In today’s world, home appliances have become essential to our daily routines. One such indispensable tool is the machine used for handling laundry. To ensure its longevity and efficiency, it’s important to familiarize oneself with its internal structure and how various elements work together. Whether you’re performing routine maintenance or troubleshooting, having a clear picture of how these components are organized is invaluable.

Every such appliance is designed with precision, incorporating multiple interlocking elements that each play a critical role in its overall function. From the control mechanisms to the various connections, understanding the purpose of each component can help users maintain optimal performance and avoid potential issues. This knowledge also proves helpful when it’s time for any necessary repairs.

By examining the internal structure, you can better understand how to maintain and repair your equipment, ensuring it continues to perform as expected. Being familiar with its key elements can also help in identifying issues before they escalate, providing peace of mind for long-term use.

Overview of Key Laundry Appliance Components

Understanding the various elements that make up a modern laundry appliance is essential for ensuring its optimal performance. The primary system is composed of several interconnected parts, each contributing to different functions such as cleaning, rinsing, and spinning. These elements work in unison to provide efficiency and reliability during the washing process. Familiarity with these components allows for easier troubleshooting and maintenance, ensuring the longevity and smooth operation of the unit.

Each section of the appliance, from the drum mechanism to the control system, plays a critical role in delivering an effective laundry cycle. The structural components support the movement of the drum, while internal systems handle water management, energy efficiency, and precise timing. Together, these parts form a seamless unit, providing effective solutions for daily laundry needs.

Main Control System and Functions

The central control mechanism plays a pivotal role in ensuring efficient operation, overseeing all essential functions. It is responsible for coordinating various processes, ensuring smooth transitions between different operational stages, and maintaining consistent performance. This system is designed to provide users with an intuitive interface for selecting and adjusting settings, enhancing overall ease of use.

Key components of the control system include the central processor, input devices, and sensors, which work in tandem to monitor and manage tasks. Through advanced technology, the system can automatically adapt to different conditions, ensuring optimal results for a variety of operational needs.

The control system is also designed with safety in mind, incorporating safeguards to prevent malfunctions and ensure long-lasting reliability. Users can easily configure settings, monitor progress, and make adjustments, giving them greater control over the entire process.

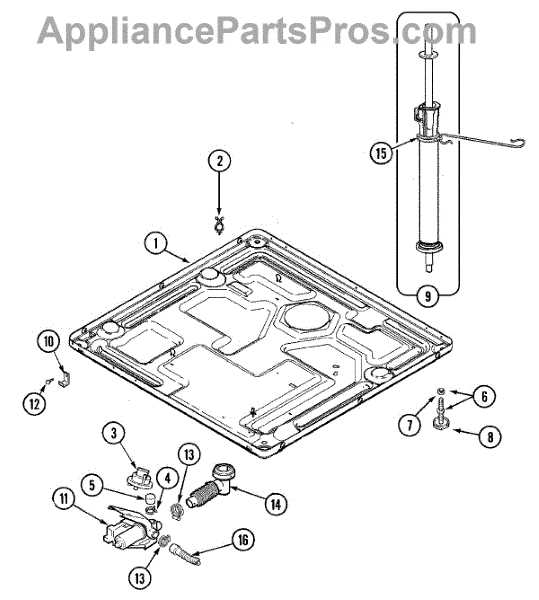

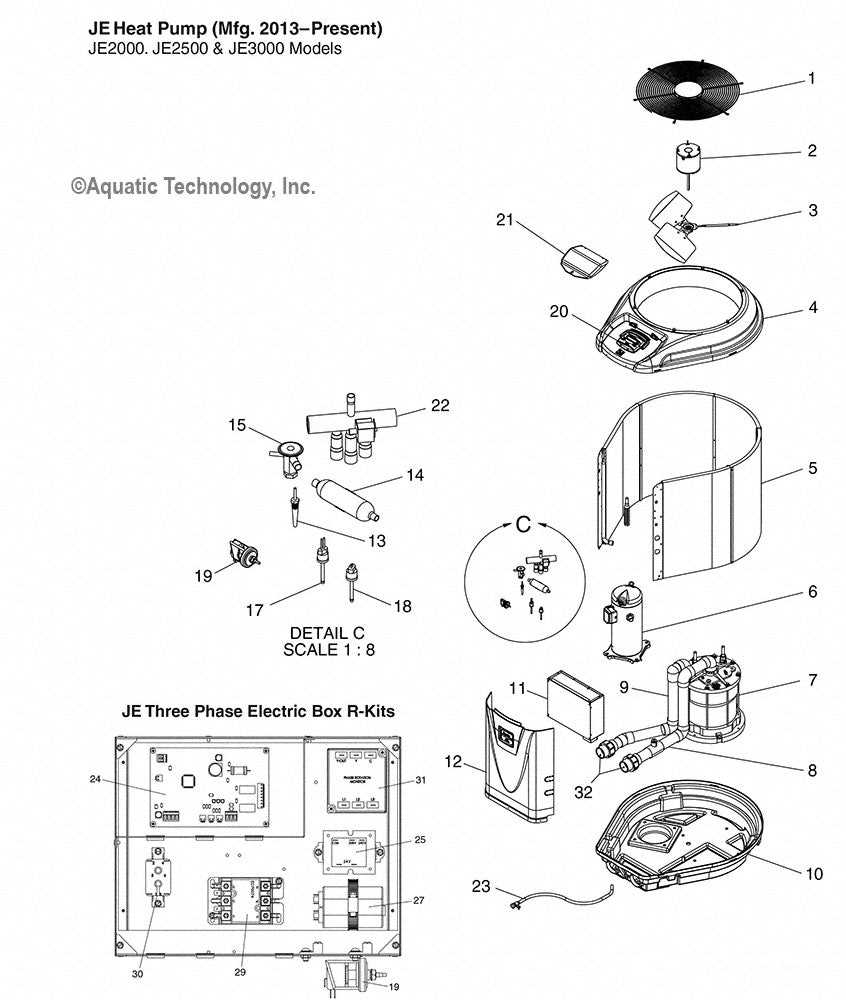

Water Inlet and Drain Assembly

The water inlet and drain system is a crucial component responsible for the controlled flow of water into and out of the machine. This system ensures that water is supplied at the right pressure and temperature, while efficiently removing it once the process is completed. A well-functioning inlet and drainage setup is vital for maintaining optimal performance and preventing issues such as leaks or improper water levels.

Water Inlet Valve Functionality

The water inlet valve manages the supply of water. It opens to allow water to flow into the unit and closes to stop it when the required level is reached. This valve is often equipped with filters to prevent debris from entering the system, protecting the internal mechanisms from damage. Regular inspection of the valve is important to ensure smooth water flow.

Drainage Mechanism and Maintenance

The drainage system efficiently expels water from the machine. The drain pump forces the water out through a drain hose, which directs it to the household plumbing. Ensuring the drain hose is properly positioned and free from blockages is essential for preventing flooding or backflow. Routine maintenance helps avoid potential issues like slow draining or standing water.

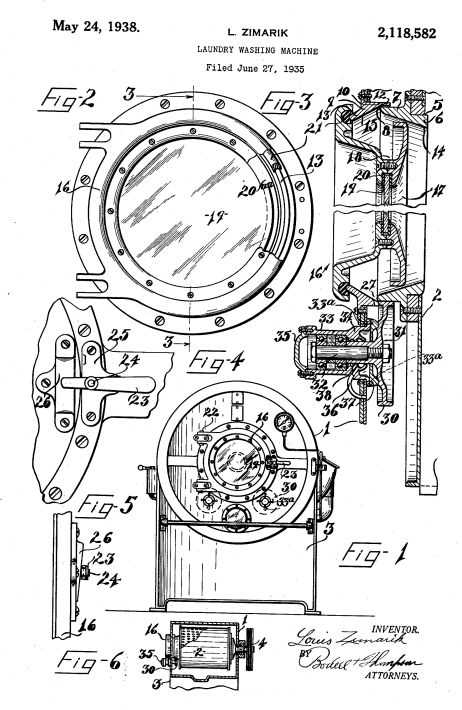

Drum and Agitator Mechanism

The drum and agitator work together to ensure effective cleaning by moving clothes and water in a coordinated manner. This part of the system is essential for achieving optimal washing performance, as it facilitates the movement of the laundry through the water and detergent, ensuring even distribution and thorough cleaning.

- The drum holds the laundry and rotates during different cycles to tumble the clothes.

- The agitator, positioned centrally, moves back and forth to create water currents, enhancing the washing process.

- The interaction between the drum’s rotation and the agitator’s movement helps in removing dirt and stains efficiently.

- Various speeds and motions are involved depending on the cycle selected, optimizing for different types of fabric and soil levels.

Both components are designed to withstand the forces applied during the washing cycles while minimizing wear and tear on fabrics. Understanding their function is crucial for troubleshooting or maintenance.

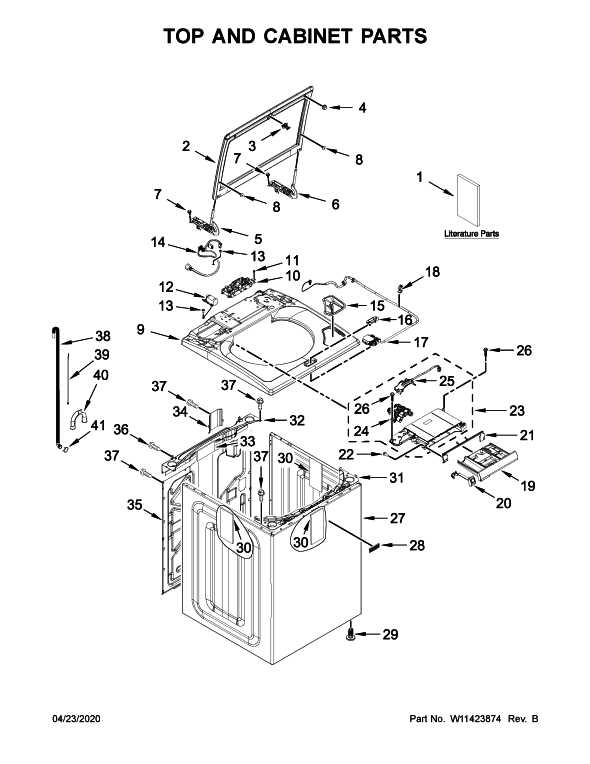

Understanding the Door and Seal Structure

The door and seal assembly plays a crucial role in maintaining the overall efficiency of the appliance. It ensures that the unit remains properly closed during cycles, preventing any leaks or malfunctions. A well-maintained seal is essential for preserving the internal components, as it helps to keep water contained and protects against wear over time.

| Component | Function |

|---|---|

| Door Hinge | Secures the door to the frame, allowing smooth opening and closing. |

| Seal Gasket | Provides a tight seal around the door, preventing water from escaping during operation. |

| Door Latch | Locks the door in place during cycles to ensure safety and prevent interruptions. |

| Inner Frame | Supports the structure of the door and holds the seal in position. |

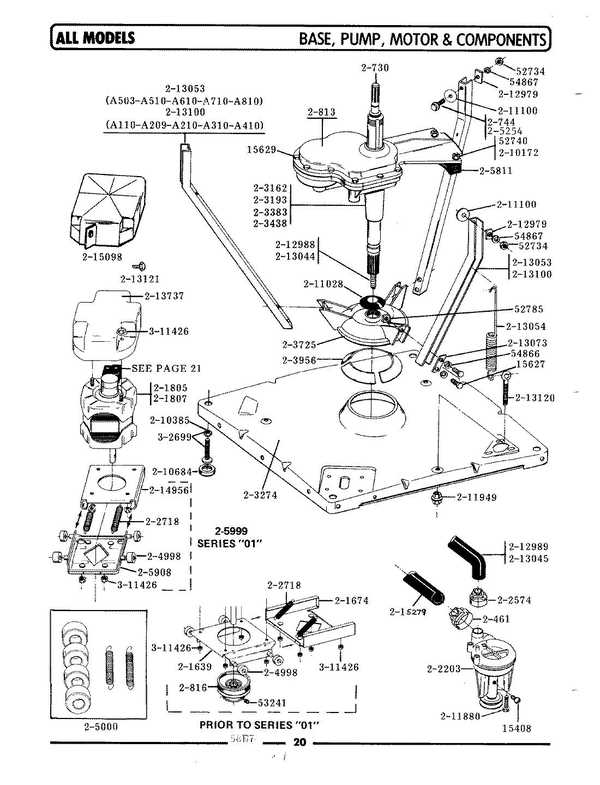

Pump System and Filtration Unit

The efficient operation of any cleaning appliance relies heavily on its pumping mechanism and filtration system. These components work in unison to ensure that water circulates effectively, while simultaneously trapping debris and contaminants to maintain optimal performance.

Functionality of the Pump

The pump serves a critical role in the movement of liquids within the appliance. It is responsible for:

- Removing used water from the drum after each cycle.

- Facilitating the intake of clean water for rinsing processes.

- Maintaining appropriate water levels for various washing programs.

Importance of the Filtration Unit

The filtration unit plays an essential part in enhancing the longevity and efficiency of the entire system. Its primary functions include:

- Capturing lint, hair, and other particles that may hinder performance.

- Preventing blockages in the drainage system.

- Ensuring clean water re-enters the drum for subsequent cycles.

Electrical Wiring and Connectivity

Understanding the intricacies of electrical connections is vital for the efficient operation of appliances. This section outlines essential elements related to the wiring systems and how they facilitate seamless functionality.

Key components involved in electrical connectivity include:

- Wiring harnesses that organize and protect electrical lines.

- Connectors ensuring reliable and secure linkages between different electrical parts.

- Power supply units that deliver the necessary voltage and current.

To maintain optimal performance, consider the following:

- Regularly inspect connections for signs of wear or corrosion.

- Ensure all wiring is properly insulated to prevent short circuits.

- Follow manufacturer guidelines for any modifications or repairs to electrical systems.

By adhering to these practices, you can enhance the longevity and safety of your appliance.

Dispenser Tray and Soap System

The dispenser tray plays a crucial role in the overall cleaning process of laundry appliances. This component is designed to efficiently distribute cleaning agents, ensuring they mix properly with water before reaching the fabrics. An effective soap system contributes to achieving optimal washing results while minimizing residue on garments.

Understanding the functionality of the dispenser tray is essential for maintaining the appliance. The tray typically features separate compartments for different types of detergents and fabric softeners, allowing for precise application during various wash cycles. This organization helps in achieving the desired results based on the specific needs of each load.

Regular maintenance of the dispenser tray is vital to prevent clogs and ensure that cleaning solutions flow smoothly. Users should periodically remove and clean the tray to avoid buildup, which can affect the performance of the appliance. Additionally, ensuring that the soap system is functioning correctly is important for effective cleaning and fabric care.

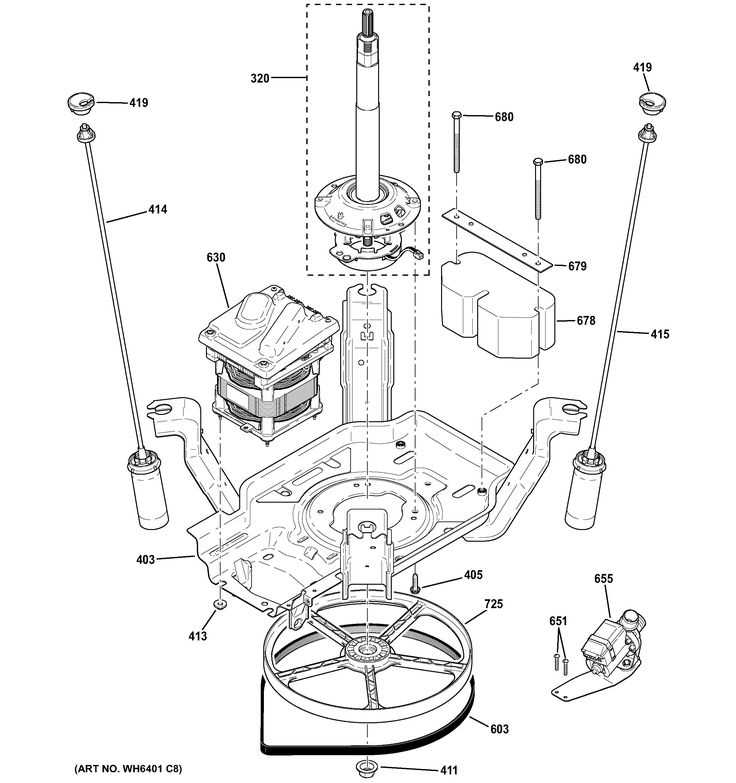

Drive Motor and Belt Configuration

The drive mechanism is a crucial component in the operation of laundry appliances, enabling effective agitation and spinning of garments. Understanding the layout and interplay of the motor and belt is essential for maintaining optimal functionality and ensuring smooth performance.

Motor Specifications

The drive motor is responsible for converting electrical energy into mechanical motion. It operates at various speeds, allowing for different cycles tailored to specific fabric types. The motor’s efficiency directly impacts the overall energy consumption of the machine.

Belt Functionality

The belt serves as a vital link between the motor and the drum, transferring power and enabling rotation. Proper alignment and tension of the belt are critical for preventing slippage and ensuring consistent performance. Regular inspection can help identify wear or damage, facilitating timely replacements.

| Component | Description |

|---|---|

| Drive Motor | Converts electrical energy to mechanical motion, varying speeds for different cycles. |

| Belt | Transfers power from the motor to the drum, requiring proper tension and alignment. |

| Motor Mount | Secures the motor in place, maintaining alignment with the belt and drum. |

| Belt Pulley | Guides the belt, ensuring proper engagement with the motor and drum for efficient operation. |

Heating Element and Temperature Control

The heating element plays a crucial role in ensuring optimal performance by regulating the temperature of the water during the washing process. A properly functioning heating mechanism is essential for effective cleaning, as it influences the detergent’s ability to dissolve and the overall efficiency of the wash cycle.

Functionality of the Heating Element

This component generates the necessary heat to warm the water, allowing for the activation of cleaning agents. It is typically made of durable materials that can withstand high temperatures. If the heating element malfunctions, it can lead to inadequate water temperatures, resulting in subpar cleaning results.

Temperature Regulation Mechanisms

Temperature control systems monitor and adjust the heat levels according to the selected wash cycle. These systems are designed to ensure that the water reaches and maintains the desired temperature throughout the washing process. Any issues with temperature regulation can significantly impact the effectiveness of the cleaning process, making it vital for users to ensure that these components are functioning correctly.

Diagnosing Common Part Failures

Identifying issues with household appliances can be a daunting task. Understanding the common signs of component malfunctions is essential for effective troubleshooting and maintenance. This section focuses on how to recognize typical failures and provides guidance on how to address them.

Identifying Symptoms of Malfunction

Recognizing symptoms is the first step in diagnosing component failures. Various indicators can suggest that something is amiss within the appliance. Common signs include unusual noises, leaks, or failure to operate as expected. Paying attention to these symptoms can help pinpoint the source of the problem.

Common Components and Their Issues

Different components may exhibit specific problems. The following table outlines several common parts and their potential failures:

| Component | Common Issues |

|---|---|

| Motor | Unusual noises, overheating, failure to start |

| Pump | Leakage, clogs, failure to drain |

| Control Board | Inconsistent operation, error codes, failure to respond |

| Belts | Fraying, slipping, breakage |

Maintenance Tips for Key Washer Parts

Regular upkeep of essential components in laundry appliances ensures optimal performance and longevity. Implementing straightforward maintenance practices can help prevent malfunctions and enhance efficiency. Here are some effective strategies to consider.

Routine Cleaning

- Wipe down the exterior with a mild detergent to keep surfaces free from grime.

- Inspect and clean the door seals to prevent mold and mildew buildup.

- Periodically check the detergent drawer for residue and clean it thoroughly.

Regular Inspections

- Examine hoses for signs of wear or leaks; replace if necessary.

- Check the filter for blockages to maintain proper water flow.

- Listen for unusual noises during operation, as they may indicate underlying issues.