When engaging with the intricate world of fabric manipulation, it’s essential to familiarize oneself with the various elements that contribute to its functionality. Each component plays a crucial role in ensuring seamless operation, allowing for creativity and precision in crafting garments and other textile products.

In this exploration, we will delve into the individual segments that comprise this essential tool. By gaining insights into these features, users can optimize their techniques and troubleshoot any issues that may arise during the creative process.

Ultimately, understanding the layout and purpose of these elements enhances one’s ability to harness the full potential of this remarkable technology, paving the way for innovative designs and improved craftsmanship.

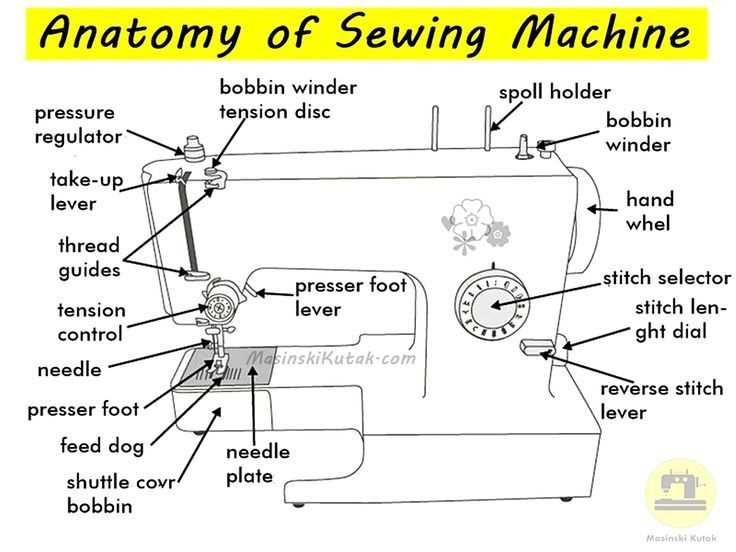

Understanding Sewing Machine Components

Exploring the essential elements of textile crafting tools reveals a fascinating interplay of mechanics and functionality. Each component plays a vital role in achieving precision and efficiency, contributing to the overall performance of the device.

Key elements include:

- Needle: The sharp implement responsible for piercing fabric and facilitating thread passage.

- Feed Dogs: The mechanism that moves the fabric forward during the stitching process.

- Bobbins: Small, cylindrical holders that store the lower thread, working in tandem with the needle.

- Presser Foot: A crucial attachment that holds the fabric in place while it is being sewn.

- Tension Control: A system that regulates the tightness of the threads, ensuring even stitches.

Understanding these elements can enhance one’s ability to troubleshoot issues and optimize the crafting experience. Each component, though distinct, contributes to the harmonious operation of the entire system.

In summary, familiarity with the various components allows users to harness the full potential of their crafting tools, making the journey of creation both enjoyable and successful.

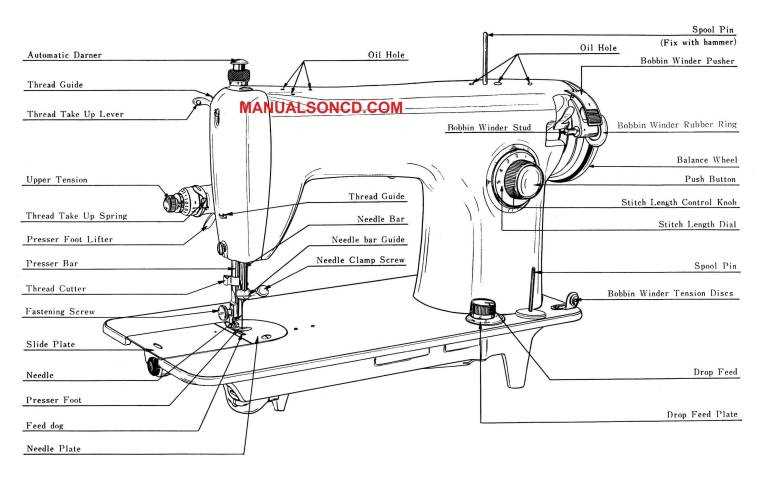

Essential Parts of a Sewing Machine

Understanding the key components of your crafting device is crucial for both beginners and experienced enthusiasts. Each element plays a vital role in ensuring that your fabric manipulation is seamless and efficient. Familiarity with these elements enhances your ability to troubleshoot and improve your crafting skills.

Needle: The needle is the primary tool for piercing fabric. It comes in various sizes and types, allowing for different fabric weights and techniques.

Bobbin: This small spool holds the thread used for the underside of stitches. It works in tandem with the needle to create secure seams.

Feed Dogs: These are the metal teeth that move the fabric through the mechanism. Their motion controls the speed and flow of the material being worked on.

Presser Foot: This component holds the fabric in place while the needle performs its work. Different styles of feet enable various sewing techniques.

Tension Discs: These discs regulate the amount of thread tension, crucial for creating balanced stitches. Proper tension adjustment ensures that the upper and lower threads interlock perfectly.

Stitch Selector: This feature allows you to choose from various stitch types, enabling creative possibilities in your projects. It determines the pattern and style of the stitches being formed.

Motor: The motor powers the entire device, driving the needle up and down and controlling the speed of operation.

Each of these components contributes to the overall functionality and versatility of your crafting apparatus, making it essential to understand their roles for effective use and maintenance.

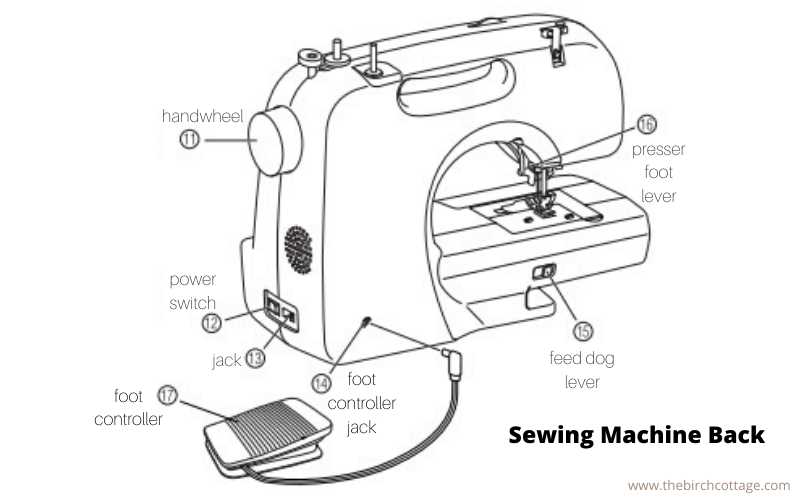

How to Identify Each Component

Understanding the various elements of your fabric handling tool is essential for effective use and maintenance. Each component plays a crucial role in the overall functionality, and recognizing them will help you troubleshoot issues and enhance your sewing experience.

Key Elements to Recognize

- Needle: This is the pointed tool that pierces the fabric to create stitches.

- Bobbin: A small spool that holds the lower thread, essential for stitching.

- Presser Foot: This element holds the fabric in place as you sew.

- Feed Dogs: These small metal teeth move the fabric forward during the stitching process.

- Tension Dial: This regulates the tightness of the threads for balanced stitching.

Visual Identification Tips

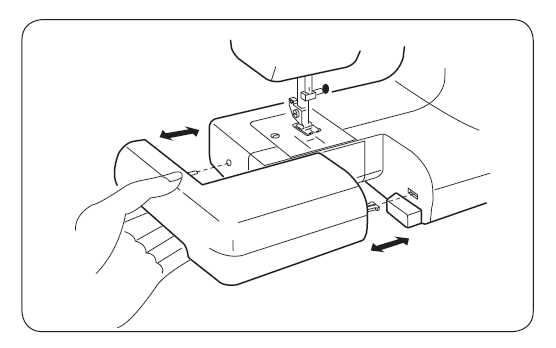

- Refer to your user manual, which often includes labeled images for clarity.

- Look for online tutorials that visually demonstrate each component’s location and function.

- Join community forums where experienced users share insights and tips on identifying specific elements.

By familiarizing yourself with these key components, you will be better equipped to utilize your fabric handling tool effectively and address any challenges that arise.

The Function of the Needle

The needle plays a pivotal role in the textile crafting process, serving as a key instrument for creating seams and joining fabrics. Its design and functionality are essential for achieving precise and consistent results.

Key functions of the needle include:

- Creating holes in the fabric for thread to pass through.

- Guiding the thread through various layers of material.

- Facilitating intricate designs and patterns.

Different types of needles are available, each tailored for specific tasks:

- Universal Needle: Versatile for various fabrics.

- Ballpoint Needle: Ideal for knits and stretchy materials.

- Quilting Needle: Designed for layered projects.

Understanding the ultimate purpose and selection of the needle enhances the quality of crafting and overall project success.

Understanding the Bobbin System

The bobbin system is a crucial component in the realm of textile arts, providing the foundation for creating intricate stitches. This mechanism operates in harmony with the upper thread, working together to form a robust and durable seam. A clear grasp of this system not only enhances the quality of stitching but also simplifies the troubleshooting process when issues arise.

Components of the Bobbin System

At the heart of this system lies the bobbin, a small cylindrical object that holds the lower thread. It is encased within a bobbin case, which secures it in place while allowing for smooth unwinding during the sewing process. The tension of the thread is vital; it must be adjusted correctly to ensure balanced stitches. Misalignment or improper tension can lead to a variety of problems, including thread bunching or uneven seams.

Maintaining the Bobbin System

Regular maintenance is essential for optimal performance. Cleaning the bobbin area and checking for lint accumulation can prevent many common issues. Additionally, replacing worn or damaged bobbins ensures consistent stitching quality. Understanding the bobbin system empowers users to achieve better results and extend the lifespan of their tools.

Role of the Feed Dogs

Feed dogs are essential components that ensure smooth fabric movement during the crafting process. Their primary function is to advance the material in a controlled manner, facilitating accurate stitching. Understanding their role is crucial for achieving optimal results in any textile project.

Functionality of Feed Dogs

- Control the forward movement of the fabric

- Engage with the presser foot to maintain tension

- Allow for precise positioning and adjustments

Types of Feed Dog Mechanisms

- Drop feed dogs for free-motion stitching

- Walking feet that move the fabric evenly

- Adjustable feed dogs for various fabric thicknesses

In summary, feed dogs play a pivotal role in ensuring the ultimate precision and efficiency of the sewing experience.

Exploring the Tension Mechanism

The balance of forces within a textile tool is crucial for achieving precise and consistent results. Understanding how tension is controlled and adjusted can significantly impact the quality of the finished product.

Key Components of the Tension System

- Tension discs

- Adjustment dial

- Feed dogs

Importance of Proper Tension

- Prevents fabric puckering

- Ensures even stitch formation

- Enhances overall durability of seams

By delving into these elements, users can achieve the ultimate efficiency in their crafting endeavors.

Importance of the Presser Foot

The presser foot plays a crucial role in ensuring precise and consistent stitching. It provides the necessary pressure to hold fabric in place, allowing for even feed during the sewing process. This component enhances control over the material, contributing to the overall quality of the finished product.

Different types of presser feet cater to various techniques, enabling users to explore a wide range of creative possibilities. Understanding their functions can significantly improve the sewing experience and outcome.

| Type of Presser Foot | Function | Common Use |

|---|---|---|

| Standard Foot | General purpose stitching | Basic seams |

| Zipper Foot | Facilitates zipper installation | Attaching zippers |

| Walking Foot | Feeds multiple layers evenly | Quilting and heavy fabrics |

| Buttonhole Foot | Creates precise buttonholes | Finishing garments |

Utilizing the appropriate presser foot not only simplifies tasks but also enhances the functionality of the equipment, making it an essential consideration for both beginners and experienced users.

Overview of the Stitch Selector

The stitch selector is a crucial element in any textile crafting tool, allowing users to customize their creations with a variety of decorative and functional stitches. This component offers flexibility and creativity, enabling artisans to choose the appropriate design for their projects, from simple seams to intricate patterns.

Functionality

This mechanism typically features a range of options, each corresponding to a specific stitch type. By engaging different settings, users can easily switch between straight, zigzag, and other unique designs, enhancing both the aesthetic and durability of their work. The intuitive layout ensures that even beginners can navigate through the choices effortlessly.

Importance in Textile Crafting

Utilizing the stitch selector effectively can greatly influence the overall outcome of a project. A well-chosen stitch can improve the fabric’s strength, add flair, or even provide necessary elasticity. Thus, understanding how to use this tool not only enriches the crafting experience but also elevates the quality of the finished piece.

Functionality of the Throat Plate

The throat plate serves a critical role in ensuring precision and stability during the fabric manipulation process. It acts as a base, providing support and guiding the material as it passes beneath the needle, thus influencing the overall quality of the stitching.

This component is designed with specific features that enhance the user experience. Its openings allow for easy access to the bobbin area while ensuring that the needle remains aligned properly. The throat plate also helps to minimize the risk of snagging, allowing for smooth transitions between different fabric types.

Moreover, the design often includes markings that assist in achieving accurate seam allowances and measurements, making it an essential tool for both beginners and experienced artisans alike. Understanding its functionality can ultimately enhance one’s skills and efficiency in textile projects.

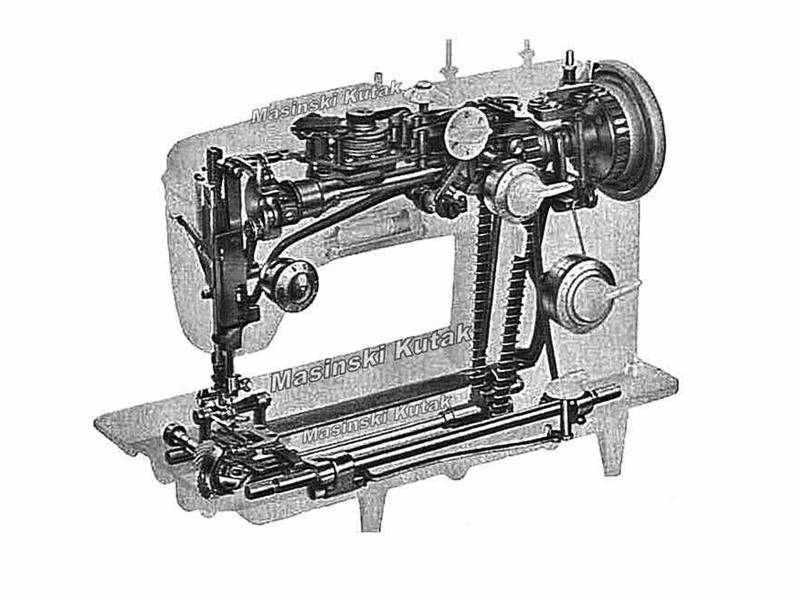

How the Motor Powers Your Machine

The heart of any textile tool lies in its ability to generate movement. This force is essential for transforming fabric and thread into finished creations, allowing artisans to express their creativity.

Typically, the motor serves several crucial functions:

- Provides the necessary torque for movement

- Regulates speed for different techniques

- Ensures consistent operation for precision

Understanding how these elements interact can enhance your experience. Here’s a closer look at the motor’s role:

- Power Generation: The motor converts electrical energy into mechanical energy.

- Speed Control: It allows for adjustments to meet various project requirements.

- Durability: A well-functioning motor ensures longevity and reliability.

By delving into these components, users can appreciate the ultimate efficiency that modern tools provide.

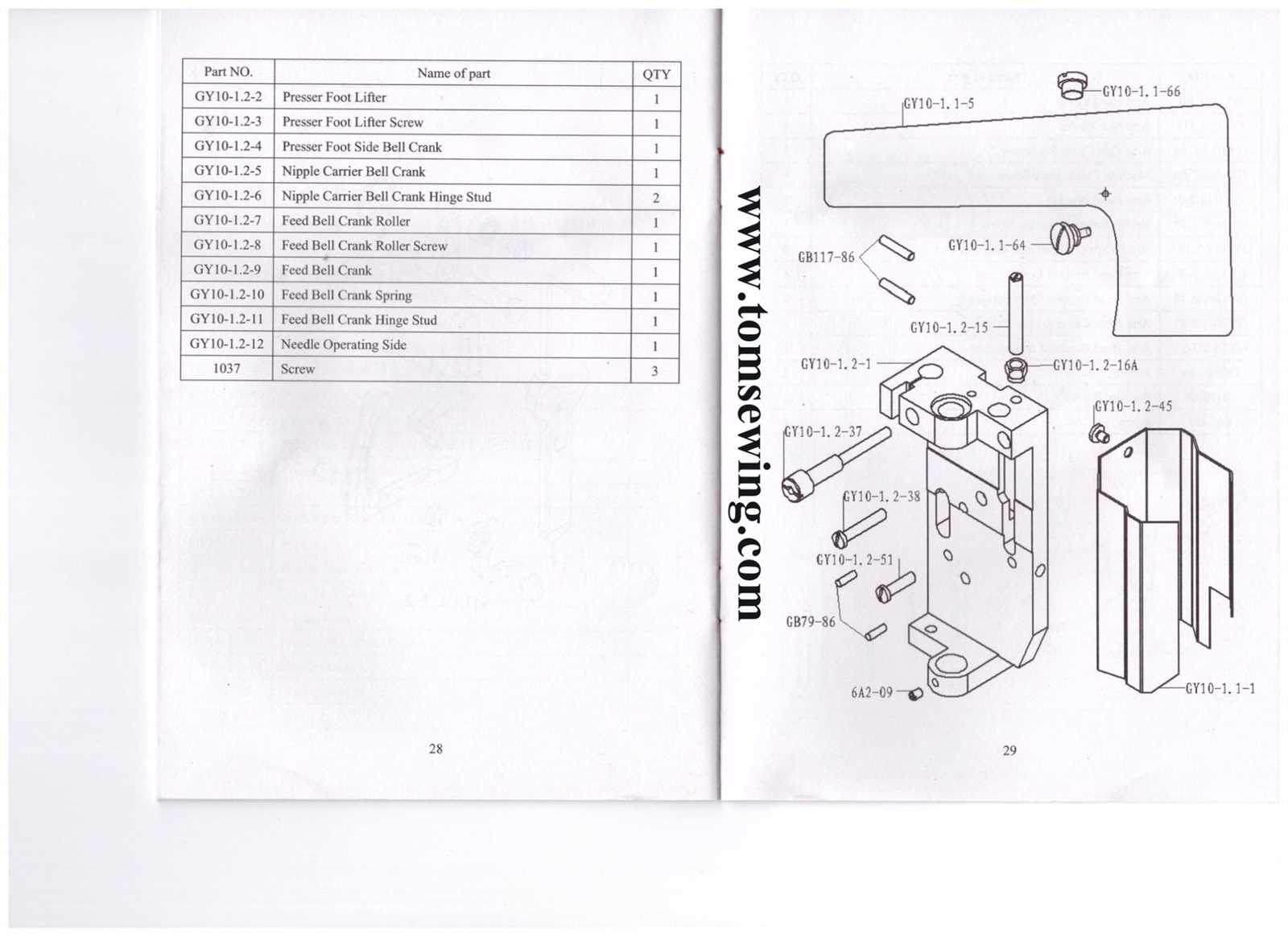

Maintenance Tips for Key Parts

Regular care of essential components ensures optimal performance and longevity. By implementing simple routines, users can prevent wear and tear, enhancing functionality and reliability.

Lubrication and Cleaning

Ensure that moving elements are well-lubricated to minimize friction. Use appropriate oils and clean surfaces to remove dust and debris, which can hinder smooth operation.

Inspection and Replacement

Periodically examine critical elements for signs of damage or excessive wear. Timely replacement of worn-out components can prevent larger issues and maintain efficiency.