Airflow v

Cooling System and Refrigerant Pathways

The cooling system operates by circulating a special fluid through a series of components, enabling efficient temperature control within the unit. This process involves a network of pathways that facilitate heat exchange, ensuring that the internal temperature remains stable and consistent. By moving through these channels, the fluid absorbs heat and then expels it outside, maintaining the desired cooling effect.

Main Components of the Cooling Circuit

In this system, various parts collaborate to regulate temperatures. A compressor, condenser, and evaporator work in unison to move the refrigerant through different stages, converting it from gas to liquid and back again. These transformations allow heat to be transferred from the interior to the external environment.

Refrigerant Flow and Heat Exchange

The refrigerant flow follows a define

Electrical Connections and Power Control

Proper management of electrical connections and power control is crucial to ensuring reliable and safe operation of any appliance. Understanding the flow of electricity, as well as how components are powered and interconnected, helps to maintain efficient functionality and avoid common issues related to energy supply.

Main Electrical Setup

The main electrical configuration includes various circuits and wiring responsible for distributing power to essential components. Ensuring that these connections are secure and free from damage is vital for preventing malfunctions.

- Inspect all wires for signs of wear or loose connections.

- Ensure all connectors are tightly secured to avoid interruptions in power flow.

- Check that the power supply meets the required voltage specifications.

Power Control Mechanisms

Power control is managed through a series of switches, sensors, and control units. These systems regulate the flow of electricity to various sections, allowing for automated adjustments based on op

Water Dispenser Mechanism and Parts

The water dispenser mechanism functions through a coordinated system that ensures the smooth flow of water from the internal reservoir to the external dispenser. It operates through a set of components designed to handle water pressure, temperature regulation, and safe delivery for everyday use. This mechanism combines various elements that work together to provide clean and efficient water dispensing.

The valve system controls the release of water from the internal tank, allowing for precise flow management. A well-maintained filtration unit ensures the quality and safety of the water, removing any impurities before it reaches the outlet.

The tubing channels water through the system, while the control panel lets users easily operate and manage the dispensing process. Regular checks of the key elements are essential to keep the water system in good condition, ensuring continuou

Freezer Compartment Organization

Efficient management of the freezer space is crucial for maintaining food quality and accessibility. By strategically arranging items, you can maximize storage capacity while ensuring that you can easily find what you need. A well-organized freezer not only helps in minimizing waste but also enhances your overall cooking experience.

Start by categorizing your frozen goods into groups such as meats, vegetables, and ready-to-eat meals. Utilize clear containers or labeled bags to keep similar items together. This approach not only streamlines your access but also aids in monitoring inventory, helping to avoid duplicate purchases. Ensure that frequently used items are placed at eye level for easy reach.

Consider using stackable bins or baskets to create vertical space, which can significantly improve accessibility. Additionally, leaving space for air circulation helps maintain consistent temperatures throughout the compartment. Regularly check and rotate items to ensure freshness, discarding anything past its prime. By implementing these strategies, your freezer can become a functional and organized space that supports your culinary needs.

Door Seals and Insulation Details

Effective door seals and insulation are crucial components that significantly enhance the energy efficiency and overall performance of refrigeration units. These elements work together to prevent temperature fluctuations and reduce energy consumption, ensuring optimal cooling conditions for stored items.

Quality seals are designed to fit snugly around the edges of doors, creating an airtight barrier that minimizes cold air escape. This functionality not only helps maintain a consistent internal temperature but also prolongs the lifespan of the appliance.

Key features of door seals and insulation include:

- Material Composition: High-quality rubber or silicone materials are commonly used for their durability and resistance to wear.

- Installation: Proper installation is essential to ensure a tight fit; any gaps can lead to significant energy loss.

- Maintenance: Regular inspection and cleaning of seals can prevent damage and maintain their effectiveness over time.

- Thermal Insulation: Insulation materials play a vital role in reducing heat transfer, further enhancing energy efficiency.

By prioritizing the integrity of seals and insulation, users can enjoy reliable performance and lower energy bills, making these components essential for any refrigeration system.

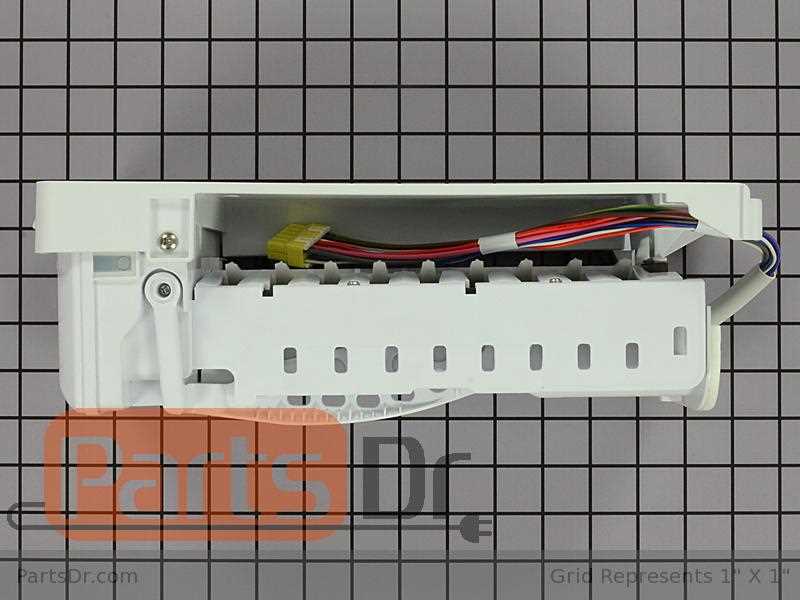

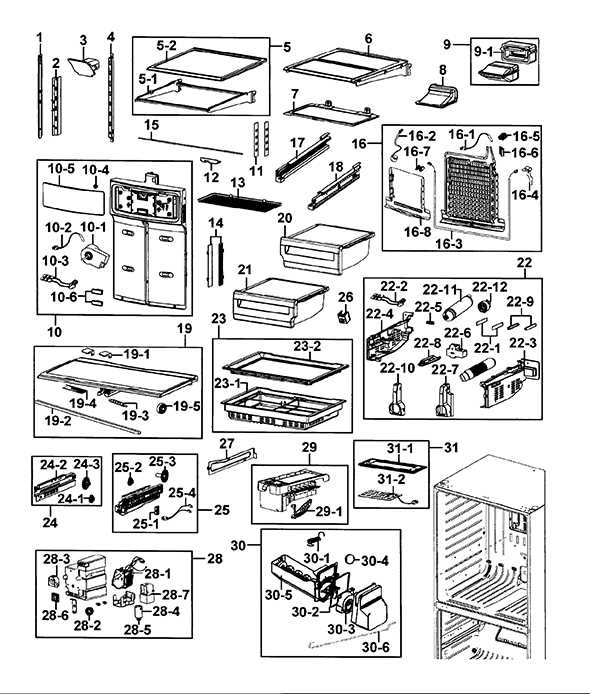

Ice Maker Assembly Diagram

The ice-making unit is a crucial component in ensuring that your appliance provides a steady supply of frozen water. Understanding its layout and individual elements can aid in maintenance and troubleshooting.

This section delves into the various parts that make up the ice maker assembly, highlighting their functions and interconnections.

- Ice Mold: This is where water freezes to form ice cubes.

- Heating Element: Helps in releasing the ice cubes from the mold.

- Water Inlet Valve: Controls the flow of water into the mold.

- Ice Ejector: Assists in pushing the ice cubes out of the mold once frozen.

- Control Module: Regulates the entire ice-making process.

Familiarity with these components can enhance your understanding of how to troubleshoot issues related to ice production and ensure optimal performance of your appliance.

Maintenance of the Condenser Unit

Regular upkeep of the condenser unit is crucial for ensuring efficient operation and prolonging the lifespan of the appliance. Proper maintenance prevents common issues that can arise from neglect, ultimately leading to improved performance and reduced energy consumption.

Essential Maintenance Steps

- Clean the condenser coils regularly to remove dust and debris.

- Ensure proper airflow around the unit by keeping the area free from obstructions.

- Inspect and replace any worn or damaged parts as necessary.

- Check for refrigerant leaks and ensure the system is charged correctly.

Signs of Potential Issues

- Unusual noises coming from the unit.

- Increased energy bills without a change in usage patterns.

- Inconsistent cooling performance.

- Visible frost build-up on the coils.

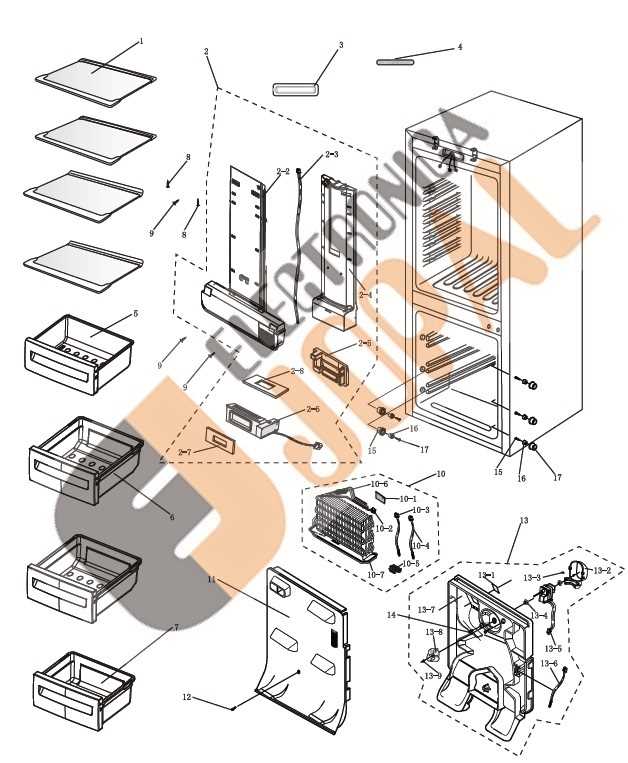

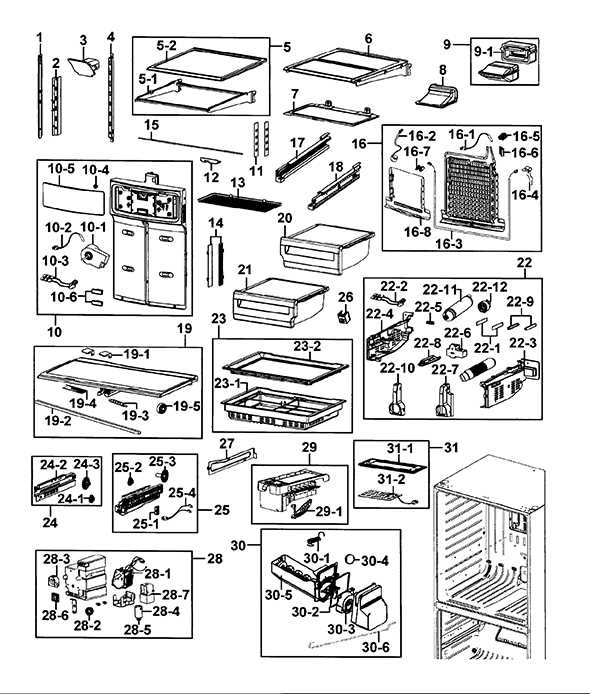

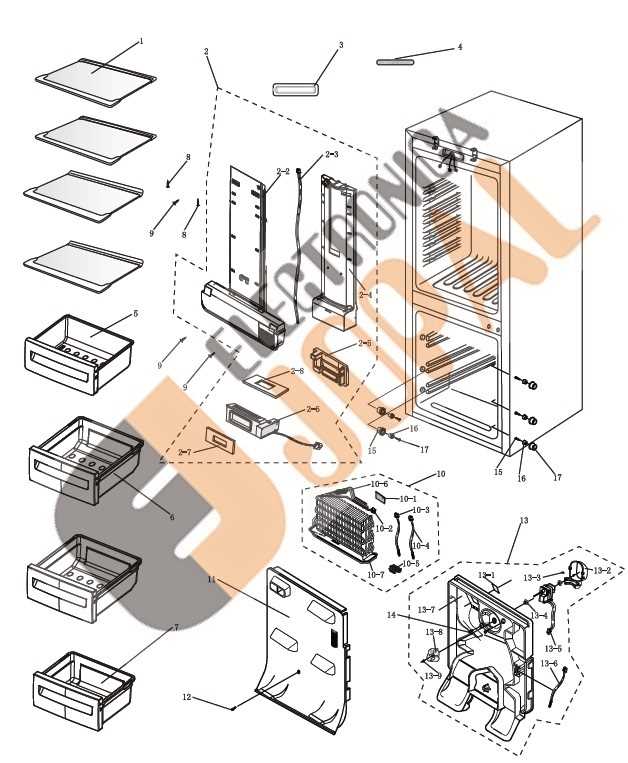

Shelves and Drawers Configuration

The arrangement of shelves and drawers within a refrigeration unit plays a crucial role in maximizing storage efficiency and accessibility. A well-thought-out design allows users to organize food items and beverages effectively while ensuring easy retrieval.

Types of Shelves

- Adjustable Shelves: These can be repositioned to accommodate various sizes of items, enhancing flexibility in storage.

- Fixed Shelves: These provide stable support for heavier items and are ideal for storing bulkier products.

- Tempered Glass Shelves: Known for their durability and easy cleaning, these shelves offer a sleek appearance while allowing light to penetrate, helping users locate items easily.

Drawer Options

- Crisper Drawers: Designed for fruits and vegetables, these drawers maintain optimal humidity levels, extending the freshness of produce.

- Meat Drawers: These compartments typically offer lower temperatures to keep meat products fresh longer.

- Utility Drawers: Versatile storage spaces that can accommodate a variety of items, such as snacks or kitchen supplies, depending on user needs.

Replacing Internal Filters and Valves

Maintaining the efficiency of your cooling appliance involves periodic replacement of essential components such as internal filters and valves. These parts play a crucial role in ensuring optimal performance, enhancing the longevity of the unit, and improving energy efficiency.

Filters help trap dust and impurities, ensuring that the air circulating within the appliance remains clean. Over time, these filters can become clogged, leading to decreased airflow and potential overheating. Replacing them regularly can significantly improve the unit’s performance.

Similarly, valves control the flow of refrigerants and other fluids within the system. If these components become faulty, it can lead to leaks or inefficient cooling. Identifying the signs of wear and promptly replacing these valves will not only restore functionality but also prevent further damage.

When replacing these components, it is essential to follow the manufacturer’s guidelines for proper installation. Utilizing the correct replacement parts and ensuring a secure fit will help maintain the appliance’s integrity and functionality.