Exploring the intricacies of vehicle navigation involves delving into a complex system designed to facilitate precise movement and handling. This essential mechanism plays a crucial role in ensuring stability and responsiveness while driving. A comprehensive grasp of its components is vital for anyone interested in automotive mechanics or simply seeking to enhance their understanding of how vehicles operate.

Within this framework, various elements work in harmony to enable smooth transitions and adjustments. Each component serves a specific function, contributing to the overall efficiency of directional movement. Understanding these elements not only demystifies the operation but also empowers individuals to engage more effectively with maintenance and troubleshooting.

As we dissect the structure and functionality of these crucial mechanisms, we will uncover the relationships between each element, illustrating how they collectively contribute to an optimal driving experience. With clarity and insight, we aim to illuminate the complexity behind what may seem like a straightforward task–guiding a vehicle along its path.

Understanding Car Steering Systems

The mechanism responsible for guiding vehicles is a complex assembly that ensures smooth navigation and control. By grasping the fundamentals of this system, one can appreciate its critical role in driving safety and responsiveness. Various components work in harmony to translate driver input into precise movements, allowing for effortless maneuvering.

| Component | Function |

|---|---|

| Column | Transmits motion from the driver to the assembly. |

| Rack | Converts rotational movement into linear motion. |

| Pinion | Engages with the rack for directional control. |

| Linkages | Connect various elements for coordinated movement. |

| Hydraulic System | Enhances force application for easier handling. |

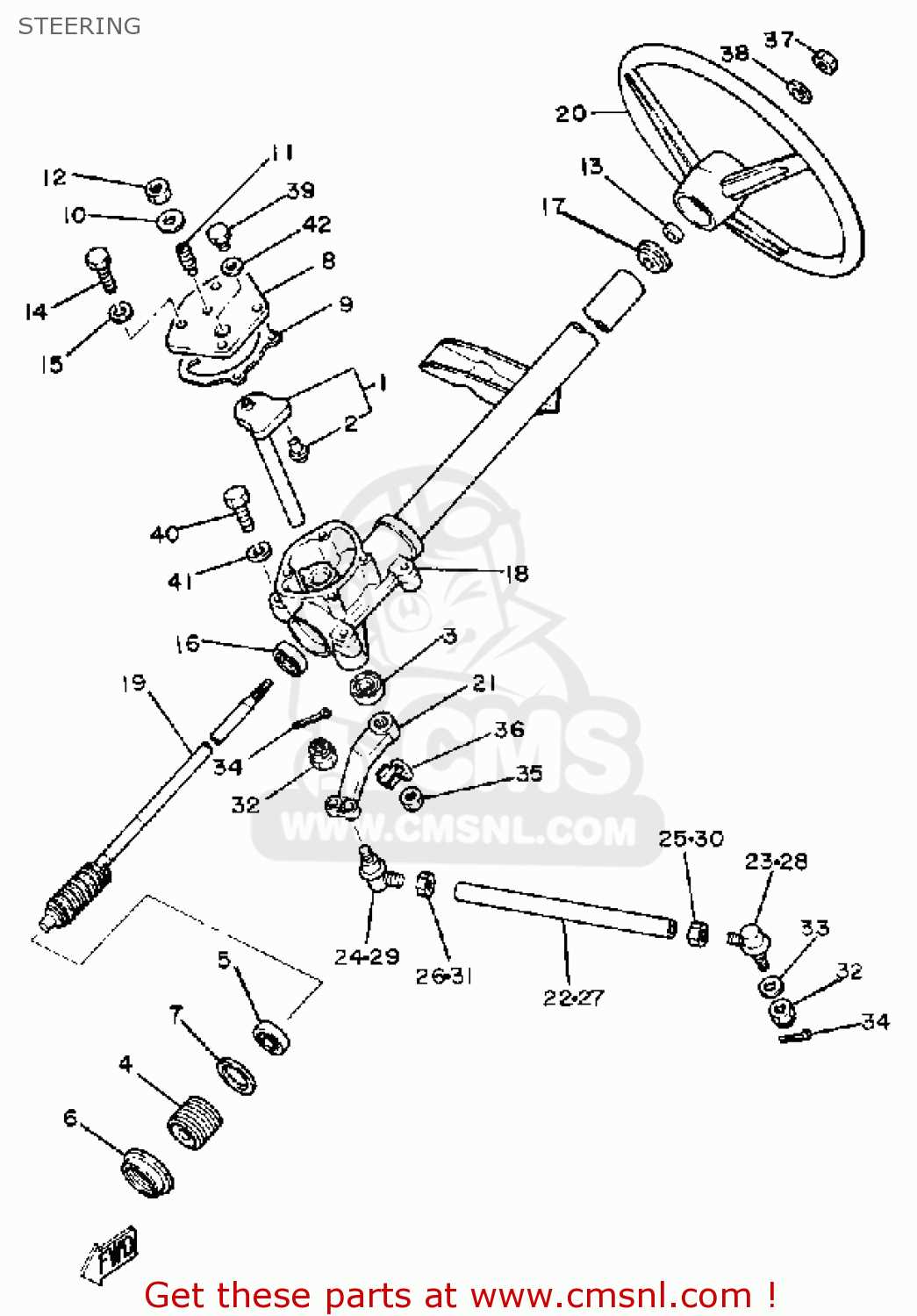

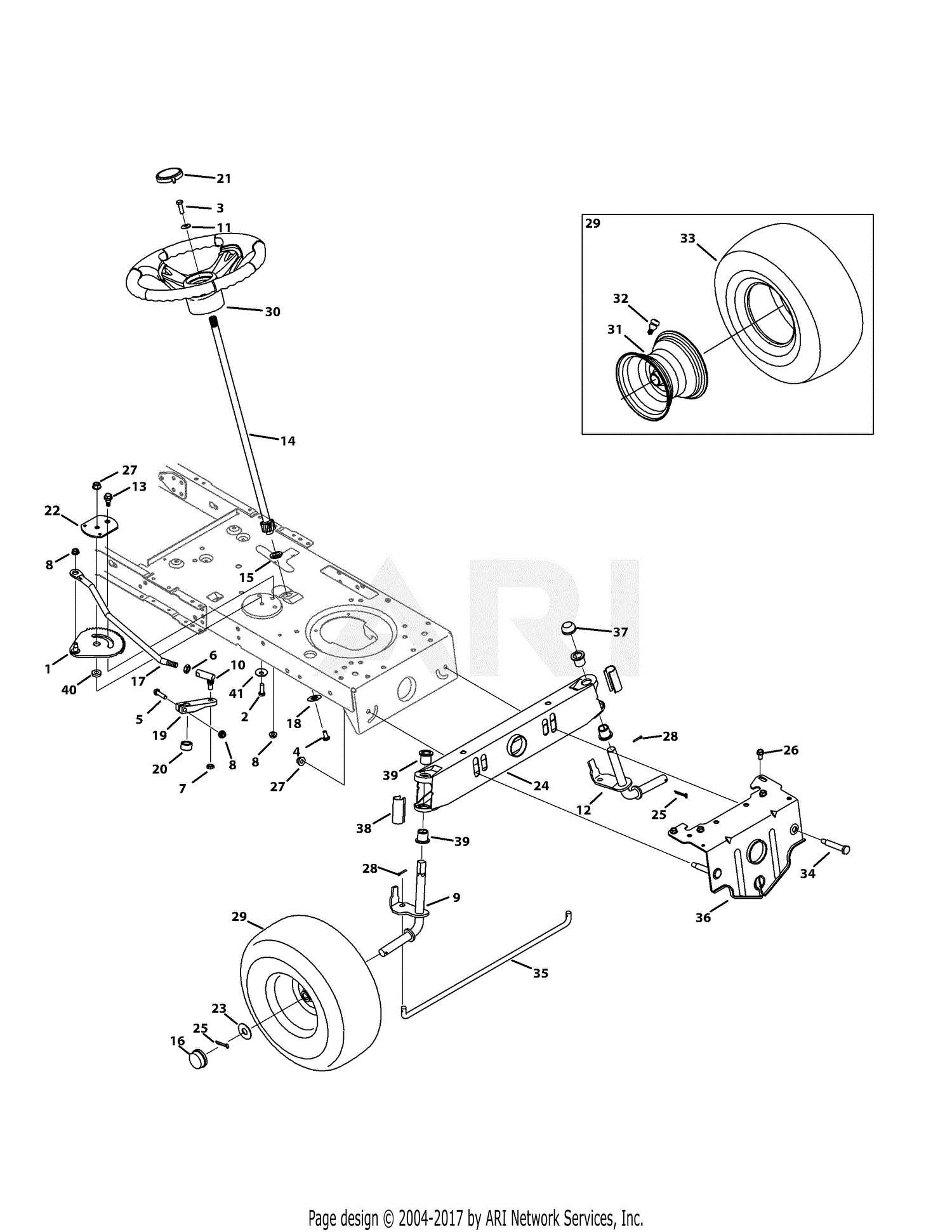

Key Components of Steering Mechanism

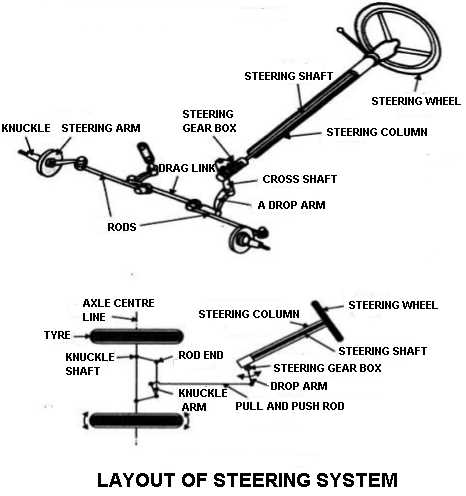

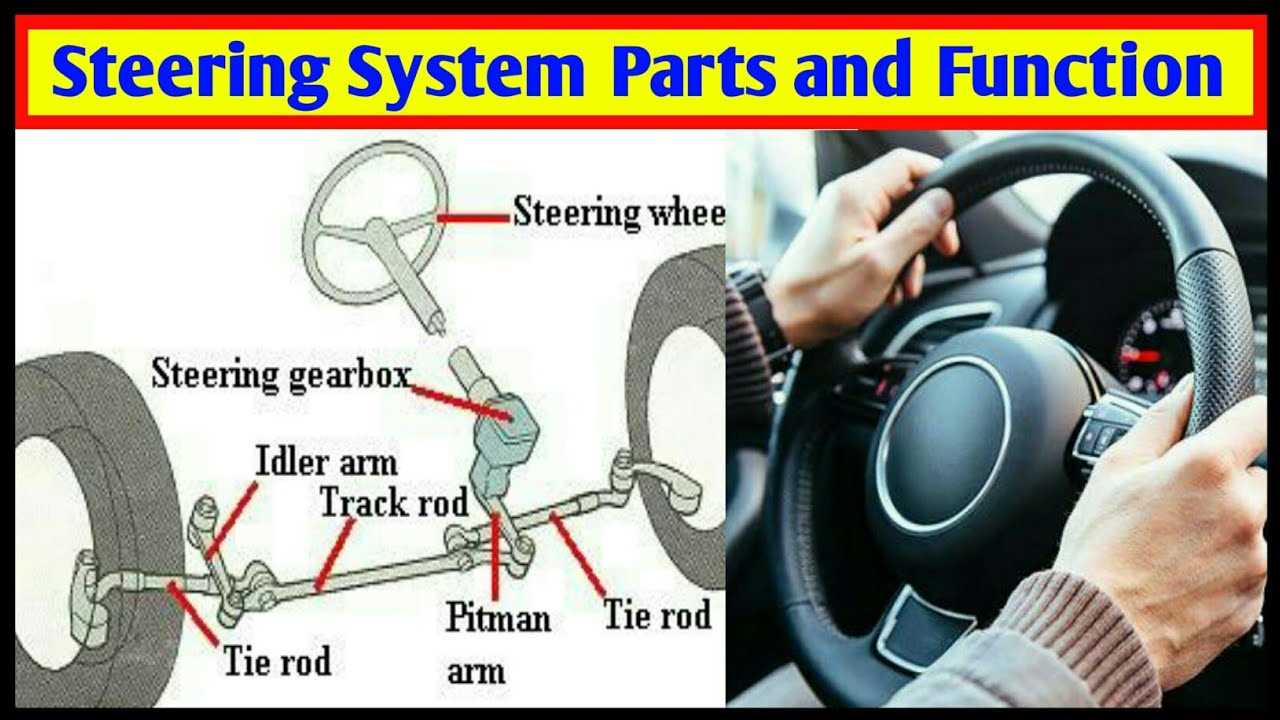

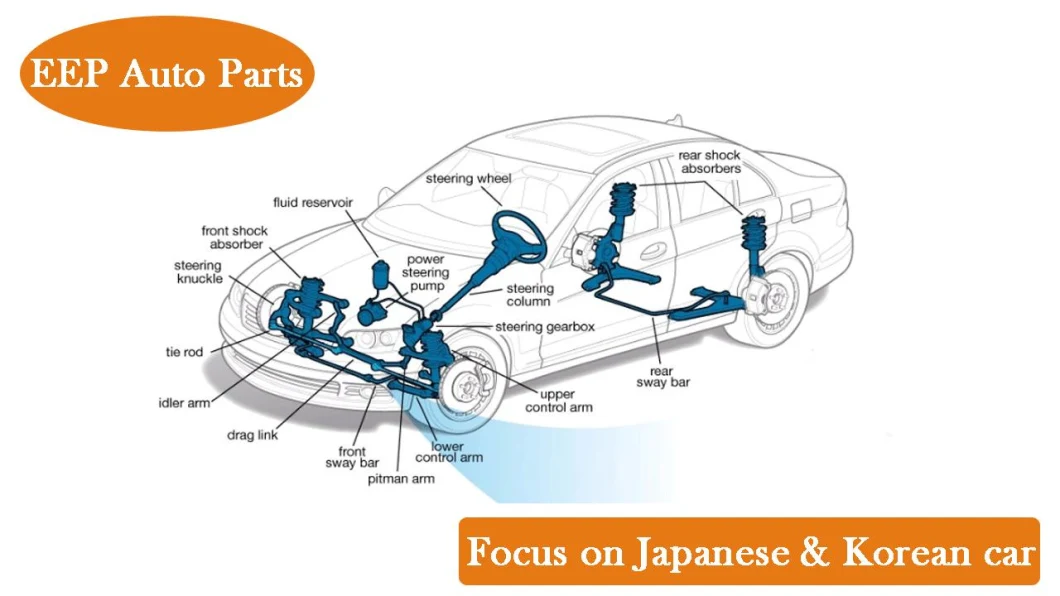

The mechanism that directs vehicle movement consists of various essential elements, each contributing to overall functionality and responsiveness. Understanding these components is crucial for grasping how the system operates effectively under different conditions.

Essential Elements

The following are the primary components that work together to ensure precise control:

| Component | Description |

|---|---|

| Column | Connects the control wheel to the system, allowing for user input. |

| Rack and Pinion | Transforms rotational motion into linear motion, facilitating directional change. |

| Linkage | Transmits motion from the control wheel to the wheels, ensuring accurate response. |

| Power Assist | Enhances effort required for turning, making handling easier. |

Functionality Overview

Each element plays a vital role in ensuring smooth and efficient operation. The interaction between these components determines the responsiveness and precision of the directional control, ultimately affecting the overall driving experience.

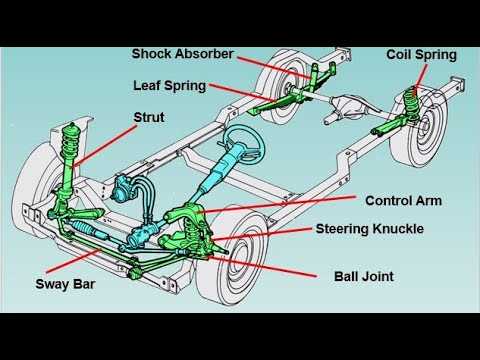

Types of Steering Gear Designs

The design of the mechanism that controls direction is crucial for vehicle performance and handling. Various configurations are employed to achieve precise control and responsiveness, each with its own advantages and applications.

Common Designs

- Rack and Pinion: Utilizes a circular gear that meshes with a linear gear, offering direct feedback and simplicity.

- Recirculating Ball: Features a series of ball bearings that reduce friction, commonly used in heavier vehicles.

- Electric Power Assist: Integrates an electric motor to enhance steering effort, improving efficiency.

Advanced Mechanisms

- Variable Ratio: Adjusts the gear ratio based on the steering angle, providing better control at different speeds.

- Active Steering: Employs electronic systems to alter steering response dynamically, enhancing stability.

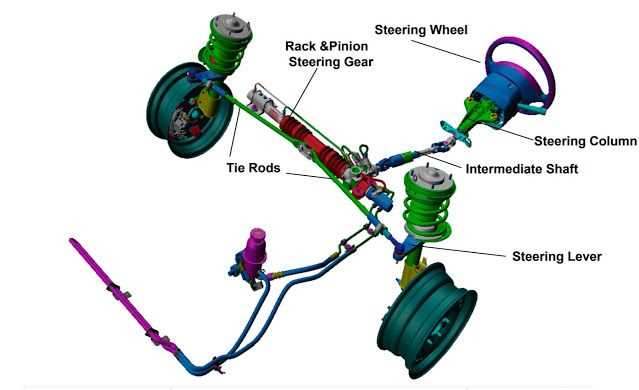

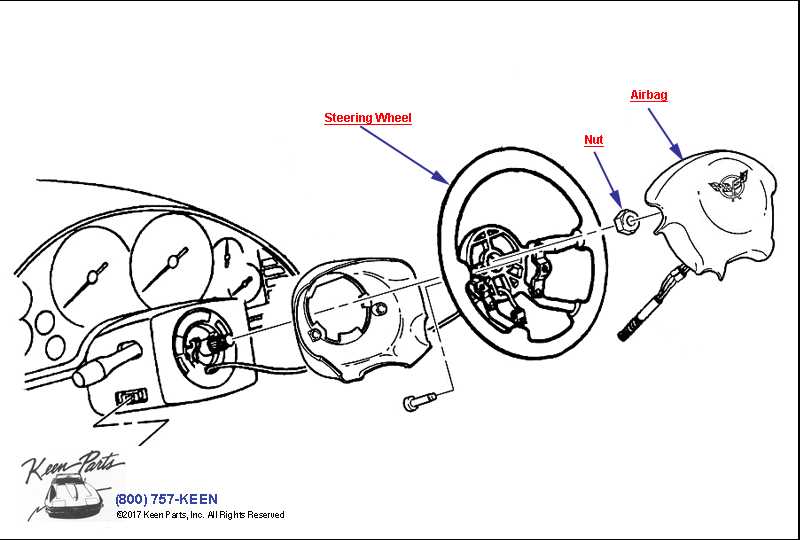

Function of the Steering Column

The steering column plays a crucial role in connecting the driver’s input with the vehicle’s directional control. It serves as the main conduit for the transfer of movement from the driver’s hands to the wheels, ensuring precise navigation and handling. This component is essential for providing stability and responsiveness, allowing the operator to maintain control while maneuvering.

Moreover, the assembly often incorporates various features such as ignition switches and controls for different functions, enhancing the overall user experience. Its design not only focuses on functionality but also prioritizes safety, designed to absorb energy during a collision, thereby protecting the driver and passengers.

In summary, the column is integral for both functionality and safety, influencing the overall driving experience significantly.

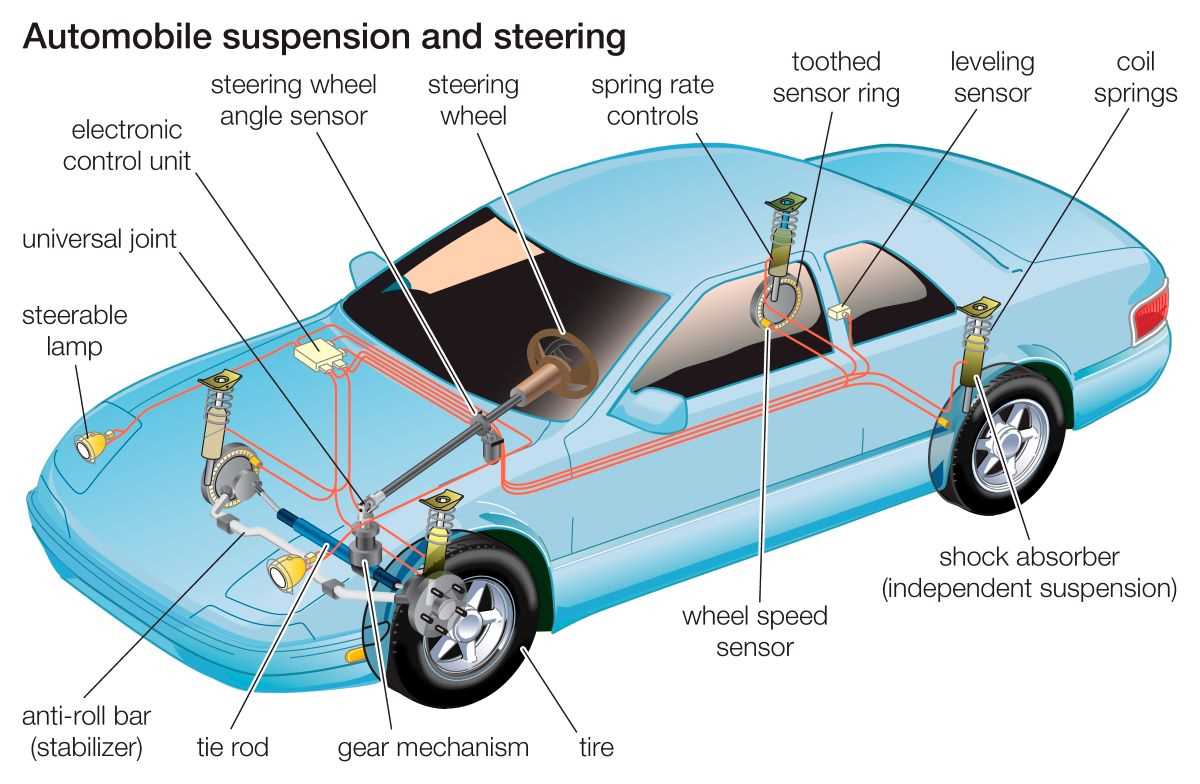

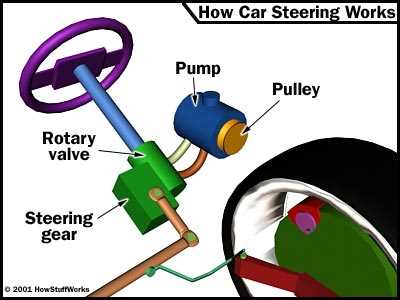

Role of Power Steering Systems

The integration of power-assisted mechanisms has revolutionized the driving experience by enhancing control and comfort. These systems employ advanced technology to facilitate smoother maneuvering, allowing operators to navigate with ease and precision, especially at lower speeds or during tight turns.

Enhancement of Control: By reducing the effort required to turn the wheel, power-assisted systems provide greater stability and responsiveness. This leads to improved handling, making it easier for individuals to maintain directional accuracy in various driving conditions.

Increased Comfort: The reduced physical strain associated with operating the steering wheel minimizes fatigue during long journeys. This comfort factor contributes significantly to overall driver satisfaction and safety.

Furthermore, the incorporation of these systems can positively impact the longevity of the vehicle’s components, as they help mitigate wear and tear on mechanical elements by allowing for more gentle inputs. Ultimately, the role of power assistance is crucial in modern vehicles, blending safety, efficiency, and user-friendly operation.

Steering Rack vs. Steering Box

When it comes to vehicle maneuverability, the mechanisms responsible for guiding the wheels play a crucial role. Two primary systems are commonly utilized, each offering unique characteristics and functionalities that impact performance, responsiveness, and overall driving experience.

Overview of Mechanisms

The first system employs a linear approach, utilizing a rack and pinion setup that translates rotational motion into lateral movement. This design is favored for its direct feedback and efficiency, making it popular in modern vehicles. Conversely, the second system operates through a more complex arrangement, where a gear mechanism converts input into motion. This design has historically been favored for larger vehicles, providing robustness and reliability.

Comparison Table

| Feature | Rack and Pinion | Gear Box |

|---|---|---|

| Design | Simpler, more direct | Complex, multi-gear |

| Responsiveness | Highly responsive | Less responsive |

| Weight | Lightweight | Heavier |

| Usage | Common in modern vehicles | Often found in trucks and SUVs |

| Maintenance | Lower maintenance | Higher maintenance |

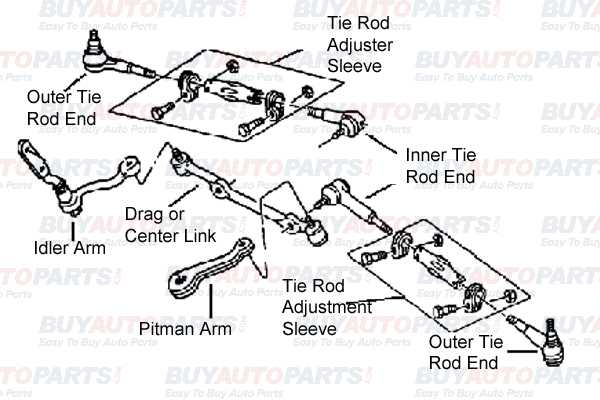

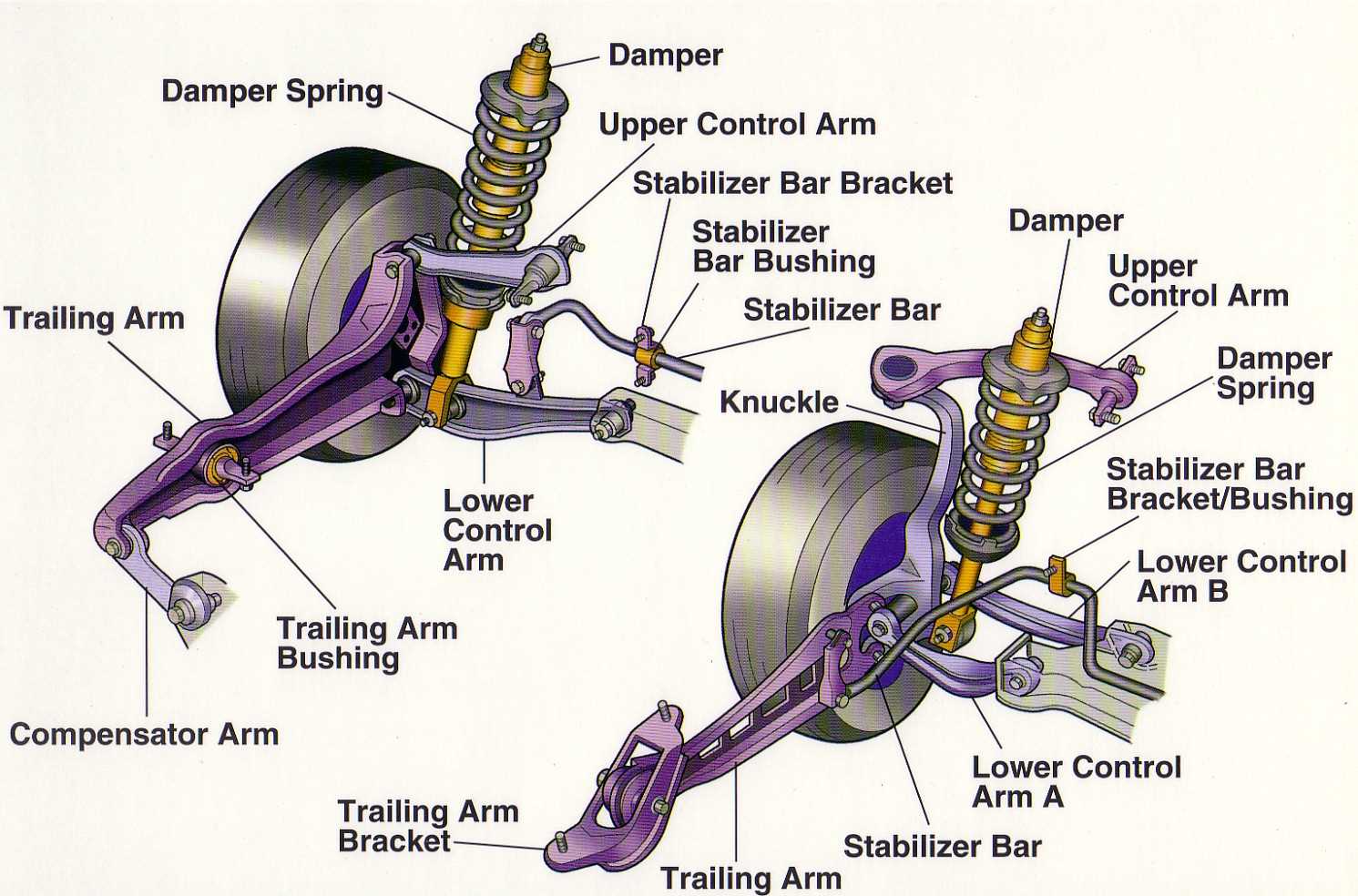

Importance of Steering Linkages

Linkages play a crucial role in ensuring the smooth operation and control of any vehicle. They serve as the connective tissue between various components, allowing for precise maneuvering and stability. Understanding their significance is essential for both safety and performance.

The key functions of linkages include:

- Transmitting forces from the control mechanism to the wheels.

- Facilitating adjustments for optimal handling and response.

- Ensuring that directional changes are executed smoothly.

Neglecting the maintenance and functionality of these linkages can lead to:

- Increased wear on other vehicle components.

- Compromised handling and control, increasing the risk of accidents.

- Higher repair costs due to extensive damage over time.

In summary, maintaining these critical linkages not only enhances the overall driving experience but also ensures safety on the road.

Maintenance Tips for Steering Parts

Regular upkeep of vital components is essential for ensuring optimal performance and safety. Proper attention to these elements can prevent costly repairs and enhance longevity, ultimately contributing to a smoother driving experience.

Routine Inspections

Conduct periodic evaluations of the critical mechanisms to identify wear and tear. Look for signs of damage such as cracks or rust. Early detection is key in maintaining functionality and preventing further issues.

Lubrication and Cleaning

Keep all moving elements lubricated to reduce friction and avoid premature deterioration. Additionally, clean surfaces regularly to remove dirt and debris that can impede performance. A well-maintained system operates more efficiently and reliably.

Diagnosing Steering System Issues

Identifying problems within the control mechanism of a vehicle can be crucial for safety and performance. Understanding the symptoms and conducting a thorough examination will enable drivers to pinpoint underlying issues effectively. This section explores key indicators and methods to assess the condition of the system.

Noises during operation often signal potential trouble. Unusual sounds, such as grinding or whining, can suggest wear or a need for lubrication. Vibration felt in the handling can indicate misalignment or damage, affecting overall maneuverability.

Another common issue involves fluid leaks. Observing any puddles or stains beneath the vehicle can point to failing seals or hoses, requiring immediate attention. Additionally, checking fluid levels can provide insights into the health of the entire mechanism.

Lastly, responsive behavior during turns should be evaluated. If the vehicle feels unsteady or if excessive play is present in the control mechanism, a closer inspection is necessary to ensure safety and reliability.

Common Steering Component Replacements

Maintaining the optimal function of your vehicle’s navigation system is essential for safe driving. Over time, certain components may wear out or become less effective, necessitating timely replacements to ensure smooth handling and control. This section explores the most frequently replaced elements within the system, highlighting their importance and signs of potential failure.

Ball Joints: These crucial connections allow for flexibility in movement. Regular inspections can reveal signs of wear, such as noise or looseness, indicating it’s time for a replacement.

Tie Rod Ends: These links transmit forces from the steering mechanism to the wheels. If you notice uneven tire wear or steering play, it might be an ultimate sign that these parts need to be replaced.

Rack and Pinion: This assembly converts rotational motion into linear motion, making it vital for precise maneuvering. Any leakage or difficulty in turning can suggest that replacement is necessary.

Power Steering Pump: This component provides the hydraulic pressure needed for effortless steering. If you hear whining noises or experience sluggish response, consider replacing the pump.

Steering Column: This structure supports the wheel and houses various mechanisms. Issues like wobbling or difficulty in adjustment can signal that it’s time for a replacement.

Impact of Steering on Vehicle Control

The mechanism that allows a driver to guide their vehicle plays a crucial role in overall maneuverability and safety. Proper functionality of this system directly influences how a vehicle responds to the driver’s inputs, affecting stability and handling across various driving conditions.

Key Factors Influencing Control

- Response Time: Quick feedback from the mechanism enhances the driver’s ability to react to unexpected situations.

- Precision: Accurate movement ensures that the vehicle follows the intended path, minimizing overcorrection.

- Feedback: Sensory feedback helps the driver gauge road conditions and vehicle dynamics, improving decision-making.

Consequences of Malfunction

- Increased Risk: Poor functionality can lead to loss of control, particularly during emergency maneuvers.

- Uneven Tire Wear: A malfunctioning system may cause uneven distribution of forces on tires, affecting their longevity and performance.

- Driver Fatigue: Excessive effort required to manage a poorly functioning mechanism can lead to fatigue, further impairing control.

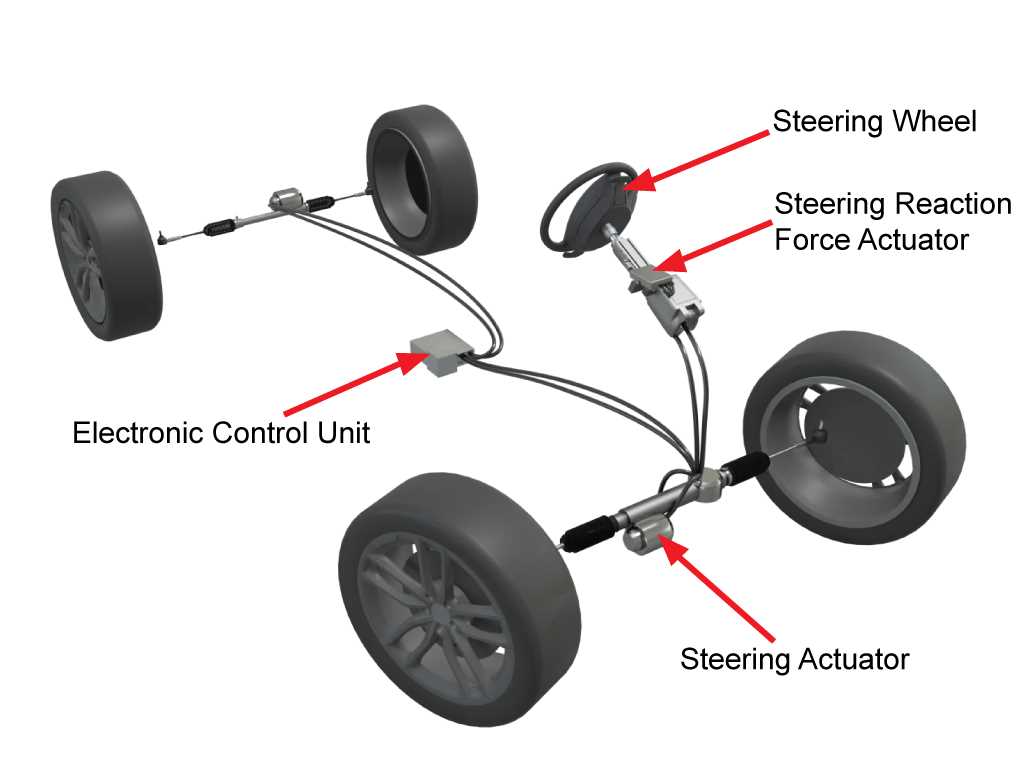

Future Innovations in Steering Technology

As the automotive industry evolves, the mechanisms that allow for directional control are poised for significant advancements. The focus is shifting towards enhancing precision, safety, and user experience through innovative technologies. These emerging solutions aim to redefine how operators interact with their vehicles, offering a glimpse into a more automated and responsive future.

Key areas of innovation include:

- Electromechanical Systems: Utilizing electric motors for improved responsiveness and reduced weight.

- Adaptive Control: Systems that adjust based on driving conditions and user preferences for optimized handling.

- Haptic Feedback: Incorporating tactile responses to enhance the connection between the operator and the vehicle’s dynamics.

- Autonomous Navigation: Integrating AI to allow for hands-free operation and seamless navigation through complex environments.

- Smart Materials: Employing advanced composites that adapt to varying loads and enhance durability.

In addition to these advancements, safety features are expected to become more sophisticated, integrating real-time data analytics to predict and mitigate potential hazards. The goal is to create a holistic driving experience that is both intuitive and secure.

As these technologies continue to develop, the future of vehicle directional control promises not only enhanced performance but also a transformative shift in how individuals engage with their transportation modes.