Understanding the inner workings of various mechanical systems is crucial for maintaining and repairing equipment effectively. Each element in these machines plays a pivotal role in ensuring smooth operation and overall reliability. Whether you’re fine-tuning a device or replacing a worn-out element, having a clear overview of how each component fits together is essential.

Mechanical breakdowns can often be traced to a single element within the system. By familiarizing yourself with the structure and connections of each piece, you can ensure the longevity of the machine and prevent unnecessary failures. This guide offers detailed insights into key elements, helping you identify and replace them efficiently.

Moreover, a thorough understanding of individual components allows for more effective troubleshooting, ensuring that even the smallest issues are quickly addressed before they escalate into larger problems. By following this guide, you will gain clarity on how different mechanical pieces function together, making maintenance a straightforward task.

Understanding the Briggs and Stratton 1150 Series

When it comes to reliable power sources for various equipment, this engine model stands out as a highly efficient and well-engineered choice. Known for its durability and performance, this power unit has been designed to meet the needs of both casual users and professionals. Its innovative construction ensures optimal output and minimal maintenance, making it a preferred option in its category.

Let’s explore some of the key features that make this motor model so effective:

- Optimized fuel efficiency for extended use without frequent refueling.

- Advanced airflow design, which promotes better cooling and prolongs engine life.

- Robust construction, allowing it to withstand challenging conditions and heavy workloads.

- User-friendly operation, providing easy starting mechanisms and smooth functionality.

With the right maintenance and care, this model will serve its purpose for a long time, making it a dependable choice for various applications.

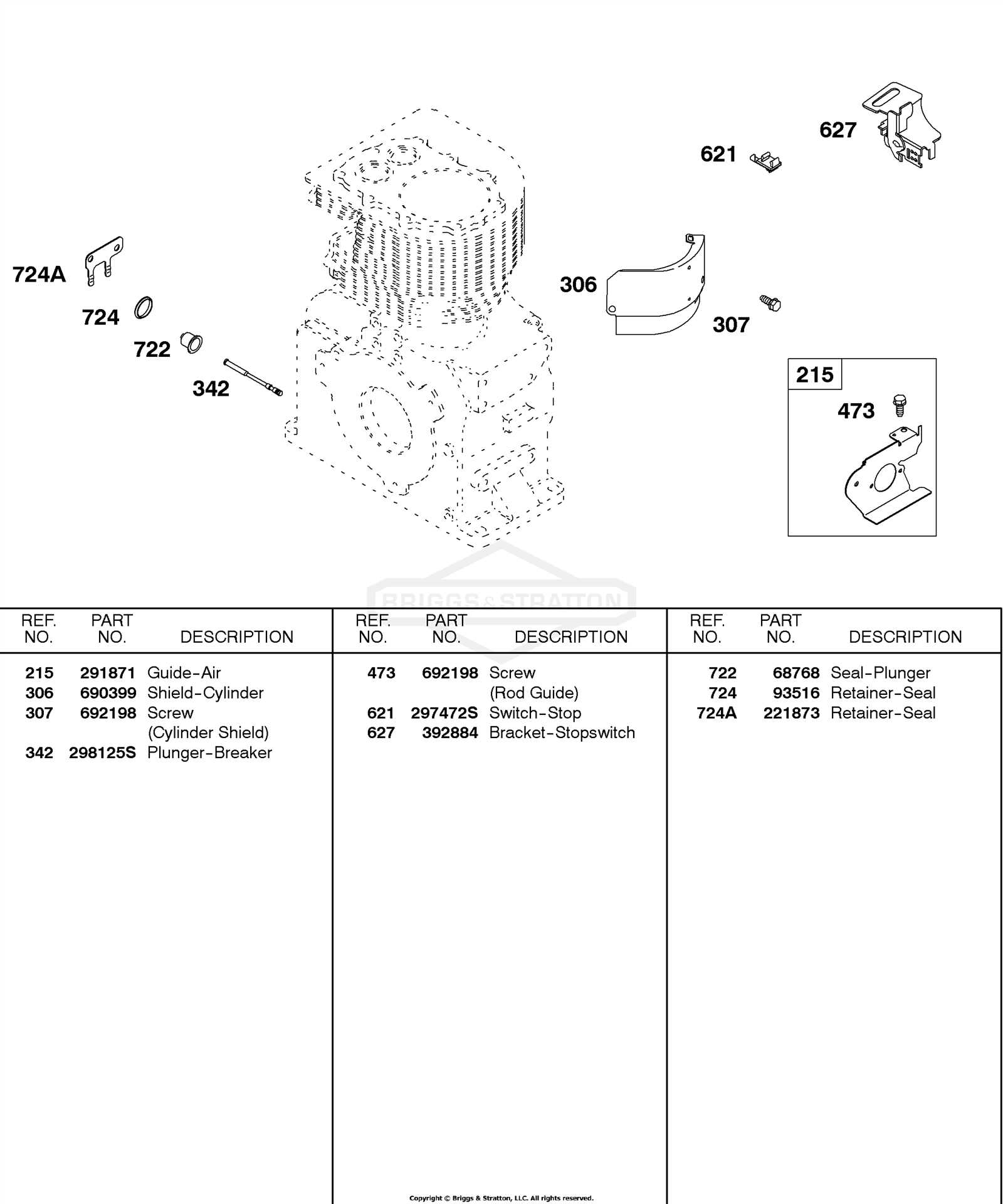

Key Components of the Engine

The engine operates efficiently due to the interaction of several critical elements. These components work in harmony, ensuring the smooth conversion of fuel into mechanical energy. Each element plays a significant role in maintaining the engine’s performance and reliability.

Cylinder and Piston

The cylinder is where the power generation occurs, with the piston moving up and down inside it. This movement creates the necessary force to drive the machinery, enabling the engine to perform its function. Both parts must work with precision to maximize output and efficiency.

Ignition System

The ignition system is responsible for initiating the combustion process. It sparks the fuel, creating an explosion that powers the movement of the piston. A well-functioning ignition system ensures that the engine starts reliably and operates at optimal levels.

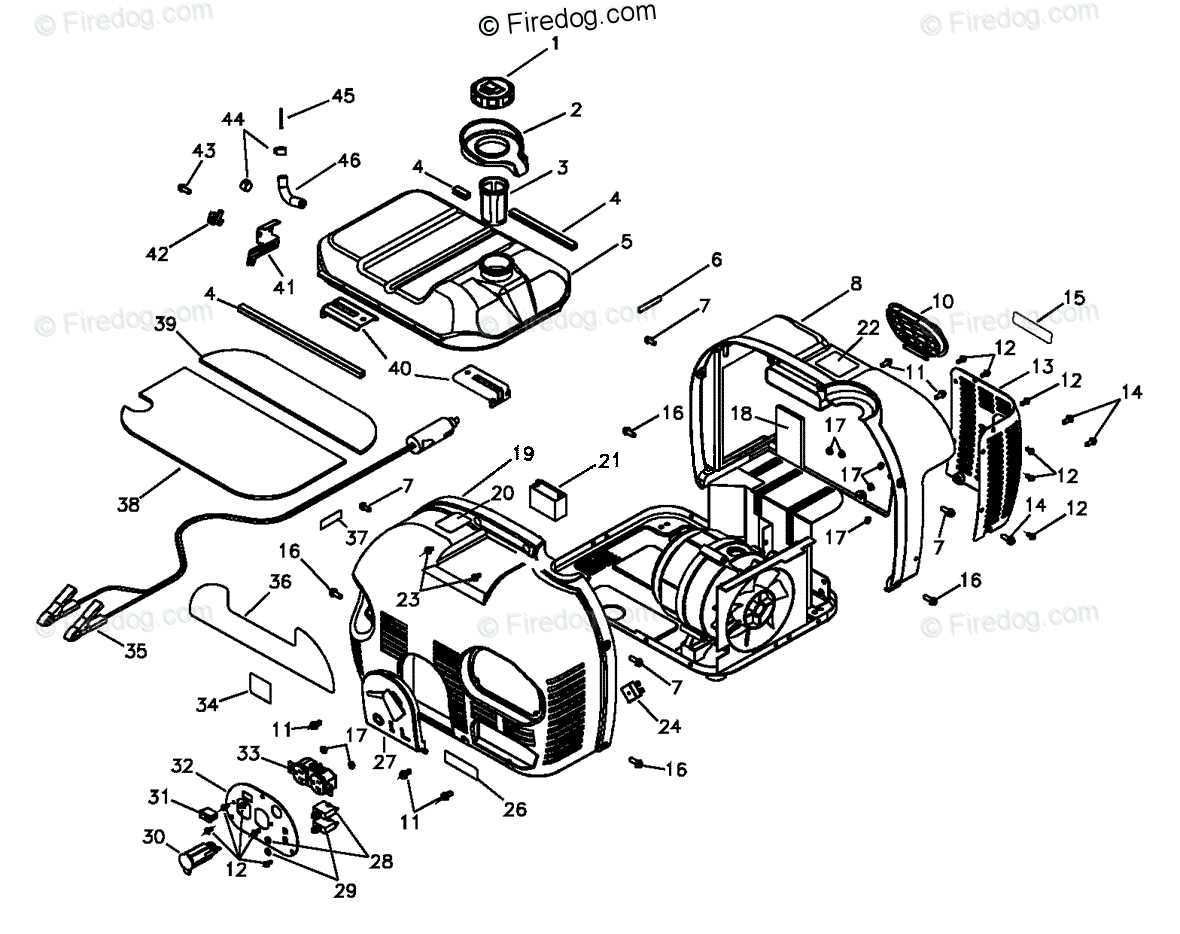

Exploring the Fuel System Assembly

The fuel system is a critical component of any engine, ensuring the proper flow and regulation of fuel to maintain efficient operation. This section delves into the overall structure and function of the assembly responsible for fuel delivery. Understanding how the different elements work together is essential for keeping the engine running smoothly.

The system is composed of various interconnected elements that manage fuel intake, mixing, and distribution. Each part plays a crucial role in controlling the flow and ensuring that the right mixture reaches the combustion area at the correct time. A clear understanding of these processes helps in diagnosing potential issues and maintaining optimal performance.

Maintaining the fuel system is key to avoiding common operational problems. Regular inspection of the assembly ensures that no blockages or malfunctions occur, which could otherwise disrupt the engine’s efficiency. By keeping these components clean and functioning properly, the overall reliability and lifespan of the engine are significantly improved.

Overview of the Ignition Parts

The ignition system is crucial for starting and maintaining the engine’s performance. Its components work together to ensure the proper timing and distribution of electrical power. Understanding these elements can help in maintaining smooth operation and troubleshooting issues.

Key Components of the Ignition System

Several elements contribute to the effective functioning of the system. Each component has a specific role, ensuring the engine receives the necessary spark at the correct moment for optimal efficiency.

| Component | Function |

|---|---|

| Flywheel | Generates the magnetic field necessary to create an electric current. |

| Ignition Coil | Transforms the magnetic energy into high voltage to produce the spark. |

| Spark Plug | Delivers the electric current to ignite the fuel-air mixture in the engine. |

| Kill Switch | Shuts off the engine by

Understanding the Air Filter MechanismThe air filter is a crucial component responsible for ensuring clean airflow into the engine. Its primary function is to trap unwanted particles, preventing them from entering the internal parts of the system, which could lead to performance issues or damage. Proper maintenance and understanding of how this mechanism works can significantly enhance the longevity and efficiency of the machinery. How the Filtration System Works

The filtration process starts when air passes through the filter material, which captures debris such as dust and dirt. This prevents contaminants from reaching sensitive areas within the engine, maintaining a cleaner combustion process. A well-maintained filter allows the engine to breathe easier, promoting better fuel efficiency and smoother operation.

Maintenance Tips for Optimal PerformanceRegular checks are essential to ensure that the filter remains functional. Over time, it can become clogged with particles, reducing the airflow and putting extra strain on the engine. A few simple steps can keep the system in good shape and prevent common issues.

|