Exploring the intricacies of marine engine functionality reveals the importance of specific components that ensure seamless operation. A clear grasp of these mechanisms not only aids in maintenance but also enhances overall performance. By dissecting the essential elements involved, one can appreciate their roles in optimizing efficiency and responsiveness.

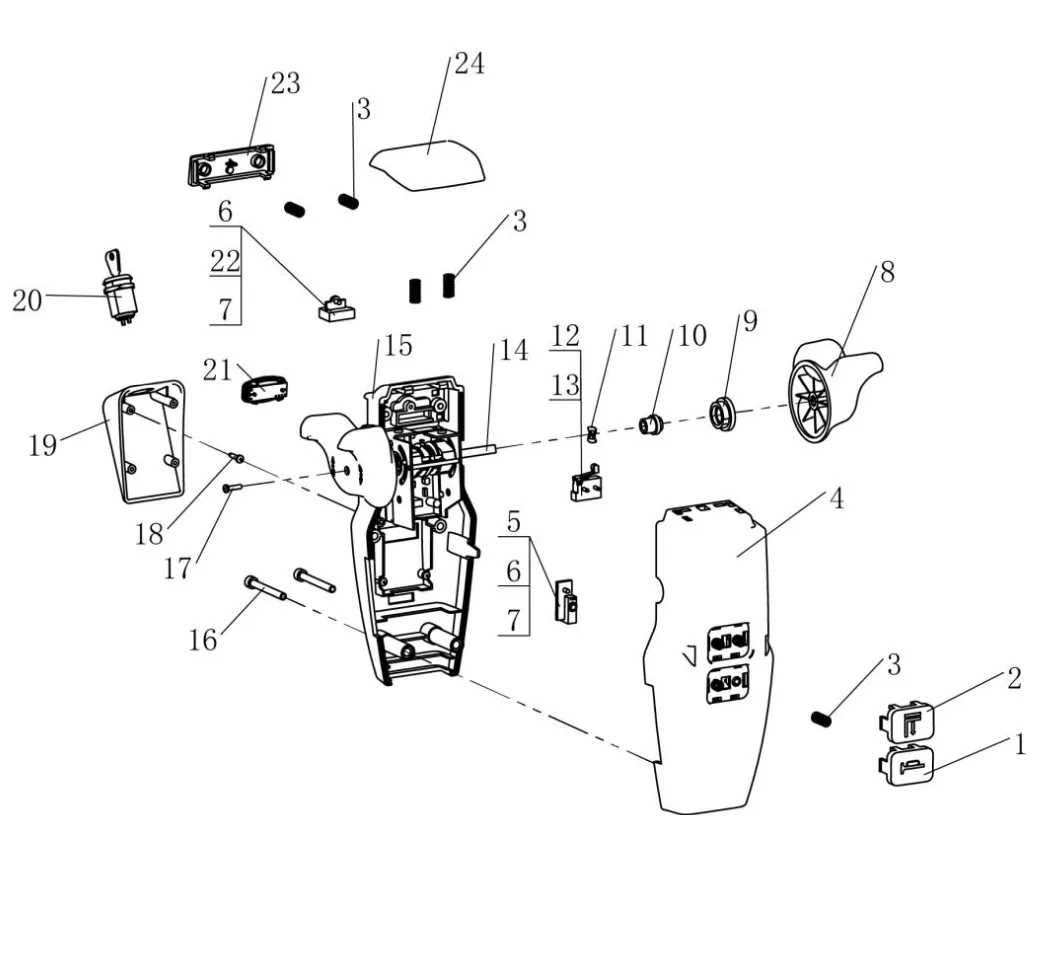

Detailed visual representations play a crucial role in comprehending the arrangement and interaction of these key components. Such illustrations provide invaluable insight, allowing users to identify each segment’s purpose and how they collaborate to achieve desired outcomes. This knowledge can prove beneficial for both novice enthusiasts and seasoned professionals.

Furthermore, understanding these mechanisms fosters informed decision-making when it comes to repairs or upgrades. With a solid foundation in the layout and functionality of these systems, users can navigate challenges with confidence, ensuring that their marine vessels operate at peak performance for years to come.

Components of Throttle Systems

The functionality of a propulsion mechanism relies on various elements working in unison to regulate engine power. Understanding these essential components is crucial for achieving optimal performance and responsiveness in marine applications. Each element plays a specific role in managing the flow of energy and ensuring smooth operation.

One primary component is the actuator, which directly influences the engine’s power output by adjusting the opening and closing of the airflow path. This mechanism often operates electronically, providing precise adjustments based on user input. Additionally, the linkage system connects the actuator to the user interface, enabling seamless communication between the operator and the engine.

Another critical element is the sensor, which monitors the position of the actuator and sends feedback to the engine management system. This information is vital for maintaining efficiency and preventing potential issues. Furthermore, the user interface, often found in the form of a lever or pedal, allows the operator to make real-time adjustments, offering a direct influence on the engine’s responsiveness.

Lastly, the housing encapsulates these components, providing protection from environmental factors while ensuring accessibility for maintenance. Understanding the interplay between these various elements is essential for anyone looking to enhance the performance and reliability of their marine engine setup.

Functionality of Throttle Control Parts

The various components involved in managing engine performance play a crucial role in ensuring smooth operation and optimal response. Each element contributes to the overall efficiency of the system, facilitating the precise delivery of power while maintaining stability. Understanding the roles these elements play can enhance the comprehension of how they interact within the mechanism.

Key Components and Their Roles

At the core of the assembly, the primary element serves to regulate the flow of fuel and air into the engine, directly influencing acceleration and speed. This mechanism typically includes a cable or electronic interface that transmits the user’s input to the engine. Additionally, sensors are integrated to provide real-time feedback, allowing for adjustments that ensure maximum efficiency under varying conditions.

Importance of Synchronization

Proper coordination among the components is essential for achieving optimal performance. When the elements work in unison, they allow for a responsive and engaging experience, enabling quick adjustments based on user demands. Any misalignment or malfunction can lead to decreased performance, emphasizing the need for regular maintenance and careful inspection.

Importance of Accurate Diagrams

Precision in visual representations is crucial for understanding the intricate workings of mechanical systems. Clear illustrations facilitate effective assembly, maintenance, and troubleshooting, enabling users to grasp complex configurations effortlessly. When details are presented accurately, it enhances the overall functionality and reliability of the components involved.

Moreover, well-crafted visuals serve as essential references for technicians and hobbyists alike. They minimize the risk of errors during installation or repair, ultimately saving time and resources. By adhering to exact specifications, these representations ensure compatibility and optimal performance, allowing for seamless integration within larger systems.

In the realm of engineering and design, high-quality visuals not only convey information but also foster innovation. They allow designers to experiment with different layouts and configurations, leading to improved efficiency and effectiveness in various applications. Thus, the significance of precision in these illustrations cannot be overstated, as it underpins the success of both individual components and the systems they comprise.

Common Issues in Throttle Controls

Various complications can arise in mechanisms that regulate the engine’s power output. Understanding these challenges is crucial for maintaining optimal performance and ensuring a safe operating environment. Below are some frequent problems encountered in these systems.

Electrical Malfunctions

Electrical issues can disrupt the function of the power management system, leading to inconsistent performance. Common symptoms include:

- Inoperative or sluggish response to user inputs.

- Erratic engine behavior during operation.

- Warning indicators illuminating on the dashboard.

Mechanical Wear and Tear

Over time, components can experience wear, which may affect their operation. Key signs of mechanical degradation include:

- Unusual noises when engaging the system.

- Physical obstructions preventing smooth movement.

- Excessive play or looseness in the linkage.

Addressing these issues promptly can enhance reliability and performance.

Maintenance Tips for Throttle Components

Proper upkeep of the essential elements that manage engine acceleration is crucial for ensuring optimal performance and longevity. Regular maintenance not only enhances efficiency but also prevents costly repairs in the future. Below are key recommendations to keep these components in excellent condition.

-

Regular Inspection:

Periodically examine all mechanisms for signs of wear, corrosion, or damage. Look for loose connections and ensure everything is securely fastened.

-

Cleaning:

Remove any debris or build-up that could hinder functionality. Use a suitable cleaner and soft cloth to gently wipe down surfaces without causing scratches.

-

Lubrication:

Apply appropriate lubricants to moving parts to reduce friction and wear. Ensure that the lubricant used is compatible with the materials in use.

-

Check Cable Tension:

Ensure that the cables have the correct tension. Too tight or too loose cables can lead to sluggish response or complete failure in operation.

-

Monitor Performance:

Pay attention to any changes in responsiveness. Unusual noises or irregular movement can indicate underlying issues that require immediate attention.

By following these maintenance tips, users can ensure the efficient operation of the components that regulate engine speed, thereby enhancing overall performance and reliability.

Identifying Throttle Control Parts

Understanding the various components involved in managing engine power is essential for maintaining optimal performance. Each element plays a crucial role in the overall functionality, ensuring smooth operation and responsiveness. Recognizing these components can aid in troubleshooting and replacement tasks.

Key elements include the mechanism that regulates the engine’s output, various connectors, and the associated wiring. Familiarity with these items allows for better diagnostics and repairs when issues arise.

| Component | Description |

|---|---|

| Lever | Responsible for initiating the action to adjust engine power. |

| Cable | Connects the lever to the mechanism, facilitating movement. |

| Connector | Links various components, ensuring signals are transmitted accurately. |

| Housing | Encases and protects the internal mechanisms from environmental factors. |

| Spring | Provides necessary tension, allowing for quick returns to default positions. |

Installation Process of Throttle Controls

Properly setting up the operating mechanism for managing speed is essential for optimal performance. This process ensures a seamless connection between the input device and the engine, contributing to a smooth and responsive operation. Following a systematic approach can simplify the task and enhance efficiency.

Preparation Steps

Begin by gathering all necessary components and tools required for the installation. Ensure the workspace is clean and organized to prevent any mishaps during the procedure. It’s advisable to consult the manufacturer’s guidelines to understand the specifications and requirements for the assembly.

Installation Procedure

Start by securely mounting the primary mechanism in the designated location. Make sure it is aligned correctly to avoid any operational issues. Next, connect the linkage or cable to the engine, ensuring it moves freely without obstruction. Once all connections are made, double-check the alignment and tighten any fittings. Finally, conduct a test to verify that the system functions as intended, making any necessary adjustments to achieve the desired responsiveness.

Compatibility with Various Engines

This section explores the adaptability of the mentioned components with a range of power units, highlighting how they can enhance performance across different marine and automotive applications. Understanding the compatibility factors is crucial for ensuring optimal functionality and efficiency.

Several elements contribute to the effective integration of these components with diverse engine types:

- Design Specifications: The structural and mechanical dimensions play a vital role in determining whether the components will fit seamlessly with specific engines.

- Performance Ratings: Each engine variant has unique performance characteristics, which can influence the overall effectiveness of the installed components.

- Installation Requirements: Different engines may necessitate distinct installation procedures, which should be considered for a smooth setup.

- Material Compatibility: The materials used in both the components and the engines must align to prevent wear and ensure longevity.

Moreover, the following factors should be taken into account for enhanced compatibility:

- Manufacturer Guidelines: Always refer to the recommendations provided by the manufacturers to ensure compatibility with various engine models.

- Testing and Validation: Conducting thorough testing on different engine types can provide insights into performance and reliability.

- Upgradability: Consider whether the components can be upgraded or modified to support future engine technologies.

Ultimately, achieving compatibility with multiple engine types not only enhances the overall functionality but also maximizes the performance potential of the entire system.

Upgrades for Enhanced Performance

Improving the functionality and responsiveness of your marine vessel can significantly elevate your overall experience on the water. By implementing various enhancements, you can achieve better acceleration, increased fuel efficiency, and a more enjoyable ride. Here, we explore several effective modifications that can optimize performance and ensure a smoother operation.

Key Enhancements to Consider

When aiming to elevate the performance of your system, consider the following upgrades that can lead to noticeable improvements:

| Upgrade | Description | Benefits |

|---|---|---|

| High-Performance Sensors | Replacing standard sensors with high-precision alternatives for better data accuracy. | Improved responsiveness and efficiency. |

| Advanced Software Tuning | Utilizing custom software to optimize performance settings. | Increased power output and better handling. |

| Upgraded Wiring Harness | Installing a high-quality wiring system for enhanced signal transmission. | Reduced latency and improved reliability. |

| Enhanced Actuation Mechanisms | Upgrading to responsive actuation devices for smoother operation. | Greater precision and reduced wear over time. |

Maintenance Considerations

In addition to upgrades, regular maintenance is crucial for sustaining optimal performance. Ensure that all components are in good condition, as wear and tear can diminish the effectiveness of any enhancements made. Frequent inspections and timely replacements will help maintain the benefits of your modifications, ensuring a reliable and enjoyable experience.

Comparative Analysis with Other Brands

This section aims to explore the distinctions and similarities between a well-known brand’s offerings and those of its competitors in the market. By evaluating various attributes such as functionality, durability, and customer satisfaction, we can gain insights into how these products stand up against one another. Understanding these differences is crucial for consumers seeking the best solutions for their needs.

Performance Metrics

When examining the performance metrics, the leading brand typically excels in several areas, including responsiveness and user experience. Competitors may offer comparable specifications, yet often fall short in real-world applications. This discrepancy highlights the importance of rigorous testing and quality assurance processes in maintaining a competitive edge.

Durability and Design

In terms of durability, the brand in focus frequently utilizes superior materials that enhance longevity, making their products more resilient to wear and tear. On the other hand, alternatives might prioritize aesthetics over sturdiness, resulting in a trade-off between visual appeal and functional reliability. Ultimately, consumers must weigh these factors according to their personal preferences and intended usage.

Expert Recommendations for Repair

When addressing issues with a specific mechanism, it’s crucial to follow systematic approaches to ensure effective restoration. Experienced technicians often emphasize the importance of understanding the underlying components and their interactions. This knowledge can lead to more informed decisions during the repair process.

Step-by-Step Approach

Adopting a methodical strategy can significantly enhance repair outcomes. Here are key steps to consider:

- Thoroughly inspect the entire assembly for signs of wear or damage.

- Document all observations to keep track of any irregularities.

- Refer to technical resources for detailed specifications of each component.

- Utilize the right tools to avoid causing further damage during the process.

Common Issues and Solutions

Understanding frequent challenges can help in prompt resolution. Here are some common problems and recommended fixes:

- Inconsistent Performance: Check for loose connections and ensure all fasteners are tightened.

- Unresponsive Mechanism: Inspect for blockages or obstructions that may hinder movement.

- Wear and Tear: Replace any frayed or damaged components to restore functionality.

Resources for Throttle Control Diagrams

When working with mechanical components, having access to reliable references is essential for effective maintenance and troubleshooting. Various resources can aid in understanding the assembly and functionality of these systems, ensuring proper handling and operation.

Below are some valuable resources that can enhance your knowledge and skills:

- Manufacturer Websites: Many producers offer online resources, including manuals and specifications for their products. These documents often include detailed images and descriptions that facilitate better comprehension.

- Online Forums and Communities: Engaging with enthusiasts and experts in online communities can provide insights and shared experiences regarding component functionality and repair. Platforms such as Reddit and specialized boating forums are excellent places to start.

- Technical Manuals: Printed or digital manuals specific to the machinery often contain extensive information on assembly, operation, and maintenance practices. These are invaluable for understanding the components involved.

- YouTube Tutorials: Visual learners can benefit from video guides that demonstrate various tasks related to assembly and maintenance. Many creators share step-by-step instructions that can simplify complex procedures.

Utilizing these resources will help you gain a deeper understanding of the mechanisms at play, improving both your skills and confidence in handling these components.