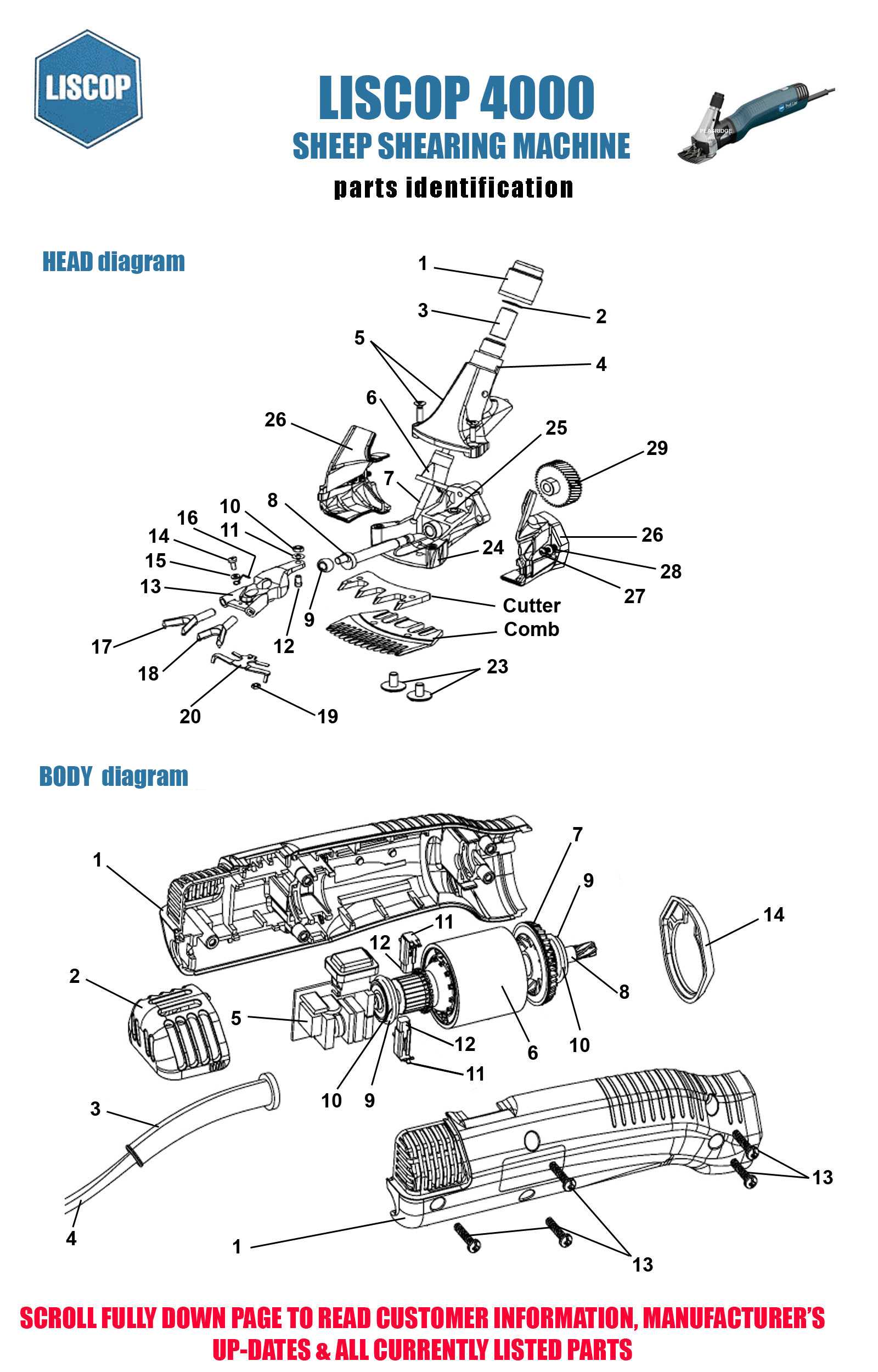

In the realm of mechanical systems, having a clear representation of individual elements is crucial for efficient maintenance and repair. An organized layout allows users to easily identify each part’s role and interconnection within the overall structure, enhancing both functionality and user experience.

When exploring intricate assemblies, a detailed illustration becomes the ultimate tool for technicians and hobbyists alike. It serves as a guide, enabling one to delve into the specifics of each component, ensuring that any adjustments or replacements can be made with confidence and precision.

Moreover, comprehending these visual aids can significantly improve troubleshooting processes. By recognizing how various elements interact, users can swiftly diagnose issues, leading to timely solutions and reduced downtime.

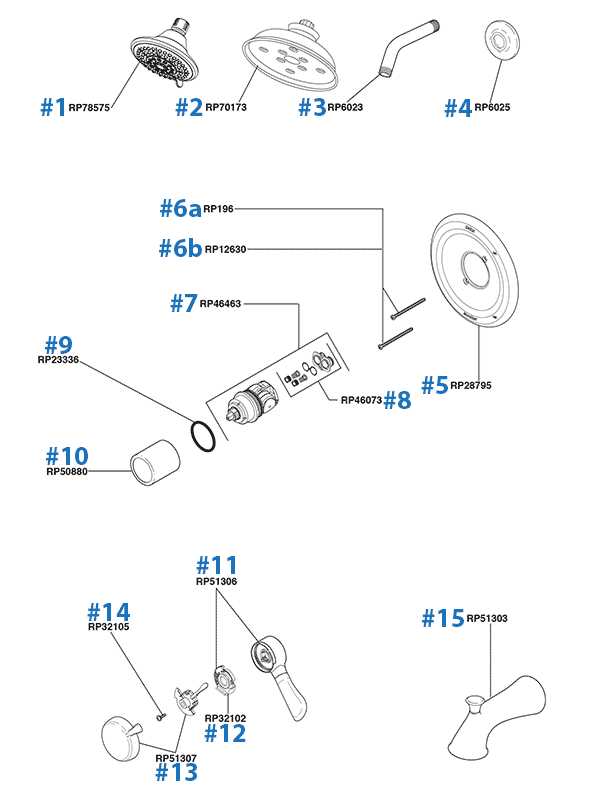

Overview of Delta 1300 Series Parts

This section provides a comprehensive look into the components associated with the specified model, highlighting their functions and importance. Understanding these elements is crucial for effective maintenance and repair.

- Essential Components: Key elements that ensure optimal performance.

- Functional Roles: Each item plays a specific role in the overall operation.

- Maintenance Tips: Guidelines for keeping everything in working order.

By delving into the various elements, users can gain insights that lead to better handling and longevity of their equipment.

Understanding the Parts Diagram

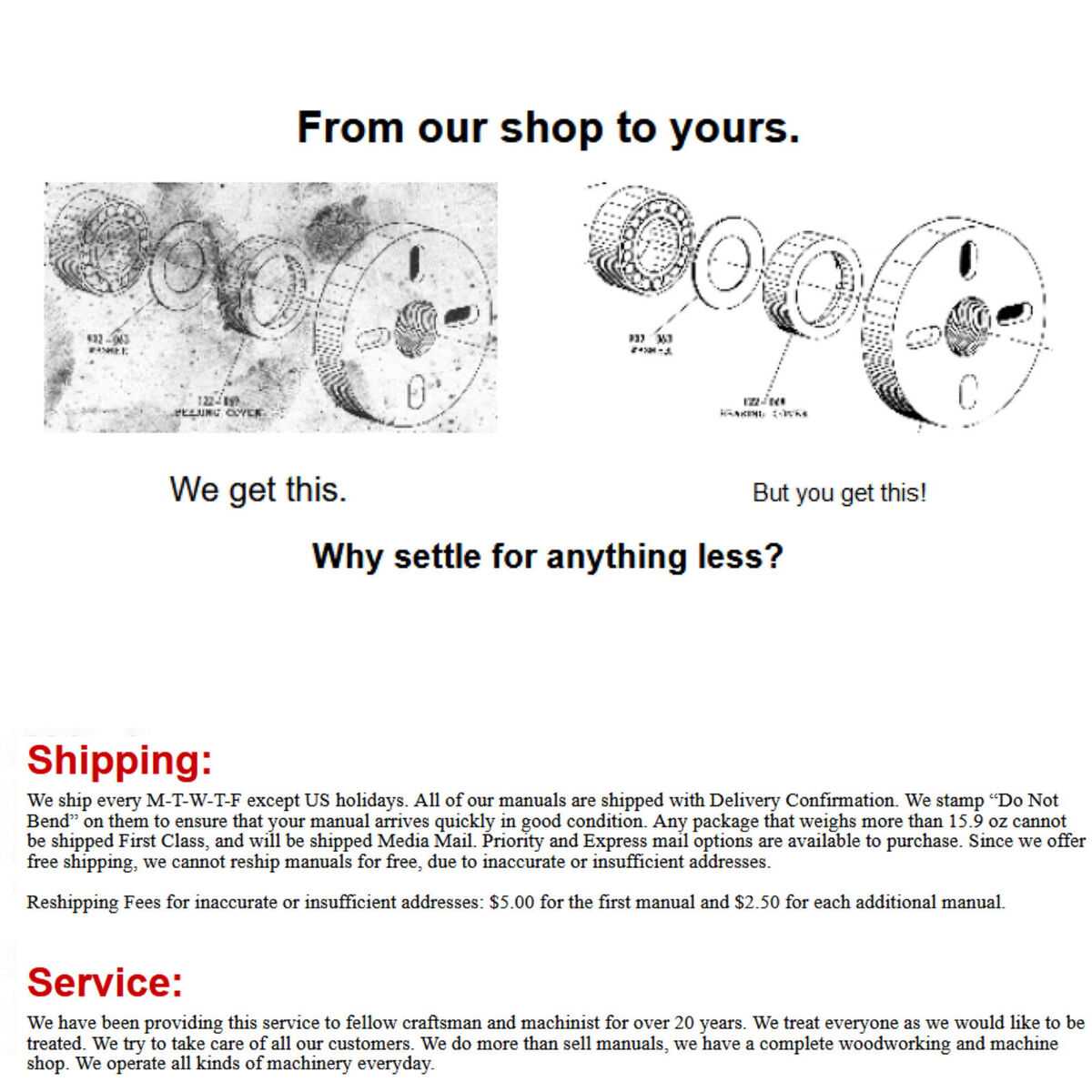

Comprehending the visual representation of components is essential for effective maintenance and repair. This illustration serves as a guide, offering insights into the various elements and their interconnections, allowing users to navigate through the intricacies of the machinery.

Importance of Clarity

A clear visual layout enhances understanding, ensuring that individuals can quickly identify each element. This clarity minimizes errors during assembly or disassembly, making the process smoother and more efficient.

Utilizing the Illustration Effectively

To make the most of the visual guide, one should familiarize themselves with the labels and symbols used. Each notation provides crucial information that aids in troubleshooting and identifying replacement needs, ultimately streamlining the maintenance workflow.

Key Components of Delta 1300 Series

Understanding the essential elements of this product line is crucial for optimal performance and maintenance. Each component plays a significant role in ensuring efficiency and longevity, making knowledge of their functions imperative for users.

1. Power Supply: The source of energy that drives the entire system, it must be reliable and efficient to support all operations.

2. Control Unit: This integral piece allows for the regulation and monitoring of the system, ensuring precision in operations.

3. Pump Assembly: Essential for fluid movement, this component must be durable and effective to maintain the desired flow rate.

4. Filter Mechanism: Vital for maintaining cleanliness, this part prevents contaminants from affecting overall functionality.

5. Structural Frame: The backbone of the setup, providing stability and support for all other components, ensuring they operate smoothly.

Familiarity with these key elements enhances the user experience and facilitates troubleshooting when necessary.

Benefits of Using Genuine Parts

Utilizing authentic components offers numerous advantages that contribute to the overall efficiency and longevity of your equipment. When you choose original items, you ensure compatibility and optimal performance, reducing the likelihood of issues arising from inferior alternatives.

Quality Assurance

Original components undergo rigorous testing to meet high standards, guaranteeing reliability and durability. This quality translates into less frequent replacements and lower maintenance costs over time.

Enhanced Performance

Using authentic components maximizes the functionality of your machinery, allowing it to operate at peak efficiency. This enhances productivity and minimizes downtime, ultimately leading to better results.

| Advantage | Description |

|---|---|

| Reliability | Ensures consistent performance without unexpected failures. |

| Compatibility | Designed to work seamlessly with existing systems. |

| Long-Term Savings | Reduces total ownership costs by minimizing repairs and replacements. |

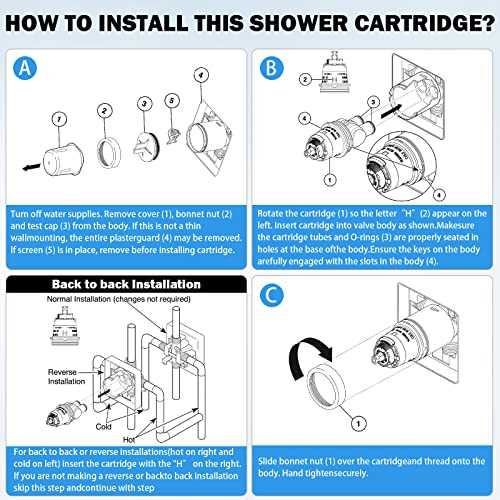

How to Read the Parts Diagram

Understanding an assembly blueprint is crucial for effective maintenance and repairs. This visual representation provides essential information about the components and their arrangement, allowing users to identify and source the necessary items efficiently.

Key Components of the Blueprint

- Labels: Each section is usually marked with specific identifiers for easy reference.

- Numbering: Items are often numbered, correlating with a list for clarity.

- Symbols: Common symbols may denote particular functionalities or types of components.

Steps to Analyze the Blueprint

- Begin by familiarizing yourself with the overall layout.

- Identify key components using the labels and symbols.

- Cross-reference numbers with the accompanying list for detailed descriptions.

- Note any additional notes or tips provided in the document.

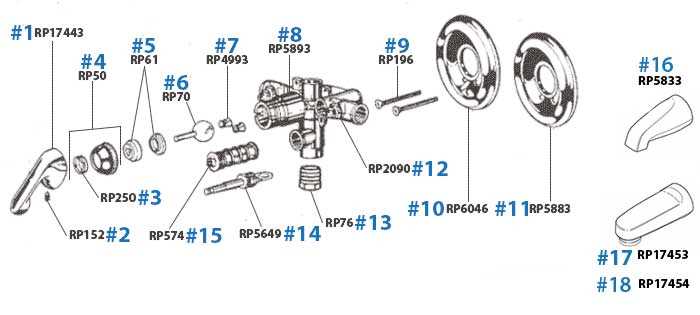

Common Issues and Replacement Parts

In any mechanical system, certain problems frequently arise that necessitate the replacement of specific components. Understanding these common challenges can streamline maintenance and enhance the longevity of the equipment.

Frequent Problems Encountered

Wear and tear can lead to leaks, decreased performance, or complete failures. Common issues include seals deteriorating over time, causing leaks, and valves becoming stuck or malfunctioning. Regular inspections can help identify these concerns before they escalate.

Essential Components for Replacement

When addressing issues, having the right components on hand is crucial. Key replacements include gaskets for sealing, springs for tension, and cartridges for smooth operation. Keeping a supply of these essentials ensures quick repairs and minimal downtime.

Step-by-Step Assembly Guide

This guide provides a detailed walkthrough for assembling your equipment efficiently and accurately. By following the outlined steps, you’ll ensure a smooth construction process and achieve optimal performance from your unit.

Preparation

Before you begin, gather all necessary components and tools. Familiarize yourself with the included elements and check for any missing items. Organizing your workspace will enhance your efficiency and prevent confusion during assembly.

Assembly Steps

1. Base Assembly: Start by securing the foundational parts together, ensuring stability. Refer to the included reference for alignment. 2. Component Installation: Next, attach each segment sequentially, verifying tight connections for safety. Follow the sequence carefully to avoid misalignment.

Maintenance Tips for Delta 1300

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. Implementing a few simple practices can help maintain efficiency and prevent costly repairs.

1. Routine Cleaning: Keep surfaces free from dust and debris. Use a soft cloth and mild cleaner to wipe down components regularly.

2. Lubrication: Apply appropriate lubricants to moving parts as specified in the manual. This reduces friction and enhances operational smoothness.

3. Inspection: Periodically check for wear and tear. Look for cracks or loose fittings that may require immediate attention.

4. Proper Storage: Store in a dry, climate-controlled environment to prevent corrosion and damage from moisture.

5. Follow Manufacturer Guidelines: Adhere to the recommended maintenance schedule and procedures outlined in the user manual for best results.

Where to Purchase Parts Online

Finding components for your equipment has never been easier, thanks to the abundance of online resources available today. Various platforms offer an extensive selection, allowing enthusiasts and professionals alike to source what they need quickly and efficiently.

Recommended Websites

Many trusted e-commerce sites specialize in supplying replacement components. Websites like Amazon and eBay feature user reviews, ensuring a reliable shopping experience. Additionally, specialized retailers often provide in-depth catalogs, making it simpler to identify compatible items.

Considerations for Online Shopping

When purchasing, always check for warranties and return policies to safeguard your investment. Reading customer feedback can also guide you in making informed choices, ensuring you receive the highest quality and ultimate satisfaction.

Customer Support for Delta 1300 Series

Effective assistance is essential for ensuring optimal performance and user satisfaction. Support services aim to provide users with the necessary resources to troubleshoot and resolve issues swiftly.

- Comprehensive FAQs

- Online chat for immediate assistance

- Technical guides and manuals available for download

- Contact options for personalized support

In addition to standard inquiries, users can access specialized resources tailored to common challenges. This proactive approach helps to minimize downtime and enhance user experience.

- Identify the issue clearly.

- Consult available documentation.

- Reach out for further assistance if needed.

Ultimately, a robust support system fosters confidence and loyalty among users, ensuring they can make the most of their equipment.

Comparing Delta 1300 with Other Models

This section explores the distinctions and similarities between a specific model and its contemporaries in the market. By analyzing various attributes, users can make informed choices based on functionality, design, and performance.

Key Features Comparison

- Performance: Evaluate the efficiency of each model under similar conditions.

- Design: Examine aesthetic and ergonomic differences.

- Durability: Assess material quality and longevity.

- Maintenance: Consider ease of upkeep across different units.

User Feedback and Reviews

- Gather insights from user experiences across various platforms.

- Identify common praises and complaints regarding each model.

- Look for trends in satisfaction that can guide future purchases.

Frequently Asked Questions about Parts

This section aims to address common inquiries regarding components used in various equipment. Understanding the specifics can help users make informed decisions when seeking replacements or enhancements.

General Inquiries

Many users often wonder about compatibility and availability. Knowing how to identify the right components can save time and ensure proper functioning.

Maintenance and Care

Proper maintenance is crucial for longevity. Users frequently seek advice on how to care for their equipment to prevent wear and tear.

| Question | Answer |

|---|---|

| How do I find compatible components? | Check the model number and specifications in the user manual or online resources. |

| What maintenance practices should I follow? | Regularly clean, lubricate, and inspect for wear to ensure optimal performance. |

| Where can I purchase replacements? | Authorized retailers and online marketplaces offer a wide selection of components. |

| How often should I replace my equipment? | This depends on usage; however, regular inspections can help determine the need for replacements. |