The intricate system responsible for guiding a vehicle’s movement consists of numerous elements working in harmony. Each component plays a vital role in ensuring smooth navigation, enhancing both safety and performance on the road.

For enthusiasts and professionals alike, familiarizing oneself with these mechanisms can greatly improve maintenance practices. A detailed visual representation of these components allows for a deeper appreciation of their function and interrelation.

In this section, we will delve into the essential items involved in directional control, highlighting their ultimate importance in vehicle operation. This knowledge not only aids in repairs but also fosters a greater understanding of automotive engineering.

Understanding F350 Steering Components

Grasping the intricacies of vehicle control mechanisms is essential for optimal performance and safety. This segment delves into the fundamental elements that facilitate directional guidance in heavy-duty vehicles, ensuring both driver comfort and vehicle stability.

Key components involved in this system include:

- Column Assembly: This element houses the control mechanisms and connects the driver’s input to the system.

- Linkages: These rods and connectors transfer motion and force from the column to the wheels.

- Box Mechanism: This crucial component transforms rotational motion into lateral movement, aiding in maneuverability.

- Control Arms: These arms support the wheel assembly and allow for movement while maintaining alignment.

- Knuckles: These joints enable the wheels to pivot, facilitating turns and curves.

Each of these elements plays a significant role in achieving precise control and responsiveness. Regular maintenance and understanding of these components can significantly enhance the overall driving experience.

Key Parts of the Steering System

The mechanism that directs a vehicle’s movement is composed of several essential components, each playing a vital role in ensuring smooth navigation and control. Understanding these elements is crucial for maintaining optimal functionality and performance.

Essential Components

Among the primary elements are those that facilitate the transfer of motion from the driver to the wheels. These components work together to create a responsive system that enhances driving experience and safety.

| Component | Description |

|---|---|

| Column | Connects the steering wheel to the gear mechanism, allowing for directional changes. |

| Gearbox | Transforms the rotational motion of the wheel into lateral movement, influencing the angle of the wheels. |

| Linkage | Transfers movement from the gearbox to the wheels, ensuring accurate turning and alignment. |

| Power Assist | Enhances steering effort, making it easier to maneuver, especially at low speeds. |

Maintenance Considerations

Regular inspection and maintenance of these key components are essential for prolonging the lifespan of the system. Addressing wear and tear promptly can prevent larger issues, ensuring a safe and enjoyable driving experience.

Importance of Proper Steering Alignment

Ensuring accurate directional control is essential for any vehicle’s performance and safety. When the alignment of the guiding mechanism is off, it can lead to a multitude of issues, affecting handling, tire wear, and overall driving experience.

Correct alignment directly influences how the vehicle responds to driver inputs. If the wheels are not properly oriented, the vehicle may pull to one side, making it challenging to maintain a straight path. This not only causes driver fatigue but can also increase the risk of accidents, especially in adverse weather conditions.

Furthermore, misalignment can lead to uneven tire wear, significantly reducing the lifespan of the tires. This not only results in additional costs for replacements but can also compromise traction and stability, impacting the vehicle’s ability to perform optimally.

Regular checks and adjustments are crucial for maintaining proper alignment, contributing to improved fuel efficiency and a smoother ride. Investing in this aspect of vehicle maintenance is vital for ensuring long-term functionality and safety on the road.

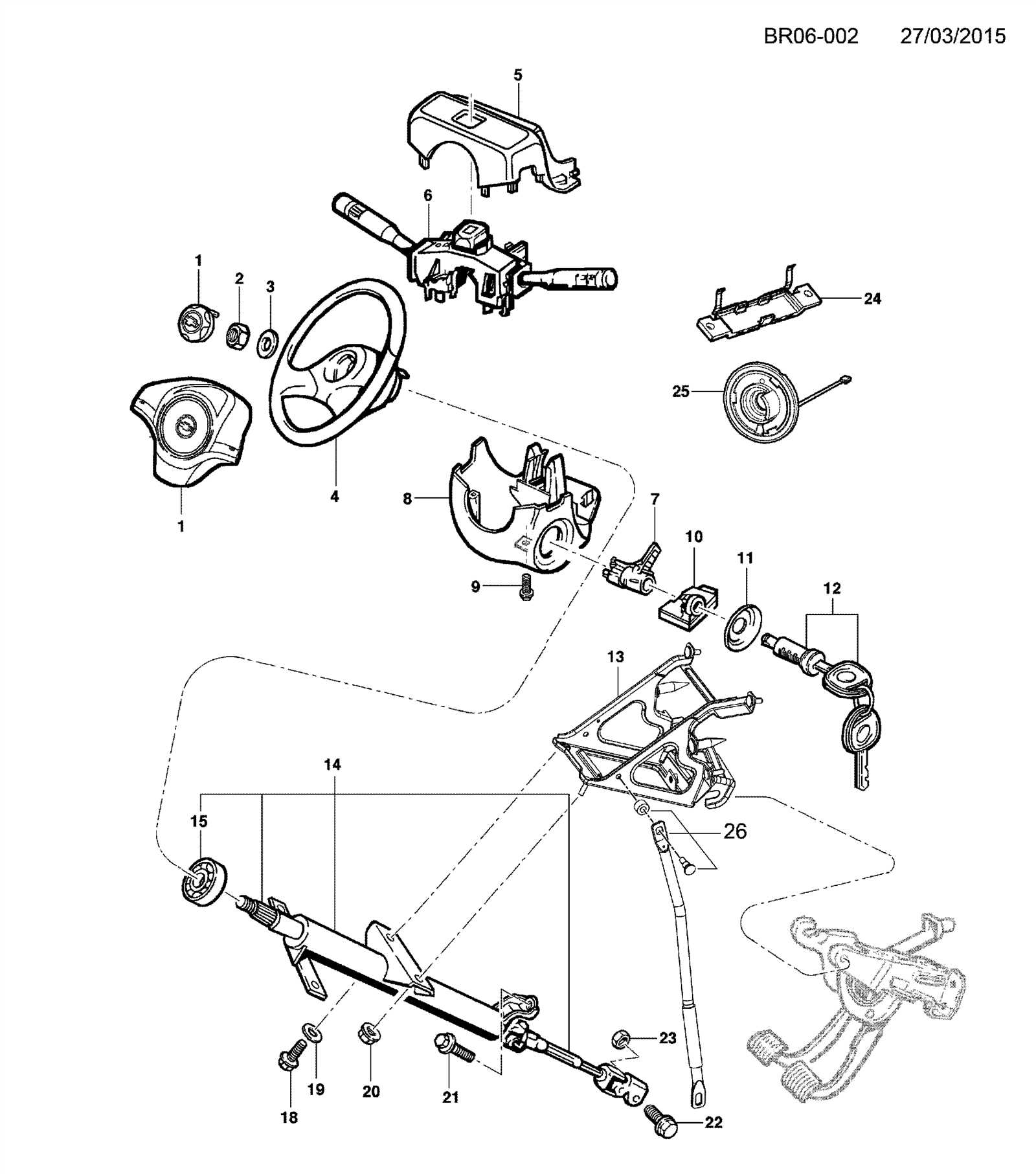

How to Read a Steering Diagram

Understanding a visual representation of a vehicle’s control system is essential for maintenance and repair. This guide will help you navigate the components and their interconnections effectively.

- Identify Symbols: Familiarize yourself with common symbols used in the illustration. Each symbol represents a specific element.

- Trace Connections: Follow the lines that connect various elements. These indicate how components interact with one another.

- Refer to the Legend: Utilize the legend or key, if available, to decode any unfamiliar markings.

- Check Flow Directions: Pay attention to arrows that indicate the flow or movement within the system.

- Understand Functions: Research the role of each part to grasp its significance in the overall mechanism.

By mastering these steps, you will ultimately enhance your ability to troubleshoot and maintain your vehicle’s control system.

Common Issues with Steering Parts

Understanding frequent complications associated with directional control components is crucial for maintaining vehicle performance and safety. These issues can lead to significant handling problems, affecting both comfort and control while driving. Identifying symptoms early can help in addressing them effectively.

Wear and Tear

One of the most prevalent problems stems from regular usage. Components may experience gradual degradation, leading to misalignment and decreased responsiveness. Regular inspections can help in catching these issues before they escalate, ensuring a smoother driving experience.

Noises and Vibrations

Unusual sounds or vibrations during operation often signal underlying difficulties. Clunking or grinding noises might indicate loose connections or damaged elements, while excessive vibrations could point to imbalances. Prompt attention to these signs is vital to prevent further damage.

Replacement Tips for Steering Components

When it comes to upgrading essential maneuvering elements, ensuring proper selection and installation is crucial. This guide will provide key insights into the replacement process, focusing on enhancing performance and safety.

Choosing the Right Components

- Research compatibility with your vehicle model.

- Consider the quality of materials; opt for durable options.

- Check for warranty offers from manufacturers.

Installation Guidelines

- Always refer to the manufacturer’s manual for specific instructions.

- Use appropriate tools to avoid damaging components.

- Ensure all connections are secure and correctly aligned.

- Test the functionality post-installation to confirm proper operation.

Tools Needed for Steering Repair

When tackling the intricacies of vehicle guidance systems, having the right instruments is essential for a successful repair. Proper tools not only ensure efficiency but also enhance safety during the process. Below is a comprehensive list of necessary equipment to aid in the restoration of these critical components.

- Socket Set: A variety of socket sizes is crucial for loosening and tightening bolts.

- Wrenches: Both adjustable and fixed wrenches are needed to access different fasteners.

- Torque Wrench: Ensures that components are tightened to the manufacturer’s specifications.

- Ball Joint Separator: A specialized tool for safely removing joints without causing damage.

- Pickle Fork: Useful for separating parts without excessive force.

Additionally, consider the following tools to further facilitate the repair process:

- Hammer: A rubber mallet can assist in dislodging stuck components.

- Fluid Extractor: Ideal for removing old lubricant or fluid from the system.

- Grease Gun: Essential for applying lubricant to moving parts.

- Multimeter: To test electrical connections and ensure proper functionality.

- Jack and Jack Stands: For lifting the vehicle safely and securely.

By gathering these essential tools, you can effectively address any challenges that arise during the repair of the vehicle’s guidance mechanisms.

Signs of Steering Malfunction

Identifying issues with your vehicle’s control system is crucial for safety and performance. Certain indicators can signal that something is amiss, potentially leading to compromised handling and increased risk on the road. Being aware of these signs can help you address problems before they escalate.

Common Indicators

Pay attention to unusual noises, such as grinding or whining, which may suggest internal issues. Additionally, if you notice a decrease in responsiveness when turning or difficulty maintaining a straight path, it could indicate underlying complications that need urgent attention.

Visual Cues

Inspect for leaks or fluid spots under your vehicle, as these can point to hydraulic problems. Furthermore, check for wear on the components; cracks or bends in rods can signify serious faults that require immediate action.

F350 Steering System Maintenance Guide

Proper upkeep of your vehicle’s directional mechanism is crucial for ensuring safe and reliable operation. Regular inspections and timely interventions can help prevent serious issues, prolonging the life of vital components.

Regular Inspections

Conduct routine evaluations of the entire directional system, focusing on the linkage and control elements. Look for signs of wear, such as cracks or excessive play, and ensure all connections are secure.

Fluid Checks and Adjustments

Maintaining appropriate levels of hydraulic fluid is essential. Regularly check for leaks and replace the fluid as recommended by the manufacturer. Clean components regularly to avoid contaminants affecting performance. Timely maintenance can significantly enhance the overall function of the system.

Upgrading Your F350 Steering Setup

Enhancing the control and maneuverability of your vehicle can significantly improve your driving experience. Upgrading your vehicle’s handling system not only boosts performance but also ensures better safety and responsiveness on the road. With a few strategic enhancements, you can achieve the ultimate precision and comfort while driving.

First, consider evaluating the existing components to identify areas that require improvement. This may include replacing outdated mechanisms with more advanced alternatives that offer improved durability and efficiency. Modern upgrades often include reinforced linkages and precision-engineered supports designed for heavy-duty applications.

Next, integrating adjustable features can allow for personalized settings, enhancing overall functionality. These enhancements not only cater to different driving styles but also ensure that the vehicle remains stable under various conditions. Investing in high-quality materials will also extend the lifespan of your new setup.

Lastly, proper installation and regular maintenance are crucial to maximizing the benefits of your upgrades. Regular checks and adjustments can prevent wear and ensure optimal performance over time. With the right modifications, your vehicle will not only perform better but also provide an unparalleled driving experience.

DIY Steering System Inspection Process

Regular examination of your vehicle’s control mechanisms is essential for safe operation. This process allows you to identify potential issues early, ensuring optimal functionality and longevity of the components. By performing a thorough check, you can enhance your driving experience and prevent costly repairs down the line.

Start by parking the vehicle on a flat surface and ensuring it is securely turned off. Begin with a visual inspection of the linkages, looking for signs of wear, rust, or damage. Make sure all connections are tight and free of any debris that could interfere with movement.

Next, check for any unusual noises while turning the wheel. Noises such as grinding or popping may indicate underlying problems. Additionally, test the responsiveness of the mechanism by turning the wheel to ensure smooth operation without excessive resistance.

Finally, consider checking the fluid levels if applicable, as well as any seals for leaks. Addressing minor issues promptly can prevent them from becoming significant hazards. With these steps, you can ensure that your vehicle remains reliable and safe on the road.

FAQs About F350 Steering Parts

This section addresses common inquiries related to components that guide vehicle maneuverability, enhancing understanding and providing clarity for enthusiasts and owners alike.

- What are the signs of wear in these components?

Common indicators include difficulty in handling, unusual noises, or uneven tire wear.

- How often should these components be inspected?

Regular inspections are recommended every 30,000 miles or at least once a year.

- Can I replace these components myself?

While some may attempt DIY replacements, professional assistance is advisable for complex issues.

- What tools are needed for replacement?

Basic hand tools like wrenches, sockets, and a jack are typically required.

- How can I find the right components for my vehicle?

Refer to the vehicle manual or consult with a trusted supplier for proper specifications.

Resources for F350 Owners

For those who own a heavy-duty vehicle, having access to reliable information and support can greatly enhance the ownership experience. Various resources can provide essential guidance on maintenance, repairs, and upgrades, ensuring that your vehicle remains in top condition.

Online forums and communities are invaluable for connecting with fellow enthusiasts. These platforms allow users to share experiences, troubleshoot issues, and exchange tips. Additionally, manufacturer websites often offer detailed manuals and instructional videos, helping owners navigate the complexities of their vehicles.

Parts retailers and local auto shops are crucial resources for sourcing high-quality components. They often provide expert advice on compatibility and installation, ensuring that your vehicle operates safely and efficiently. Lastly, dedicated blogs and YouTube channels can serve as excellent supplementary resources, offering in-depth reviews and how-to guides tailored to your needs.