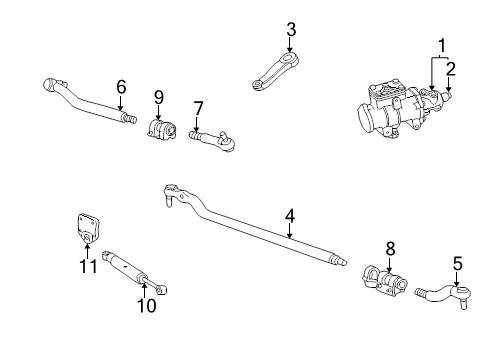

In the realm of automotive engineering, the intricate network responsible for guiding a vehicle is crucial for both performance and safety. This section delves into the essential elements that contribute to the mechanism of directional control, providing insights into their functions and interrelations. A well-functioning system is vital for ensuring that drivers can navigate effectively and respond swiftly to various driving conditions.

Each component plays a significant role in the overall functionality, from the mechanisms that enable turning to the linkages that connect the various parts. A comprehensive overview of these components not only enhances one’s understanding of vehicle dynamics but also aids in maintenance and troubleshooting. Recognizing the importance of each element fosters better care and efficiency in automotive systems.

As we explore the various aspects of this vital system, it becomes evident that a detailed visualization can significantly aid in grasping the complexities involved. Whether for repair purposes or general knowledge, familiarizing oneself with these components is invaluable for anyone interested in automotive technology.

This section aims to outline the essential elements that constitute a vehicle’s directional control mechanism. By exploring these components, readers will gain a comprehensive understanding of how they work together to ensure safe and reliable navigation. Each aspect plays a critical role in the overall functionality, contributing to both performance and comfort during operation.

Key Elements of Directional Control

- Control Mechanism

- Connecting Links

- Rotational Assemblies

- Power Assistance Components

- Feedback Devices

Functionality and Importance

Each component serves a specific function that contributes to the effectiveness of the entire system. Understanding these roles allows for better maintenance and troubleshooting.

- Ensures accurate navigation

- Enhances driver comfort

- Facilitates smooth maneuverability

By examining the interaction between these elements, one can appreciate the complexity and precision required for optimal vehicle performance.

Types of Steering Mechanisms

In the realm of automotive engineering, various mechanisms exist to facilitate the control and direction of vehicles. Each type serves a distinct purpose, enhancing maneuverability and safety. Understanding these mechanisms is crucial for effective vehicle operation and maintenance.

Manual Steering Systems

Manual systems are traditional designs that require physical effort from the driver to navigate the vehicle. These setups typically involve a series of rods and gears that directly connect the steering wheel to the wheels, allowing for a straightforward, mechanical approach to control.

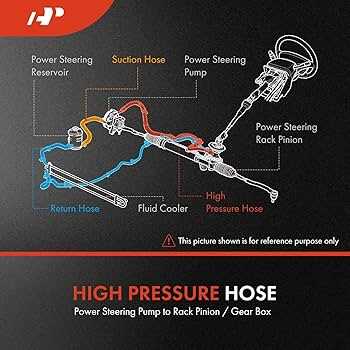

Power-Assisted Systems

Power-assisted mechanisms, on the other hand, utilize hydraulic or electric components to reduce the driver’s workload. These systems provide additional force to help steer the vehicle, making it easier to maneuver, especially at low speeds or during parking maneuvers.

| Type | Advantages | Disadvantages |

|---|---|---|

| Manual | Simple design, low maintenance | Requires more physical effort, less responsive |

| Power-Assisted | Less effort required, improved control | More complex, potential for mechanical failure |

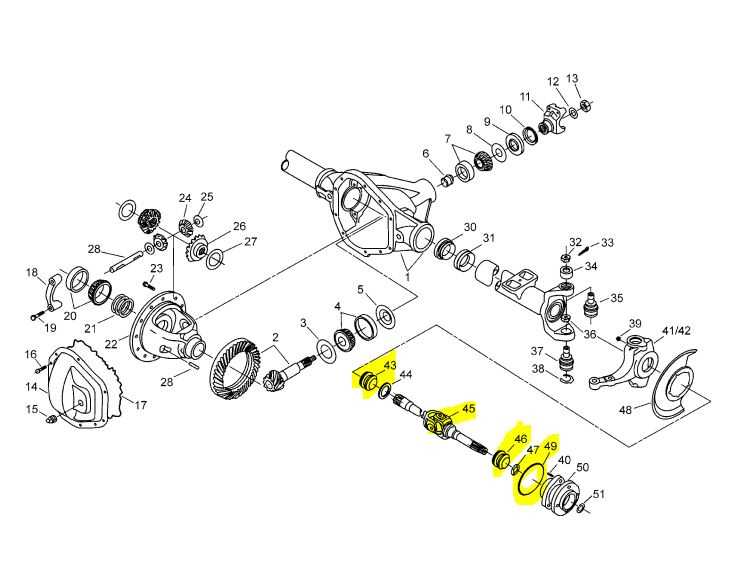

Key Functions of Steering Components

The effectiveness and safety of any vehicle largely depend on the functionality of its control mechanisms. These essential elements work together to ensure smooth navigation and precise maneuvering. Understanding their roles can enhance the appreciation of how vehicles operate, contributing to a more informed maintenance approach.

Control and Directional Guidance

One of the primary roles of these components is to provide the driver with the ability to direct the vehicle effectively. This involves translating the driver’s input into movements that adjust the trajectory of the vehicle. The efficiency of this function can significantly impact handling and stability, particularly during sharp turns or emergency situations.

Force Distribution and Feedback

Another critical function is the distribution of forces between the vehicle and the road surface. This ensures that the vehicle remains stable while navigating various terrains. Additionally, these mechanisms provide feedback to the driver, allowing for a more intuitive driving experience. The design of these elements is crucial for maintaining comfort and control during operation.

| Function | Description |

|---|---|

| Directional Control | Enables precise navigation and adjustment of vehicle path. |

| Stability Maintenance | Ensures vehicle remains balanced and secure on the road. |

| Force Distribution | Balances the forces acting on the vehicle to enhance control. |

| Driver Feedback | Provides sensory information to the driver for better handling. |

Common Issues in Steering Systems

In any vehicle, the mechanism that directs movement is vital for safe operation. Over time, various challenges may arise, impacting performance and responsiveness. Understanding these issues can help in timely maintenance and repair, ensuring a smooth driving experience.

Frequent Problems Encountered

- Loose Connections: Components may become loose, leading to imprecise control.

- Fluid Leaks: Hydraulic systems can develop leaks, resulting in insufficient pressure for operation.

- Worn Components: Continuous use may wear down essential elements, causing deterioration in handling.

- Noisy Operation: Unusual sounds during use often indicate underlying mechanical issues.

Symptoms to Monitor

- Unresponsiveness during turns or maneuvers.

- Vibration or shaking felt in the control mechanism.

- Difficulty in returning to a straight position after turning.

- Unusual noises or grinding sounds when engaging the control system.

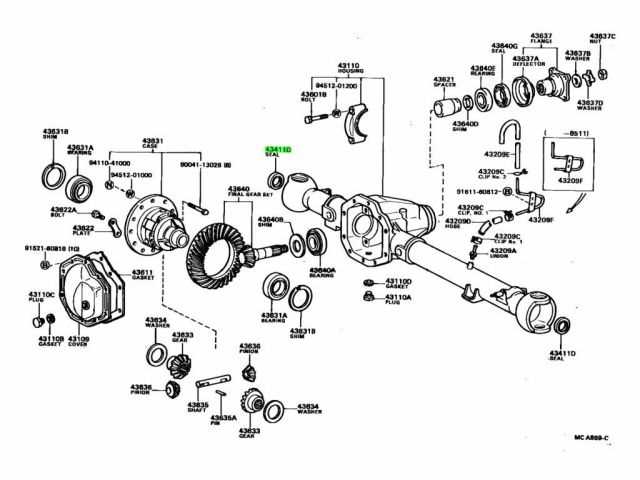

Identifying Wear and Tear

Recognizing signs of degradation in vehicle components is crucial for ensuring optimal performance and safety. Over time, various elements experience stress and strain, leading to diminished functionality. Regular inspections can help in detecting issues early, preventing further damage and costly repairs.

When assessing components, look for visible signs such as cracks, rust, or unusual wear patterns. Noise during operation can also indicate a problem; listen for any unusual sounds that may suggest friction or misalignment. Fluid leaks are another red flag, as they can signify deterioration in seals or connections.

Additionally, check for play in the connections; excessive movement may suggest worn bushings or joints that require replacement. Keeping an eye on these indicators will help maintain the reliability and longevity of your vehicle’s systems.

Maintenance Tips for Steering Components

Proper upkeep of directional control mechanisms is essential for ensuring optimal vehicle performance and safety. Regular inspections and preventive measures can significantly extend the lifespan of these critical systems while enhancing overall driving experience.

Regular Inspections

Perform routine checks on all associated elements to identify wear or damage early. Look for any unusual noises or vibrations during operation, as these may indicate underlying issues that require attention. Ensure that connections are secure and that fluid levels are within recommended ranges.

Lubrication and Cleaning

Maintain cleanliness and proper lubrication of moving parts to prevent friction and corrosion. Utilize suitable lubricants and clean all components to remove dirt and debris that may impede functionality. This practice helps maintain smooth operation and prolongs the service life of the system.

Choosing Quality Replacement Parts

When it comes to ensuring optimal performance and longevity of your vehicle’s handling system, selecting high-quality components is essential. The right choices can significantly enhance your driving experience while ensuring safety on the road. This section focuses on the factors to consider when sourcing replacements for worn or damaged elements.

Key Factors to Consider

- Material Quality: Look for components made from durable materials that can withstand wear and tear.

- Compatibility: Ensure the replacements are designed to fit your vehicle model precisely to avoid any issues during installation.

- Brand Reputation: Opt for reputable manufacturers known for producing reliable and high-performing items.

Benefits of Quality Components

- Enhanced Safety: Quality replacements reduce the risk of failure, improving overall vehicle safety.

- Improved Performance: Well-made components contribute to better handling and responsiveness.

- Cost-Effectiveness: Investing in durable items can save money in the long run by reducing the frequency of replacements.

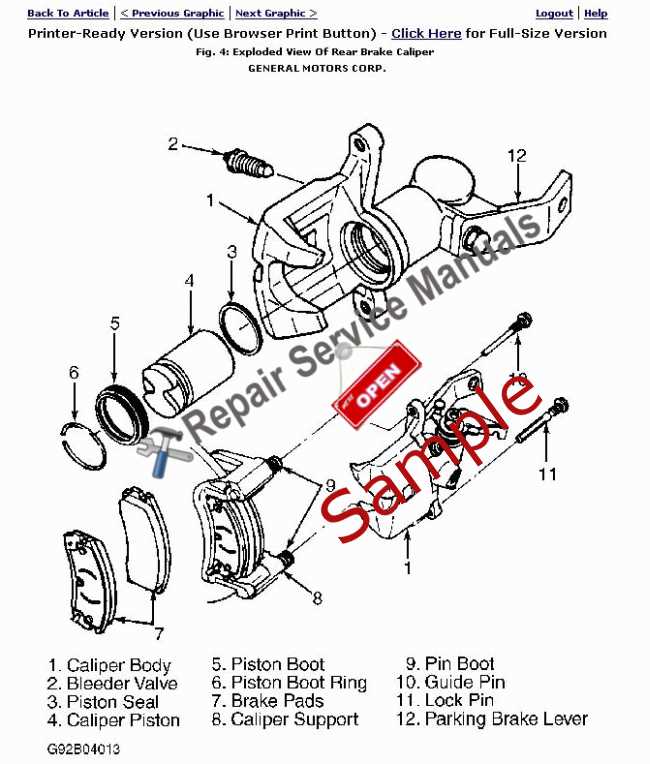

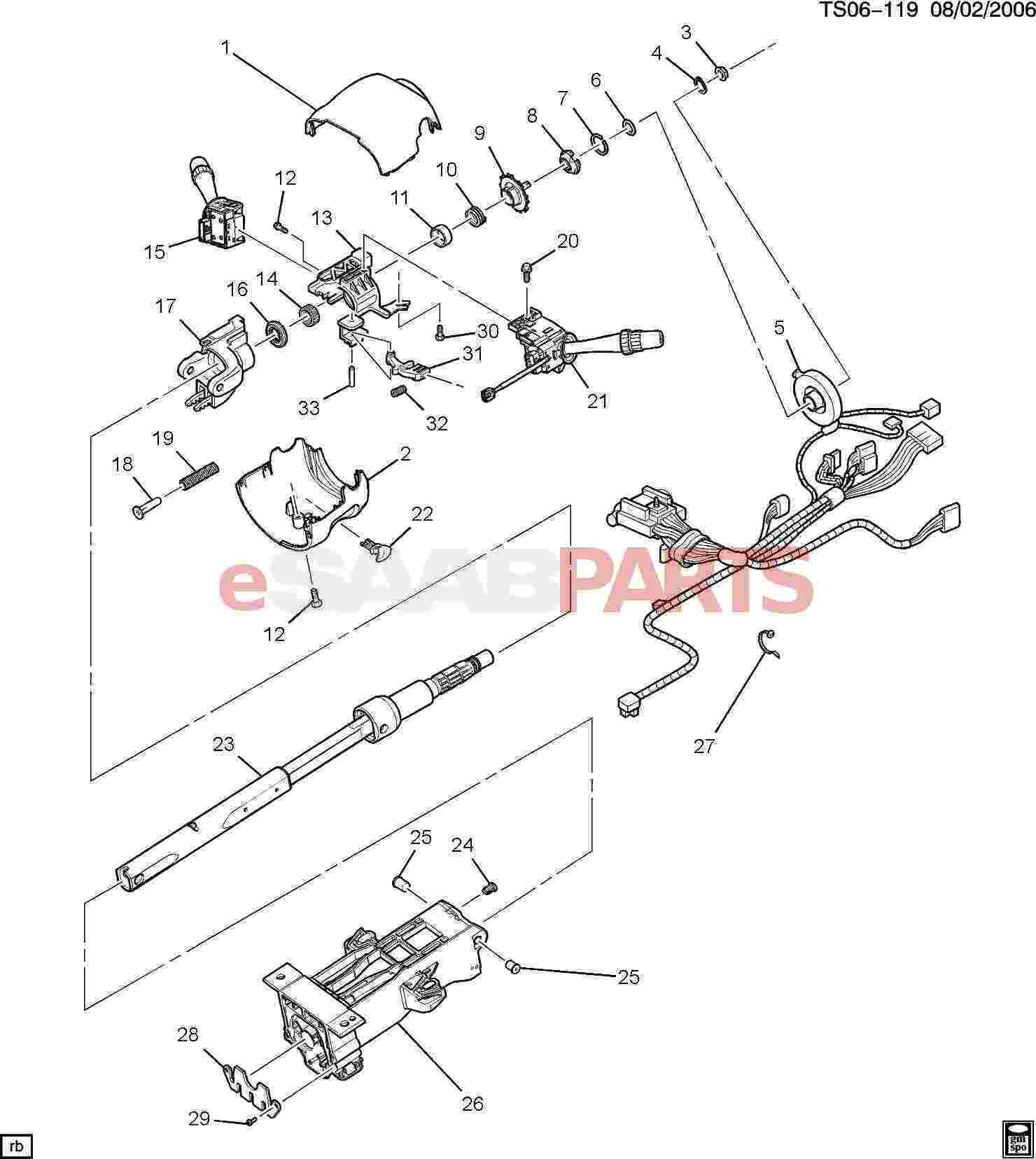

Installation Procedures for Steering Parts

Proper installation of control components is crucial for maintaining vehicle handling and safety. This section outlines the essential steps involved in the fitting of these elements to ensure optimal performance and longevity.

Begin by gathering all necessary tools and equipment, including wrenches, sockets, and safety gear. It’s important to work in a well-ventilated area, ensuring ample space to maneuver around the vehicle. Before commencing, consult the specific guidelines relevant to the components being installed.

Start by securely lifting the vehicle, using jack stands to ensure stability. Remove any protective covers or components that may obstruct access to the assembly area. Carefully detach the existing elements, taking note of their configuration for reference during reassembly.

Align the new components with the existing mounting points, ensuring they are oriented correctly. Fasten the parts using the appropriate bolts, tightening them to the manufacturer’s specified torque settings. It is essential to verify that all connections are secure to prevent future issues.

Once the installation is complete, double-check all work and ensure that nothing is left loose. Lower the vehicle back to the ground and perform a thorough inspection of the installation area. Finally, take the vehicle for a test drive to evaluate the functionality and responsiveness of the newly installed components.

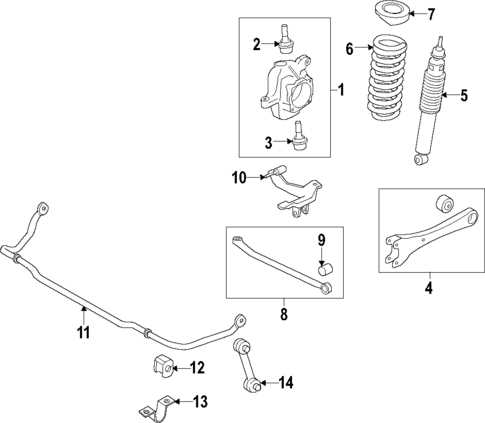

Importance of Proper Alignment

Ensuring correct alignment is crucial for the optimal functioning of any vehicle. Misalignment can lead to uneven tire wear, compromised handling, and a decrease in overall performance. Addressing these issues not only enhances safety but also extends the lifespan of various components.

Impact on Performance

When components are aligned correctly, the vehicle performs better in several ways:

- Improved steering response

- Enhanced fuel efficiency

- Longer lifespan of tires

Safety Considerations

Proper alignment plays a significant role in safety. A well-aligned vehicle reduces the risk of accidents by providing better control and stability. Drivers are more likely to respond effectively to sudden changes in road conditions or emergencies when their vehicle is functioning as intended.

Tools Needed for Steering Repair

When undertaking the task of restoring the directional control mechanism of a vehicle, having the right equipment is essential for a successful outcome. Proper tools not only facilitate the repair process but also ensure safety and accuracy. Below is a list of indispensable implements that will aid in this endeavor.

Essential Hand Tools

Among the most critical items are hand tools that provide the necessary leverage and precision. A wrench set is vital for loosening and tightening various fittings. Additionally, a screwdriver set is required for accessing different types of fasteners. Don’t forget to include pliers and a hammer, as these tools often come in handy during disassembly and reassembly tasks.

Specialized Equipment

In some cases, specialized tools may be needed for more complex repairs. A torque wrench ensures that connections are tightened to the manufacturer’s specifications, preventing damage from over-tightening. Moreover, a ball joint separator or tie rod end puller can be crucial when working with critical components that require careful handling.

Upgrading Steering Systems for Performance

Enhancing the control mechanisms in vehicles is essential for achieving optimal performance, particularly in demanding driving conditions. By focusing on key modifications, enthusiasts can significantly improve responsiveness and overall handling characteristics. These upgrades not only elevate the driving experience but also ensure greater safety and stability during operation.

One of the primary areas for improvement involves the incorporation of high-performance components. Replacing standard components with those designed for enhanced precision can yield noticeable differences. This includes implementing advanced linkages and gears that provide improved feedback and agility, resulting in a more connected feel between the driver and the road.

Additionally, the installation of premium dampers and bushings contributes to better stability and reduced vibrations. By selecting components with superior materials and engineering, drivers can experience enhanced durability and responsiveness. Regular maintenance of these systems is also crucial, as it helps maintain their functionality and performance over time.

Ultimately, upgrading the control systems not only optimizes vehicle handling but also personalizes the driving experience. Whether for racing, off-roading, or daily use, these modifications can transform any vehicle into a more capable and enjoyable machine.

Resources for Further Research

Exploring additional materials can significantly enhance your understanding of vehicle components and their mechanisms. A variety of sources provide insights into maintenance, assembly, and troubleshooting. The following resources are valuable for those looking to deepen their knowledge and acquire practical skills related to automotive systems.

Books and Manuals

- Automotive Repair Manual Series – Comprehensive guides covering a wide range of vehicle models.

- Factory Service Manuals – Official documentation from manufacturers detailing specifications and repair procedures.

- Automotive Engineering Textbooks – In-depth exploration of vehicle design and functionality.

Online Resources

- YouTube Channels – Video tutorials offering visual demonstrations of repair and assembly processes.

- Automotive Forums – Community-driven platforms for sharing experiences, tips, and troubleshooting advice.

- Manufacturer Websites – Access to technical bulletins, recalls, and product updates.