Every lawn care enthusiast knows the importance of a well-functioning machine. A crucial aspect of maintaining optimal performance lies in comprehending the intricate mechanisms that allow for precise navigation. This section delves into the essential elements that contribute to the overall functionality of your garden vehicle.

Exploring the Inner Workings of the control system provides valuable insights into how different components interact. Familiarity with these mechanisms can enhance both efficiency and safety while operating your equipment. By gaining a clear perspective on each segment, operators can identify potential issues before they escalate.

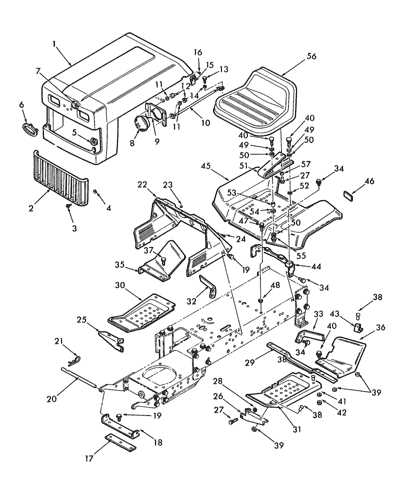

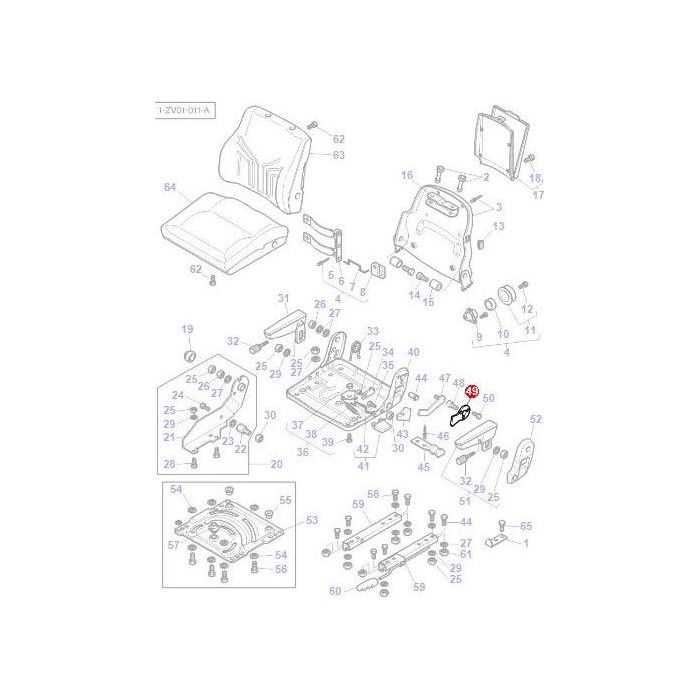

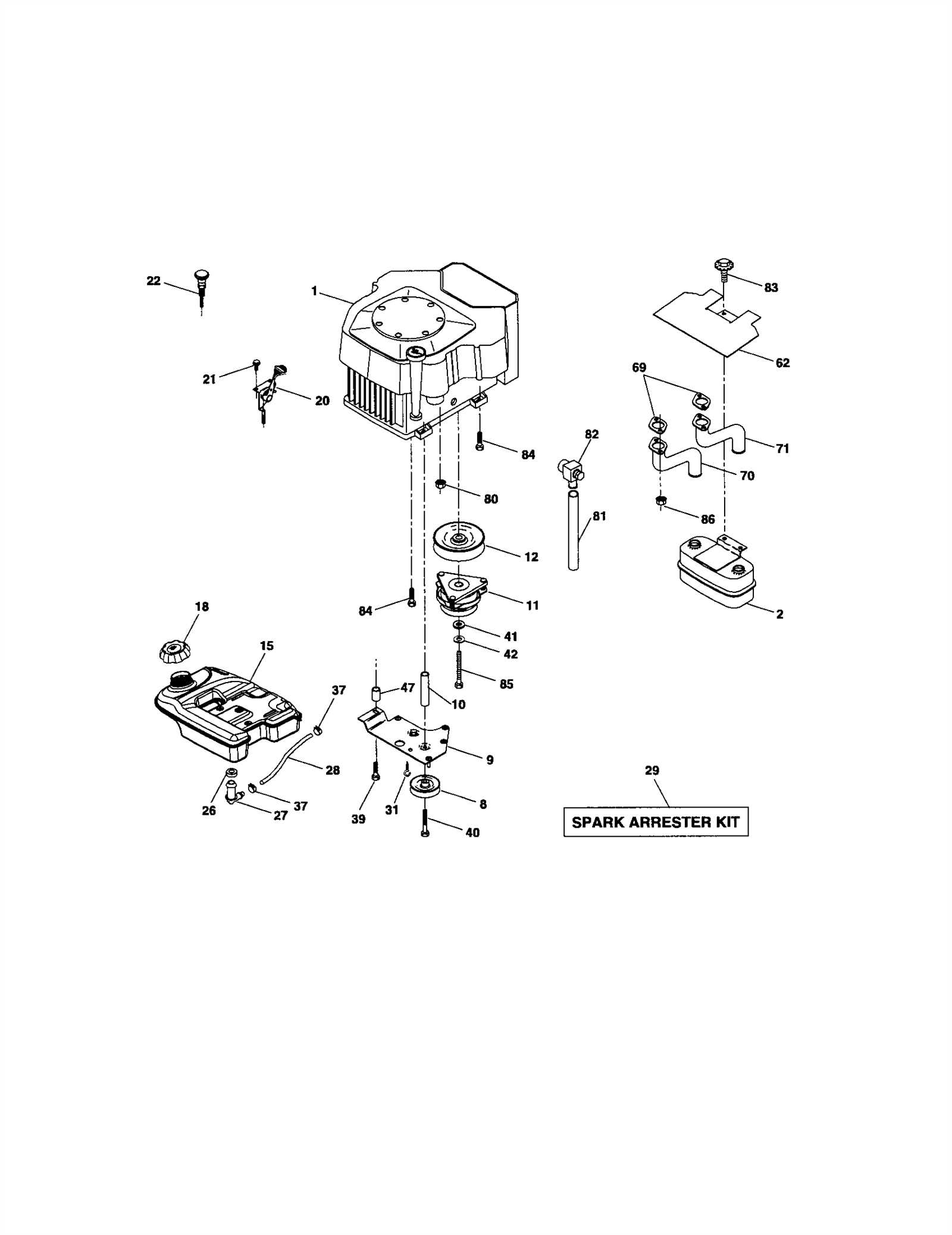

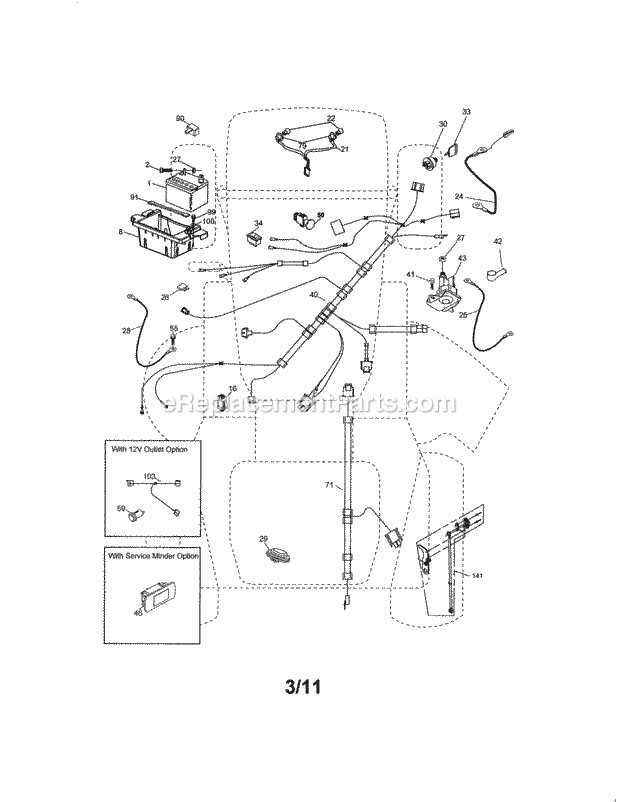

Visual aids play a significant role in understanding complex assemblies. Having a clear representation can simplify the troubleshooting process, enabling users to pinpoint discrepancies quickly. A thorough grasp of the layout and connections ensures a smoother maintenance experience, ultimately prolonging the life of the machinery.

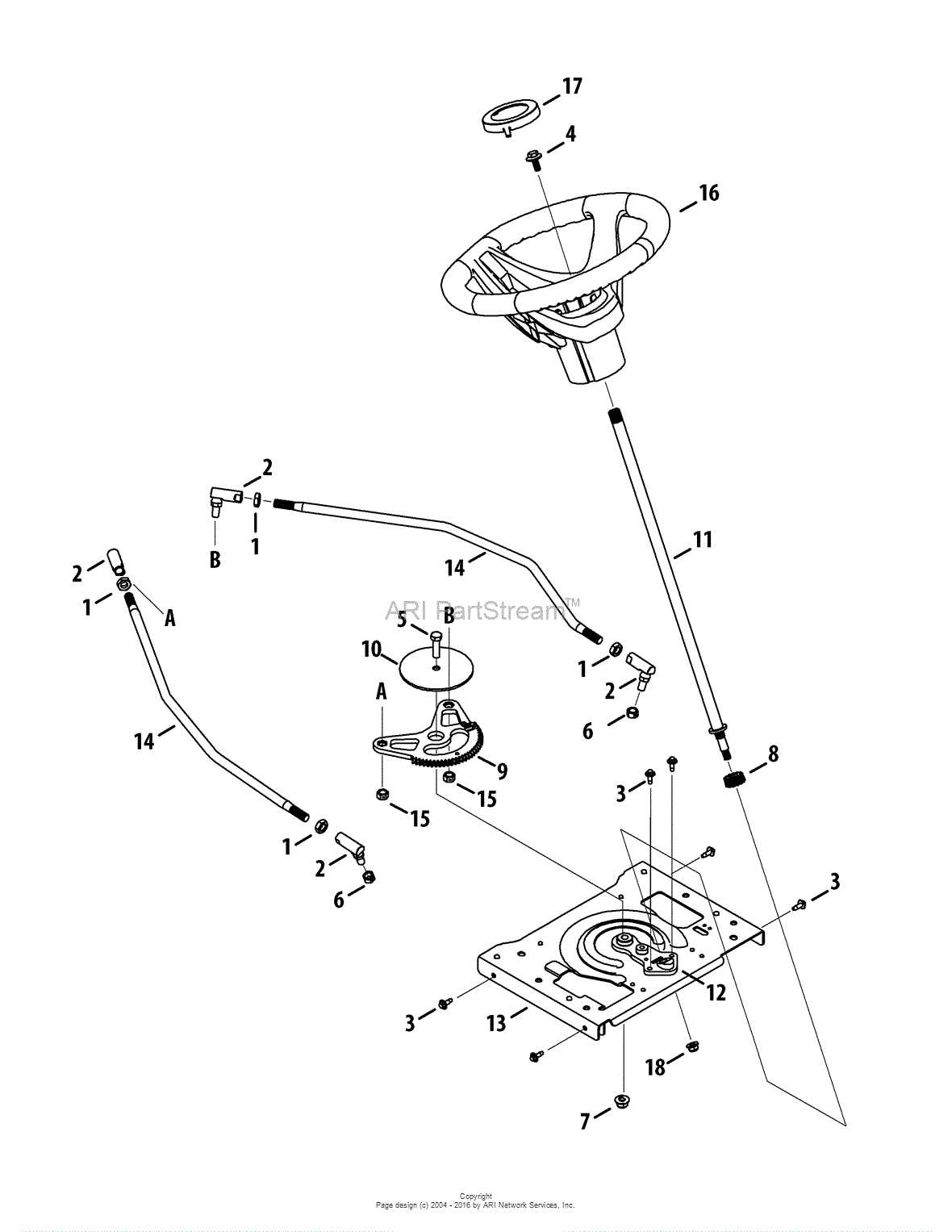

Understanding Craftsman GT5000 Steering System

The maneuvering mechanism of riding mowers plays a crucial role in ensuring smooth operation and precise navigation across various terrains. This system is designed to provide the operator with excellent control and responsiveness, making it easier to handle the machine effectively. A clear comprehension of how this mechanism functions is essential for proper maintenance and troubleshooting.

At the core of this system lies a combination of components that work in harmony to facilitate directional movement. Each element contributes to the overall efficiency, from the pivotal linkages that connect the control interface to the wheels, to the adjustment features that allow for fine-tuning. Understanding the relationship between these components can significantly enhance performance and user experience.

Regular inspection and maintenance of the maneuvering system are vital to ensure longevity and optimal functionality. Identifying wear and tear or any misalignments early on can prevent more significant issues down the line. By familiarizing oneself with the operational principles and maintenance requirements, users can keep their machines running smoothly for years to come.

Importance of Steering Parts in Lawn Tractors

The functionality and efficiency of lawn care machinery significantly depend on the components that facilitate directional control. These elements are crucial for maneuvering and ensure a smooth operation, allowing users to navigate various terrains effectively. Understanding their role can enhance maintenance practices and overall performance.

Enhancing Maneuverability

Precision in navigation is vital for achieving an even cut and maintaining the aesthetics of lawns. Quality directional components contribute to enhanced maneuverability, enabling operators to easily handle obstacles and navigate tight spaces. This precision reduces the risk of damage to the turf and minimizes the time spent on maintenance tasks.

Safety and Stability

Reliability in directional control is essential for safe operation. Well-functioning components contribute to stability, reducing the likelihood of accidents caused by unexpected movements. Regular inspection and timely replacement of these elements not only enhance safety but also prolong the lifespan of the equipment, ensuring it remains a dependable tool for lawn care.

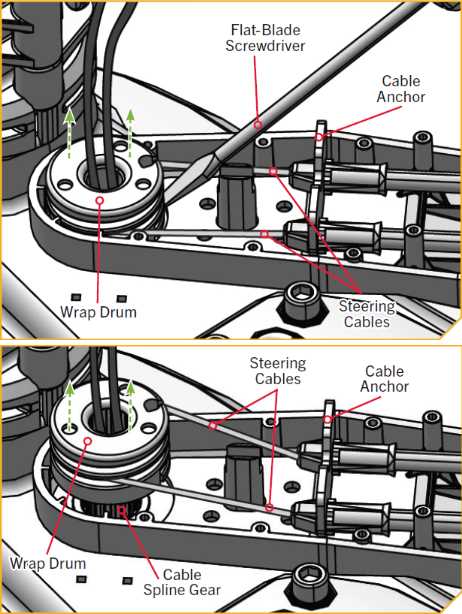

Identifying Key Components of Steering Assembly

Understanding the essential elements of the directional control system is crucial for effective maintenance and troubleshooting. Each component plays a significant role in ensuring smooth maneuverability and stability, contributing to the overall performance of the machinery. By familiarizing oneself with these elements, users can better manage and resolve any issues that may arise.

Main Elements of the Direction Control System

The directional control mechanism comprises several integral parts that work in unison. Each element has a specific function, and recognizing them can help in diagnosing potential problems.

| Component | Function |

|---|---|

| Wheel Assembly | Facilitates movement and provides traction. |

| Linkage System | Connects various components, translating motion. |

| Pivot Points | Allows rotation and maneuverability. |

| Control Arm | Enables precise adjustments to the directional path. |

| Bearings | Reduces friction, ensuring smooth operation. |

Importance of Each Element

Every component has a distinct impact on the efficiency of the directional control system. Regular inspections and maintenance of these elements are essential to prevent breakdowns and enhance the lifespan of the equipment. Understanding their functions allows for timely interventions and informed repairs.

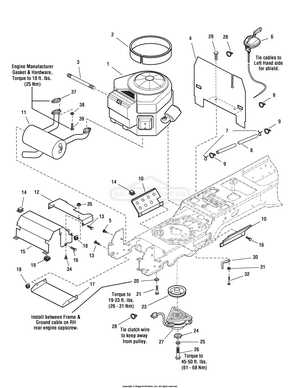

Common Issues with GT5000 Steering Mechanism

The operation of a riding mower’s directional system can encounter various challenges that affect performance and user experience. Understanding these common problems is essential for effective maintenance and repair.

Wear and Tear

Over time, components may suffer from fatigue due to frequent use. This can lead to decreased responsiveness and potential misalignment. Regular inspection and timely replacement of worn-out elements are crucial for optimal functionality.

Improper Lubrication

Insufficient lubrication can result in increased friction, leading to difficulties in maneuvering. Ensuring that all moving components are well-lubricated can help maintain smooth operation and prolong the lifespan of the mechanism.

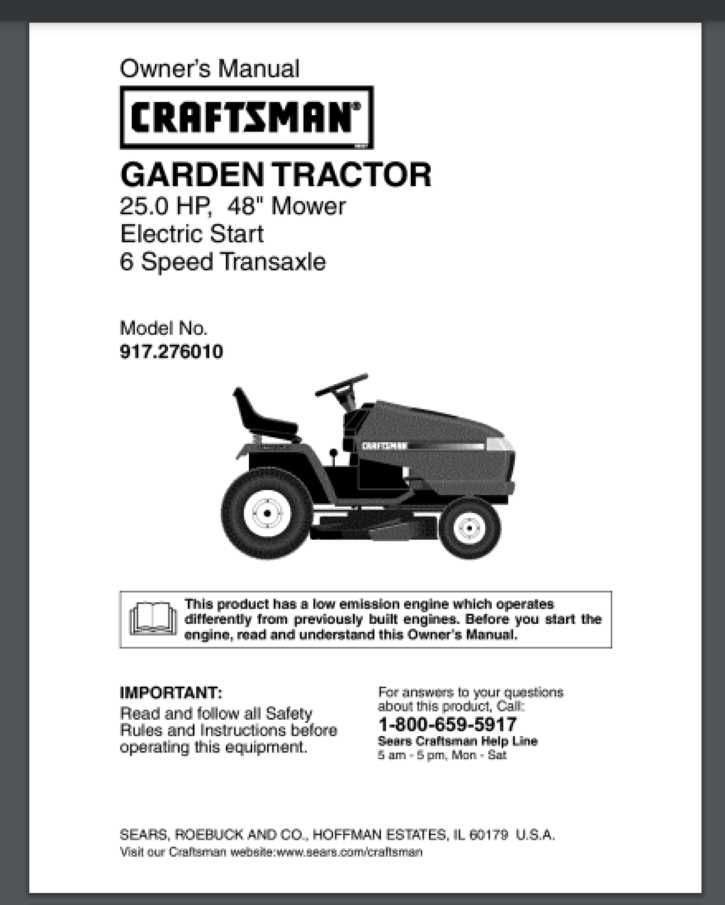

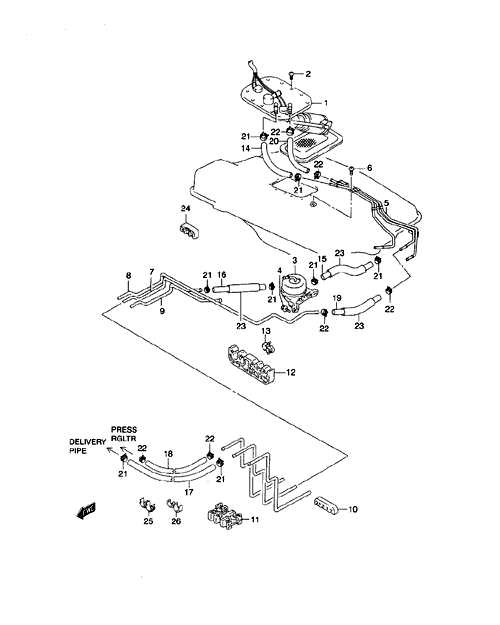

How to Access Steering Parts Diagram

Understanding the layout and components of your machine’s control system is essential for effective maintenance and repair. By having a visual reference, you can easily identify and troubleshoot issues, ensuring your equipment functions optimally. This guide will help you locate and utilize a visual reference for the components involved in steering mechanisms.

Finding the Reference

To start, check the manufacturer’s official website or customer support resources. Many brands provide downloadable manuals or schematics in their product sections. Search using the model number, and look for sections dedicated to repairs or maintenance. You may also find helpful resources in online forums or community groups where enthusiasts share tips and diagrams.

Utilizing Online Resources

Another effective approach is to explore specialized websites that focus on machinery repair. These platforms often host a variety of visual references that can be accessed for free or through a subscription. Utilizing these resources allows for a deeper understanding of the assembly and functionality of the steering system.

Maintenance Tips for Steering Components

Ensuring the longevity and functionality of directional control systems is crucial for optimal performance. Regular upkeep not only enhances safety but also improves maneuverability and responsiveness. Below are essential recommendations for maintaining these critical components.

Regular Inspections

Conduct routine evaluations of the control mechanism. Look for signs of wear, such as cracks, rust, or any unusual noises during operation. Early detection of issues can prevent more extensive damage and costly repairs.

Lubrication Practices

Proper lubrication is vital for smooth operation. Utilize high-quality grease or oil as recommended in the manufacturer’s guidelines. Ensure that all moving elements are adequately coated to reduce friction and extend their lifespan. Reapply lubricant periodically to maintain optimal performance.

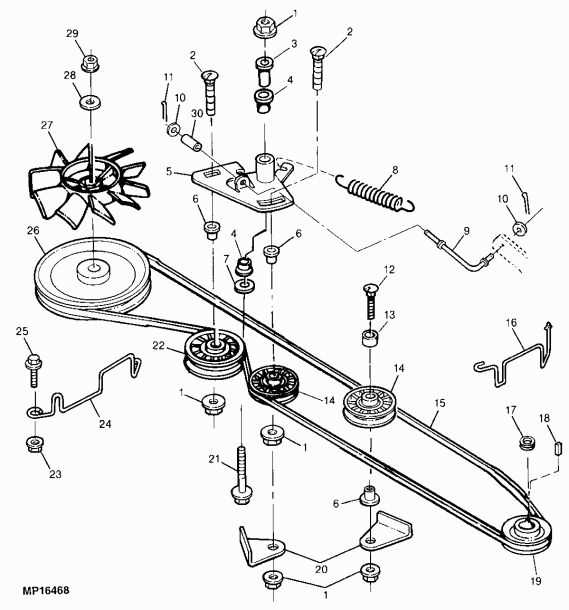

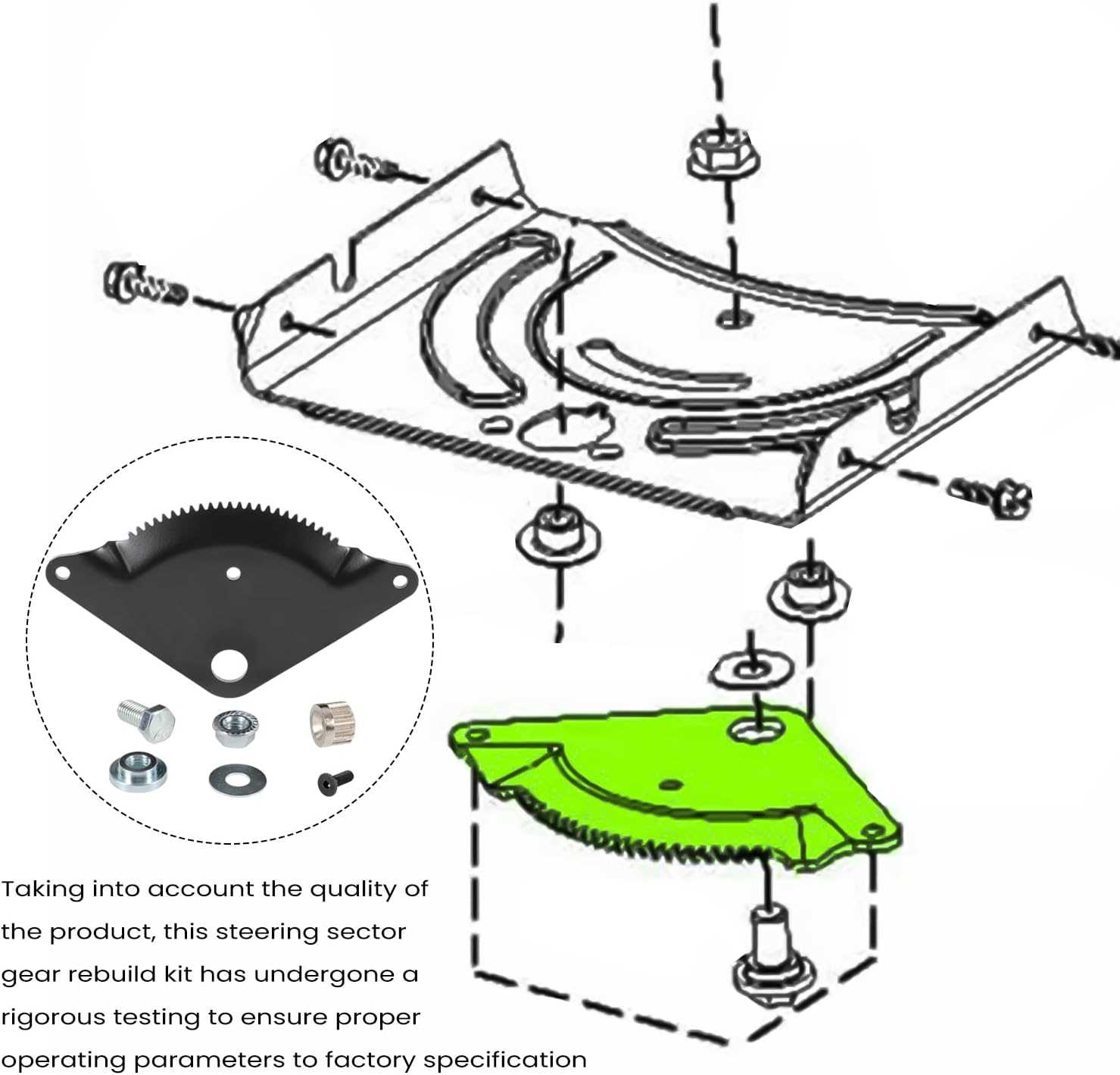

Replacing Worn-Out Steering Parts

Maintaining the functionality of your vehicle’s directional control system is crucial for safety and performance. Over time, components may degrade, leading to decreased responsiveness and handling. Regular inspection and timely replacement can enhance maneuverability and ensure a smoother driving experience.

Signs of Wear

- Difficulty in turning or maneuvering

- Unusual noises during operation

- Excessive play in the control mechanism

- Visible damage or corrosion on components

Replacement Steps

- Gather necessary tools and replacement components.

- Safely lift and secure the vehicle.

- Remove the damaged component carefully.

- Install the new component, ensuring proper alignment.

- Test the system for functionality before returning to normal use.

Tools Required for Steering Repairs

When it comes to fixing directional control systems, having the right tools at your disposal is crucial. A well-equipped workspace can significantly streamline the repair process, ensuring efficiency and accuracy. Below is a list of essential equipment needed for effective repairs in this area.

Essential Hand Tools

- Wrenches (adjustable and socket)

- Screwdrivers (flathead and Phillips)

- Pliers (needle-nose and standard)

- Torque wrench

- Hammer (rubber and steel)

Specialized Equipment

- Ball joint separator

- Gear puller

- Alignment tool

- Measuring tape

- Hydraulic jack

Having these tools will not only facilitate the repair tasks but also help in ensuring the safety and longevity of the system being worked on.

Safety Precautions During Repairs

When undertaking maintenance tasks, ensuring safety should always be a priority. Proper precautions not only protect the individual performing the work but also safeguard the equipment being repaired. Adhering to specific guidelines can significantly reduce the risk of accidents or injuries.

Essential Safety Measures

- Wear appropriate personal protective equipment (PPE) such as gloves, goggles, and masks.

- Ensure the work area is well-lit and free from clutter.

- Disconnect the power source before beginning any repairs.

- Use tools correctly and check them for any defects before use.

- Keep a fire extinguisher nearby in case of emergencies.

Additional Tips

- Read the user manual for specific safety instructions.

- Work with a partner when handling heavy components.

- Store hazardous materials in labeled containers.

- Maintain a first aid kit accessible at all times.

Finding Genuine Replacement Parts

When it comes to maintaining outdoor machinery, sourcing authentic components is crucial for optimal performance and longevity. Ensuring that you use the right elements not only enhances functionality but also safeguards your investment. This section delves into the importance of acquiring reliable substitutes and provides guidance on how to do so effectively.

Quality Assurance: One of the primary benefits of selecting original components is the assurance of quality. Genuine items are designed specifically for your equipment, ensuring a perfect fit and compatibility. This minimizes the risk of malfunctions that can arise from inferior substitutes.

Where to Look: Start your search at authorized dealers and reputable retailers that specialize in outdoor equipment. Many manufacturers also have official websites where you can directly purchase original components. Always verify the authenticity of the seller to avoid counterfeit items.

Understanding Part Numbers: Familiarize yourself with part numbers associated with your machine. This knowledge will help you locate the correct replacements swiftly. Each number corresponds to a specific item, making your search more efficient.

Consulting Manuals: Reference the owner’s manual or service guide for detailed information about required components. These documents often include valuable insights into compatibility and installation procedures, facilitating a smoother replacement process.

Seeking Professional Advice: If you’re uncertain about which component to choose, consider consulting a professional technician. Their expertise can guide you towards the right selections and provide installation assistance if needed.

Comparing GT5000 with Other Models

This section explores the distinctions and similarities among various models within the same category. By analyzing their features, performance, and design, we aim to provide insights into how each unit stands in relation to the others.

Feature Overview

| Model | Engine Power | Cutting Width | Weight |

|---|---|---|---|

| Model A | 20 HP | 42 inches | 500 lbs |

| Model B | 22 HP | 46 inches | 550 lbs |

| Model C | 24 HP | 48 inches | 600 lbs |

Performance Comparison

When assessing the overall effectiveness, several factors such as maneuverability, durability, and maintenance ease come into play. Each model presents unique strengths, making them suitable for different user needs and environments.

Upgrading Steering for Enhanced Performance

Improving the control and handling of your machinery can significantly enhance its overall efficiency and user experience. By focusing on specific components, you can achieve greater responsiveness and stability, allowing for smoother operation in various conditions.

Key Components to Consider

Prioritize elements such as the wheel mechanism and linkages. Upgrading to high-quality materials can reduce wear and enhance durability. Additionally, incorporating adjustable features allows for personalized handling that caters to your specific needs.

Benefits of Enhanced Control

Better handling translates to improved maneuverability, making tasks easier and more enjoyable. Enhanced precision reduces fatigue and increases safety, enabling users to work with confidence and efficiency in diverse environments.