In the realm of winter maintenance tools, a thorough comprehension of individual components plays a crucial role in ensuring optimal performance. Each piece contributes to the overall functionality, making it essential for users to familiarize themselves with the intricate assembly of their machinery. By grasping the relationship between various elements, operators can enhance efficiency and prolong the lifespan of their equipment.

Exploring the structure and function of these essential implements not only aids in effective troubleshooting but also empowers users to undertake necessary repairs and maintenance. Knowledge of each constituent part allows for a more informed approach to operation, enabling seamless execution of tasks during harsh winter conditions. A clear visual representation can further simplify this understanding, providing a roadmap for effective usage and care.

Moreover, being well-versed in the specific roles of each segment fosters confidence among operators. This understanding leads to informed decisions regarding repairs, replacements, and upgrades, ultimately contributing to a smoother and more reliable performance throughout the cold season. Emphasizing the importance of familiarization with the machinery’s layout can significantly enhance the user experience, transforming challenges into manageable tasks.

Powersmart Snow Blower Overview

This section provides a comprehensive look at an essential tool designed for clearing pathways during winter months. These machines are engineered to efficiently handle various types of wintry precipitation, ensuring safety and accessibility in outdoor spaces.

Understanding the functionality and features of these devices is crucial for effective operation. Here are some key aspects:

- Power Source: These machines can be powered by gasoline or electricity, each offering distinct advantages.

- Clearing Width: The size of the clearing width determines how much area can be tackled in a single pass, influencing overall efficiency.

- Chassis Design: The construction of the frame impacts durability and maneuverability, essential for navigating various terrains.

Maintenance is vital for longevity and performance. Regular checks on components such as:

- Belts

- Blades

- Engine oil

will ensure the unit operates smoothly throughout the season. Understanding the inner workings and potential issues can significantly enhance the user experience, making winter tasks less daunting.

Understanding Snow Blower Components

Mastering the elements of a winter clearing machine is essential for effective operation and maintenance. Each component plays a critical role in ensuring optimal performance, making it important to familiarize oneself with their functions and interconnections.

Key Components Overview

- Engine: Powers the entire mechanism, providing the necessary force to operate.

- Auger: The rotating blade that collects and breaks up the material.

- Chute: Directs the expelled material away from the cleared path.

- Controls: Allow the operator to adjust speed and direction easily.

- Skid Shoes: Help maintain an appropriate distance from the ground surface.

Maintenance and Care

- Regularly inspect the engine and fuel system for any issues.

- Check the condition of the auger and ensure it is free of debris.

- Lubricate moving parts to prevent wear and tear.

- Examine the chute for blockages and clear as necessary.

- Test the controls to ensure they respond correctly.

Understanding these essential elements will not only enhance efficiency but also prolong the lifespan of the equipment, allowing for smoother operation throughout the winter months.

Importance of Maintenance Parts

Regular upkeep of outdoor equipment is crucial for ensuring optimal performance and longevity. Components that require periodic attention help to prevent potential failures, thereby safeguarding the investment and enhancing operational efficiency. Understanding the significance of these elements is essential for users aiming to maintain their machinery in peak condition.

Benefits of Regular Maintenance

Proper care of essential components offers numerous advantages. Firstly, it reduces the risk of unexpected breakdowns, allowing users to rely on their equipment when needed most. Secondly, consistent maintenance can improve fuel efficiency, ultimately lowering operational costs. Furthermore, maintaining key elements can enhance safety, minimizing the likelihood of accidents due to malfunction.

Key Components to Monitor

| Component | Function | Maintenance Tip |

|---|---|---|

| Drive Belts | Transfer power from the engine | Inspect for wear and replace as necessary |

| Filters | Clean air and fuel for the engine | Change regularly to ensure optimal performance |

| Lubrication Points | Reduce friction between moving parts | Apply appropriate grease or oil periodically |

| Skids | Protect the machinery and ensure stability | Check for wear and replace if damaged |

Common Issues with Snow Blowers

During the winter months, various mechanical devices designed to clear frozen precipitation can encounter a range of challenges. Understanding these common problems can help users maintain their equipment effectively and ensure optimal performance when needed the most.

Engine Problems

One prevalent issue is related to the engine. Users may experience difficulty starting the machine, which can often be attributed to fuel-related concerns. Stale fuel or incorrect fuel mixture can lead to poor ignition. Regularly checking and replacing the fuel can help mitigate these issues.

Clogging and Blockages

Another frequent concern involves clogging within the discharge chute. Accumulations of ice and debris can obstruct the flow of material, resulting in reduced efficiency. To prevent this, it’s crucial to clear any obstructions promptly and to ensure that the mechanism is well-maintained throughout the winter season.

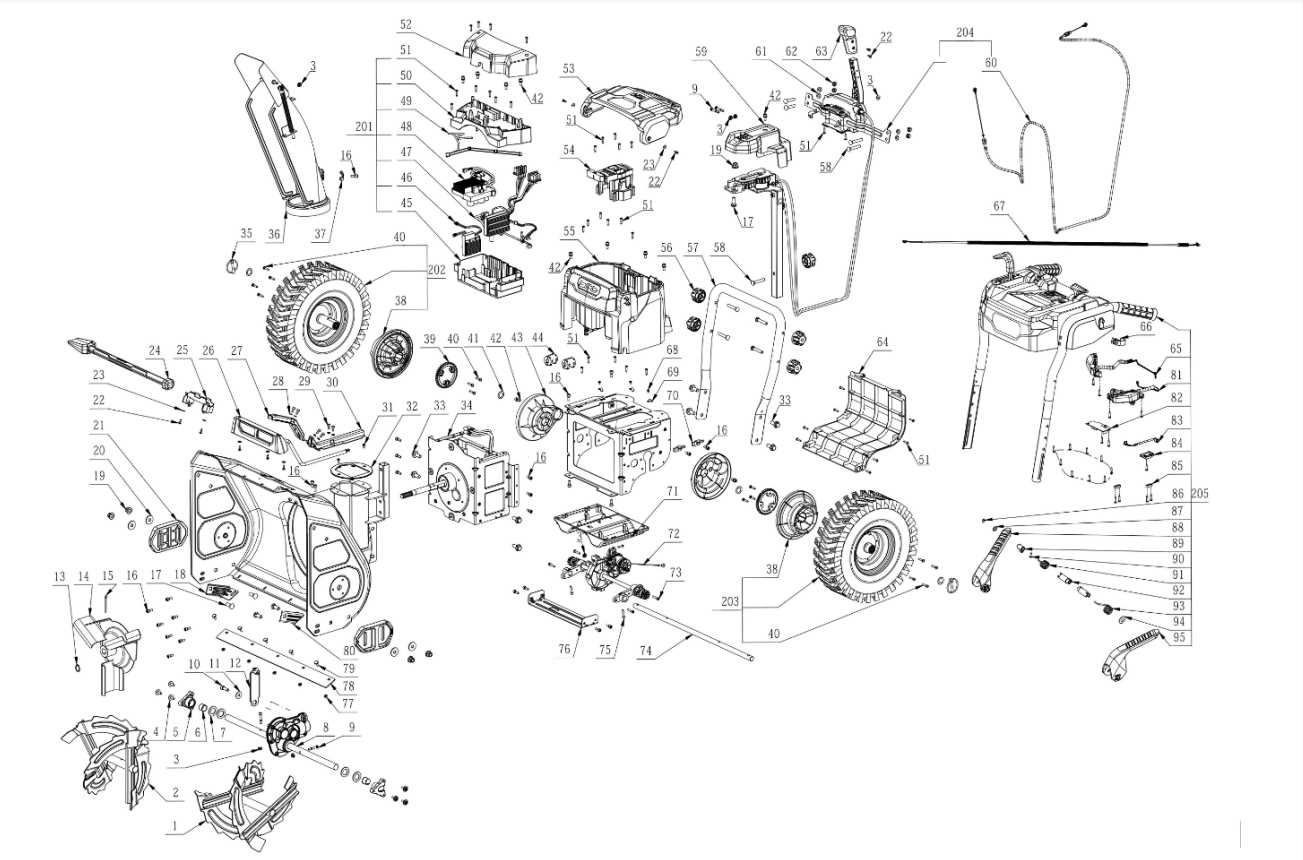

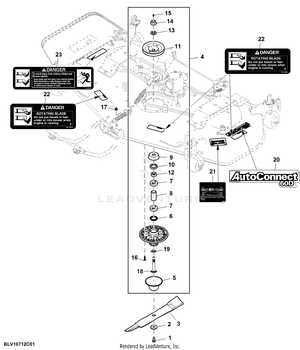

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repairs. Such illustrations provide a visual guide, helping users identify individual elements and their relationships. By familiarizing yourself with the layout and symbols used, you can streamline your repair process and ensure accuracy in replacing or fixing parts.

Identifying Components

Begin by examining the labeled sections within the illustration. Each item is usually accompanied by a reference number or letter, making it easier to locate specific elements. Take note of the grouping of parts; this often indicates how they interact or are assembled together. Familiarizing yourself with common terminology used in these visuals can greatly enhance your comprehension.

Understanding Relationships

Next, focus on the connections between different components. Lines and arrows often depict how parts fit together or function in unison. Pay attention to any annotations or notes that might indicate special assembly instructions or warnings. By grasping these relationships, you can avoid potential pitfalls during repairs and ensure that everything is installed correctly.

Identifying Key Replacement Parts

Understanding the essential components of your machine is crucial for maintaining optimal performance and longevity. Recognizing these vital elements not only aids in effective repairs but also ensures that your equipment operates smoothly throughout its lifespan.

Main Components to Focus On

- Engine: The heart of the device, responsible for powering all functions.

- Auger: Essential for breaking up and moving material efficiently.

- Chassis: The framework that houses and supports all other components.

- Drive System: Enables mobility and control of the equipment.

- Shear Pins: Protect the auger from damage during heavy use.

Additional Considerations

- Consult the user manual for specific part numbers and compatibility.

- Look for signs of wear or damage to determine which components need replacement.

- Regular maintenance can prolong the life of these crucial parts.

Where to Buy Snow Blower Parts

When it comes to maintaining your outdoor equipment, finding the right components is essential for optimal performance. Various options are available for sourcing these essential items, whether you need replacements for wear and tear or upgrades for better efficiency. Knowing where to look can save you time and ensure you get quality materials for your needs.

Local retailers often carry a selection of necessary components, providing the advantage of immediate access and the ability to consult with knowledgeable staff. Additionally, many specialized stores focus on outdoor machinery, offering a wider range of options and expert advice. These establishments can be particularly helpful if you’re unsure about what specific items you require.

For those comfortable with online shopping, numerous websites cater specifically to outdoor equipment enthusiasts. These platforms typically feature detailed catalogs, allowing you to browse through a comprehensive inventory from the comfort of your home. Reading customer reviews can also guide you in selecting high-quality components and reputable sellers.

Another great resource is manufacturer websites, which often provide direct access to genuine items. This option ensures that you receive the right specifications and compatibility for your equipment. Some manufacturers also offer support services, including advice on installation and maintenance.

Consider checking local classifieds and online marketplaces as well. These venues can sometimes yield great deals on both new and gently used components, giving you the chance to save money while still securing what you need.

Ultimately, the best approach combines various sources, ensuring you have multiple options and can make informed decisions based on availability, quality, and price.

DIY Repair Tips for Homeowners

For homeowners, tackling repairs on your own can be a rewarding and cost-effective approach. With a little guidance and the right tools, you can address various issues around your property without relying on professional services. This not only saves money but also enhances your understanding of your equipment and how it operates.

Start by gathering all necessary tools and materials before beginning any repair project. Having everything at hand will streamline the process and reduce the likelihood of interruptions. It’s also wise to consult user manuals or online resources specific to your equipment to familiarize yourself with its components and functionality.

Next, always prioritize safety. Wear appropriate protective gear and ensure your workspace is tidy and well-lit. Disconnect any power sources before attempting repairs to prevent accidents. Taking time to assess the problem thoroughly can save you from making unnecessary mistakes.

Don’t hesitate to document the disassembly process. Taking pictures or notes can be incredibly helpful for reassembly. If you find unfamiliar parts, researching their functions online can clarify their roles and assist you in troubleshooting.

Lastly, be patient. Some repairs may take longer than expected, but persistence will pay off. Embracing a DIY mindset can not only empower you but also give you a sense of accomplishment once the task is completed.

Benefits of Using Genuine Parts

Utilizing authentic components for your equipment brings numerous advantages that enhance performance, longevity, and overall efficiency. These elements are designed specifically to fit and function with your machine, ensuring optimal operation and minimizing the risk of failures.

Enhanced Performance

Genuine components are engineered to meet the exact specifications of your machinery. This results in:

- Smoother operation, reducing vibrations and noise.

- Improved efficiency, allowing the equipment to perform at its best.

- Consistency in functionality, ensuring reliable performance in various conditions.

Increased Longevity

Investing in authentic components can significantly extend the life of your equipment. Consider the following:

- Quality materials that withstand wear and tear over time.

- Precise engineering that prevents unnecessary strain on other parts.

- Manufacturer support, which often includes warranties for genuine components.

By choosing genuine items, you not only protect your investment but also enjoy peace of mind knowing that your equipment is in optimal condition.

Seasonal Maintenance Checklist for Equipment

Proper upkeep of machinery ensures optimal performance and longevity. A comprehensive checklist tailored for different seasons can help prevent issues and enhance efficiency. Regular maintenance is crucial for reliable operation and safety.

Below is a suggested seasonal maintenance checklist:

Spring Maintenance

- Inspect and clean the engine air filter.

- Change the oil and replace the oil filter.

- Sharpen or replace cutting blades.

- Check fuel lines for leaks or cracks.

- Inspect belts for wear and adjust tension as needed.

Summer Maintenance

- Ensure the cooling system is functioning properly.

- Check for loose connections and tighten if necessary.

- Clean any debris from vents and cooling fins.

- Inspect tires for proper inflation and tread wear.

- Test safety features to ensure they operate correctly.

Autumn Maintenance

- Prepare equipment for winter storage.

- Drain and replace fuel with stabilizer.

- Inspect and clean spark plugs.

- Check battery charge and connections.

- Lubricate moving parts and joints.

Winter Maintenance

- Inspect storage area for moisture and pests.

- Cover equipment to protect from elements.

- Check all safety features before use.

- Run equipment occasionally to keep systems active.

- Review and update maintenance logs.

By following this seasonal checklist, you can ensure your machinery remains in peak condition, ready for use when needed.