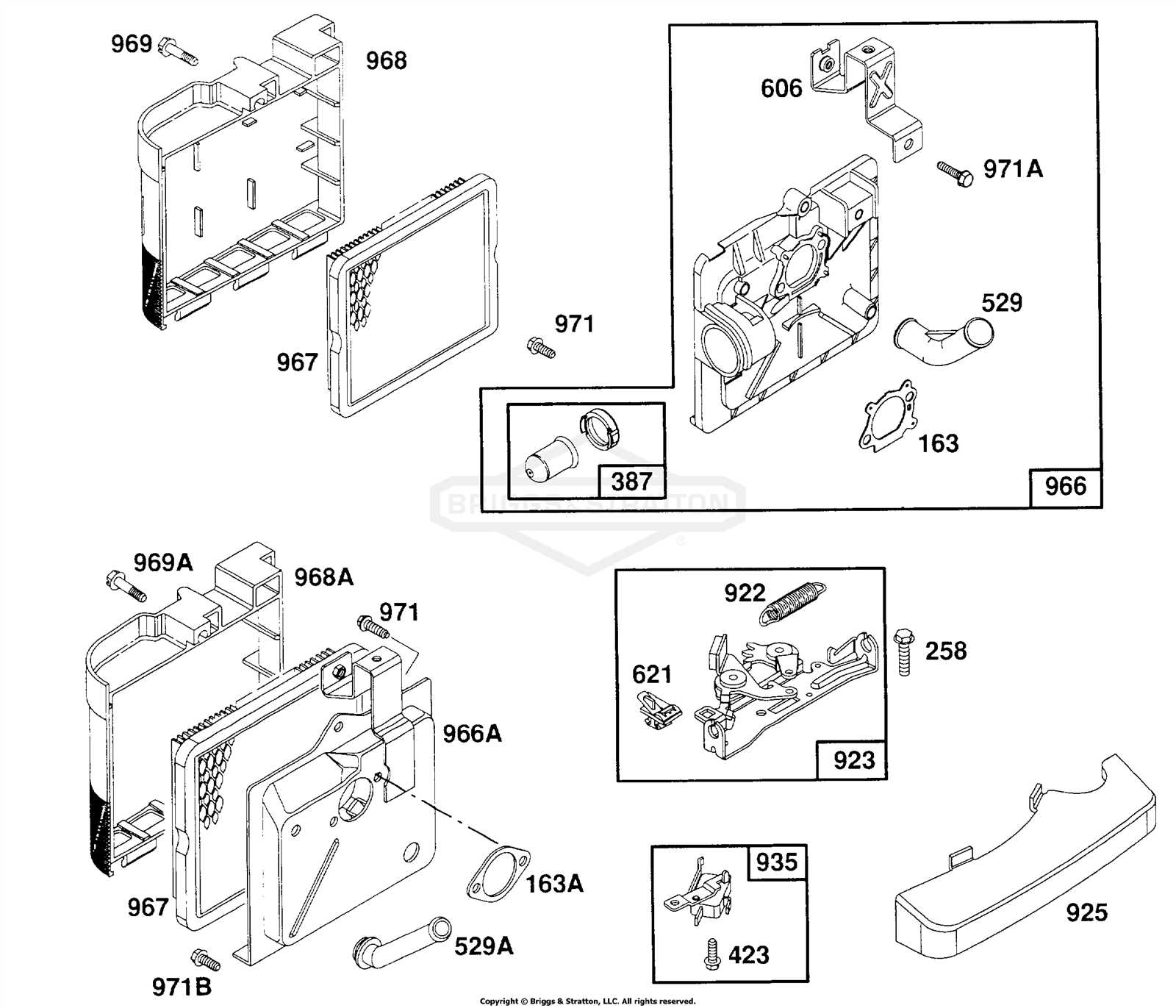

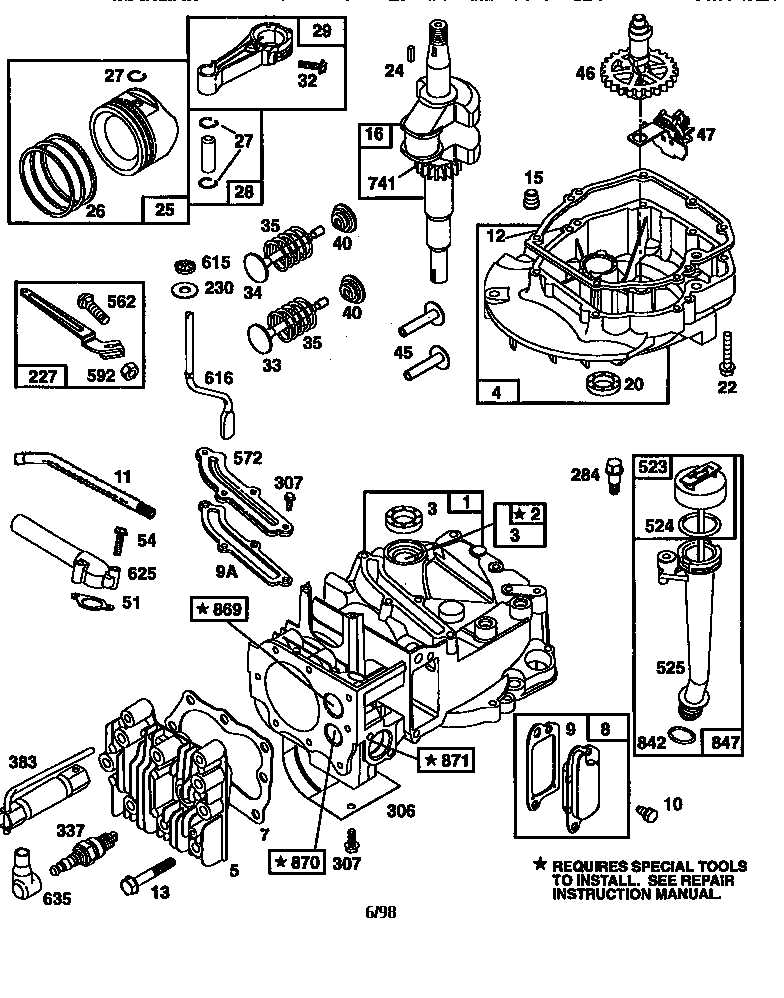

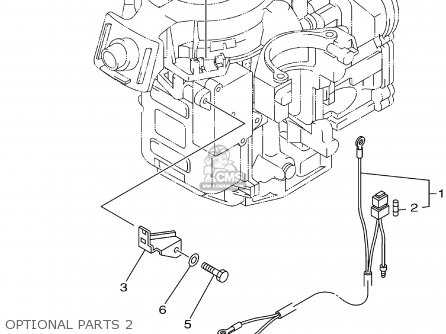

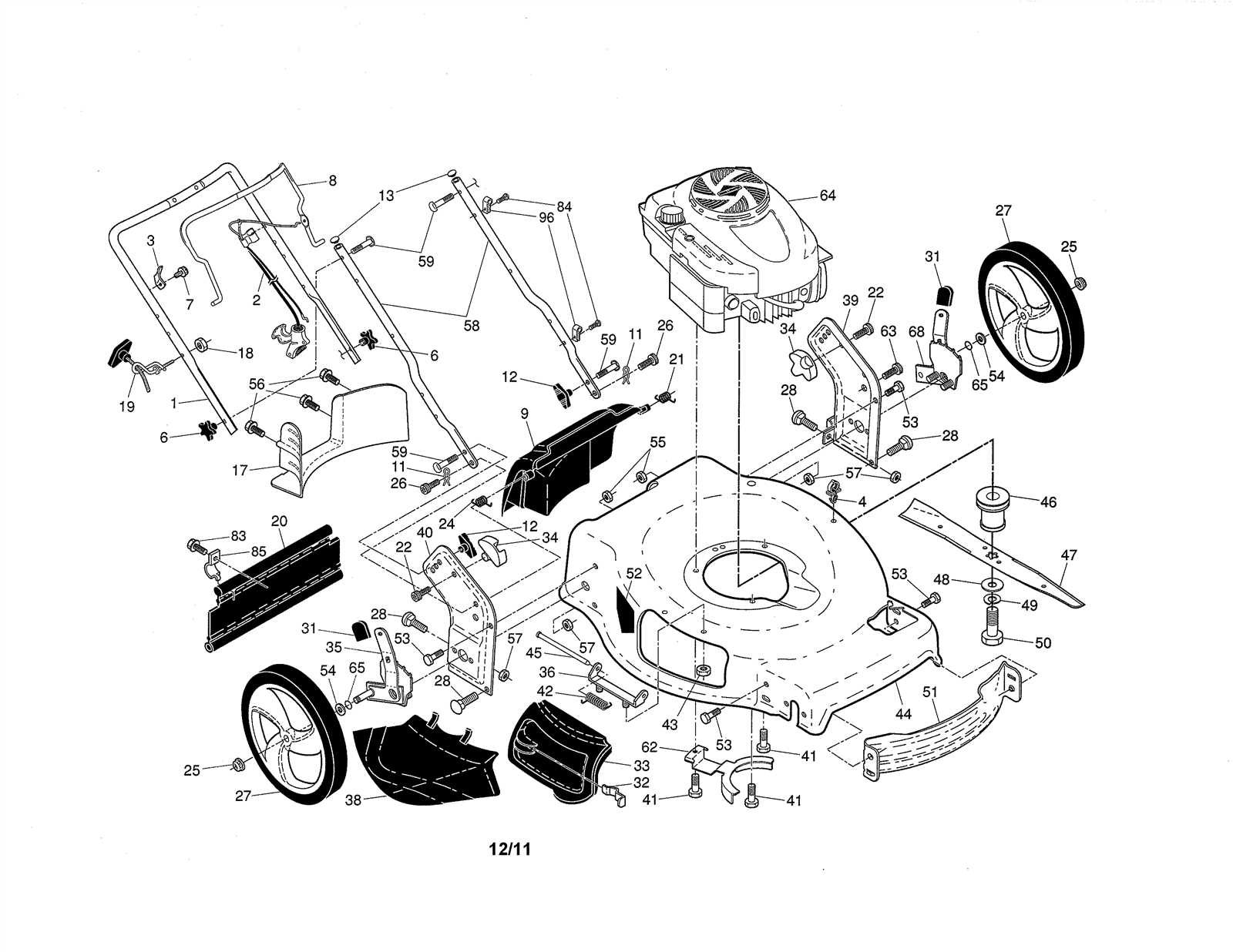

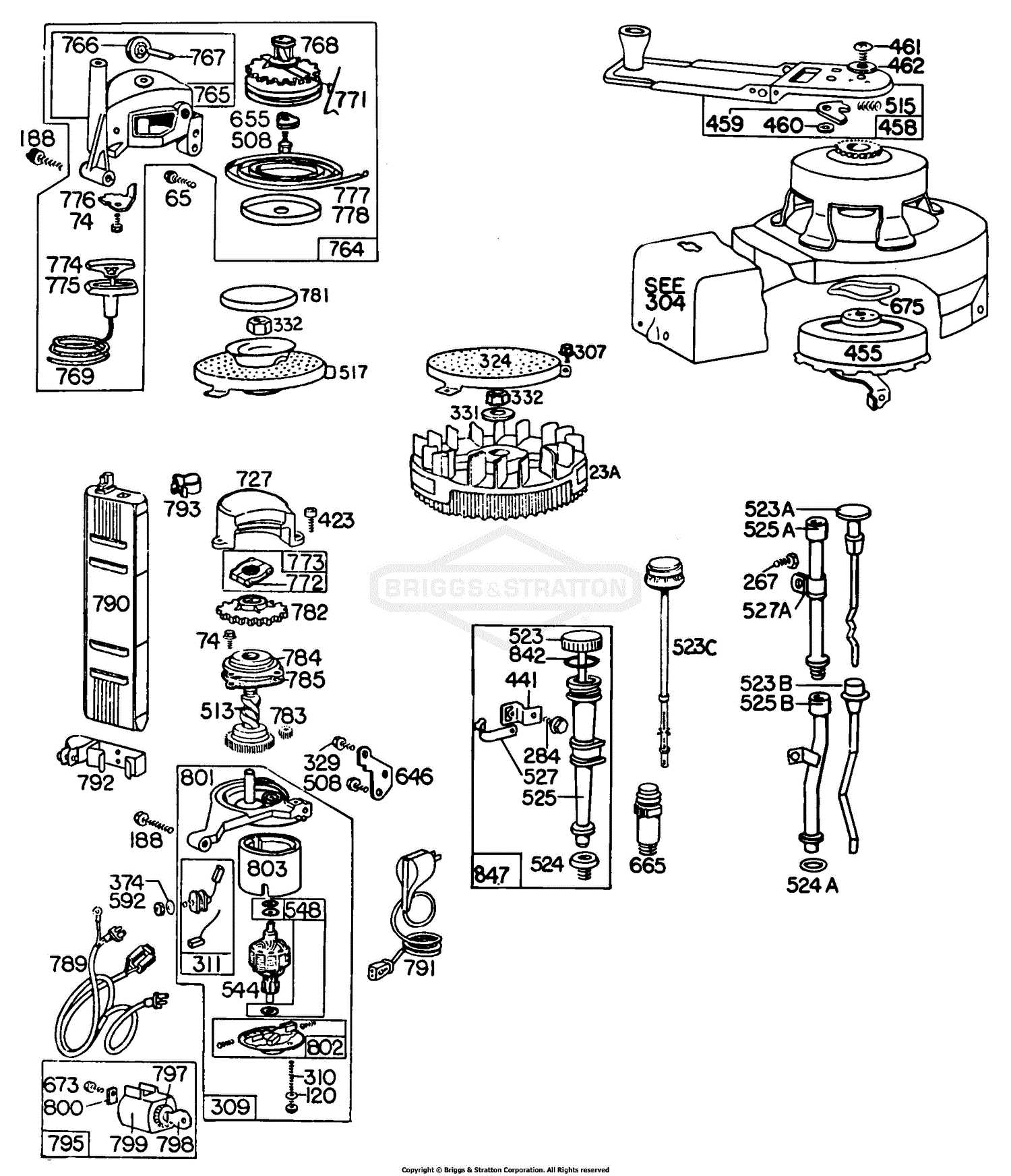

Understanding the layout of engine components is crucial for effective maintenance and repair. A well-structured visual representation allows enthusiasts and professionals alike to identify various elements easily, ensuring optimal performance and longevity. This section delves into the intricate details of an engine’s design, highlighting the relationships between different components and their functions.

When tackling repairs or upgrades, having a clear overview of each element’s placement can significantly streamline the process. From the ignition system to the fuel delivery mechanism, recognizing the intricacies of each section can help diagnose issues quickly. This knowledge is invaluable for anyone looking to enhance their expertise in engine mechanics.

Whether you are a hobbyist or a seasoned technician, mastering the layout of these components empowers you to take on various projects with confidence. The insights gained from this exploration will not only assist in troubleshooting but also deepen your appreciation for the engineering behind these powerful machines.

Understanding the essential elements of a small engine can significantly enhance maintenance and troubleshooting efforts. Recognizing these crucial parts enables users to effectively address issues and perform repairs. This section delves into the primary components that play vital roles in engine functionality.

Major Engine Parts

Each component has a specific function that contributes to the overall performance. Familiarizing oneself with these elements can lead to more informed decisions regarding repairs and replacements.

| Component | Description |

|---|---|

| Cylinder | The chamber where fuel and air mix and ignite to produce power. |

| Piston | A cylindrical piece that moves up and down within the cylinder, compressing the fuel-air mixture. |

| Crankshaft | Transforms the linear motion of the piston into rotational motion, powering the engine. |

| Camshaft | Controls the opening and closing of the engine’s valves, coordinating the intake and exhaust cycles. |

| Fuel Tank | Stores the fuel required for engine operation, supplying it to the carburetor. |

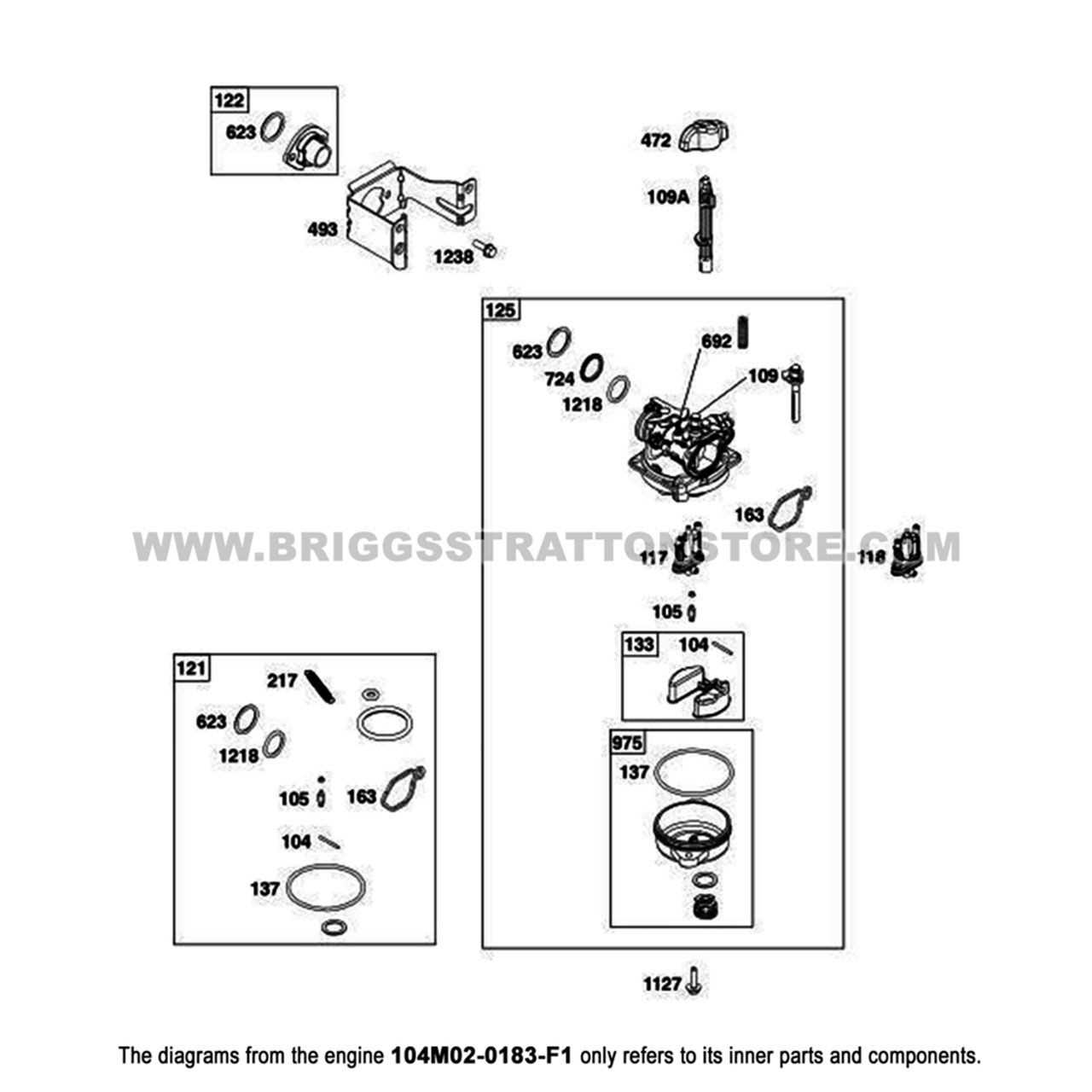

| Carburetor | Mixes the fuel with air before it enters the combustion chamber, ensuring optimal combustion. |

Additional Considerations

Proper identification and understanding of these components not only facilitate effective maintenance but also contribute to the longevity of the engine. Regular inspection of these key elements ensures optimal performance and helps prevent potential breakdowns.

Understanding Engine Specifications

Comprehending the technical details of a motor is essential for effective maintenance and performance optimization. Specifications provide insight into the capabilities and limitations of a machine, helping users to make informed decisions about repairs, upgrades, and operational efficiency. Familiarity with these characteristics enhances the overall user experience, ensuring the equipment runs smoothly and reliably.

Key Specifications to Consider

- Displacement: Refers to the total volume of the engine’s cylinders, influencing power output and efficiency.

- Compression Ratio: A critical factor that affects power generation and fuel efficiency, indicating how much the air-fuel mixture is compressed before ignition.

- Power Rating: Typically measured in horsepower, this indicates the engine’s maximum output and operational capacity.

- Torque: Represents the rotational force produced by the engine, essential for understanding its performance under load.

- Fuel Type: Different engines may require specific fuels, affecting compatibility and performance.

Importance of Regular Maintenance

Regular upkeep is crucial to preserve the operational integrity of a motor. Adhering to recommended service intervals for oil changes, air filter replacements, and other essential tasks ensures optimal performance and extends the lifespan of the equipment. Monitoring the specified components can help prevent costly repairs and maintain efficiency.

Maintenance and Care Tips

Proper upkeep is essential for ensuring the longevity and efficient performance of your engine. Regular attention to its condition can prevent costly repairs and enhance its reliability. By following a few straightforward practices, you can keep the machine running smoothly throughout its lifecycle.

Here are some vital recommendations to help you maintain your engine:

| Task | Frequency | Details |

|---|---|---|

| Check Oil Level | Before Each Use | Ensure the oil level is adequate and replace if it appears dirty or contaminated. |

| Clean Air Filter | Every 25 Hours | Inspect and clean the air filter to prevent debris from affecting performance. |

| Inspect Spark Plug | Every 50 Hours | Check for wear and replace if necessary to ensure proper ignition. |

| Sharpen Blades | Seasonally | Keep blades sharp for optimal cutting performance and efficiency. |

| Clean Fuel System | Annually | Flush and clean the fuel system to prevent buildup and ensure smooth operation. |

Adhering to these maintenance guidelines will not only enhance performance but also extend the operational life of your equipment. Regular check-ups are key to avoiding unnecessary issues.

Common Issues and Solutions

When operating small engines, users often encounter various challenges that can affect performance and efficiency. Identifying these common problems is essential for timely resolution and maintaining optimal functionality. Below are some frequently observed issues along with their corresponding solutions to enhance the reliability of your equipment.

Engine Won’t Start

A prevalent issue among small engines is the inability to start. This can be attributed to several factors, including fuel blockage, a malfunctioning spark plug, or insufficient oil levels. To address this, ensure the fuel is fresh and free from contaminants. Check the spark plug for wear or damage and replace it if necessary. Additionally, verify that the oil level is adequate and replace it if it’s low.

Unusual Noises

Unusual sounds during operation can indicate underlying problems such as loose components or internal wear. Regular maintenance checks should include inspecting bolts and screws for tightness. If rattling or grinding noises persist, it may be necessary to disassemble the unit for a more thorough examination or consult a professional for assistance.

Replacement Parts Availability

When maintaining outdoor power equipment, ensuring the accessibility of necessary components is crucial for optimal performance. Many users seek reliable sources to procure quality replacements that adhere to specifications and standards. This section outlines the options for acquiring essential elements for various engine models.

Local Retailers and Online Platforms

Local hardware stores and specialized machinery retailers often stock a range of compatible replacements. Additionally, numerous online platforms provide a broader selection, allowing customers to compare prices and availability. It is advisable to check both avenues to find the best options tailored to individual requirements.

OEM vs. Aftermarket Components

When selecting replacements, users typically face a choice between original equipment manufacturer (OEM) components and aftermarket alternatives. OEM parts are designed specifically for certain machines, ensuring a precise fit and performance. In contrast, aftermarket options may offer cost savings but can vary in quality and compatibility. Carefully assessing these choices will lead to informed decisions that align with performance expectations.

Tools Needed for Repairs

Undertaking maintenance tasks requires a specific set of instruments to ensure efficiency and effectiveness. Having the right tools at hand not only facilitates the repair process but also enhances safety and precision. Understanding the essential implements can greatly simplify the restoration and upkeep of your equipment.

Essential Hand Tools

Among the primary implements needed are hand tools, including wrenches, screwdrivers, and pliers. These items are crucial for loosening or tightening various components. A socket set is particularly useful for accessing hard-to-reach bolts, while a selection of screwdrivers will allow for tackling different types of fasteners.

Power Tools and Accessories

In addition to hand tools, incorporating power tools can expedite the repair process. A cordless drill is advantageous for quickly removing or installing screws, while a worklight ensures visibility in darker areas. Furthermore, having a reliable air compressor can assist with cleaning and blowing out debris from various components.

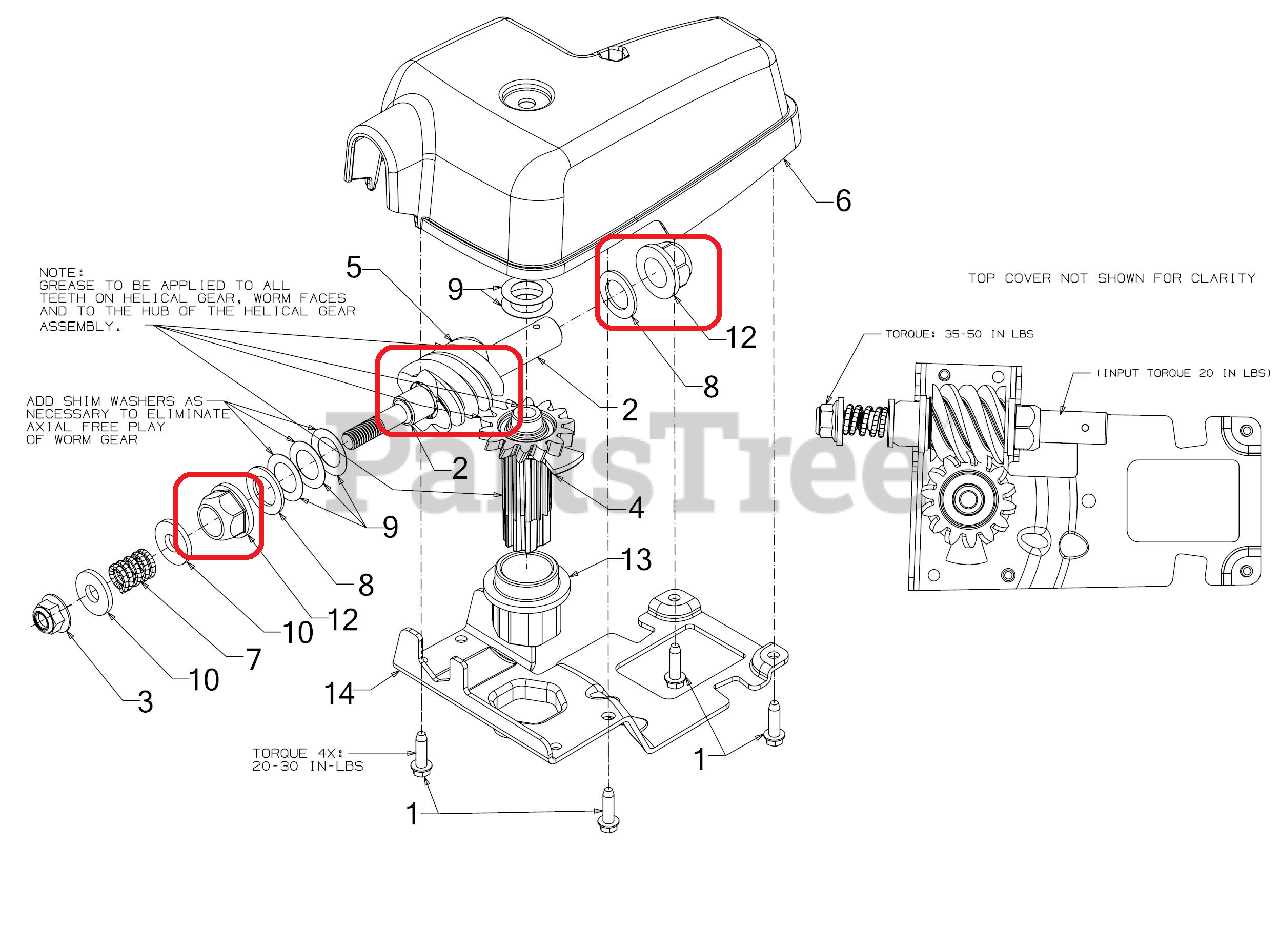

Step-by-Step Assembly Guide

This section provides a comprehensive approach to assembling your engine components effectively. Following a systematic process ensures that each element is correctly positioned and functions harmoniously within the overall mechanism. Adhering to these instructions will help you achieve a successful assembly, resulting in optimal performance.

Preparation and Tools

Before beginning the assembly, gather all necessary tools, including wrenches, screwdrivers, and pliers. Ensure that all components are clean and free from debris. Familiarize yourself with each part to understand its role in the assembly. Organizing the workspace will facilitate a smooth workflow and minimize the risk of losing small pieces.

Assembly Steps

Start by positioning the main housing securely. Attach the crankshaft and ensure it rotates freely. Next, install the piston and connecting rod, followed by the cylinder head. Make sure to tighten the bolts to the specified torque to prevent leaks. Finally, assemble the ignition system and air filter, ensuring all connections are secure. Review each step to confirm that everything is correctly aligned and fastened.

Safety Precautions for Handling

Ensuring safety while working with outdoor machinery is crucial to prevent injuries and accidents. Adhering to recommended guidelines helps maintain a secure environment during operation and maintenance. Understanding potential hazards and taking necessary precautions will significantly reduce risks associated with equipment handling.

General Safety Measures

Before engaging with any machinery, it is essential to wear appropriate personal protective equipment (PPE), such as gloves and safety goggles. Additionally, always work in a well-ventilated area to avoid inhaling harmful fumes. Be aware of your surroundings and keep children and pets at a safe distance while operating or servicing the equipment.

Operational Guidelines

Before starting any engine, ensure all components are correctly secured and that there are no leaks. Familiarize yourself with the user manual to understand specific operational instructions and safety features. Never bypass safety mechanisms, and regularly inspect the equipment for wear and tear to ensure optimal performance.

FAQs on Engine Parts

This section addresses common inquiries related to components of small engines, providing clarity and guidance for users seeking to understand their machinery better. Whether you are troubleshooting issues or looking to perform maintenance, these frequently asked questions aim to enhance your knowledge and confidence.

What are the signs that a component needs replacement?

Common indicators include unusual noises, poor performance, or visible wear and tear. If an element appears damaged or fails to function as expected, it may be time to consider a replacement.

How do I identify the right component for my engine?

Check the engine’s manual for specifications or model numbers. Many manufacturers provide detailed information about compatible elements to ensure proper fitting and function.

Can I use aftermarket components?

Aftermarket options are often available, but it’s crucial to ensure they meet quality standards and are compatible with your specific model. Using high-quality alternatives can often provide satisfactory performance.

How often should I perform maintenance on my engine?

Regular upkeep is essential for optimal performance. It’s generally recommended to follow the maintenance schedule outlined in the user manual, which may include routine checks and part replacements based on usage and operating conditions.

Where can I find replacement components?

Replacement elements can typically be sourced from authorized dealers, online retailers, or local hardware stores specializing in engine supplies. Always verify that the parts match the required specifications for your model.