The efficient operation of any machinery relies on the proper functioning of its individual elements. Each component plays a crucial role in ensuring that the overall system works seamlessly. Recognizing these elements can significantly enhance the user experience and prolong the lifespan of the equipment.

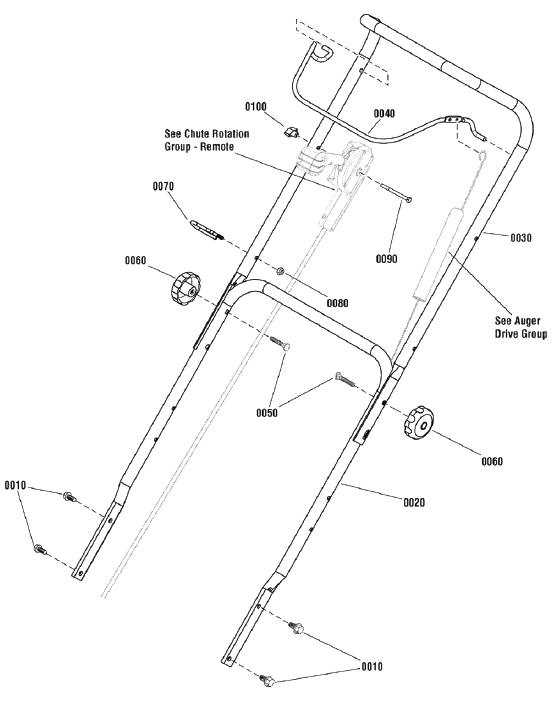

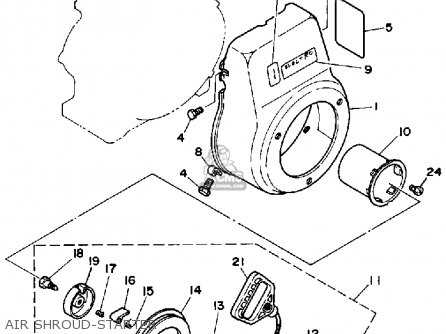

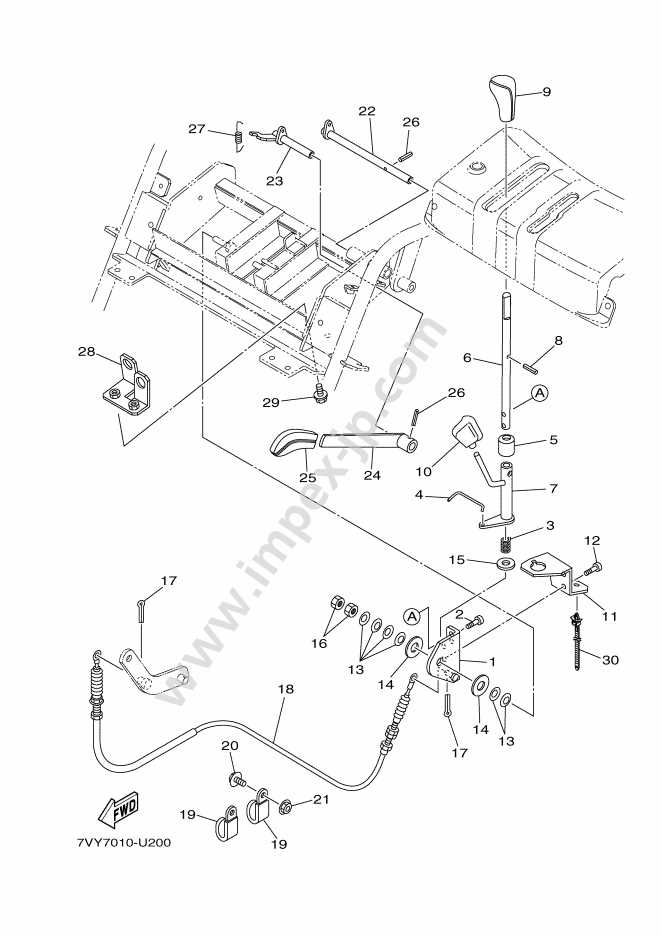

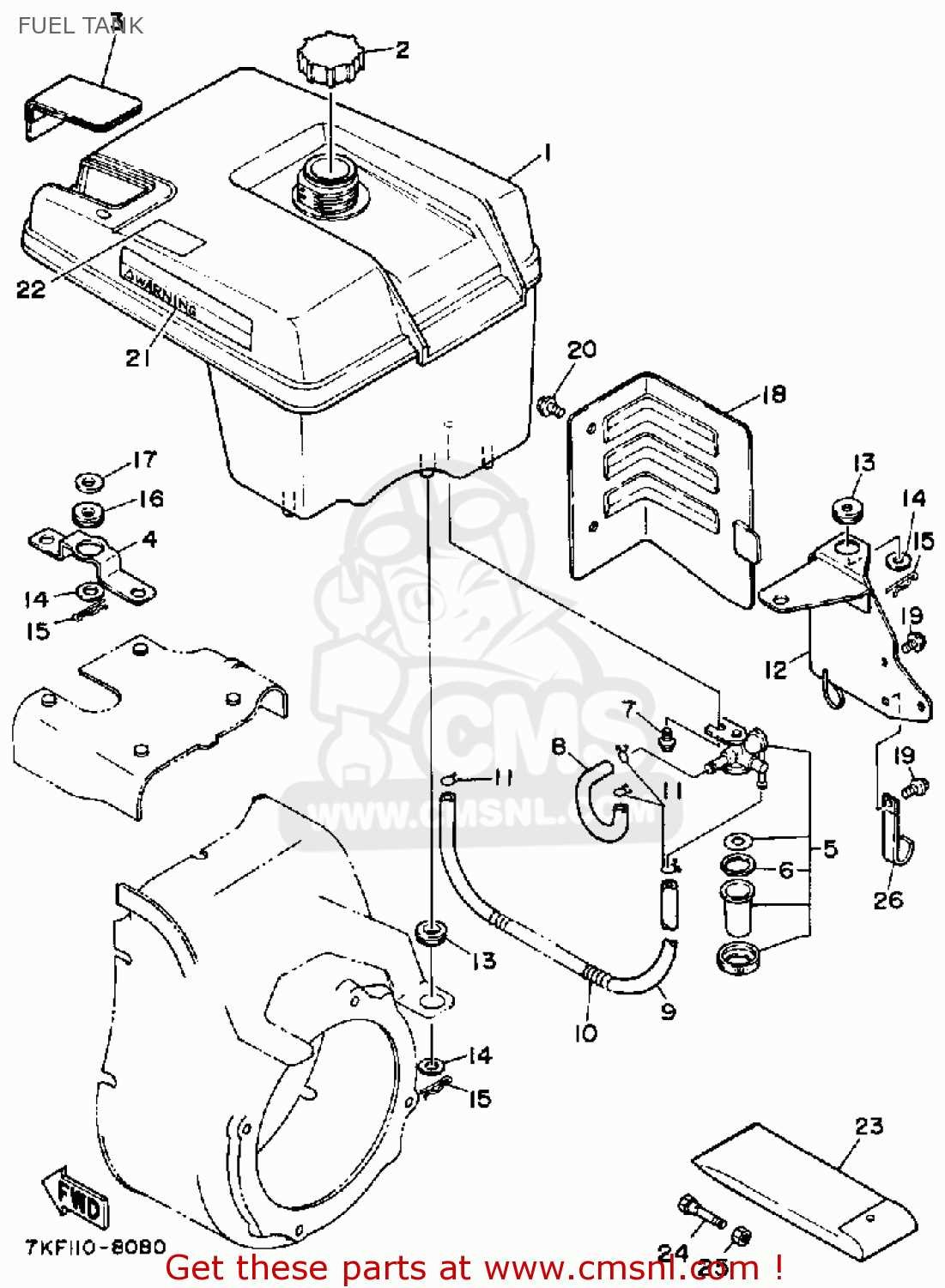

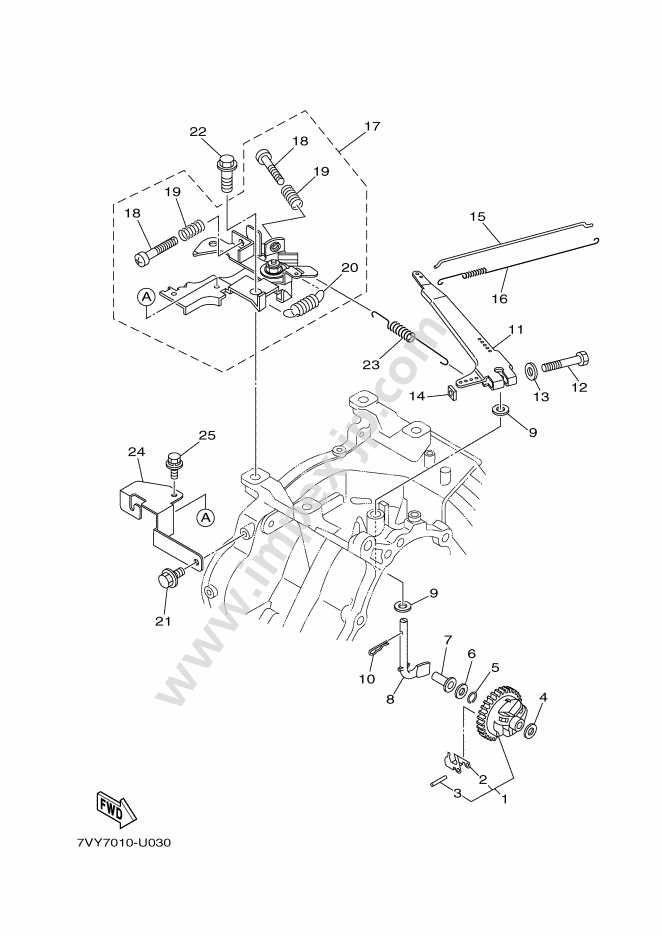

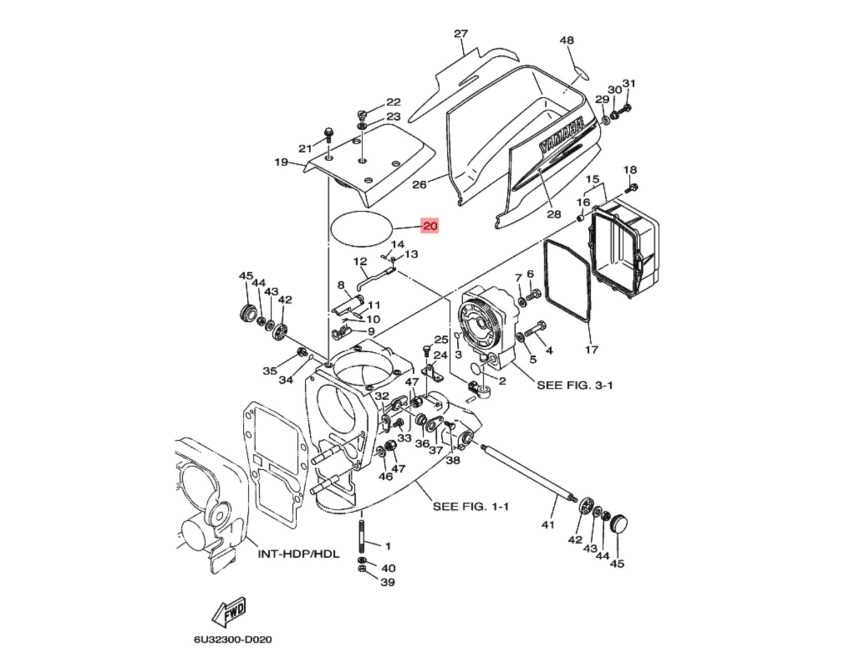

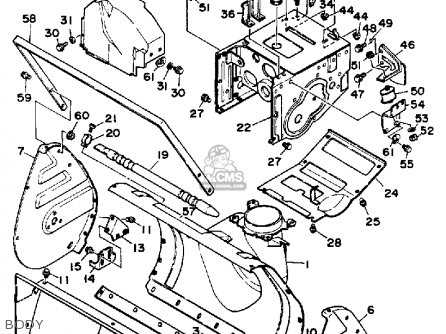

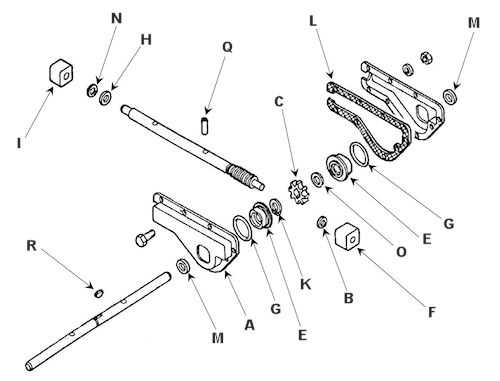

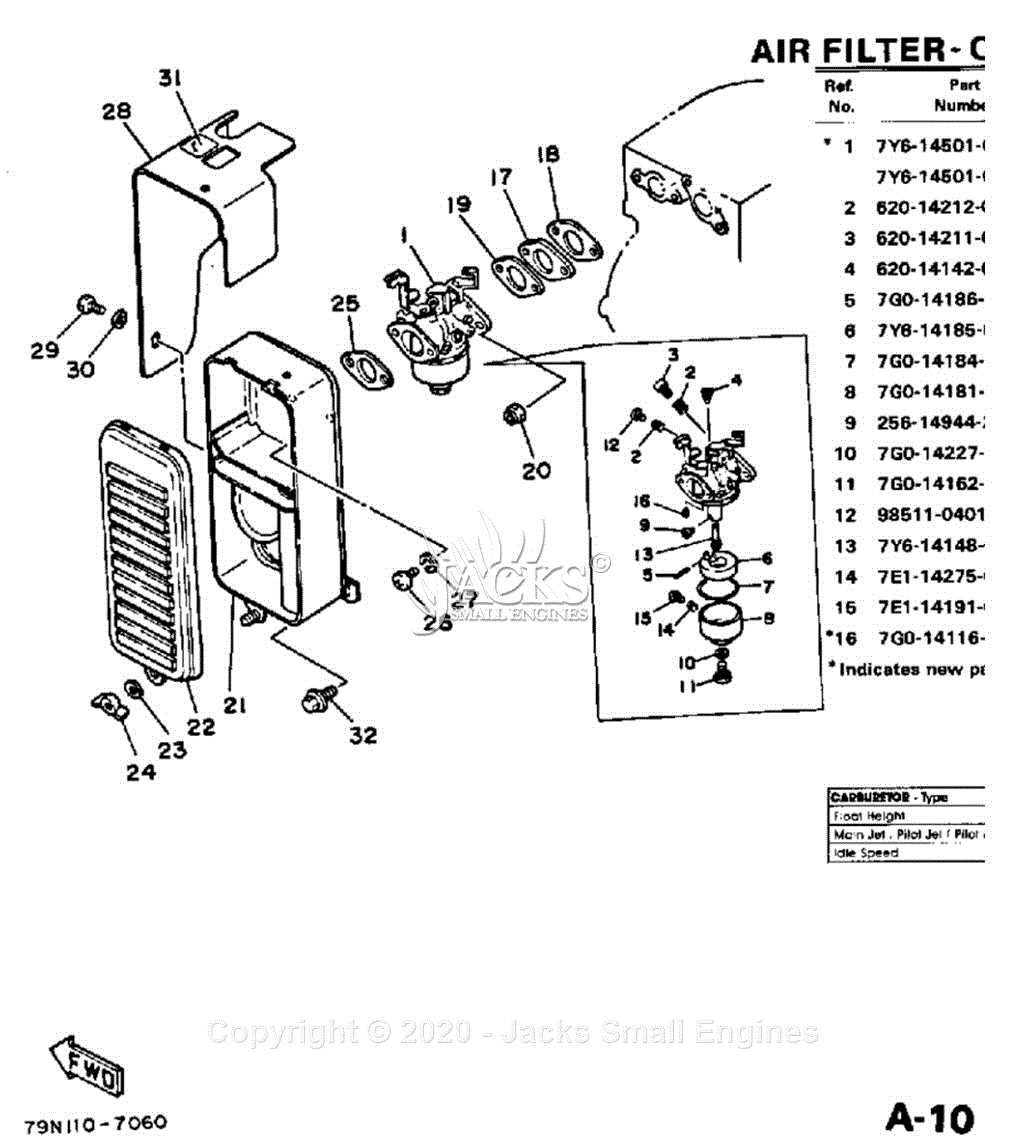

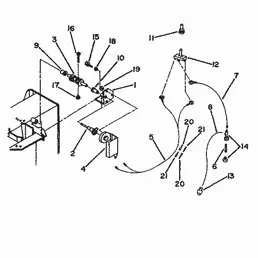

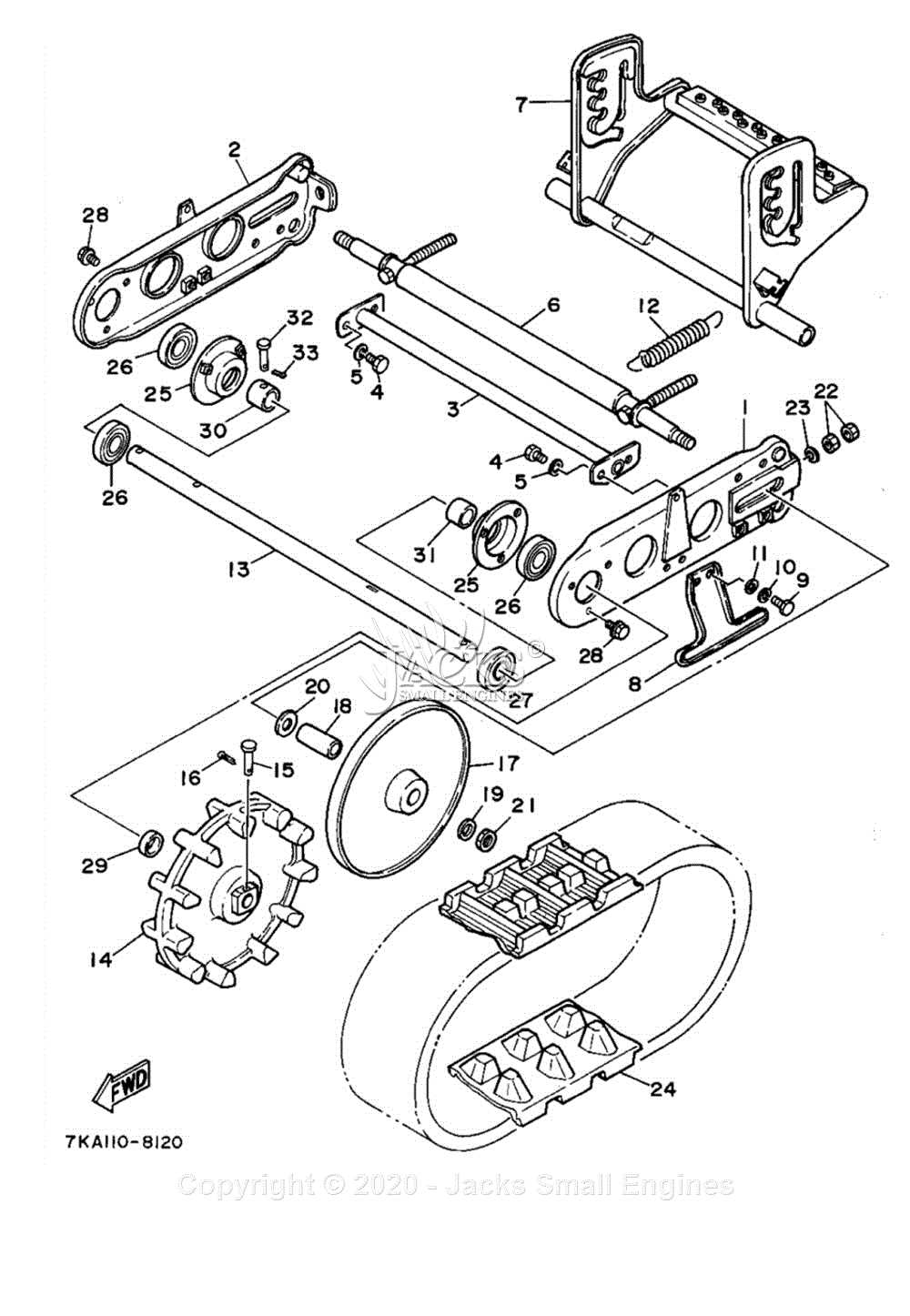

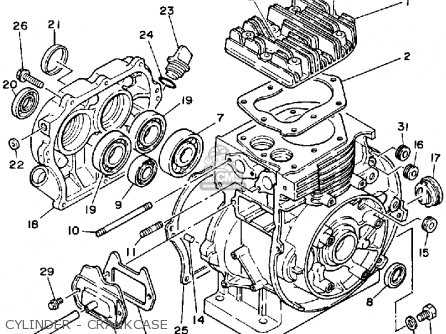

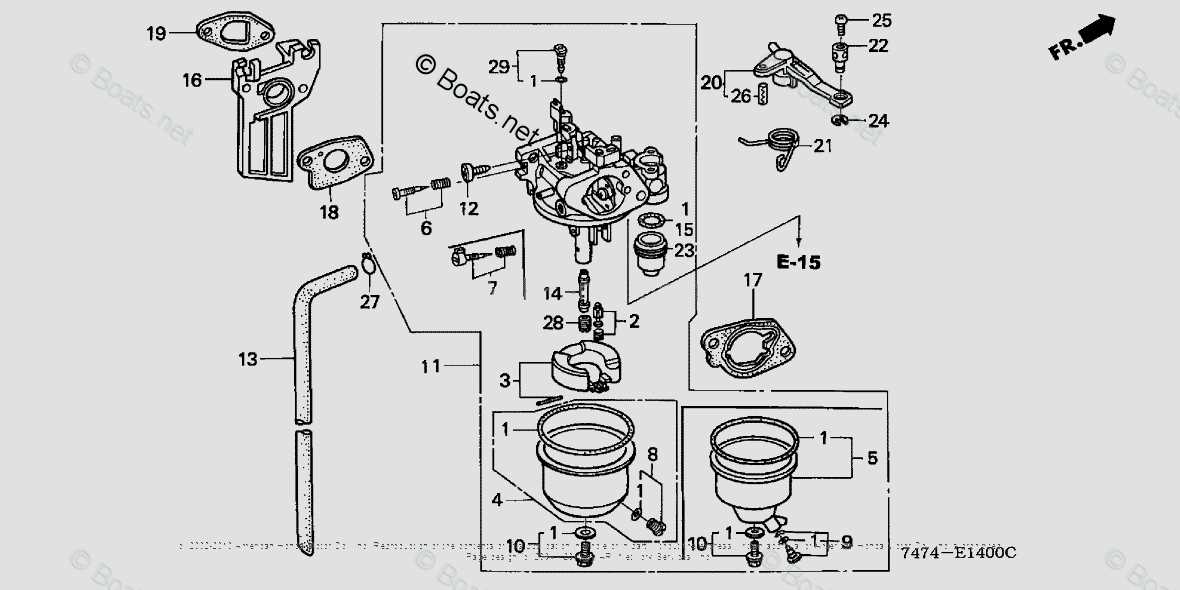

To aid in this understanding, visual representations are invaluable. They provide a clear and concise overview of the various sections and their respective roles within the machine. By familiarizing oneself with these illustrations, users can better navigate their maintenance tasks and identify any areas requiring attention.

Moreover, having access to detailed breakdowns can facilitate troubleshooting and repairs. When challenges arise, knowing where to look and what to check can save time and reduce frustration. This knowledge empowers users to take charge of their machinery, fostering confidence in its upkeep.

Understanding Yamaha Snowblower Components

This section provides insights into the various elements that make up a snow-clearing machine. Each component plays a vital role in ensuring efficient operation and reliability during winter conditions.

Main Functional Elements

Several critical components work together to achieve optimal performance. Key functionalities include the propulsion system, the clearing mechanism, and the control features that allow for user-friendly operation.

Maintenance and Care

Proper upkeep of these components is essential for longevity and efficiency. Regular inspections and timely replacements can prevent operational failures and ensure smooth functionality throughout the snowy season.

| Component | Description | Maintenance Tips |

|---|---|---|

| Drive System | Responsible for movement and traction. | Check belts for wear; lubricate moving parts. |

| Auger Assembly | Cuts through snow and directs it out of the chute. | Inspect for damage; clear debris regularly. |

| Chassis | Framework supporting all components. | Ensure no rust; clean and touch up paint as needed. |

Key Parts of Snowblower Mechanism

The efficient operation of a snow-clearing device relies on various essential components, each playing a significant role in ensuring optimal performance during winter tasks.

Main Components

- Engine: Powers the entire system, providing the necessary energy for movement and operation.

- Auger: This rotating mechanism gathers and channels the snow towards the discharge chute.

- Discharge Chute: Directs the expelled snow away from the pathway, allowing for clear passage.

- Skid Shoes: Adjustable elements that control the height of the device, ensuring effective contact with the ground.

Support Elements

- Controls: User-friendly interfaces that allow for easy adjustments of speed and direction.

- Chassis: The frame that supports all components, providing stability and durability.

- Fuel System: Supplies energy to the engine, essential for its functioning.

- Wheels or Tracks: Enhance mobility over various surfaces, aiding in maneuverability.

Commonly Used Replacement Items

When maintaining outdoor machinery, certain components are frequently replaced to ensure optimal performance. These items play a crucial role in the overall functionality and longevity of the equipment.

Some of the most sought-after components include belts, which provide the necessary traction for movement; filters that keep the engine clean; and shear pins designed to protect critical parts from damage. Regularly checking and replacing these essentials can prevent larger issues down the line.

Additionally, spark plugs are vital for efficient ignition, while fuel lines ensure a smooth flow of energy to the engine. Keeping a stock of these commonly needed items can facilitate quicker repairs and less downtime during the busy seasons.

Maintenance Tips for Longevity

Ensuring the extended life of your equipment involves consistent care and attention. Regular maintenance not only enhances performance but also minimizes the risk of unexpected failures.

Start by inspecting components for wear and tear. Replace any damaged or worn parts promptly to avoid further issues. Clean the machine regularly to prevent the buildup of debris, which can hinder functionality.

Check fluid levels frequently and replace them as recommended by the manufacturer. This includes lubricants and fuel, which play critical roles in operation. Keep an eye on the filters as well; replacing them at regular intervals ensures optimal performance.

Storing your equipment in a dry, sheltered area can protect it from harsh weather conditions that may cause damage. Always follow the manufacturer’s guidelines for seasonal preparations, such as winterization, to maintain reliability.

Finally, keeping a log of maintenance activities can help track what has been done and when, ensuring nothing is overlooked. Consistent upkeep will lead to a more reliable and durable machine.

Identifying Snowblower Model Variants

Understanding the different versions of a specific outdoor equipment can greatly enhance the maintenance and repair process. Each variant may come with unique features and specifications that cater to various user needs.

To distinguish between models, examine the identifying numbers or labels typically found on the unit. These identifiers often provide crucial information about the specific configuration and capabilities. Additionally, reviewing the manufacturer’s documentation can offer insights into the differences and intended uses of each version.

Common Characteristics: Look for variations in design elements such as engine size, chute configuration, and additional features. Recognizing these aspects can help in selecting appropriate accessories and ensuring compatibility during repairs.

Utilizing online resources or forums can also facilitate discussions with other users, enhancing knowledge about the distinct attributes of each model. Engaging with a community can provide invaluable tips and recommendations tailored to specific variants.

How to Access Parts Diagrams

To effectively locate the necessary illustrations for your machine, it’s crucial to know where to search. These visual aids provide essential information regarding components and their arrangements, ensuring proper maintenance and repairs.

Begin by visiting the manufacturer’s official website, where you’ll find a dedicated section for technical resources. Look for links labeled as “support” or “resources.” These sections often house detailed guides and helpful images.

Additionally, consider checking authorized retailers or repair shops, as they may offer manuals and schematics specific to your model. Online forums and communities can also be valuable resources, providing user-shared diagrams and insights.

Finally, ensure you have the model number at hand to streamline your search process. This will help you access the correct illustrations tailored to your equipment.

Ordering Genuine Yamaha Parts

When it comes to maintaining equipment, sourcing authentic components is crucial for optimal performance and longevity. Acquiring original elements ensures compatibility and reliability, ultimately enhancing the overall functionality of your machinery.

Why Choose Authentic Components?

Utilizing genuine elements provides several advantages, including:

- Improved durability and performance

- Perfect fit and compatibility

- Extended lifespan of the equipment

How to Place an Order

Ordering authentic components can be done through various channels. Here’s a simple guide:

| Step | Description |

|---|---|

| 1 | Identify the specific component needed for your machinery. |

| 2 | Visit the official website or authorized dealer. |

| 3 | Provide necessary details, including model and part number. |

| 4 | Confirm your order and choose a suitable payment method. |

| 5 | Track your order until it arrives. |

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and troubleshooting of machinery. Various tools not only streamline the repair process but also enhance safety and efficiency. Below are key instruments that every technician should consider.

Basic Hand Tools

- Wrenches

- Screwdrivers

- Pliers

- Socket Set

Specialized Instruments

- Torque Wrench

- Multimeter

- Diagnostic Scanner

- Grease Gun

Equipping yourself with these essential tools will greatly facilitate the repair process, ensuring that all tasks are completed with precision and care.

Troubleshooting Common Issues

Addressing frequent challenges with your equipment can enhance performance and prolong its lifespan. Understanding the typical problems and their solutions is essential for effective maintenance.

Starting Difficulties

If your machine fails to start, ensure that the fuel is fresh and the spark plug is functioning properly. A clogged fuel line or a dirty air filter can also hinder ignition.

Operational Inefficiencies

Should the device operate inefficiently, check for blockages in the intake or discharge areas. Additionally, inspect the belts and cables for wear or damage, as these can impact overall functionality.

Comparing Aftermarket vs. OEM Parts

When it comes to replacing components for machinery, users often face a choice between two distinct categories: original manufacturers’ offerings and alternatives produced by third parties. Each option carries its own set of advantages and disadvantages, impacting performance, cost, and reliability.

Advantages of Aftermarket Options

- Generally more affordable, allowing for budget-friendly repairs.

- Availability in a wider range of options, catering to various preferences.

- Possibility of enhanced features or improved performance over standard components.

Benefits of Original Equipment Manufacturer Components

- Ensured compatibility with the specific machinery model.

- Higher likelihood of maintaining warranty coverage.

- Consistent quality and reliability from trusted sources.

Ultimately, the decision between these two options depends on individual priorities such as budget constraints, desired performance, and the importance of manufacturer support.

Importance of Regular Inspections

Conducting routine evaluations of equipment is crucial for maintaining optimal performance and extending longevity. Regular assessments help identify potential issues before they escalate into significant problems, ensuring a smooth operation during critical periods.

- Proactive Maintenance: Early detection of wear and tear allows for timely repairs.

- Safety Assurance: Regular checks minimize the risk of accidents or malfunctions.

- Cost Efficiency: Preventative measures can save money by avoiding costly repairs down the line.

- Performance Optimization: Ensures that the equipment operates at peak efficiency.

Incorporating a schedule for consistent evaluations can significantly enhance reliability and functionality, ultimately leading to better performance and reduced downtime.

Upgrades for Improved Performance

Enhancing the functionality of your machine can lead to significant efficiency gains. By incorporating certain enhancements, you can ensure optimal operation, prolong the lifespan of components, and tackle various conditions more effectively.

Essential Enhancements

- Higher capacity engines for increased power output

- Advanced blade technology for better snow handling

- Improved auger designs to reduce clogging

Maintenance Tips for Longevity

- Regularly inspect and replace worn-out components.

- Utilize high-quality lubricants for moving parts.

- Store the equipment properly during off-seasons to prevent damage.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance on machinery is crucial for preventing accidents and injuries. Following certain guidelines can help create a secure environment and promote efficient work practices.

| Precaution | Description |

|---|---|

| Personal Protective Equipment | Always wear gloves, goggles, and sturdy footwear to protect against hazards. |

| Work Area Cleanliness | Keep the workspace organized and free of debris to avoid slips and falls. |

| Power Sources | Disconnect any power sources before starting repairs to prevent accidental activation. |

| Tool Inspection | Regularly check tools for damage and ensure they are in good working condition. |

| Manual Reference | Consult the manufacturer’s guidelines to ensure proper procedures are followed. |