The intricate assembly of a vehicle’s directional control system is essential for ensuring safe and precise handling. This section delves into the various components that make up this vital mechanism, offering insights into their functions and interrelationships. By comprehending the individual elements and how they work together, one can better appreciate the engineering that underpins modern automotive design.

To effectively navigate the complexities of the directional control system, a visual representation can be invaluable. This overview aims to provide clarity on the arrangement and purpose of each element, facilitating a deeper understanding for enthusiasts and professionals alike. Whether you are troubleshooting an issue or simply seeking knowledge, this exploration will serve as a valuable resource.

By examining the configuration of these components, readers will gain insight into the operational principles that govern vehicle maneuverability. The interplay between these elements not only affects performance but also contributes to overall safety. With this knowledge, one can approach maintenance and repairs with greater confidence and competence.

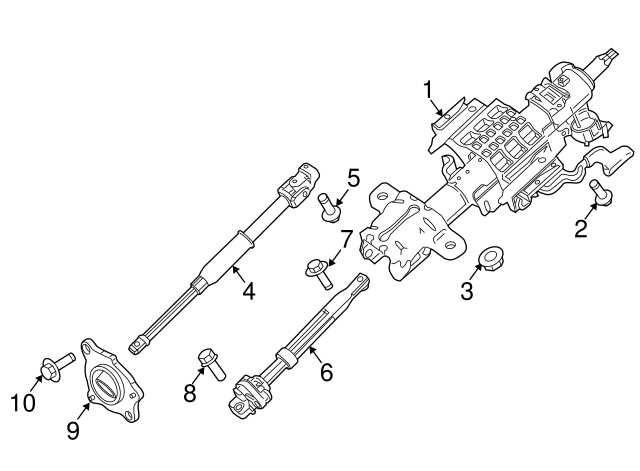

Understanding the Steering Column Functionality

The component in question plays a pivotal role in the control and navigation of a vehicle. It not only supports various controls but also serves as a crucial connection between the driver and the vehicle’s operational mechanisms. This intricate assembly ensures that the driver can maneuver effectively, making it essential for both safety and performance.

Key Components and Their Roles

Within this assembly, several key elements contribute to its overall functionality. The primary element is often the mechanism that allows for the adjustment of angles and positions, providing comfort and accessibility for drivers of different heights. Additionally, integrated controls for features such as indicators, headlights, and wipers facilitate seamless operation, ensuring that drivers can maintain focus on the road.

Safety Features and Considerations

Safety remains a top priority in the design of this assembly. It is equipped with features that protect occupants during a collision, such as collapsible structures that absorb impact energy. Regular maintenance and inspections are essential to ensure these safety mechanisms function correctly, thereby enhancing the overall driving experience.

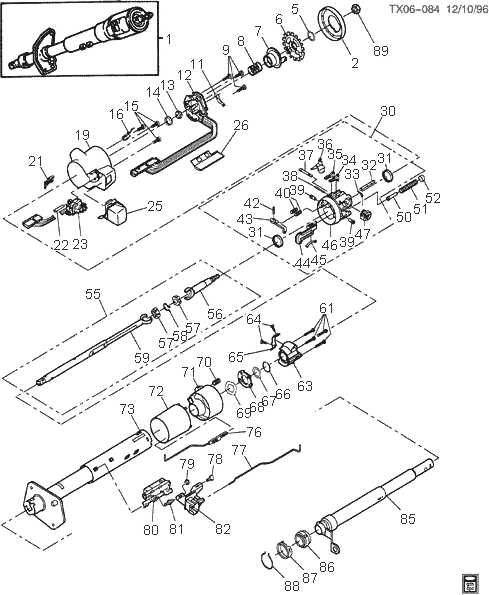

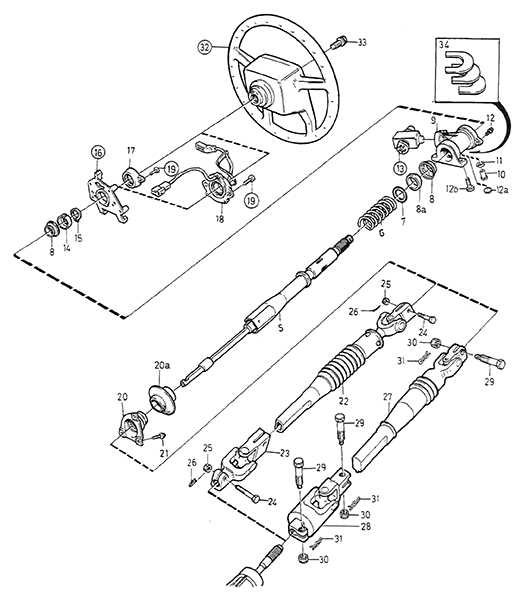

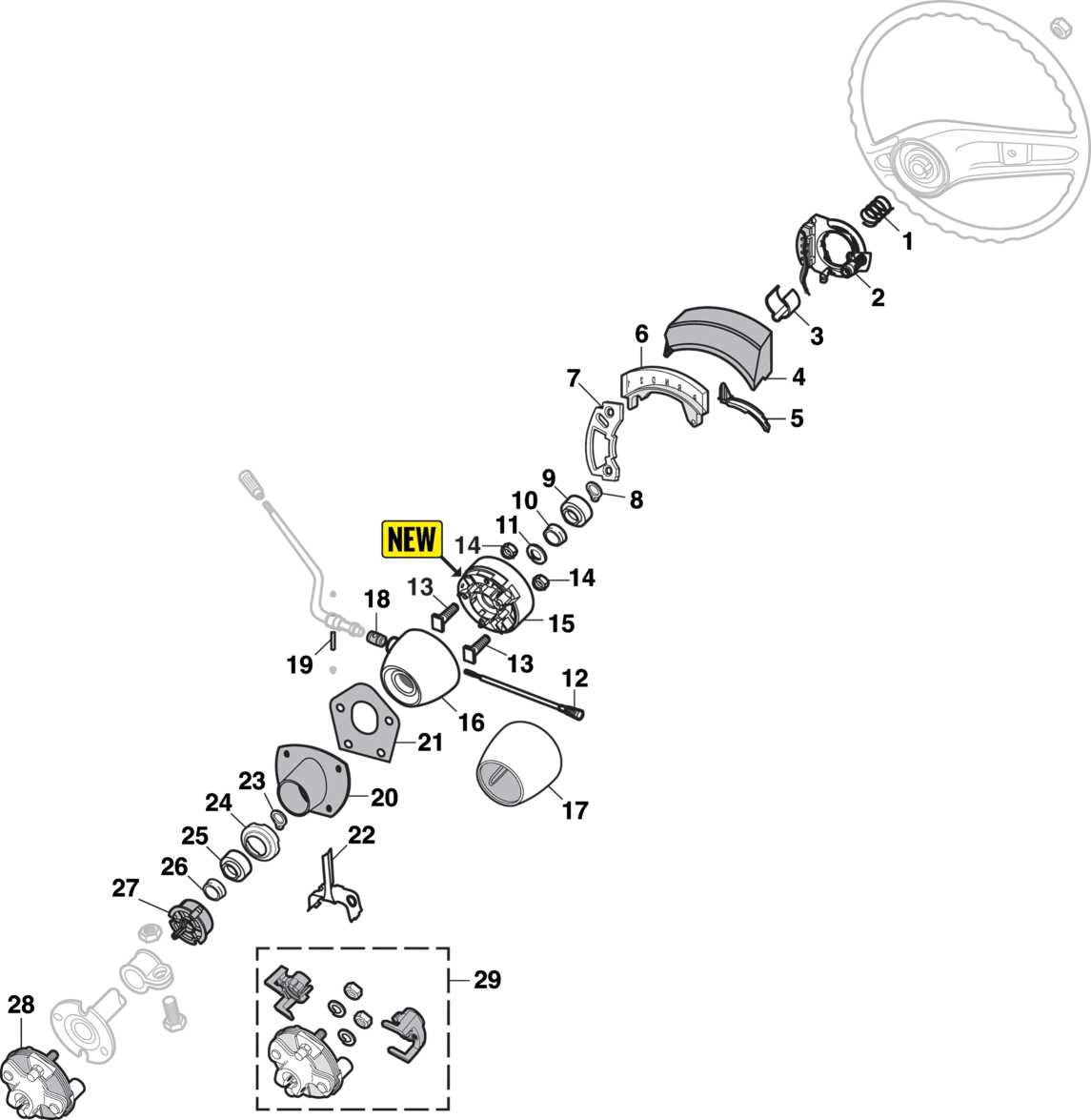

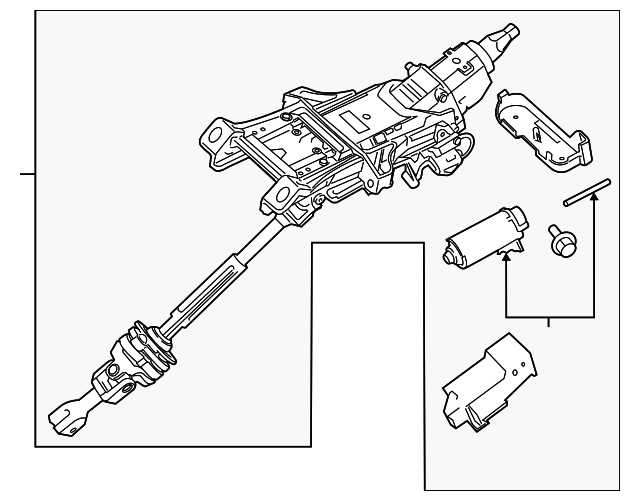

Key Components of Steering Assemblies

The assembly responsible for vehicle navigation consists of several essential elements that work in harmony to ensure precise control and maneuverability. Understanding these components is vital for comprehending how they contribute to overall vehicle dynamics and driver comfort.

1. Shaft Mechanism

The shaft mechanism serves as the central conduit for transmitting rotational movement from the driver’s input to the necessary components. It is typically designed for durability, capable of withstanding significant forces while maintaining flexibility for ease of use.

2. Gear Interface

At the heart of the assembly lies the gear interface, which translates the rotational motion into directional movement. This component is crucial for adjusting the angle of the vehicle’s wheels, providing the responsiveness needed during various driving conditions.

Regular maintenance of these components is essential for ensuring a safe and enjoyable driving experience. Identifying and addressing wear and tear early on can prevent more significant issues down the line.

How to Identify Column Parts

Understanding the components of a vehicle’s control assembly is essential for maintenance and repairs. Each element plays a crucial role in ensuring smooth operation and safety. By familiarizing yourself with these elements, you can effectively diagnose issues and perform necessary replacements.

Begin with visual inspection: Examine the assembly closely for distinct shapes and sizes. Look for the main structure that houses various mechanisms. Identify any features that stand out, such as levers, knobs, or connectors. Familiarity with these characteristics will aid in recognizing the different components.

Consult reference materials: Utilize manuals or online resources that provide detailed descriptions and illustrations. These references can help you correlate your observations with specific functions and placements of the elements. Pay attention to terminology used, as it may vary across sources.

Identify common issues: Learn about frequent problems associated with each component. Understanding the typical failures or wear signs can guide you in determining which parts may require attention. For example, if a control lever feels loose or unresponsive, it could indicate a need for replacement.

Seek assistance from experts: If you’re unsure about identifying specific elements, consult with knowledgeable individuals in the field. Mechanics or automotive enthusiasts can provide insights based on their experience. Their expertise can help clarify any uncertainties you may have.

Common Issues with Steering Columns

Issues with vehicle control mechanisms can significantly impact the driving experience and safety. Understanding the common problems that can arise in these components is essential for proper maintenance and timely repairs.

- Loose Connections: Worn-out bolts or improper installation can lead to unstable handling, causing vibrations or play in the mechanism.

- Electrical Failures: Malfunctions in the wiring or connectors can result in non-functioning accessories, such as lights and indicators.

- Worn Bearings: Over time, bearings may wear down, leading to noise and difficulty in operation.

- Corrosion: Exposure to moisture and road salt can cause rust, weakening metal components and impacting performance.

- Misalignment: Improper installation or damage can cause the mechanism to be misaligned, resulting in uneven handling and excessive wear.

Regular inspections and prompt attention to these issues can help maintain the integrity of vehicle control systems, ensuring a safe and smooth driving experience.

Maintenance Tips for Longevity

Proper care and attention can significantly extend the lifespan of essential vehicle components, ensuring optimal performance and safety. Regular maintenance practices are vital to prevent premature wear and tear, which can lead to costly repairs and replacements.

1. Regular Inspections: Periodically examine the critical components for signs of wear or damage. Look for any unusual sounds, vibrations, or steering responses that may indicate underlying issues.

2. Lubrication: Ensure that all moving parts are adequately lubricated. This reduces friction and minimizes the risk of damage. Use high-quality lubricants recommended for your vehicle type.

3. Cleanliness: Keep the area around the mechanisms clean and free from debris. Dirt and grime can interfere with smooth operation and lead to accelerated wear.

4. Tightening Fasteners: Regularly check and tighten any loose bolts or screws. Vibration can cause fasteners to loosen over time, impacting the overall integrity of the system.

5. Fluid Levels: Maintain appropriate levels of hydraulic fluid if applicable. Low fluid levels can result in poor performance and potential system failure.

6. Seek Professional Help: If any issues arise that you cannot address, consult a professional mechanic. Timely intervention can prevent minor problems from escalating into major repairs.

Tools Required for Repairs

To effectively carry out maintenance or repairs on the assembly that directs vehicle movement, a selection of appropriate instruments is essential. Utilizing the right tools not only facilitates the process but also ensures safety and accuracy during the task.

Essential Instruments

Gathering the following tools will prepare you for a successful repair experience:

| Tool | Description |

|---|---|

| Socket Set | A comprehensive range of sockets for loosening and tightening various fasteners. |

| Torque Wrench | For applying precise torque to fasteners, ensuring they are secure without over-tightening. |

| Screwdriver Set | Includes both flathead and Phillips screwdrivers for different types of screws. |

| Pliers | Useful for gripping, twisting, and cutting wire or small components. |

| Wire Cutters | For cutting electrical wires neatly and accurately. |

Additional Recommendations

Depending on the complexity of the repairs, consider having the following on hand:

| Tool | Description |

|---|---|

| Flashlight | To illuminate hard-to-see areas during the repair process. |

| Multimeter | A device for measuring electrical properties and diagnosing issues. |

| Safety Gear | Includes gloves and goggles to protect against injuries during repairs. |

| Parts Organizer | To keep small components sorted and easily accessible during the repair. |

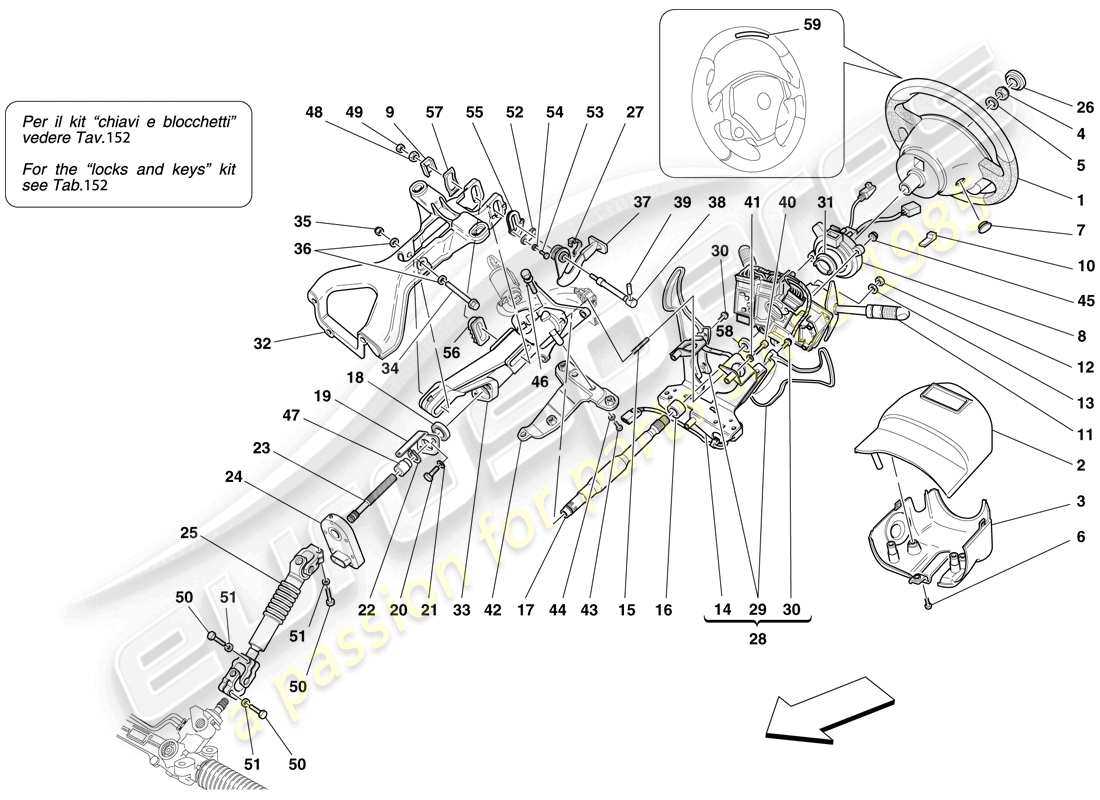

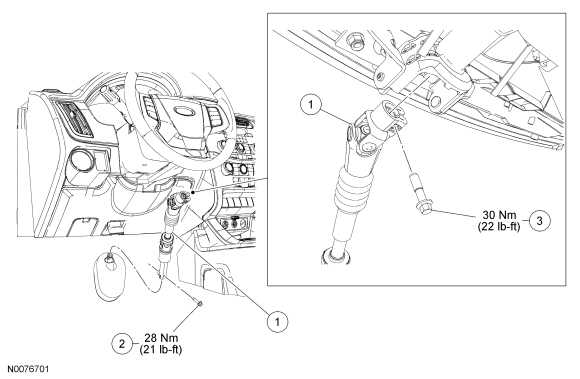

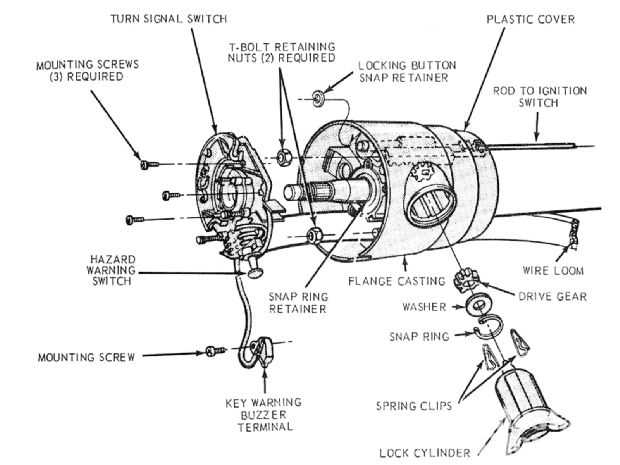

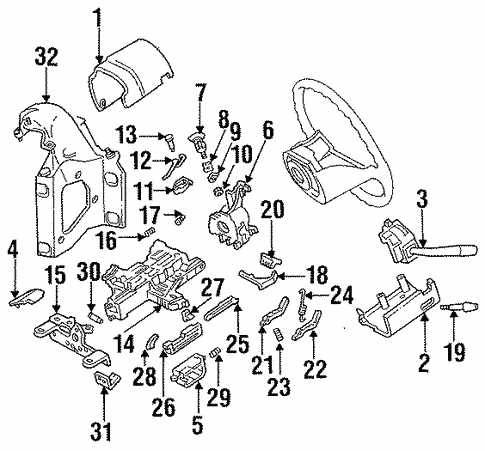

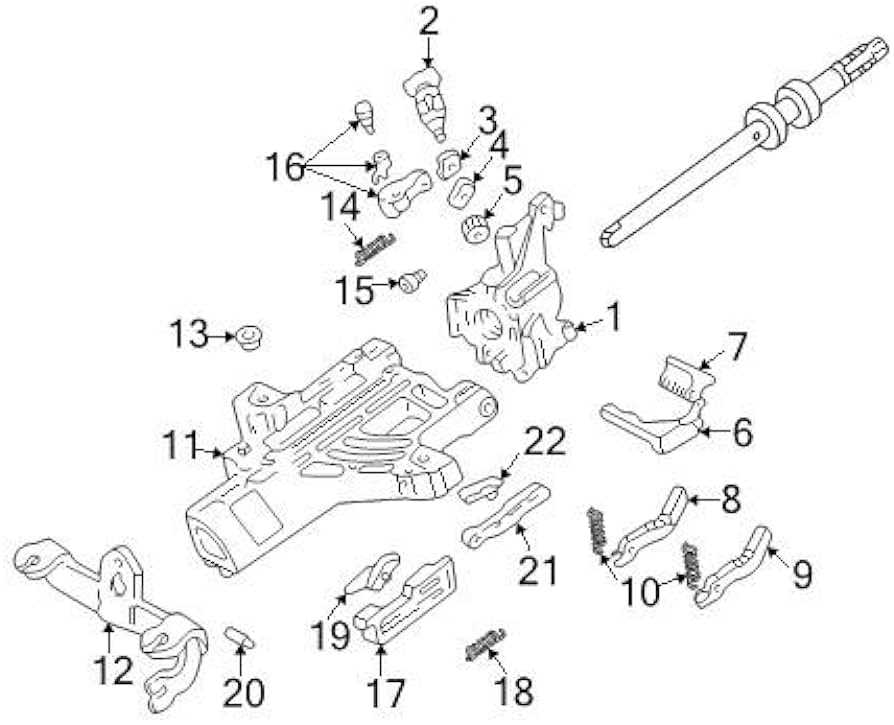

Diagram Interpretation for Beginners

Understanding visual representations of components can be challenging for those new to the subject. These illustrations serve as a guide, helping users identify various elements and their functions within a system. Gaining proficiency in reading these visuals enhances comprehension and aids in effective troubleshooting.

When approaching a representation of components, keep the following points in mind:

- Familiarize Yourself with Symbols: Each illustration uses specific symbols to represent different items. Learning what these symbols mean is the first step in understanding the whole.

- Identify Key Components: Focus on the main elements illustrated. Recognizing these parts can help you grasp their significance and how they interact.

- Follow the Flow: Many illustrations show how elements connect and function together. Observing this flow is crucial for understanding the overall operation.

As you gain experience, interpreting these visuals will become easier. Regular practice and application of this knowledge will lead to increased confidence and skill.

Wiring Connections in Steering Systems

Understanding the electrical connections within control mechanisms is crucial for maintaining optimal functionality. These connections facilitate communication between various components, ensuring that the entire system operates seamlessly. From sensors to switches, each element plays a vital role in the overall performance and safety of the vehicle.

Importance of Accurate Wiring

Precise wiring is essential for the reliable operation of the control assembly. Incorrect connections can lead to malfunctions, potentially compromising vehicle handling and safety. Regular inspections and maintenance of these electrical pathways can help prevent issues and prolong the life of the components involved.

Common Wiring Components

Several key elements are involved in the electrical network of control systems. Connectors, relays, and harnesses work together to facilitate communication and power distribution. Understanding the function of each component can aid in troubleshooting and repairs, ensuring that drivers experience a safe and responsive driving experience.

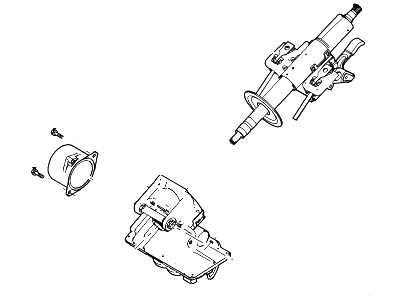

Upgrading Your Steering Column

Enhancing the control interface in your vehicle can significantly improve both performance and comfort. Upgrading components related to the directional system allows for a smoother driving experience and can add modern features that enhance usability.

When considering an upgrade, it’s essential to focus on several key aspects:

- Compatibility: Ensure that any new components are compatible with your existing setup to avoid installation issues.

- Functionality: Look for upgrades that offer additional features, such as enhanced adjustability or integrated technology.

- Quality: Invest in high-quality materials to ensure durability and reliability over time.

The process of upgrading can include:

- Removing the existing assembly carefully to prevent damage to surrounding components.

- Installing new parts that offer improved ergonomics and usability.

- Testing the new setup to ensure everything operates smoothly and as expected.

Upgrading can not only improve the functionality of your vehicle but also enhance its overall aesthetic. Consider personalization options to tailor the interface to your preferences, making your driving experience truly unique.

Replacing Worn-Out Parts Effectively

Maintaining optimal performance in your vehicle requires timely replacement of deteriorated components. Addressing these issues promptly ensures not only enhanced functionality but also extends the lifespan of the overall system. This section discusses effective strategies for identifying and replacing damaged elements within your assembly.

To begin with, it’s crucial to recognize the signs of wear that may indicate a need for replacement. Common symptoms include unusual noises, reduced responsiveness, or visible damage. Regular inspections can help detect these issues early on.

Once you’ve identified the components that require attention, the next step is to source quality replacements. Opting for high-grade alternatives is vital for ensuring reliability and longevity. Additionally, consider consulting your vehicle’s manual or a trusted resource for specifications and compatibility information.

Installation of the new components can be straightforward if you follow a structured approach. Below is a simple guide to assist you in this process:

| Step | Description |

|---|---|

| 1 | Gather necessary tools and new components. |

| 2 | Disconnect the battery and remove any obstructing elements. |

| 3 | Carefully remove the worn-out item, taking note of the arrangement. |

| 4 | Install the new component, ensuring a secure fit. |

| 5 | Reassemble any removed parts and reconnect the battery. |

| 6 | Test the functionality to ensure everything operates smoothly. |

By adhering to these steps and focusing on quality replacements, you can effectively restore functionality and maintain the integrity of your vehicle’s system.

Importance of Steering Column Alignment

Proper orientation of the control mechanism is crucial for ensuring optimal vehicle handling and safety. Misalignment can lead to various issues, affecting not only performance but also the overall driving experience. Understanding the significance of this alignment can help in maintaining your vehicle effectively.

Effects of Misalignment

When the control mechanism is not properly aligned, several problems may arise:

- Uneven tire wear, leading to increased replacement costs.

- Inaccurate response to directional input, making the vehicle harder to control.

- Increased strain on other components, potentially leading to premature failure.

- Reduced comfort for passengers due to vibrations and noise.

Benefits of Proper Alignment

Ensuring correct alignment offers numerous advantages:

- Enhanced safety through improved handling and control.

- Extended lifespan of tires and other related components.

- Increased fuel efficiency, saving money in the long run.

- Improved driving comfort, leading to a better overall experience.

Frequently Asked Questions on Repairs

This section aims to address common inquiries related to maintenance and restoration tasks for vehicle control systems. Whether you are a novice or an experienced technician, understanding these aspects can enhance your troubleshooting skills and efficiency.

- What are the signs that indicate a need for repair?

Some common indicators include:

- Unusual noises during operation

- Difficulty in maneuvering

- Loose components

- How can I determine which component needs replacement?

Begin by inspecting the entire assembly for wear and tear. Use a diagnostic tool if necessary, and refer to manufacturer guidelines for detailed information on specific elements.

- Are there any DIY solutions for minor issues?

Yes, minor problems such as tightening loose bolts or cleaning contacts can often be handled without professional assistance. However, ensure you have the right tools and follow safety precautions.

- What is the typical cost of repairs?

The cost can vary widely based on the complexity of the issue and the specific components involved. It’s advisable to obtain quotes from several repair shops before proceeding.

- How often should maintenance be performed?

Regular checks should be conducted according to the vehicle’s service schedule, typically every 15,000 to 30,000 miles, or annually, whichever comes first.