When it comes to maintaining your outdoor machinery, having a clear visual representation of its components is essential. This approach not only aids in identifying each element but also streamlines the repair and maintenance processes. Knowing how the various pieces fit together can significantly enhance your efficiency during upkeep tasks.

In this guide, we will delve into the intricate layout of essential machinery parts. By examining these components, you will gain valuable insights into their functions and interrelations. This understanding empowers users to perform maintenance tasks with confidence and accuracy, ensuring that the equipment operates at peak performance.

Moreover, having access to a detailed overview allows for quicker troubleshooting and replacement of worn-out items. Whether you’re a seasoned professional or a DIY enthusiast, this knowledge is indispensable for extending the lifespan of your equipment and optimizing its functionality.

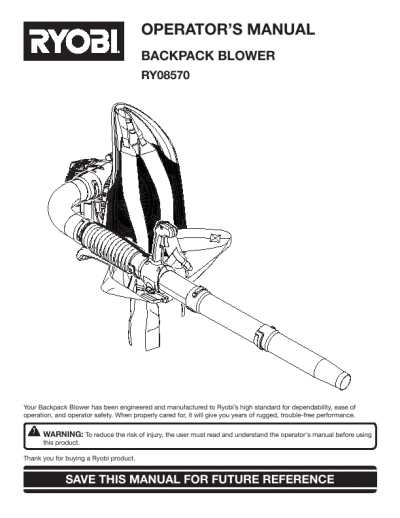

Understanding Ryobi Backpack Blowers

This section delves into the essential components and functionality of a portable yard maintenance tool designed for efficient outdoor cleaning. By comprehending the structure and features of this equipment, users can enhance performance and longevity.

Key aspects to consider include:

- Power Source: Evaluating the energy supply, whether it’s gas or electric, impacts usability and efficiency.

- Airflow Mechanics: Understanding how air movement is generated aids in optimizing cleaning tasks.

- Weight Distribution: The design influences user comfort and maneuverability during operation.

In addition, awareness of common components can facilitate better maintenance:

- Engine: The heart of the device, determining power and efficiency.

- Fan: Responsible for air circulation, its design affects performance.

- Filters: Crucial for maintaining air quality and ensuring optimal operation.

Grasping these elements enables users to maximize the effectiveness of their equipment, making yard upkeep more manageable and efficient.

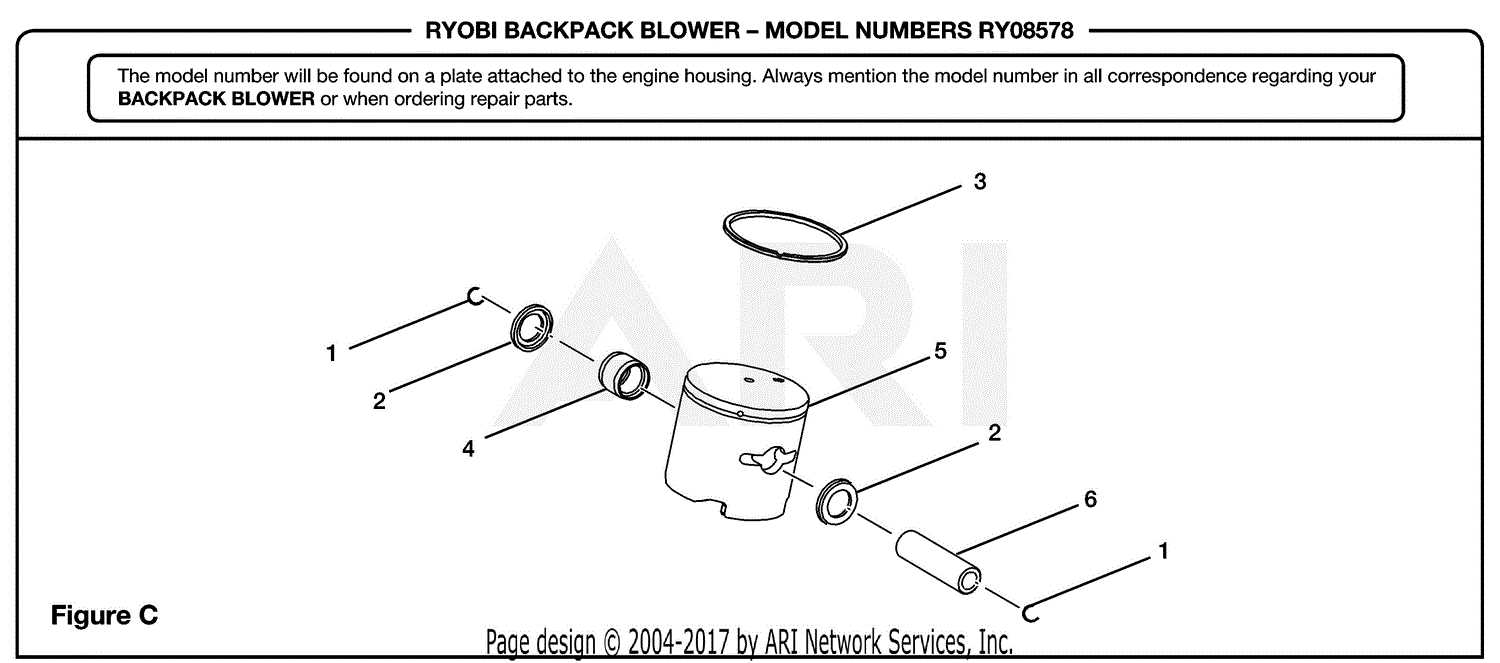

Key Components of the Ryobi Blower

Understanding the essential elements of this equipment is crucial for optimal performance and maintenance. Each segment plays a significant role in ensuring efficient operation and longevity, contributing to overall effectiveness.

Power Unit: This is the heart of the machine, providing the necessary energy to drive all functions. Its performance directly impacts the output strength.

Air Intake: This component is responsible for drawing in air, which is vital for the combustion process or the functioning of electric systems, depending on the model.

Fan Assembly: The fan creates the airflow needed for dispersing debris. Its design influences both speed and volume of the air produced.

Fuel System: In gas-operated models, this system manages the mixture of fuel and air, which is essential for smooth operation and efficiency.

Control Handle: This part allows the user to manipulate settings and manage airflow, ensuring ease of use and comfort during operation.

Exhaust System: Responsible for directing emissions away from the user, this element is crucial for safety and environmental considerations.

By exploring these fundamental components, users can better appreciate how each plays a role in achieving the ultimate performance of the equipment.

Importance of Regular Maintenance

Benefits of Consistent Upkeep

- Enhanced Performance: Regular checks and servicing keep machines running smoothly and efficiently.

- Increased Lifespan: Proper maintenance can extend the operational life of equipment significantly.

- Cost Savings: Preventative care reduces the likelihood of major repairs, saving money in the long run.

- Safety: Regular inspections ensure that all safety features are functioning correctly, reducing the risk of accidents.

Key Maintenance Practices

- Check and replace filters regularly to ensure proper airflow and efficiency.

- Inspect fuel and oil levels; replace as needed to maintain optimal function.

- Clean the exterior to prevent debris buildup, which can affect performance.

- Sharpen blades and other cutting components to ensure effective operation.

- Follow manufacturer guidelines for scheduled service intervals.

In conclusion, committing to regular maintenance is essential for maximizing the performance and durability of outdoor machinery. By integrating these practices into your routine, you ensure a reliable and efficient experience every time you use your equipment.

Common Issues with Backpack Blowers

Portable air-moving devices are essential tools for maintaining outdoor spaces, yet they can encounter a range of complications that hinder their performance. Understanding these common challenges can help users troubleshoot effectively and keep their equipment running smoothly.

Performance Problems

One prevalent issue is a noticeable decrease in air output. This may result from clogged filters, damaged impellers, or blocked exhaust systems. Regular maintenance, including cleaning and replacing components, is vital to prevent these issues. Ignoring such signs can lead to further deterioration and costly repairs.

Starting Difficulties

Another frequent complaint involves challenges when attempting to initiate operation. Problems can stem from various sources, including stale fuel, faulty spark plugs, or issues with the ignition system. Ensuring fresh fuel and proper tuning are key steps in addressing this issue. Routine checks can enhance reliability and extend the lifespan of the device.

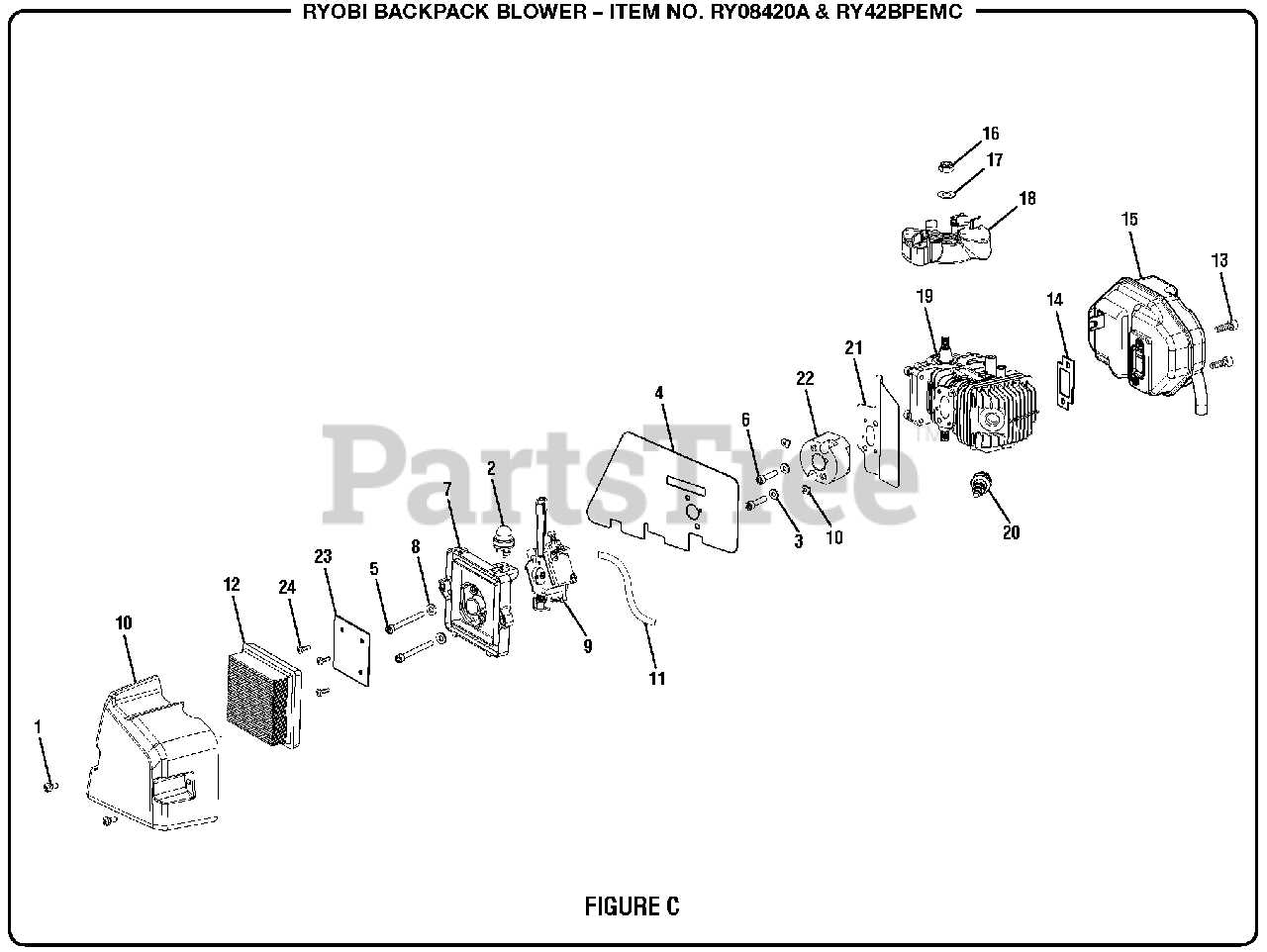

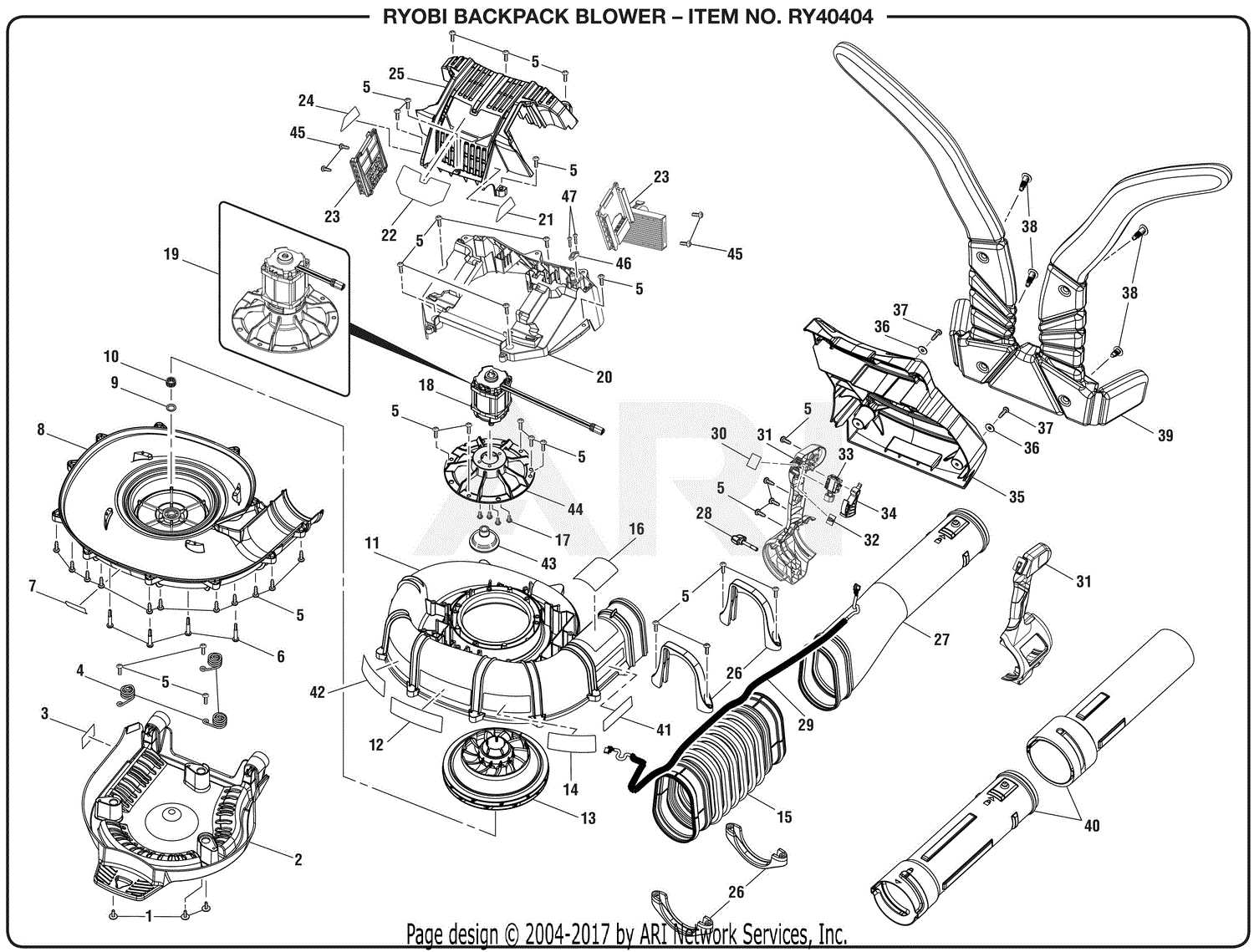

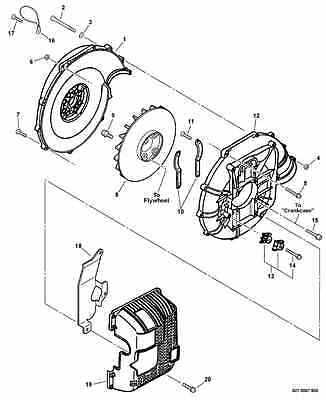

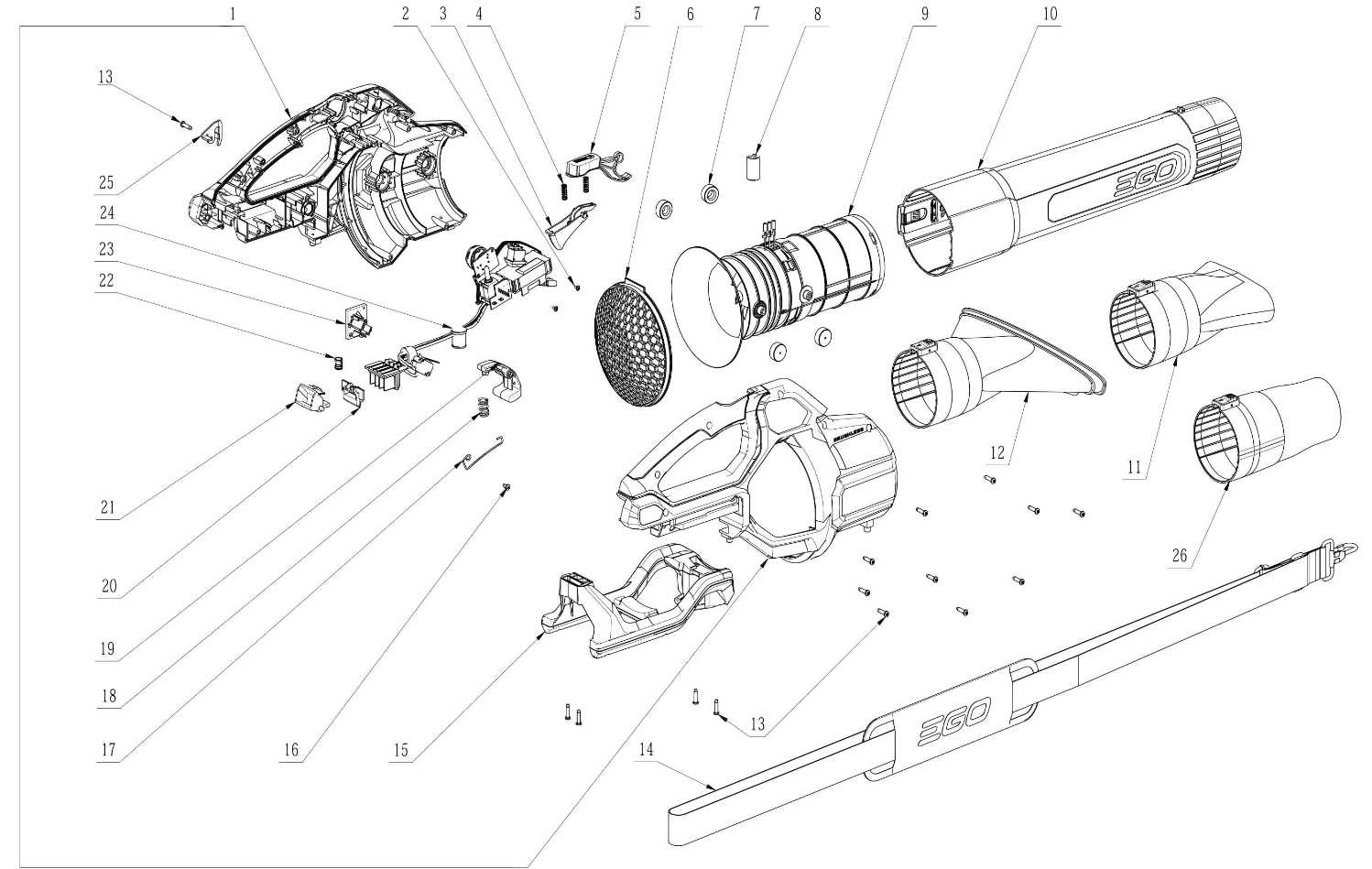

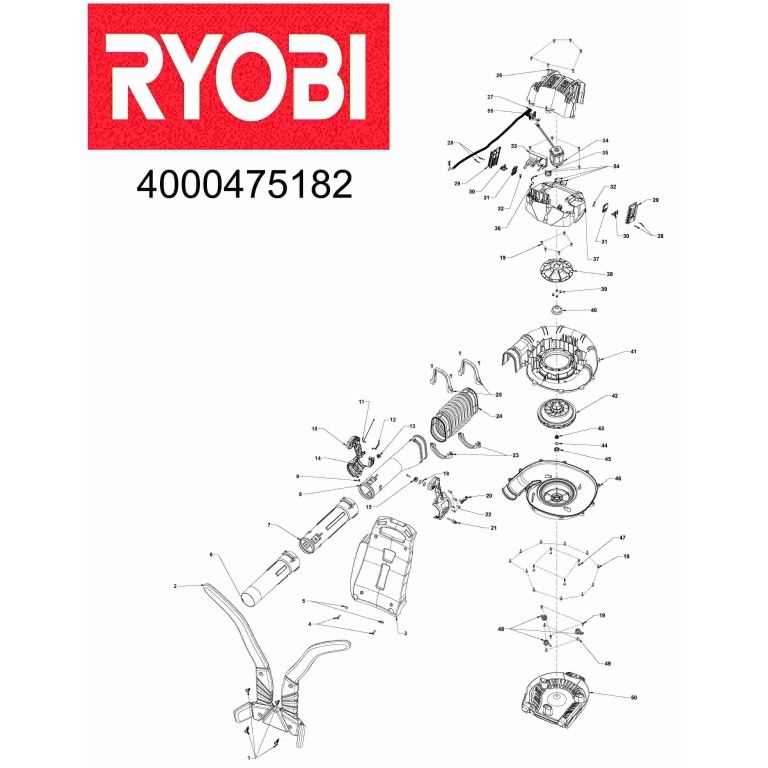

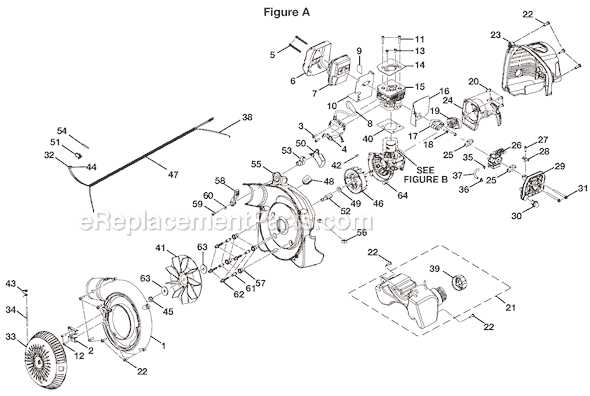

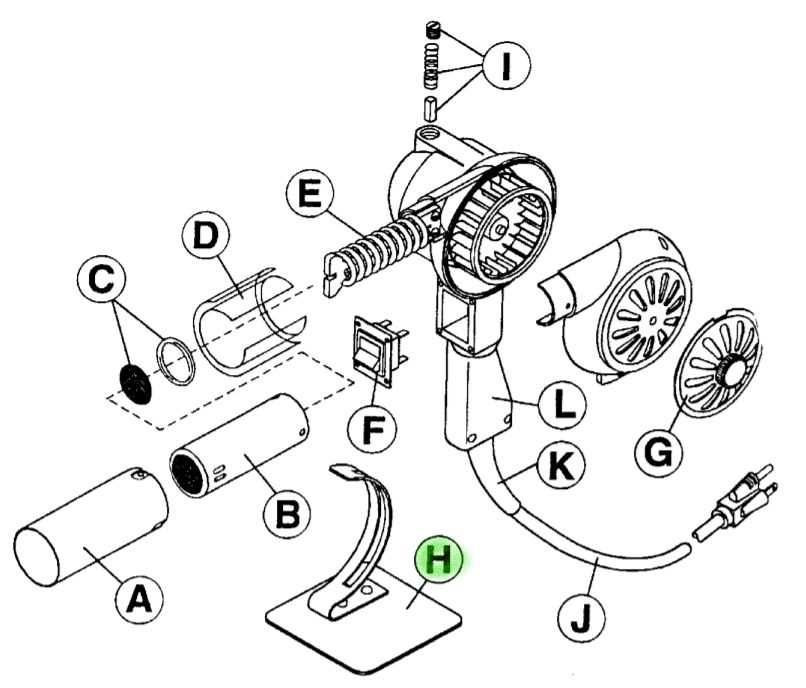

How to Read a Parts Diagram

Understanding a schematic can greatly enhance your ability to identify components and their functions in any machinery. By familiarizing yourself with the layout and symbols used, you can efficiently locate and replace parts when necessary.

Key Elements of a Schematic

- Labels: Each element is typically labeled for easy identification.

- Numbers: These often correspond to a list of components or parts.

- Connections: Lines indicate how different components are interconnected.

Tips for Effective Reading

- Start by reviewing the entire layout to get a sense of the arrangement.

- Focus on one section at a time to avoid confusion.

- Refer to the accompanying legend or key for clarification of symbols.

Replacing Worn-Out Components

Ensuring optimal performance of outdoor equipment often involves addressing wear and tear on its essential elements. Over time, certain components may degrade, affecting functionality and efficiency. Recognizing the signs of deterioration and taking proactive steps can enhance longevity and reliability.

Identifying Wear and Tear

Common indicators of aging elements include unusual noises, reduced power output, and difficulty starting. Regular inspections can help pinpoint specific areas needing attention. Keeping an eye on these symptoms can prevent further damage and costly repairs.

Steps for Replacement

Once worn components are identified, acquiring high-quality replacements is crucial. Follow manufacturer guidelines for installation, ensuring a proper fit. After replacement, testing the equipment can confirm that performance has returned to optimal levels.

Tools Needed for Repairs

When tackling maintenance or fixing tasks, having the right equipment is essential for efficiency and effectiveness. The appropriate tools not only facilitate smoother repairs but also enhance safety and accuracy in your work.

| Tool | Purpose |

|---|---|

| Screwdriver Set | To remove and tighten screws securely. |

| Socket Wrench | For loosening or tightening bolts with ease. |

| Pliers | To grip, twist, or cut wire and other materials. |

| Utility Knife | For precise cutting of materials and components. |

| Multimeter | To test electrical components and connections. |

Where to Find Replacement Parts

Finding the right components for your outdoor equipment can greatly enhance its performance and longevity. Various sources are available to help you acquire the necessary items efficiently and affordably.

Online Retailers

Many online platforms offer a vast selection of components. Websites such as Amazon and eBay often feature both new and refurbished options, making it easy to compare prices and reviews.

Local Dealers

Visiting authorized dealers in your area can provide immediate access to quality items. These specialists often have expert knowledge and can assist you in identifying the correct components for your specific model.

Tips for Efficient Blower Operation

Maximizing the performance of your outdoor equipment requires understanding its operation and maintenance. By implementing a few key strategies, users can achieve optimal results while minimizing wear and tear.

Regular Maintenance

Routine checks and servicing can enhance functionality and longevity. Ensure air filters are clean, fuel is fresh, and components are securely fastened.

Proper Technique

Adopting the right approach can significantly impact effectiveness. Positioning and movement play crucial roles in achieving the desired outcome.

| Tip | Description |

|---|---|

| Check Fuel Levels | Always operate with adequate fuel to avoid interruptions. |

| Adjust Speed Settings | Use variable speeds for different tasks to enhance efficiency. |

| Use a Comfortable Harness | A well-fitted harness reduces fatigue during prolonged use. |

DIY Repair Techniques for Users

Engaging in self-repair can be both rewarding and economical for enthusiasts seeking to maintain their outdoor equipment. This section explores practical strategies that empower users to tackle common issues, enhancing both knowledge and skill.

Understanding Your Equipment: Familiarize yourself with the device’s components through manuals and online resources. Knowledge of each part’s function is crucial for effective troubleshooting.

Essential Tools: Invest in basic tools such as screwdrivers, wrenches, and pliers. Having the right equipment readily available can simplify the repair process significantly.

Step-by-Step Approach: Break down the repair process into manageable steps. Documenting each stage not only helps in organizing your work but also aids in identifying any missteps during reassembly.

Safety First: Always prioritize safety by wearing appropriate gear and ensuring the equipment is turned off and disconnected from power sources before starting any repairs.

Consulting Online Communities: Leverage forums and social media groups where experienced users share insights and solutions. These platforms can provide valuable advice and troubleshooting tips.

By following these techniques, users can enhance their confidence and ability to repair their machinery effectively, ultimately leading to a longer lifespan for their tools.

Safety Precautions When Repairing Equipment

Ensuring personal safety during maintenance tasks is crucial to prevent accidents and injuries. Familiarizing oneself with safety protocols can significantly reduce risks associated with handling tools and machinery.

Essential Safety Guidelines

- Always wear appropriate personal protective equipment, such as gloves and safety goggles.

- Work in a well-ventilated area to avoid inhaling harmful fumes.

- Disconnect the power source before starting any repair work.

- Use tools that are in good condition and suitable for the task at hand.

Handling Tools and Components

- Be aware of sharp edges or moving parts that could cause injury.

- Store tools properly to prevent accidents when not in use.

- Follow manufacturer instructions for any repairs or replacements.