Sensor Interfaces: Connect external sensors to the board, providing feedback on temperature, moisture, and other

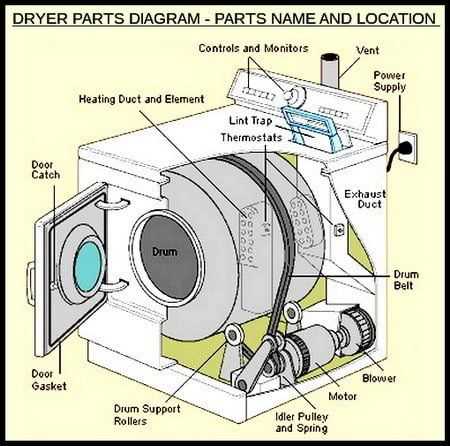

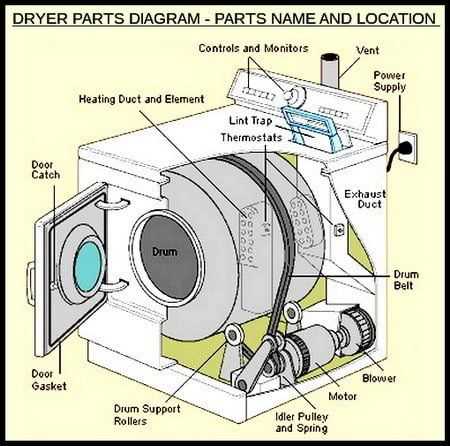

Explaining the Dryer Motor and Its Function

The motor is a central component in the operation of many household machines designed for airflow and movement of internal parts. It provides the necessary force to drive mechanical processes, ensuring that the machine performs its tasks efficiently. Understanding its role is key to grasping how the entire system operates.

Main Role of the Motor

At the heart of the appliance, the motor’s primary job is to power the rotating elements, which are essential for consistent performance. This rotation allows for even distribution of heat or motion, depending on the system’s design, making it crucial for smooth operation. The motor converts electrical energy into mechanical motion, which drives the system to function as intended.

How It Powers Internal Components

Through a series of belts and pulleys, the motor transfers energy to various internal mechanisms. This

The Role of Thermal Fuses in Dryers

Thermal fuses are essential components in various home appliances designed to provide safety and prevent overheating. Their primary function is to act as a safeguard, ensuring that devices operate within safe temperature limits. In the event of excessive heat, these fuses are engineered to break the electrical circuit, thereby halting operation and reducing the risk of fire hazards.

How Thermal Fuses Work

When the temperature exceeds a predetermined threshold, the thermal fuse reacts by melting a metal connection within its housing. This action effectively cuts off the power supply to the appliance. Here are key aspects of their operation:

- Designed to respond quickly to heat.

- Automatically resets when conditions normalize, ensuring user safety.

- Typically installed in series with heating elements to ensure effective temperature regulation.

Importance of Regular Maintenance

Maintaining and monitoring these critical components is vital for the longevity and safety of home appliances. Regular checks can help identify potential issues before they escalate into major problems. Key maintenance practices include:

- Inspecting for signs of damage or wear.

- Ensuring proper ventilation around the appliance.

- Replacing fuses that have tripped to maintain optimal performance.

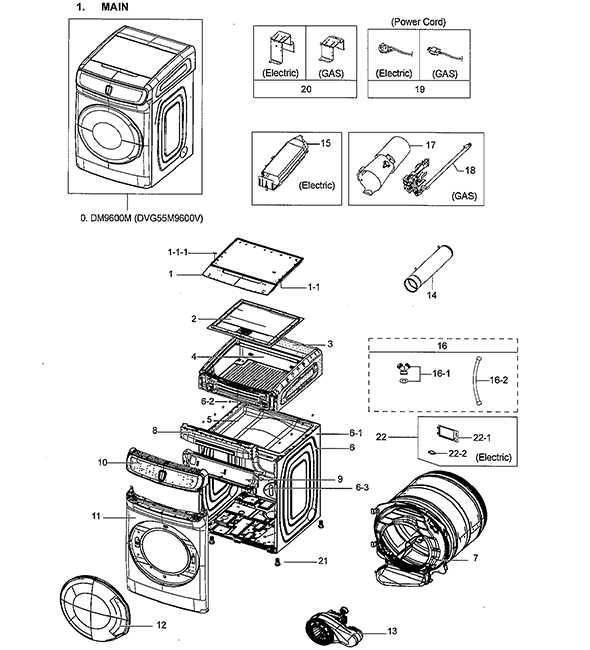

Importance of the Drum and Belt System

The drum and belt assembly plays a crucial role in the functioning of any garment drying appliance. This system is responsible for the efficient movement of clothes during the drying process, ensuring even heat distribution and thorough drying. Understanding its significance helps in maintaining the overall performance and longevity of the appliance.

Key Functions of the Drum and Belt Assembly

- Clothes Rotation: The drum rotates to allow garments to tumble freely, which prevents clumping and facilitates even drying.

- Heat Distribution: As the drum spins, it evenly distributes heat, helping to evaporate moisture effectively.

- Preventing Damage: The movement of clothes in the drum reduces wear and tear, minimizing the risk of fabric damage.

Common Issues Related to the Drum and Belt Assembly

- Wear and Tear: Over time, the belt may stretch or break, leading to drum malfunction.

- Drum Imbalance: An improperly balanced load can cause excessive vibrations, potentially damaging internal components.

- Noise: A worn belt or drum can lead to unusual sounds during operation, indicating a need for inspection or replacement.

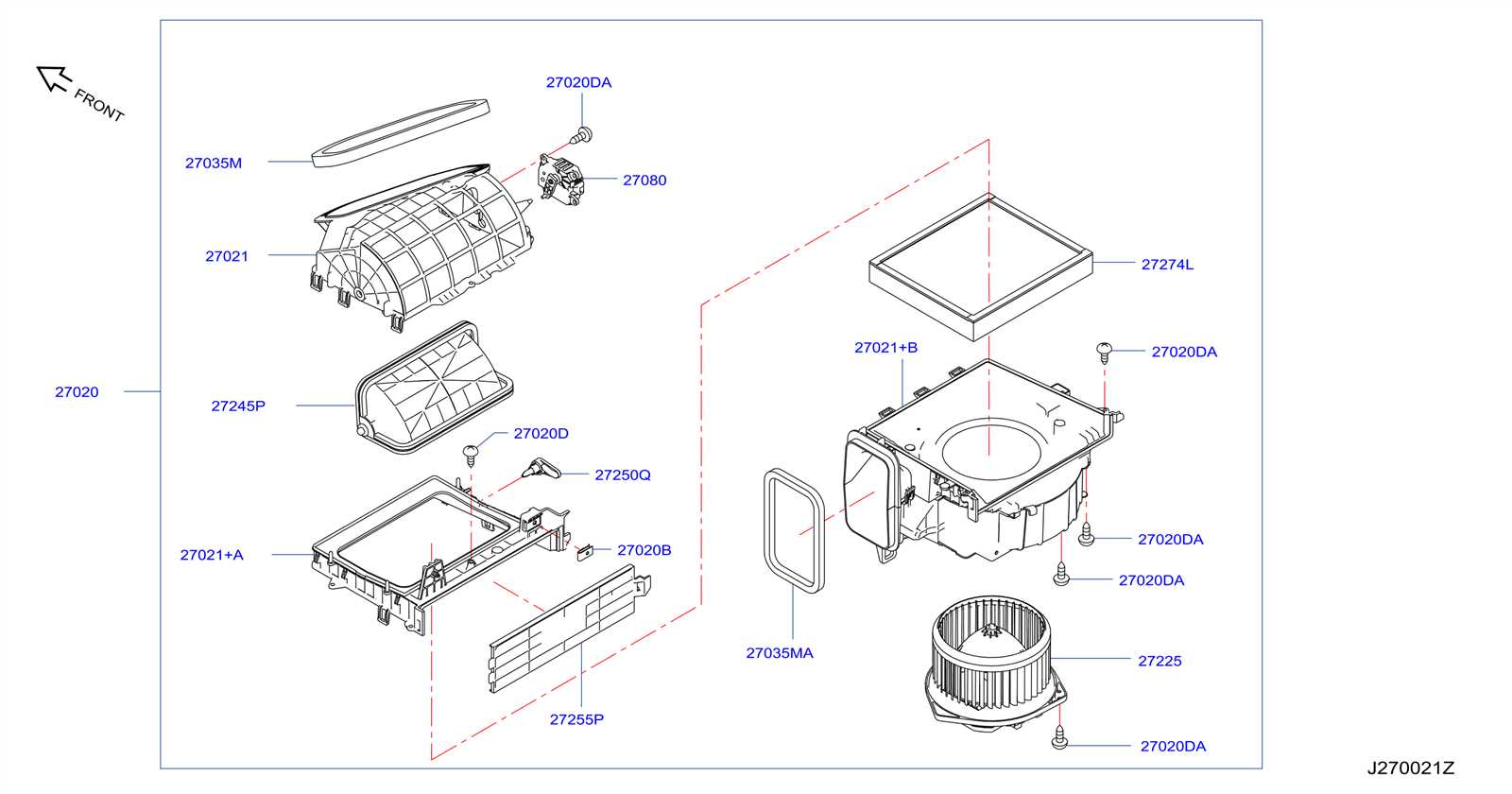

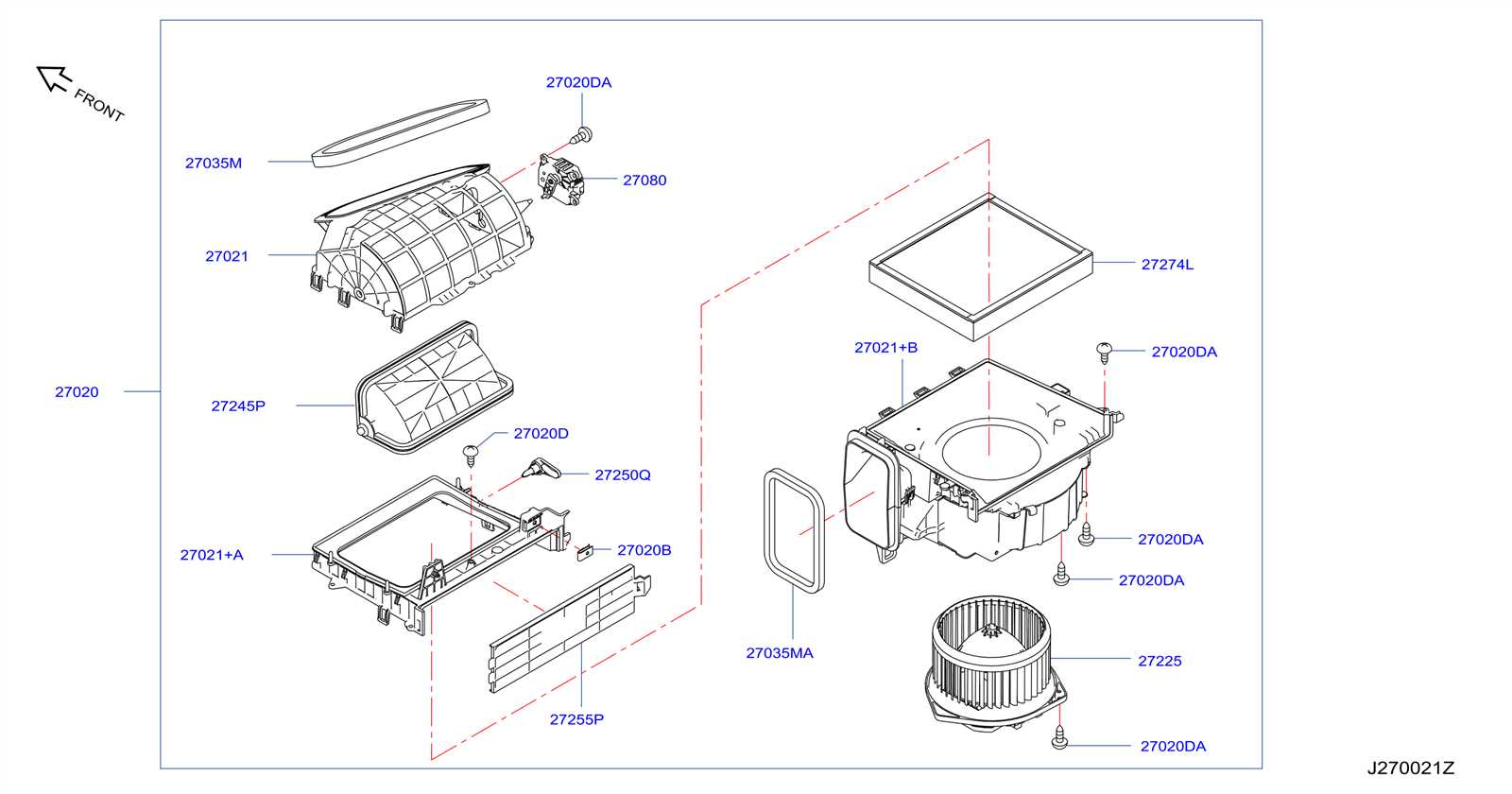

Exploring the Blower Assembly and Ventilation

The blower assembly plays a crucial role in the effective operation of drying appliances by facilitating the movement of air. This component is responsible for generating the airflow necessary to remove moisture from garments, ensuring efficient performance. Proper ventilation is essential for maintaining optimal temperature and humidity levels within the appliance, promoting both efficiency and longevity.

Understanding the design and function of the blower assembly allows users to appreciate its significance in the overall drying process. The assembly typically includes a fan, housing, and motor, all working in unison to circulate air throughout the system. Regular maintenance, such as cleaning lint filters and checking for obstructions, is vital to keep the airflow unobstructed and the appliance functioning smoothly.

Moreover, effective ventilation enhances the drying process by expelling damp air outside and drawing in fresh air. This exchange helps maintain consistent temperatures, which is critical for achieving optimal drying results. Ensuring that the ventilation system is clear and functioning properly can lead to improved efficiency and reduced energy consumption.

Diagnosing Common Electric Dryer Problems

Identifying issues in a home appliance can often seem daunting, but with a systematic approach, many problems can be resolved efficiently. Understanding the common malfunctions helps users troubleshoot effectively, ensuring smooth operation and longevity of the appliance.

Frequent Issues Encountered

Appliances may exhibit a variety of symptoms that indicate underlying troubles. Common problems include the appliance not starting, improper heating, or unusual noises during operation. Recognizing these signs early can prevent further complications.

Troubleshooting Guide

| Issue |

Possible Cause |

Suggested Action |

| No Power |

Blown fuse or tripped circuit breaker |

Check the fuse box and reset the breaker if necessary. |

| Insufficient Heat |

Clogged vent or faulty heating element |

Inspect the vent for blockages and test the heating element. |

| Unusual Noises |

Worn rollers or foreign objects |

Examine the drum for loose parts and remove any debris. |

Replacing Sensors and Thermostats in Dry

Maintaining optimal performance in drying appliances often requires replacing specific components, such as temperature sensors and thermostats. These elements are crucial for regulating heat and ensuring efficient operation, preventing potential damage to clothing and the appliance itself.

Here’s a guide to effectively replace these vital components:

-

Gather Necessary Tools and Materials:

- Replacement sensors and thermostats

- Screwdriver set

- Multimeter for testing

- Safety gloves

-

Unplug the Appliance:

Always disconnect the unit from the power source before starting any repairs to ensure safety.

-

Access the Components:

Remove the outer casing or access panel of the appliance to reach the internal components. This may require unscrewing various fasteners.

-

Locate the Sensors and Thermostats:

Identify the specific locations of the sensors and thermostats. Refer to the user manual for guidance if necessary.

-

Test the Existing Components:

Before replacing, use a multimeter to check if the current sensors and thermostats are functioning correctly.

-

Remove Faulty Parts:

Carefully detach the malfunctioning sensors and thermostats. Keep track of any screws or connectors for reinstallation.

-

Install New Components:

Place the new sensors and thermostats in the same locations as the old ones, securing them with screws or connectors.

-

Reassemble the Appliance:

Replace the outer casing or access panel, ensuring all screws are tightened and secure.

-

Test the Appliance:

Reconnect the unit to the power source and run a test cycle to ensure that the new components are functioning properly.

Following these steps can help maintain the efficiency of your drying machine, ensuring it operates smoothly and effectively for years to come.