When the winter season arrives, having reliable machinery to handle the snow is essential for maintaining accessibility and safety. Knowing the intricate parts of your equipment can significantly enhance its performance and longevity. Understanding how each element contributes to overall functionality is crucial for effective operation and maintenance.

In this section, we will explore the various components of your winter apparatus, detailing their roles and interconnections. Gaining insight into these elements will empower you to make informed decisions regarding repairs, upgrades, or replacements. By familiarizing yourself with the essential features, you can ensure that your equipment operates at peak efficiency during the cold months.

By delving into the specific aspects of these machines, you will be better equipped to tackle common issues that may arise. Whether you are troubleshooting a malfunction or simply seeking to enhance performance, comprehending the makeup of your machinery will prove invaluable. Embracing this knowledge not only fosters confidence but also promotes a smoother winter experience.

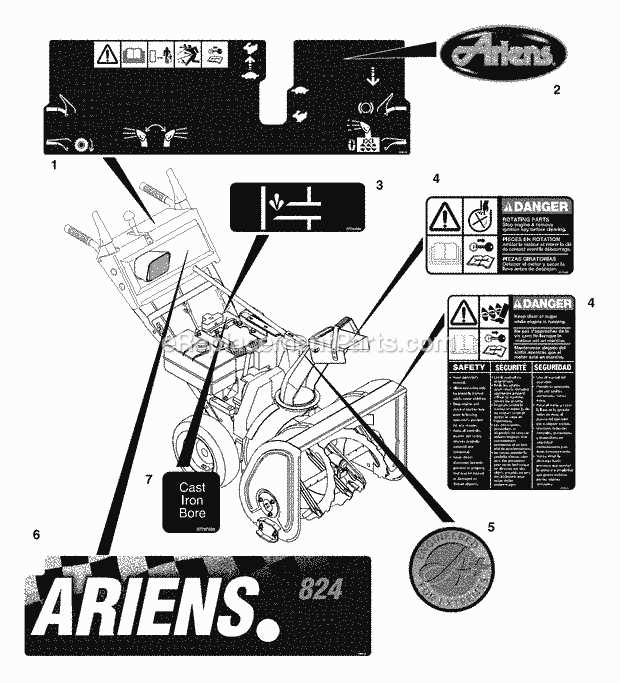

Ariens ST824 Snowblower Parts Overview

This section provides an insightful look into the essential components that make up a high-performance winter machine. Understanding each element’s function and interaction enhances the efficiency and longevity of the equipment, ensuring optimal performance during snowy conditions.

Key Components and Their Functions

Each essential component plays a critical role in the overall operation. For instance, the engine is responsible for powering the system, while the auger effectively gathers and moves snow. Additionally, the chute directs the discharged snow, allowing for precise placement away from the pathway.

Maintenance and Replacement Considerations

Regular maintenance of these components is vital for preserving functionality. It’s advisable to routinely check for wear and tear, ensuring that each part operates smoothly. When replacement is necessary, opting for high-quality alternatives can significantly enhance the machine’s performance and lifespan.

Essential Components of the Snowblower

Understanding the critical elements of a snow-clearing machine is vital for effective operation and maintenance. Each component plays a specific role in ensuring efficient performance, contributing to the overall effectiveness of the equipment in managing winter conditions.

Key Elements and Their Functions

Among the primary components are the auger, which is responsible for gathering snow, and the impeller, which helps propel the cleared snow away from the path. The engine provides the necessary power, while the transmission system allows for speed adjustments, ensuring smooth maneuverability in various terrains.

Maintenance and Upkeep

Regular inspection of these essential parts is crucial for optimal functionality. Proper care not only enhances performance but also extends the lifespan of the machine. Keeping components clean and free from debris ensures that they operate efficiently, reducing the risk of breakdowns during peak usage times.

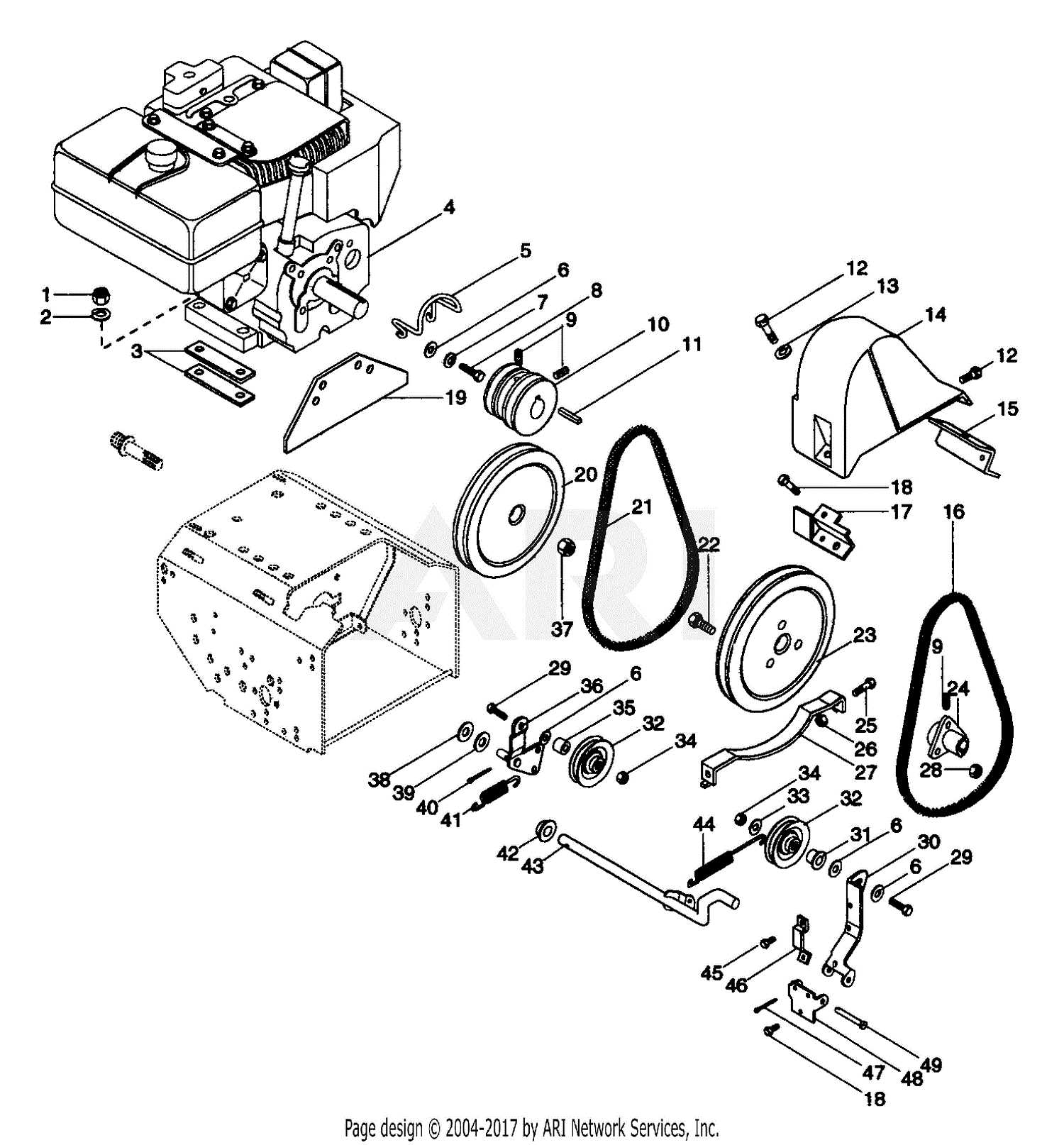

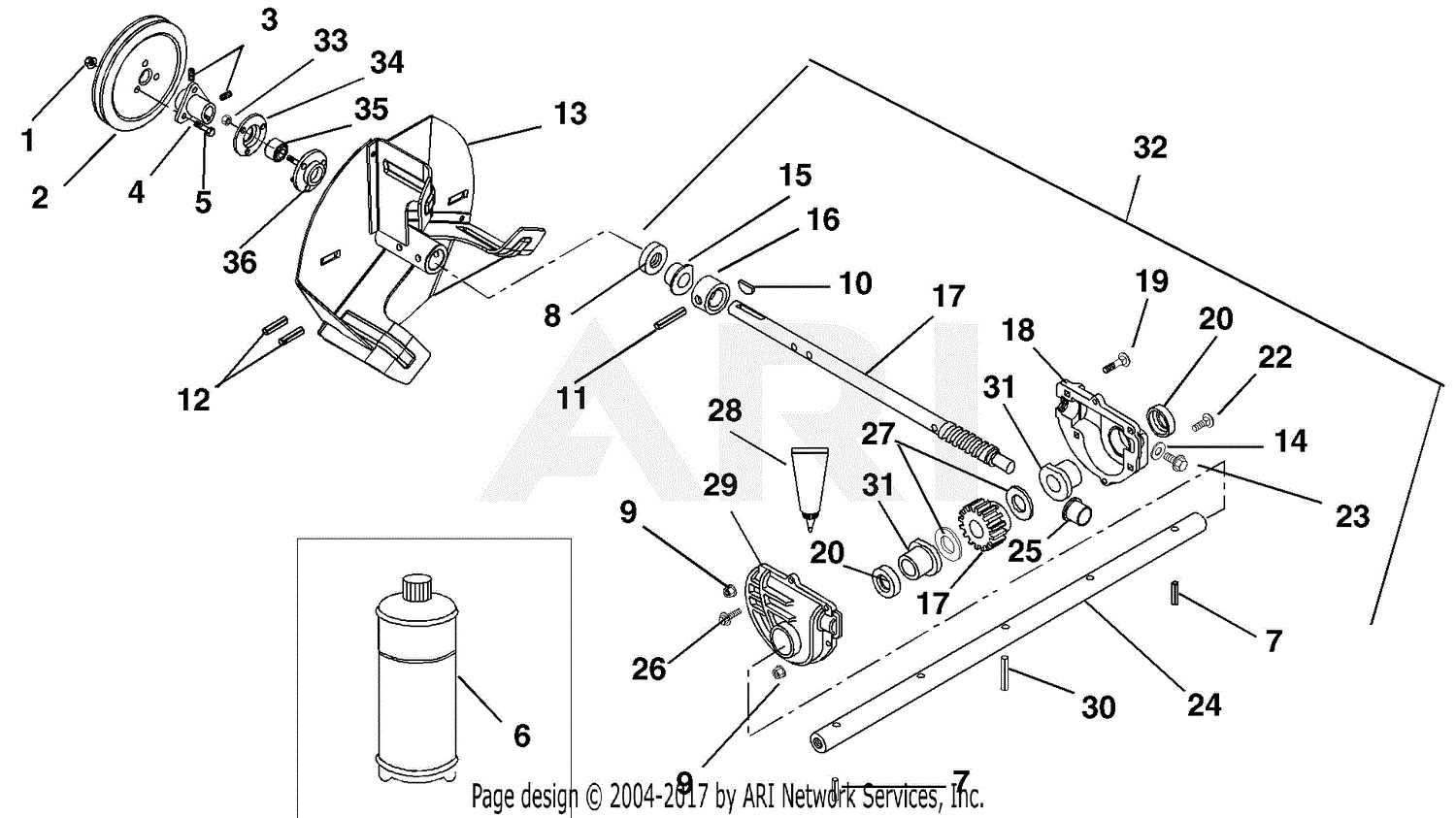

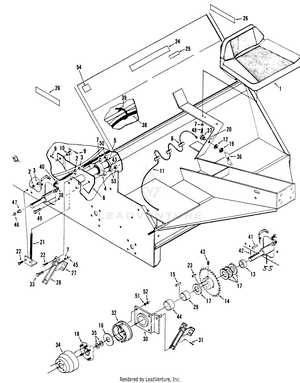

Understanding the Parts Diagram

Grasping the visual representation of components is essential for efficient maintenance and repairs. Such illustrations serve as valuable guides, showcasing how various elements interconnect and function together within the machinery. By familiarizing oneself with these visuals, users can navigate potential issues more effectively and ensure optimal performance.

Importance of Visual References

These visuals not only simplify the identification of individual components but also highlight their specific roles. Understanding each part’s function can greatly enhance troubleshooting processes and enable users to source appropriate replacements when needed.

Interpreting Connections

Recognizing how components relate to one another is vital. This knowledge empowers users to undertake repairs with confidence, ensuring that all elements work in harmony. A comprehensive understanding can ultimately lead to a more efficient operation and prolonged lifespan of the equipment.

Common Replacement Parts Needed

When maintaining a reliable outdoor clearing machine, certain components may need to be replaced to ensure optimal performance. Identifying these crucial items can help you keep your equipment running smoothly through the winter months.

Key Components for Maintenance

Among the frequently required replacements are the drive belts, which transfer power from the engine to the wheels. These belts can wear over time due to friction and stress, necessitating timely replacement to maintain functionality.

Additional Essential Items

Another important element is the cutting blade. This component can become dull or damaged after extended use, leading to reduced effectiveness. Regularly checking and replacing the blade will enhance the efficiency of your machine, making your snow clearing tasks more effective.

How to Access the Parts List

Finding the right components for your equipment is essential for maintaining optimal performance. This section guides you on how to locate a comprehensive list of the necessary items for your machine, ensuring you can effectively manage repairs and replacements.

Online Resources

The internet provides various platforms where you can easily search for item specifications. Many manufacturers have dedicated websites where detailed catalogs are available, often sorted by model and type.

Manual Reference

Your user manual typically includes a section outlining all necessary components. Consulting this document can save time and ensure accuracy when ordering replacements.

| Resource Type | Description |

|---|---|

| Official Website | Access to the latest catalogs and updates directly from the manufacturer. |

| Repair Manuals | Printed or digital versions that include diagrams and specifications. |

| Parts Suppliers | Third-party vendors offering detailed listings and purchasing options. |

Maintenance Tips for Longevity

Proper care is essential for maximizing the lifespan of your outdoor equipment. By following a few key practices, you can ensure that your machinery operates smoothly and efficiently for years to come. Regular maintenance not only prevents breakdowns but also enhances performance, making your tasks easier and more enjoyable.

Regular Inspections

Conducting routine checks on your machine is crucial. Look for any signs of wear or damage, such as frayed belts or leaks. Keeping an eye on components allows for early detection of potential issues, enabling timely repairs before they escalate into more significant problems.

Cleaning and Storage

After each use, thoroughly clean the equipment to remove dirt and debris. This practice helps prevent rust and buildup that can affect functionality. Additionally, store the machinery in a dry, protected area to shield it from harsh weather conditions, ensuring it remains in optimal working condition.

Identifying Worn or Damaged Parts

Recognizing the signs of wear or damage in machinery components is essential for maintaining optimal performance and safety. Regular inspections can help prevent further issues and extend the life of the equipment.

Key indicators to look for include:

- Visible Cracks: Check for any visible fractures on surfaces, which may indicate structural weakness.

- Uneven Wear: Examine areas for uneven or excessive wear patterns, suggesting that a component may need replacement.

- Loose Connections: Ensure all fittings and connections are secure; looseness can lead to further damage.

- Corrosion or Rust: Look for signs of corrosion, which can compromise the integrity of metal components.

During inspections, pay attention to the following:

- Inspect belts for fraying or tearing.

- Check for proper lubrication on moving parts.

- Monitor performance for unusual noises or vibrations.

Addressing these issues promptly can help maintain functionality and prevent costly repairs.

Where to Buy Replacement Parts

Finding the right components for your equipment is crucial for maintaining its efficiency and longevity. There are various options available to source these essential items, whether you’re looking for online retailers, local stores, or specialized dealers.

Online Retailers

Numerous websites offer a wide selection of components. Platforms like Amazon and eBay provide user reviews and competitive prices, making them convenient options for shoppers. Additionally, manufacturer websites often feature direct purchasing options, ensuring that you receive genuine items.

Local Shops and Dealerships

Visiting local retailers can be beneficial for those who prefer immediate assistance. Hardware stores and specialized dealers typically carry common components and can help identify specific needs. Additionally, they may provide valuable advice on installation and maintenance, ensuring your machinery operates smoothly.

DIY Repairs and Installation Guide

This section provides an overview of performing repairs and installations on your outdoor equipment. Whether you’re dealing with routine maintenance or more significant repairs, understanding the process can save you time and money.

Essential Tools: Before starting, gather the necessary tools, such as wrenches, screwdrivers, and safety gear. Having the right equipment on hand is crucial for a smooth repair process.

Step-by-Step Instructions: Begin by consulting your user manual for specific guidance. Break down the repair into manageable steps, ensuring you follow each phase carefully. This approach minimizes mistakes and enhances your understanding of the machinery.

Safety Precautions: Always prioritize safety by disconnecting power sources and wearing protective equipment. This helps prevent accidents while working on your device.

In summary, mastering repairs can greatly extend the life of your equipment. With the right tools and knowledge, you can tackle various challenges effectively.

Snowblower Safety Precautions

Ensuring safety while operating outdoor clearing equipment is essential for preventing accidents and injuries. Users must be aware of various guidelines that promote a secure working environment during snow removal tasks. Following these recommendations helps minimize risks associated with the operation of such machinery.

First and foremost, always wear appropriate personal protective equipment, including sturdy footwear, gloves, and eye protection. This gear shields you from potential hazards like flying debris and slippery surfaces. Before starting the equipment, inspect it for any damages or loose parts that could lead to malfunction during use.

Additionally, never attempt to clear a blockage with your hands. Instead, turn off the engine and wait for all moving parts to come to a complete stop before addressing any issues. Always keep bystanders, especially children and pets, at a safe distance while operating the machinery to avoid accidental injuries.

Moreover, it is crucial to maintain a clear line of sight and stay alert to your surroundings. Be mindful of potential obstacles such as curbs, steps, or hidden objects under the snow. Adhering to these safety practices will help ensure a smooth and secure experience while clearing outdoor surfaces.

Frequently Asked Questions About Parts

This section addresses common inquiries regarding the components of a specific equipment model, helping users understand maintenance and replacement options better. It aims to clarify the most frequent concerns surrounding the various elements involved in the device’s operation.

What should I do if a component breaks?

If a part becomes damaged, it’s crucial to identify the specific issue and consult the appropriate resources for replacement options. Using the correct replacement ensures optimal performance and longevity.

How can I find the right replacement for my model?

To locate a suitable substitute, refer to the manufacturer’s documentation or authorized dealers. These resources typically provide detailed information about compatible components and their specifications.

Upgrading Parts for Better Performance

Enhancing the functionality of your equipment can significantly improve its efficiency and reliability during operation. By replacing or upgrading specific components, users can experience smoother performance, increased durability, and better overall results, especially in challenging conditions.

Key Areas to Consider for Upgrades

- Engine Efficiency: Upgrading the engine can lead to improved power output and fuel efficiency.

- Auger Blades: Installing high-quality blades can enhance cutting ability, allowing for quicker and more effective snow removal.

- Drive System: A more advanced drive mechanism can offer better traction and maneuverability, especially on icy surfaces.

Benefits of Component Enhancements

- Increased Reliability: Newer components often come with better materials, reducing the likelihood of failure.

- Improved Performance: Upgraded features can lead to faster operation and less fatigue during use.

- Longer Lifespan: Investing in quality parts can extend the overall life of your equipment, providing greater value over time.