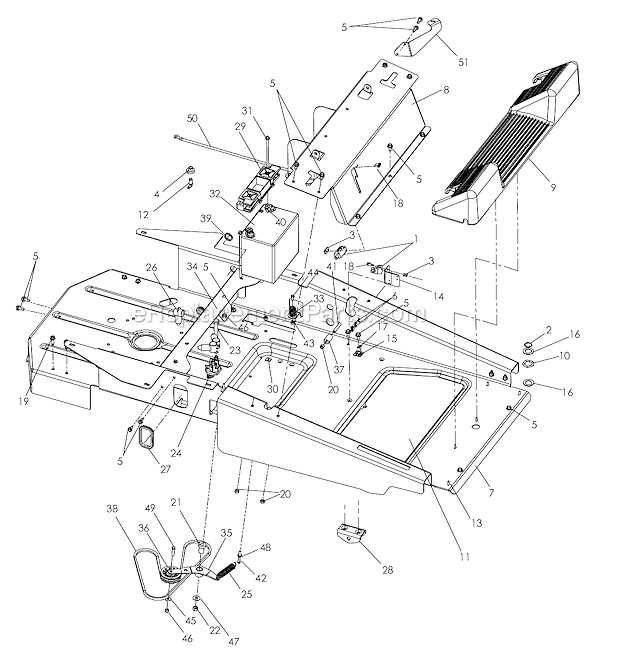

This section provides an overview of the essential components and their arrangements for a specific type of lawn care equipment. Understanding the layout and function of each element is crucial for effective maintenance and repair. By examining the configuration of these parts, users can gain insights into the machine’s operation and enhance its longevity.

Key elements to consider include:

- Engine assembly: The heart of the machinery that powers the entire system.

- Chassis structure: The frame that supports and houses various components.

- Cutting mechanism: The blades responsible for trimming grass to the desired length.

- Transmission system: The mechanism that transfers power from the engine to the wheels.

- Control panel: The interface for the operator to manage settings and functions.

For a comprehensive understanding, it’s helpful to refer to the following categories of components:

- Power Components:

- Starter motor

- Fuel tank

- Battery

- Movement Elements:

- Wheels and tires

- Steering mechanism

- Axles

- Maintenance Features:

- Air filter

- Oil filter

- Belts and hoses

By familiarizing oneself with these various segments, users can improve their ability to troubleshoot and perform necessary repairs effectively, ensuring optimal functionality throughout the operational lifespan.

Overview of Poulan Riding Mowers

This section provides a comprehensive understanding of a particular category of outdoor equipment designed for lawn maintenance. These machines are engineered to simplify the process of cutting grass over large areas, offering users both efficiency and comfort during operation. They combine powerful engines with advanced features to ensure effective performance and ease of use.

Key Features

- Powerful engines that provide robust performance

- Adjustable cutting heights for personalized lawn care

- User-friendly controls for effortless handling

- Comfortable seating for extended usage

- Durable construction designed for longevity

Benefits of Using Lawn Maintenance Equipment

- Increased efficiency in maintaining large areas of grass

- Enhanced precision in cutting and trimming

- Reduced physical strain compared to manual alternatives

- Ability to tackle various terrains and conditions

- Time-saving capabilities for busy homeowners

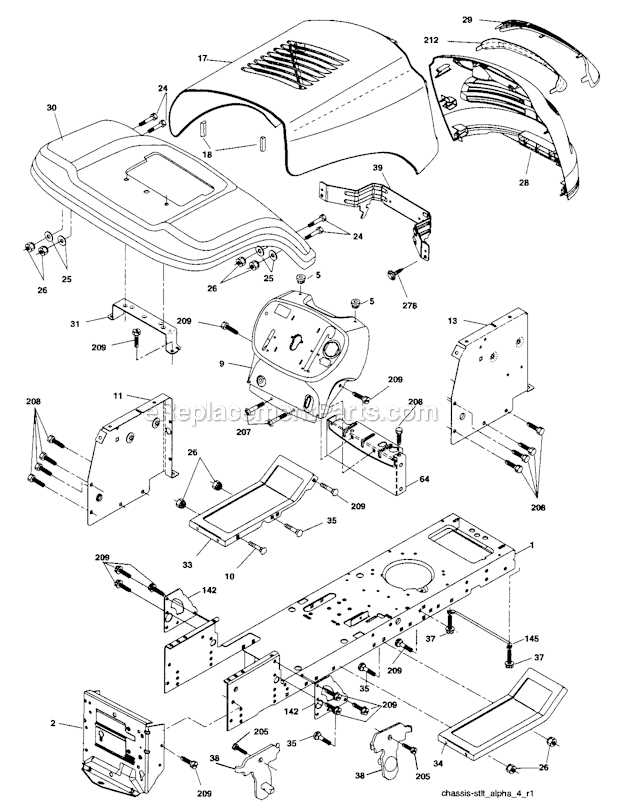

Common Components of Riding Mowers

Understanding the essential elements of lawn care machines is vital for maintenance and efficient operation. These key components work together to ensure optimal performance, providing users with the ability to manage their outdoor spaces effectively. Familiarity with these components can aid in troubleshooting and repairs, as well as enhance the overall longevity of the equipment.

Key Elements

These machines typically comprise several crucial parts that contribute to their functionality. Each element plays a specific role in enhancing performance and ease of use. Below is a table summarizing some of the main components and their functions.

| Component | Description |

|---|---|

| Engine | The powerhouse that provides the necessary energy to operate the machine. |

| Deck | The housing that contains the cutting mechanism, designed for effective grass trimming. |

| Transmission | Facilitates movement, allowing the operator to control speed and direction. |

| Wheels | Support the machine and allow for maneuverability across various terrains. |

| Controls | Levers and buttons that enable the operator to manage functions such as speed and cutting height. |

Importance of Maintenance

Regular inspection and maintenance of these components are essential for preserving functionality. Keeping each part in good condition not only prolongs the life of the machine but also ensures safety and efficiency during operation.

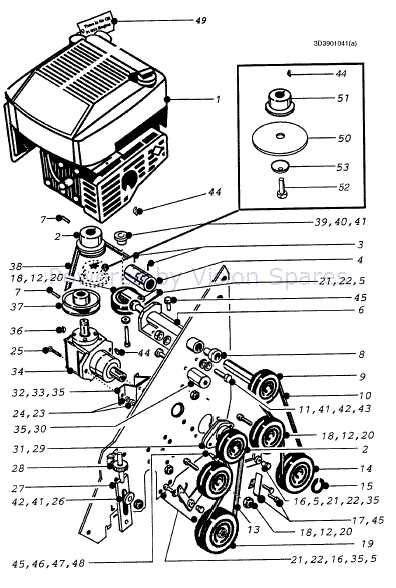

Understanding the Engine Layout

The configuration of the engine plays a crucial role in the overall functionality of the machine. A well-structured layout not only enhances performance but also contributes to ease of maintenance. Familiarizing oneself with the various components and their arrangement is essential for effective operation and troubleshooting.

Key Components of the Engine

At the heart of any machine lies its engine, comprising vital elements such as the cylinder, crankshaft, and spark plug. Each component serves a specific function, working harmoniously to generate power. The cylinder is where fuel combustion occurs, while the crankshaft converts this combustion into rotational force. Additionally, the spark plug ignites the air-fuel mixture, ensuring efficient operation.

Understanding the Layout for Maintenance

A clear understanding of the engine’s layout can simplify maintenance tasks. Knowing the location of essential components allows for quicker access when repairs or replacements are necessary. Regular inspections and familiarity with the layout can prevent larger issues down the line, promoting the longevity of the machinery.

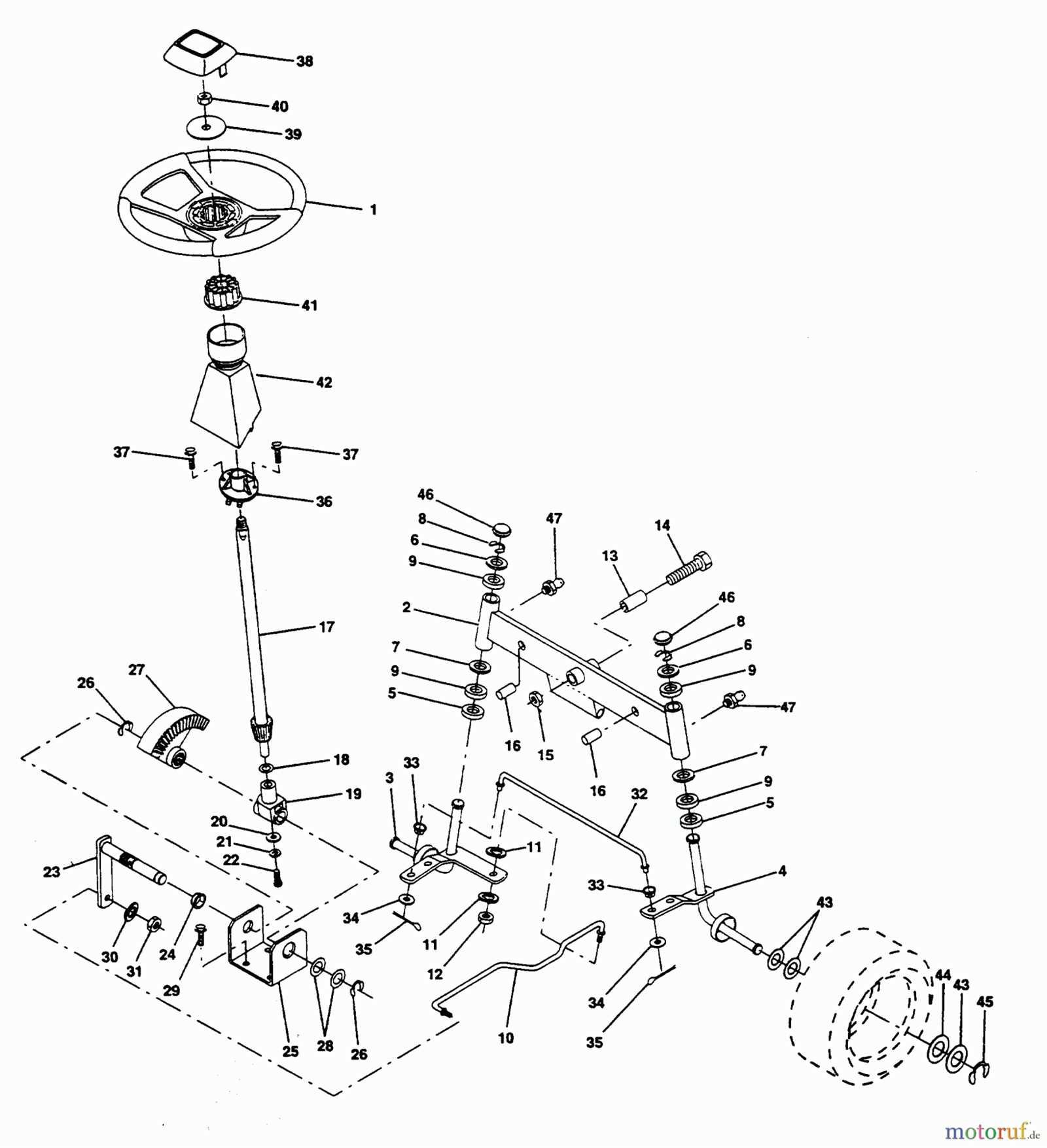

Transmission System and Its Parts

The transmission mechanism plays a crucial role in the functionality of any lawn care equipment. It facilitates the transfer of power from the engine to the wheels, enabling movement and ensuring smooth operation. Understanding the components of this system is essential for effective maintenance and troubleshooting.

Key Components of the Transmission System

- Gearbox: This component houses the gears that regulate speed and torque, allowing the equipment to navigate various terrains efficiently.

- Driveshaft: This long rod transmits power from the engine to the wheels, ensuring that energy is delivered where it is needed most.

- Clutch: The clutch controls the engagement and disengagement of the engine from the drivetrain, enabling smooth starts and stops.

- Belts and Pulleys: These components work together to transfer power within the system, allowing for efficient movement and flexibility in operation.

Maintenance Tips

- Regularly check and replace worn belts to prevent slippage and ensure optimal performance.

- Inspect the gearbox for leaks or damage, as this can lead to significant operational issues.

- Ensure that the clutch is functioning properly to avoid difficulties in starting or stopping.

- Lubricate moving parts as necessary to reduce friction and wear.

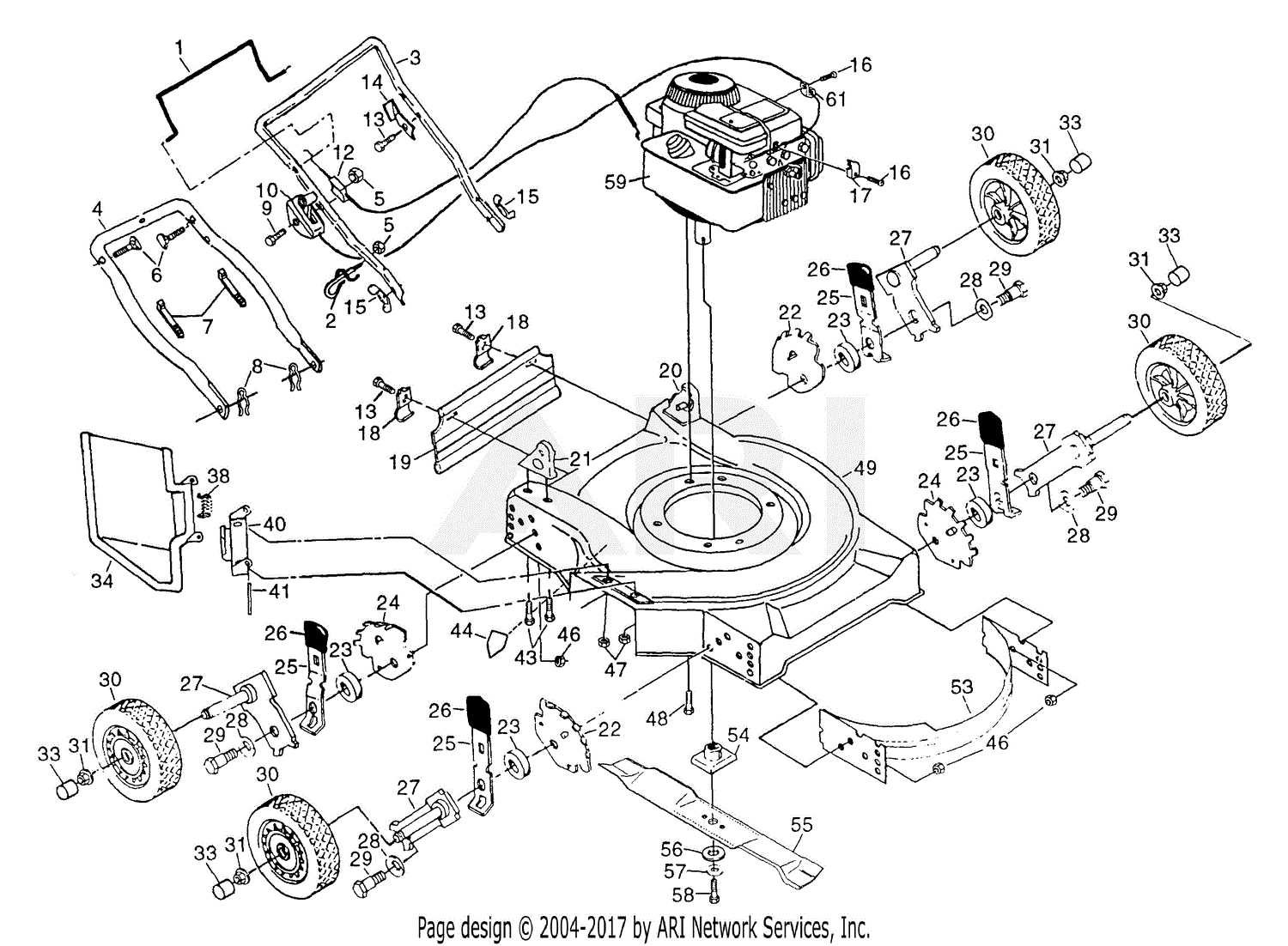

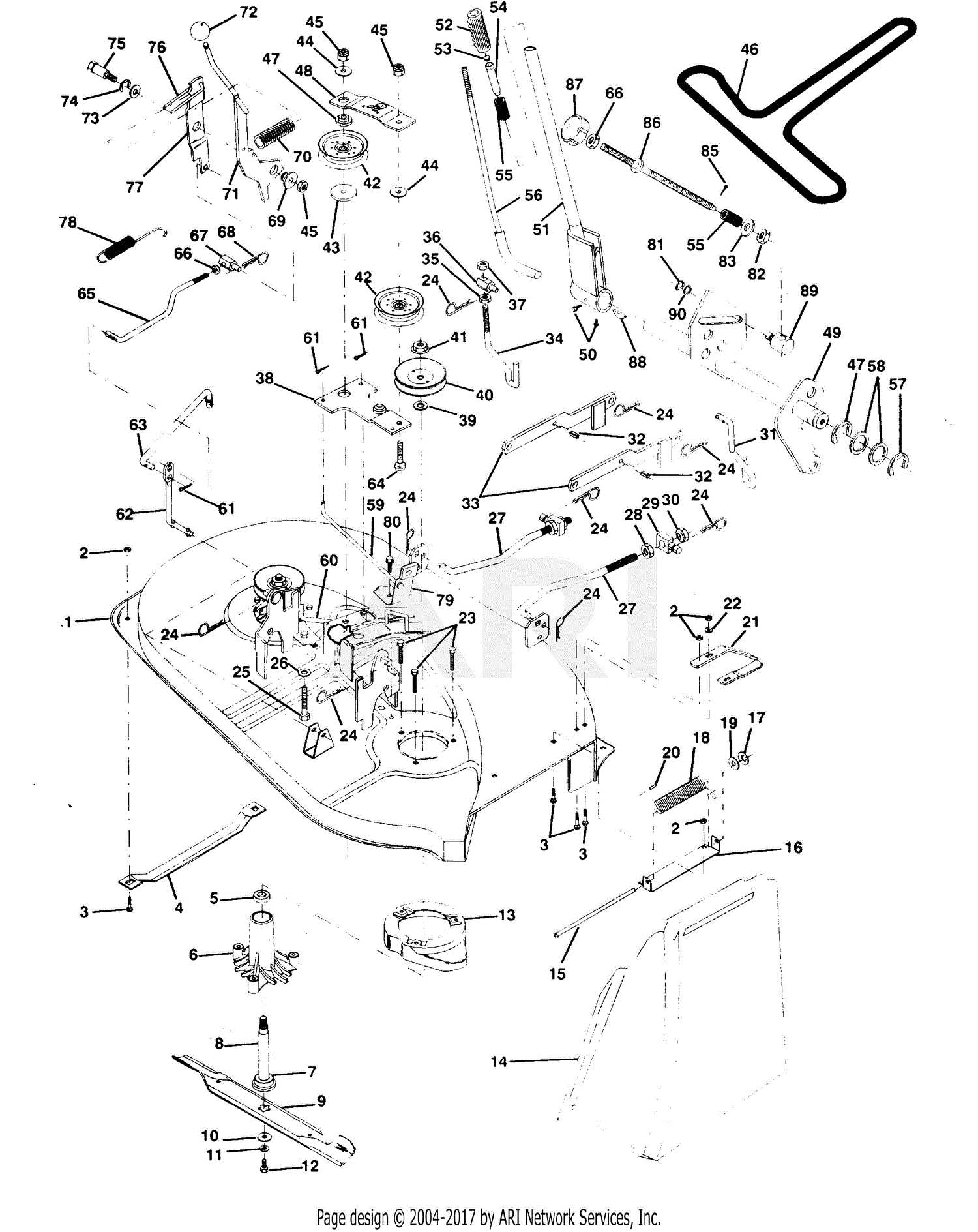

Deck Assembly Explained

The assembly responsible for cutting vegetation is a crucial component of many outdoor machines. Understanding how this assembly is structured and functions can greatly enhance maintenance and repair efforts. This section delves into the various elements that make up this essential unit, providing insight into its operation and maintenance requirements.

Components of the Assembly

The assembly consists of several key components that work together to ensure efficient cutting performance. Each part has a specific role and contributes to the overall functionality of the unit. Familiarity with these components can aid in troubleshooting and repairs.

| Component | Description |

|---|---|

| Blades | Sharp implements designed to cut grass at a desired height. |

| Deck | The housing that encloses the blades and supports the assembly. |

| Spindles | Rotational devices that drive the blades, allowing them to spin and cut effectively. |

| Belt | A flexible band that transmits power from the engine to the spindles. |

Maintenance Tips

Regular maintenance of the assembly is essential for optimal performance. This includes checking for wear and tear, ensuring proper alignment of components, and keeping the area clean. Proper care can extend the life of the assembly and improve cutting efficiency.

Cutting Mechanism Details

The effectiveness of any lawn care equipment largely depends on the efficiency of its cutting system. This critical component is designed to achieve an even and precise cut, ensuring a well-maintained appearance for the landscape. Understanding the various elements involved in this mechanism can enhance both performance and maintenance routines.

Components of the Cutting System

At the heart of the cutting assembly are the blades, which are typically made of high-strength steel for durability. These blades rotate at high speeds, creating a sharp, clean cut through the grass. The arrangement of the blades plays a significant role in the overall cutting width, which determines how much area can be covered in one pass. Additionally, the inclusion of a belt system facilitates the transfer of power from the engine to the blades, ensuring efficient operation.

Adjustability and Maintenance

Many cutting systems feature adjustable heights, allowing users to customize the length of the grass based on seasonal needs. Regular upkeep, such as sharpening blades and checking for wear, is essential to maintain optimal performance. Proper maintenance not only enhances cutting efficiency but also prolongs the lifespan of the equipment.

Electrical System Components

The electrical system in any lawn care vehicle plays a crucial role in ensuring efficient operation and functionality. This system encompasses various elements that work in harmony to provide power, control, and safety features. Understanding these components is essential for effective maintenance and troubleshooting, allowing users to keep their equipment running smoothly.

Battery and Charging System

The battery serves as the heart of the electrical network, providing the necessary voltage to start the engine and power various accessories. It is typically a lead-acid type, designed to deliver high bursts of energy during ignition. The charging system, which includes components such as the alternator and voltage regulator, ensures that the battery remains charged while the engine operates, preventing unexpected power failures.

Ignition System

This system is vital for initiating engine combustion. It consists of components such as the ignition coil, spark plug, and wiring harness. When the ignition key is turned, the coil generates a high-voltage spark that ignites the fuel-air mixture in the engine’s cylinder. Proper functioning of the ignition system is crucial for reliable starting and optimal engine performance.

Maintenance Parts for Longevity

Proper upkeep of your outdoor equipment is essential for ensuring its efficiency and extending its lifespan. Regularly replacing specific components not only enhances performance but also minimizes the risk of unexpected breakdowns. Understanding the key elements that require attention can lead to better maintenance practices and a more reliable machine.

Key Components to Monitor

Focus on regularly checking and updating the following essential components:

| Component | Function | Recommended Replacement Frequency |

|---|---|---|

| Air Filter | Prevents dust and debris from entering the engine | Every 25 hours of operation |

| Oil Filter | Removes contaminants from the engine oil | Every 50 hours of operation |

| Spark Plug | Ignites the air-fuel mixture in the combustion chamber | Every 100 hours of operation |

| Blade | Ensures a clean cut of the grass | Sharpen or replace every 20-30 hours of use |

Importance of Quality Components

Investing in high-quality replacement elements is crucial for optimal functionality. Low-quality components can lead to inefficiencies, increasing fuel consumption and reducing the overall performance of the machinery. Always opt for trusted brands to ensure reliability and longevity in your equipment.

Identifying Wheel and Tire Specifications

Understanding the specifications of wheels and tires is crucial for ensuring optimal performance and safety. Proper identification of these components allows for efficient maintenance and replacement, contributing to the overall functionality of the equipment. This section focuses on the key characteristics that define the appropriate wheels and tires for various applications.

When selecting wheels and tires, it is important to consider several factors, including size, type, and compatibility with the equipment. Each specification plays a significant role in determining how well the machinery operates under different conditions.

| Specification | Description |

|---|---|

| Diameter | The overall measurement across the wheel or tire, influencing fit and stability. |

| Width | The measurement from side to side of the tire, affecting traction and load capacity. |

| Type | Indicates the design and material composition of the tire, impacting durability and performance. |

| Load Rating | A value indicating the maximum weight that the tire can support safely. |

| Pressure Rating | The recommended inflation level to maintain optimal performance and safety. |

By carefully examining these specifications, users can make informed decisions regarding wheel and tire selections, ultimately enhancing the reliability and efficiency of their equipment.

Safety Features and Their Functions

When it comes to outdoor machinery, safety is paramount. Various mechanisms are integrated into these machines to enhance operator protection and prevent accidents. Understanding these features is essential for ensuring a secure operating environment.

Common safety elements include:

- Emergency Stop Button: This feature allows users to immediately halt the operation in case of an emergency, minimizing the risk of injury.

- Safety Interlock System: This system ensures that the engine cannot start unless specific conditions are met, such as the operator being seated.

- Blade Brake: The blade brake quickly stops the cutting mechanism when the operator releases the controls, preventing unintentional contact with rotating blades.

- Protective Shields: These shields guard users from flying debris and hazards, significantly reducing the risk of injury.

- Seat Belt: Similar to automotive safety, seat belts help secure the operator, especially on uneven terrain.

By incorporating these features, manufacturers aim to enhance user safety and promote responsible usage of outdoor machinery. Regular maintenance and understanding of these systems can further contribute to a safer experience.

Accessory Options for Enhanced Performance

Improving the functionality and efficiency of your outdoor equipment can be achieved through a variety of complementary components. These enhancements not only increase productivity but also contribute to a more enjoyable user experience. From attachments that streamline tasks to tools that ensure precise operation, selecting the right accessories can significantly elevate performance.

Essential Attachments for Versatility

One of the most effective ways to enhance operational capability is by incorporating essential attachments. For instance, a high-quality grass collector can make the process of lawn care more efficient by minimizing the need for additional cleanup. Moreover, attachments such as spreaders or aerators can transform your equipment into a multi-functional tool, allowing for various tasks such as fertilization and soil aeration.

Upgrades for Improved Efficiency

Another avenue for optimizing performance involves upgrading existing components. Consider investing in a more powerful engine or better-quality blades to achieve superior cutting results. These enhancements not only ensure a cleaner cut but also reduce the time spent on each task, making your equipment more efficient and reliable.

Repair and Replacement Considerations

When dealing with mechanical equipment, understanding the nuances of maintenance and component substitution is essential for ensuring optimal performance. Whether addressing wear and tear or upgrading elements, careful evaluation of each part’s role is vital. This process not only extends the life of the machinery but also enhances its functionality, ultimately leading to a more efficient operation.

Assessing Wear and Tear

Identifying signs of degradation in various components is crucial. Regular inspections can help detect issues early, preventing more significant problems down the line. Look for unusual noises, vibrations, or performance inconsistencies, which may indicate the need for replacement. Keeping a close eye on these aspects allows for timely intervention and maintenance.

Selecting Replacement Components

When it becomes necessary to substitute any elements, choosing high-quality replacements is paramount. Ensure compatibility with existing structures to maintain the integrity of the overall system. Researching reputable suppliers and verifying product specifications can help in making informed decisions that will enhance the machinery’s longevity and effectiveness.