In the realm of outdoor equipment, comprehending the intricate structure of your device can significantly enhance its performance and longevity. This section delves into the various elements that constitute your machine, providing a clearer perspective on their functionality and interrelationships. By gaining insight into how these components work together, you can better maintain and troubleshoot your equipment.

Knowing the layout of your device’s assembly is essential for effective repairs and upgrades. Each part plays a vital role in ensuring smooth operation, and recognizing these roles can help you identify issues more efficiently. Furthermore, understanding the configuration allows you to make informed decisions when seeking replacements or enhancements.

Equipped with the knowledge of your machine’s makeup, you can approach maintenance tasks with confidence. Whether you’re addressing wear and tear or performing routine checks, familiarity with each element ensures you tackle problems head-on. Empower yourself with this understanding to achieve optimal performance in your outdoor tasks.

Understanding the essential components of a machine is crucial for effective maintenance and operation. Familiarizing oneself with these elements enhances user experience and prolongs the lifespan of the equipment.

Below are some fundamental components and their functions:

- Engine: This is the powerhouse, responsible for converting fuel into mechanical energy.

- Transmission: This mechanism transmits power from the engine to the wheels, enabling movement and speed control.

- Deck: The cutting surface that houses the blades, ensuring efficient grass trimming.

- Blades: Sharp instruments that rotate to cut grass to the desired height.

- Wheels: Allow for mobility and stability while navigating various terrains.

- Fuel Tank: Stores the necessary fuel required for engine operation.

- Battery: Supplies electrical energy to start the engine and power electrical components.

Recognizing these key components enables users to troubleshoot issues effectively and perform necessary upkeep. Regular inspections can help identify worn or damaged parts, ensuring smooth operation and safety.

Maintenance Tips for Longevity

Regular upkeep is essential to ensure optimal performance and extend the lifespan of your equipment. By following a few simple guidelines, you can maintain efficiency and prevent potential issues down the line. Here are some key practices to consider for preserving functionality and reliability.

Routine Inspections

Conducting frequent checks on your machinery allows you to identify any wear and tear before it escalates into significant problems. Examine belts, blades, and other components for signs of damage. Keeping a close eye on these elements ensures that your equipment operates smoothly and reduces the likelihood of costly repairs.

Proper Cleaning

Cleaning your equipment after each use helps to remove debris and dirt that can accumulate and cause obstructions. Focus on areas that are prone to buildup, such as underneath and around the cutting mechanisms. A clean machine not only performs better but also minimizes the risk of rust and corrosion, promoting longevity.

Common Issues and Solutions

When operating outdoor machinery, encountering certain challenges is a common occurrence. Identifying and addressing these problems efficiently can enhance performance and prolong the lifespan of the equipment. This section explores some frequent complications and their respective remedies to ensure smooth operation.

One prevalent issue is the engine failing to start. This can stem from various factors, such as an empty fuel tank, clogged filters, or faulty ignition components. To resolve this, check the fuel level, replace any dirty filters, and inspect the spark plug for damage.

Another common concern is uneven cutting. This often results from dull blades or uneven tire pressure. Regularly sharpening the blades and ensuring all tires are inflated to the correct pressure can help achieve a more uniform cut.

Lastly, overheating can occur during prolonged use. To prevent this, ensure proper ventilation around the machine and regularly clean any debris from the engine area. Additionally, checking the coolant levels can aid in maintaining optimal operating temperatures.

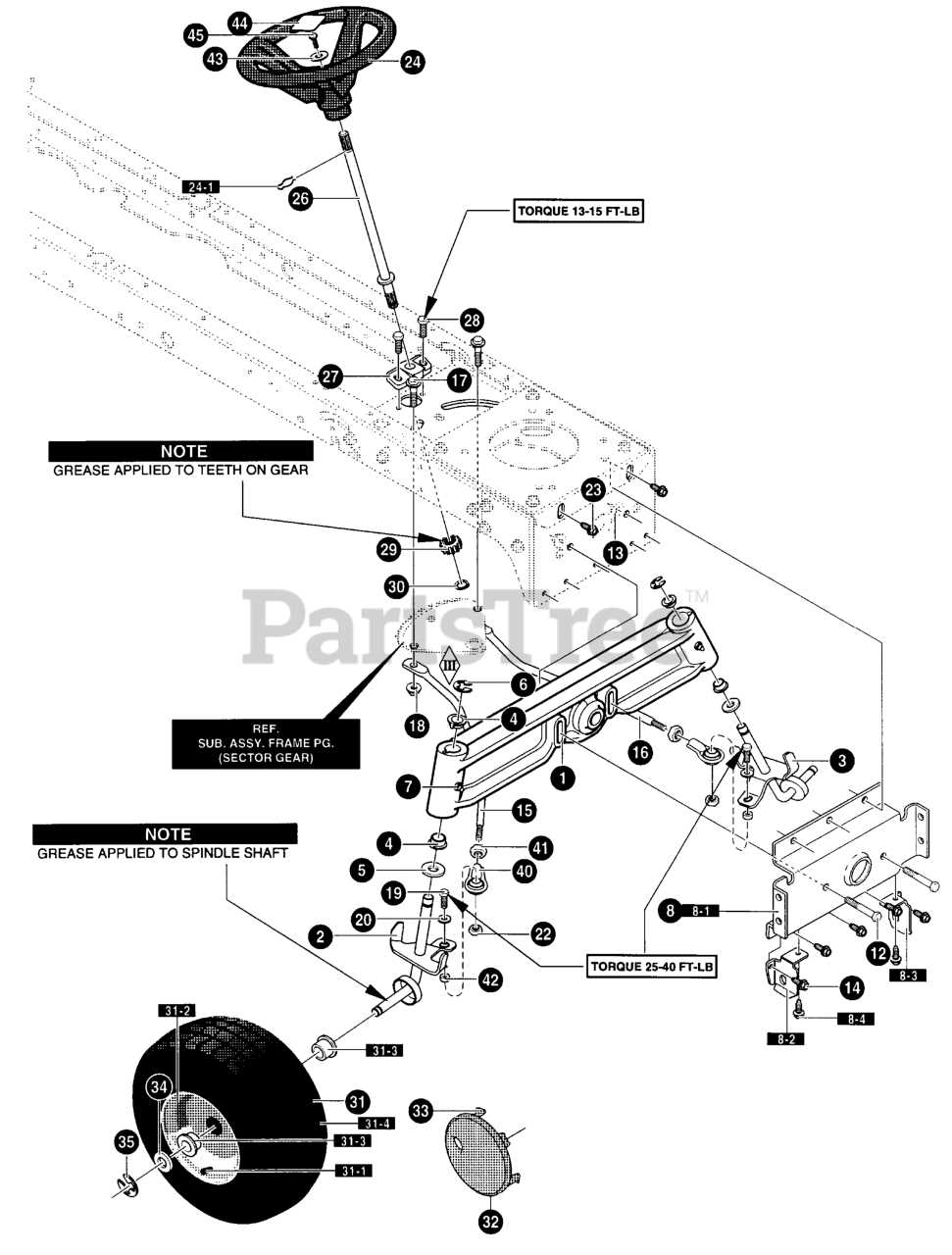

How to Access the Parts Diagram

Understanding the layout and components of your machine is crucial for effective maintenance and repairs. To find a visual representation of these elements, you can follow a few straightforward steps. This guide will help you locate the necessary resources to view and interpret the configuration of your equipment.

First, visit the official website of the manufacturer or a reputable dealer. Often, these platforms provide a section dedicated to support and resources, where you can search for your specific model. Utilize the search function by entering the model number or relevant keywords to access documentation and schematics.

In addition, online forums and user communities can be invaluable. Many experienced users share links or upload diagrams that can assist you in identifying various components. Engaging with these communities may also provide tips and insights from other owners.

Lastly, consider consulting the owner’s manual that came with your machine. These manuals frequently include sections that illustrate key components, helping you understand how each piece functions together. If you no longer have a physical copy, many manufacturers offer digital versions for download on their websites.

Ordering Replacement Parts Easily

Finding the right components for your equipment can be a straightforward process if you follow a few key steps. With the right approach, you can ensure that you receive high-quality items quickly and without unnecessary hassle.

Here are some tips to make the ordering process smoother:

- Identify the model and serial number of your device. This information is crucial for selecting compatible items.

- Visit the official website or a trusted retailer that specializes in outdoor machinery. This will help you access a wide range of options.

- Utilize online resources such as diagrams or guides that illustrate the specific components needed. This visual aid can simplify the selection process.

- Contact customer service if you have any questions about compatibility or features. Experts can provide valuable assistance.

Once you have gathered the necessary information, you can place your order:

- Select the desired components and add them to your cart.

- Review your selections for accuracy and compatibility.

- Proceed to checkout, entering your shipping and payment details.

- Confirm your order and keep an eye out for delivery notifications.

By following these steps, you can efficiently acquire the components you need to keep your equipment running smoothly.

Tools Needed for Repairs

When undertaking maintenance and repair tasks, having the right tools at your disposal is essential for achieving effective results. A well-equipped toolbox can significantly ease the process and ensure that all components are handled properly. Below is a list of necessary instruments to facilitate the repair work.

Essential Hand Tools

Basic hand tools are fundamental for any repair endeavor. These include wrenches, screwdrivers, and pliers. Each tool serves a specific purpose, allowing for the loosening and tightening of various fittings, as well as the manipulation of smaller components. Ensuring you have a variety of sizes can make a considerable difference in efficiency.

Specialized Equipment

In addition to general tools, some specialized equipment may be required for specific tasks. This could include torque wrenches for precise tightening, socket sets for easier access to bolts, and diagnostic tools to troubleshoot issues effectively. Investing in quality equipment can enhance the overall repair experience and lead to better outcomes.

Step-by-Step Repair Guide

This section provides a comprehensive approach to troubleshooting and fixing common issues encountered in outdoor machinery. By following these systematic steps, you can ensure that your equipment operates efficiently and lasts longer. Proper maintenance and timely repairs can prevent further complications and enhance the overall performance of your machine.

Identification of the Issue

Before starting any repair work, it’s crucial to identify the specific problem. Common issues may include poor performance, unusual noises, or failure to start. Take note of any symptoms and gather relevant information that may aid in diagnosing the issue.

Gather Necessary Tools and Materials

Once you have identified the problem, gather all the tools and materials required for the repair process. Having everything ready in advance will streamline your workflow and minimize downtime. Common tools include wrenches, screwdrivers, and replacement components.

| Tool/Material | Purpose |

|---|---|

| Wrench Set | For loosening and tightening bolts |

| Screwdriver Set | For removing and securing screws |

| Replacement Parts | To replace damaged or worn components |

| Cleaning Supplies | For maintaining a clean workspace |

Following these steps will guide you through the repair process effectively, ensuring that your equipment is back to optimal condition in no time.

Upgrading Your Lawn Mower Parts

Enhancing the components of your grass cutting machine can significantly improve its performance and longevity. Whether you’re looking to boost efficiency, increase durability, or simply enhance the user experience, considering upgrades can be a wise investment. By focusing on key areas, you can tailor your equipment to better meet your needs, ensuring that each session in your yard is more productive and enjoyable.

Benefits of Component Enhancements

Upgrading various elements can lead to noticeable improvements in operation. For instance, installing a high-quality cutting blade can provide a cleaner cut and reduce strain on the engine, resulting in a smoother operation. Additionally, better filters and belts can enhance overall functionality, ensuring that the machine runs at optimal levels. These enhancements not only contribute to a more effective performance but can also extend the lifespan of your equipment.

Choosing the Right Upgrades

When selecting upgrades, it’s essential to consider compatibility and quality. Researching reputable brands and components tailored for your specific model can help you make informed choices. Prioritize parts that have a proven track record of reliability and performance. Moreover, consulting user reviews or expert recommendations can provide valuable insights, allowing you to choose upgrades that truly enhance the capabilities of your grass cutting machine.

Safety Precautions During Repairs

When undertaking maintenance tasks on machinery, prioritizing safety is essential. Adhering to proper precautions not only safeguards the individual performing the repairs but also ensures the longevity and efficiency of the equipment. Below are important guidelines to follow during repair processes.

- Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and sturdy footwear.

- Ensure the machine is powered off and disconnected from any power source before starting work.

- Work in a well-ventilated area to prevent the accumulation of harmful fumes or gases.

- Keep tools and work areas organized to minimize the risk of accidents.

- Read and understand the manufacturer’s manual for specific safety instructions related to the equipment.

By following these guidelines, individuals can significantly reduce the likelihood of injuries and create a safer working environment. Regularly reviewing safety practices is equally important to stay updated on best practices.

Expert Resources for Mower Owners

Owning a lawn care machine requires access to reliable information and support to ensure optimal performance and longevity. Here, we highlight various expert resources available for enthusiasts and users looking to enhance their understanding and maintenance skills.

| Resource Type | Description | Link |

|---|---|---|

| Manufacturer’s Manuals | Official documents providing detailed guidance on operation and maintenance. | Access Manuals |

| Online Forums | Community platforms where users share tips, experiences, and troubleshooting advice. | Join Forums |

| Video Tutorials | Step-by-step guides available on various platforms demonstrating repairs and upkeep. | Watch Tutorials |

| Parts Retailers | Specialized shops that offer a wide range of components for replacements and upgrades. | Find Parts |

Frequently Asked Questions

This section addresses common inquiries related to maintenance and repair components for outdoor machinery. Here, you will find helpful information to assist you in understanding the various aspects of these essential tools.

| Question | Answer |

|---|---|

| How can I identify the correct components for my machine? | You can identify the appropriate components by referring to the model number and consulting the user manual or manufacturer’s website for specific recommendations. |

| What should I do if a part is unavailable? | If a particular part is not in stock, consider checking alternative suppliers or online marketplaces that specialize in outdoor equipment. |

| How often should I replace worn-out components? | It is advisable to inspect parts regularly and replace them when signs of wear are evident to maintain optimal performance. |

| Can I install components myself? | Many users can install parts on their own, provided they follow the instructions carefully. However, for complex repairs, seeking professional assistance may be wise. |