In the realm of winter maintenance, having a thorough understanding of your machinery’s structure is essential. Knowing how various elements function together can significantly enhance the efficiency of your snow-clearing tasks. This section delves into the intricate layout of your equipment, highlighting the essential components that contribute to its overall performance.

Proper knowledge of these elements not only aids in effective troubleshooting but also facilitates timely repairs and replacements. Whether you’re looking to maintain your device or seeking to understand its operational mechanisms, grasping the configuration of its key features will prove invaluable.

Additionally, being familiar with the arrangement of these components empowers you to make informed decisions when it comes to upgrades or modifications. This guide provides a comprehensive overview, ensuring you can navigate the complexities of your winter apparatus with confidence and ease.

Understanding Mastercraft Snowblower Components

When tackling winter’s challenges, knowing the various elements of your machine is essential for optimal performance and maintenance. Each component plays a crucial role in ensuring efficient operation and durability. Familiarizing yourself with these pieces can enhance your experience and prolong the lifespan of your equipment.

Key Functional Elements

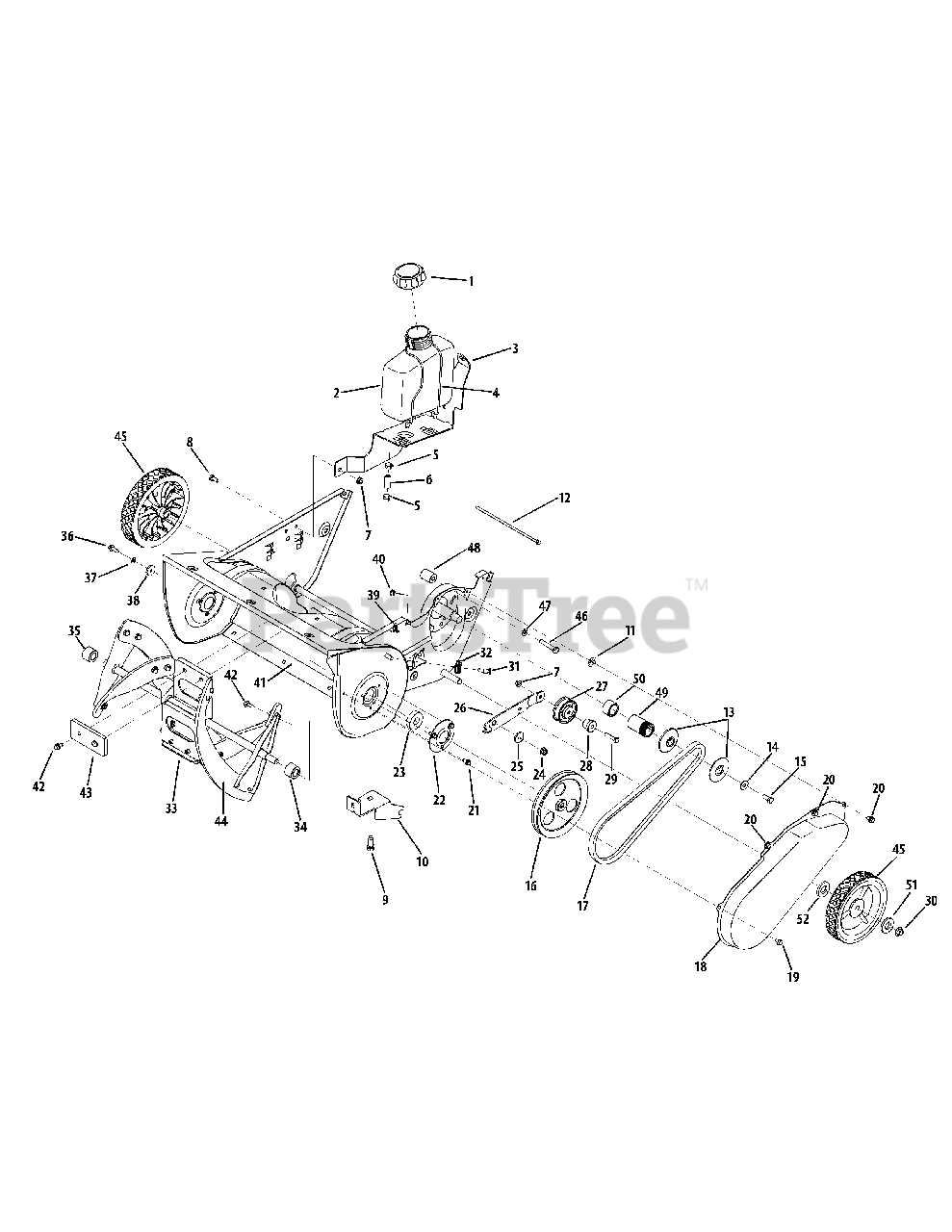

The heart of any snow-clearing apparatus lies in its core functionalities. Engines provide the necessary power, while the auger system efficiently collects and directs the snow away from your path. Other vital elements include the chassis, which supports the structure, and the controls, which allow for maneuverability and precision during operation.

Maintenance Considerations

Regular upkeep of each component is vital for sustaining performance. Inspection of the engine and lubrication of moving parts can prevent common issues that arise from wear and tear. Additionally, understanding the roles of belts and blades can aid in timely replacements, ensuring smooth and effective operation throughout the season.

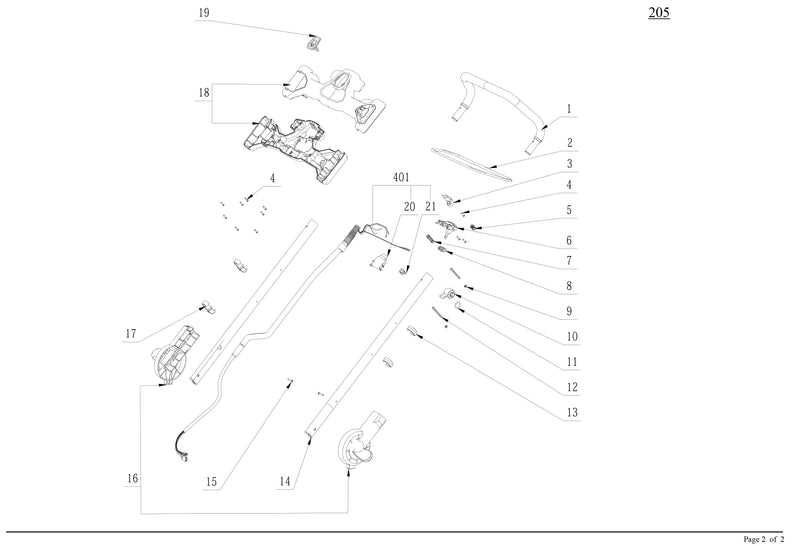

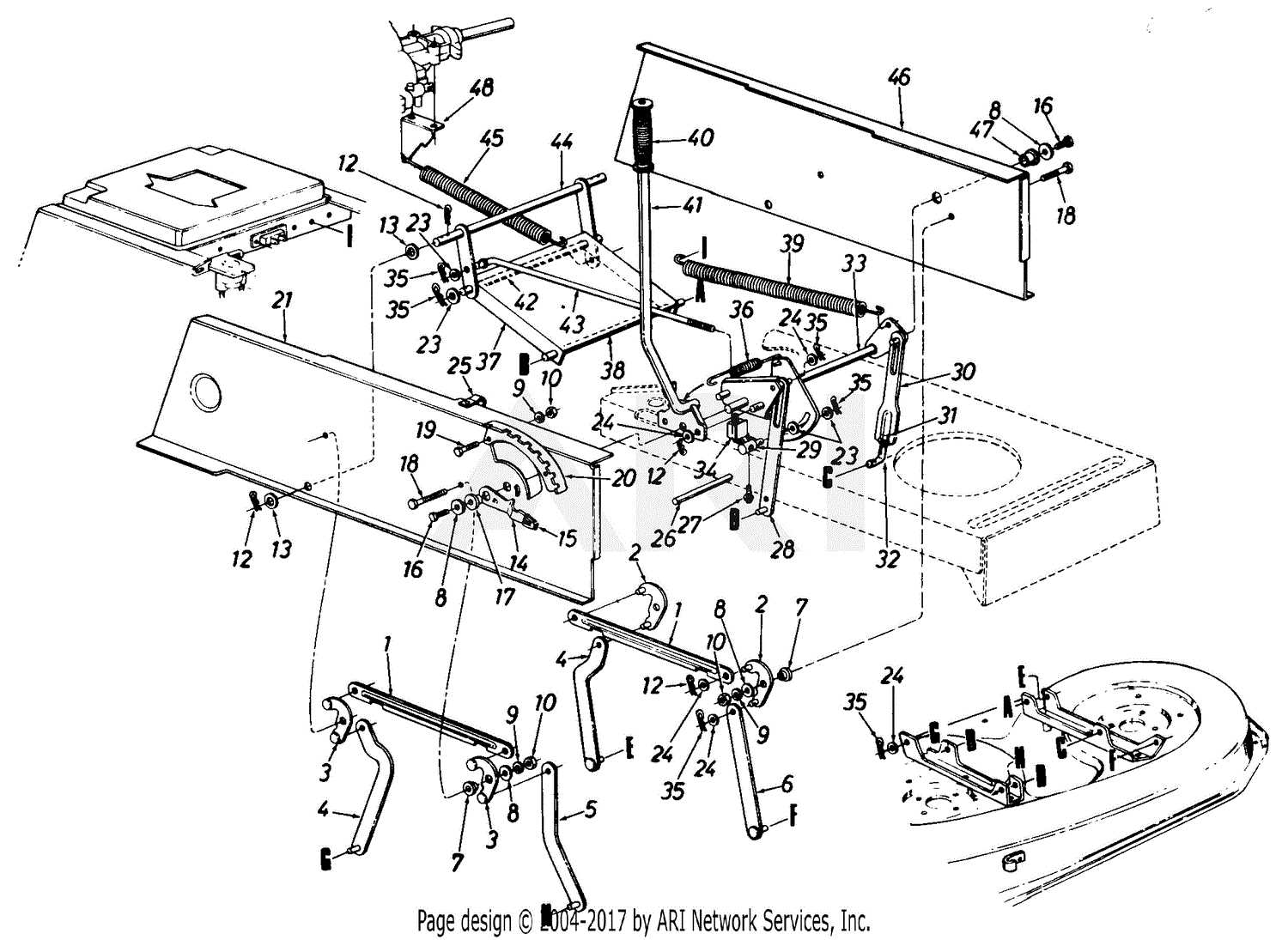

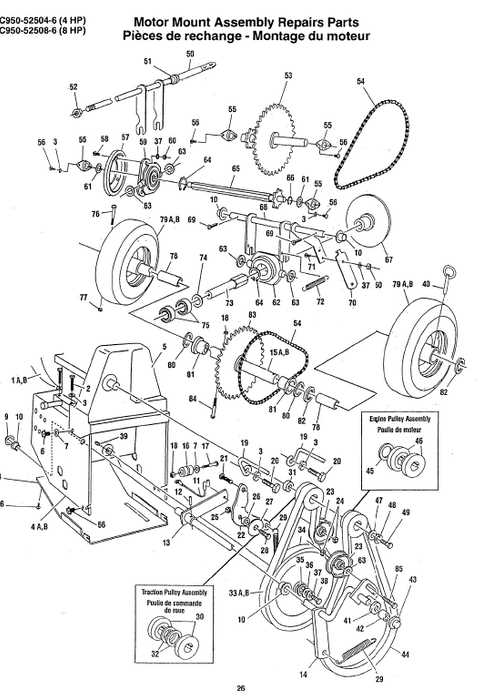

Importance of Parts Diagrams

Understanding the structure and components of a machine is crucial for effective maintenance and repair. Visual representations provide clarity, enabling users to identify individual elements and their functions within a larger system. This knowledge not only facilitates troubleshooting but also enhances overall performance and longevity.

Enhancing Repair Efficiency

When attempting repairs, having a clear illustration can significantly speed up the process. Users can quickly locate necessary components, minimizing downtime and frustration. This efficiency is particularly beneficial for those who may not be familiar with the inner workings of their equipment.

Promoting Accurate Replacements

Accurate identification of specific elements is essential for proper replacements. Visual aids reduce the risk of errors, ensuring that the right components are selected. This attention to detail ultimately leads to better functionality and fewer issues in the future.

Common Issues with Snowblower Parts

During the colder months, maintaining equipment is crucial for effective operation. Various components can experience problems, leading to inefficiencies or complete failure. Understanding common issues can help users troubleshoot effectively and ensure optimal performance.

Frequent Problems Encountered

- Clogs: Snow and ice can build up, obstructing the flow and reducing efficiency.

- Worn Belts: Over time, belts can fray or stretch, impacting the machine’s power transmission.

- Faulty Ignition: Difficulty starting often results from ignition issues, such as spark plug failure.

- Leaking Fluids: Fluid leaks can indicate problems with seals or gaskets, leading to poor operation.

Prevention and Maintenance Tips

- Regularly check and clean components to prevent clogs.

- Inspect belts for signs of wear and replace them as necessary.

- Test the ignition system periodically to catch issues early.

- Monitor fluid levels and inspect for leaks to maintain performance.

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective assembly and maintenance. These visual aids provide a clear layout of various elements, helping users identify and locate specific items needed for repairs or upgrades.

To start, familiarize yourself with the key features such as labels and numbers that correspond to each part. These references guide you in matching components with their descriptions. Additionally, pay attention to the connection points illustrated, as they indicate how parts fit together or interact within the system.

It’s also important to recognize any groupings that may signify related elements. This can simplify the process of finding replacements and understanding how each piece contributes to the overall functionality. By practicing these skills, you can enhance your efficiency and confidence in tackling any task.

Essential Maintenance for Snowblowers

Proper upkeep of winter machinery is crucial for ensuring optimal performance during the cold months. Regular attention not only extends the lifespan of the equipment but also enhances its efficiency and reliability when it’s needed the most. Here are some key maintenance tasks to consider.

- Regular Inspections: Check for wear and tear on key components, including belts, blades, and augers. Early detection of issues can prevent major failures.

- Cleaning: After each use, clear away snow and debris. This helps to prevent rust and keeps the mechanisms functioning smoothly.

- Oil Changes: Change the oil according to the manufacturer’s guidelines to ensure the engine runs smoothly and efficiently.

- Fuel Maintenance: Use fresh fuel and consider adding a fuel stabilizer. This prevents fuel degradation and ensures reliable starts.

- Spark Plug Checks: Inspect and replace spark plugs as needed to maintain ignition efficiency and engine performance.

By following these maintenance tips, users can enjoy a hassle-free experience when operating their winter equipment, ready to tackle even the heaviest snowfall.

Identifying Replacement Parts Easily

Finding suitable components for your equipment can be straightforward with the right approach. Understanding the specific needs and having a clear reference can significantly enhance your efficiency in locating the required items.

Key Steps for Identification

- Consult the user manual for guidance on compatible components.

- Take note of the model number, which provides crucial information.

- Utilize online resources that offer comprehensive catalogs.

- Reach out to customer support for expert assistance.

Helpful Resources

- Manufacturer’s website for official specifications.

- Online forums where users share experiences and tips.

- Local repair shops for hands-on advice and options.

Comparing Mastercraft Models and Parts

This section explores the distinctions and similarities among various models, focusing on their components and functionality. Understanding these nuances helps users make informed decisions tailored to their specific needs.

| Model | Engine Power | Clearing Width | Weight |

|---|---|---|---|

| Model A | 6.5 HP | 24 inches | 120 lbs |

| Model B | 7 HP | 28 inches | 130 lbs |

| Model C | 8 HP | 30 inches | 140 lbs |

Each model offers unique features that cater to different conditions, allowing users to select the most suitable option for their environment.

Finding Quality Replacement Components

When seeking high-quality substitute elements for your equipment, it’s essential to consider various factors that ensure longevity and performance. The right components can significantly enhance the efficiency and durability of your machinery, making it crucial to prioritize reliability over mere affordability.

| Criteria | Description |

|---|---|

| Material Quality | Opt for components made from durable materials to withstand wear and tear. |

| Brand Reputation | Choose reputable manufacturers known for their rigorous quality control processes. |

| Customer Reviews | Analyze user feedback to gauge the performance and reliability of the components. |

| Compatibility | Ensure the substitutes are compatible with your specific equipment model for optimal functionality. |

| Warranty | Look for products that come with a warranty to protect your investment. |

Tips for Snowblower Repair

Maintaining your winter machine is crucial for ensuring optimal performance during the snowy months. Regular inspections and timely repairs can significantly extend the life of your equipment and enhance its efficiency. Below are essential recommendations to help you navigate the repair process effectively.

Routine Maintenance Checks

Perform regular assessments to catch potential issues early. Check oil levels, inspect belts for wear, and ensure that all components are free of debris. Timely maintenance can prevent minor problems from escalating into major repairs.

Utilizing the Right Tools

Having the correct tools is vital for any repair job. Ensure you have a comprehensive toolkit that includes wrenches, screwdrivers, and pliers. Using proper equipment not only simplifies the process but also helps avoid damage to your machinery.

Where to Source Mastercraft Parts

Finding components for your outdoor equipment can be a daunting task, but with the right approach, you can easily locate what you need. There are various avenues to explore, from online marketplaces to local retailers, each offering unique advantages and a range of options for maintenance and repair.

Online Retailers

The internet is a treasure trove for sourcing specific items. Websites specializing in outdoor machinery often have extensive inventories, allowing you to compare prices and availability quickly. Make sure to read reviews and check return policies for a smoother experience.

Local Hardware Stores

Your community hardware store can be a valuable resource. Many local shops stock essential components and can often place special orders if needed. Additionally, they might provide expert advice to ensure you get the right items for your needs.

Upgrading Your Snowblower’s Performance

Enhancing the efficiency and effectiveness of your winter equipment can lead to a more productive experience during snowy conditions. Various modifications can significantly boost power, reliability, and overall functionality, ensuring you tackle even the heaviest snowfall with ease. By focusing on specific components and features, you can transform your device into a formidable tool against winter weather.

One of the primary areas to consider is the engine’s capabilities. Upgrading to a higher horsepower engine can provide more torque, allowing for smoother operation and the ability to handle deeper accumulations. Additionally, investing in a high-quality carburetor can improve fuel efficiency and enhance throttle response, resulting in a more responsive machine.

Another crucial aspect involves the clearing mechanism. Opting for a more advanced auger design can increase the amount of snow processed at a time, making your equipment more effective. Consider materials that resist wear and tear, which can prolong the lifespan of this essential component.

Furthermore, enhancing the traction system can improve maneuverability on icy surfaces. Installing better tires or chains will provide better grip, making it easier to navigate challenging terrains. This adjustment can also minimize the risk of getting stuck, ensuring a smooth operation throughout the winter months.

Lastly, regular maintenance and timely upgrades of smaller components like belts and blades can lead to noticeable improvements in performance. Keeping these elements in top condition not only enhances efficiency but also extends the overall life of your equipment. By focusing on these upgrades, you can ensure your machinery is prepared for whatever winter throws your way.