The FS 38 is a remarkable tool designed for efficient garden maintenance, embodying a blend of reliability and advanced engineering. This section delves into the intricate elements that make up this device, providing insight into its functionality and operational efficiency. A comprehensive examination of its structure can enhance user experience and facilitate better maintenance practices.

By familiarizing yourself with the various components, you can ensure optimal performance and longevity of the equipment. Each piece plays a crucial role in the overall functionality, contributing to the effectiveness of tasks ranging from trimming to clearing. Understanding these elements empowers users to diagnose issues and perform essential upkeep, ensuring the tool remains in top condition.

Moreover, having access to clear visual representations of the assembly will aid in comprehending how each component interacts with one another. This knowledge not only enhances your ability to troubleshoot but also instills confidence in operating the device. Therefore, gaining insight into the structure and roles of these components is invaluable for any user seeking to maximize their equipment’s potential.

Understanding the Stihl FS 38 Manual

The user guide for the FS 38 is an essential resource that provides crucial information for the effective operation and maintenance of the device. It serves as a comprehensive reference that helps users familiarize themselves with the equipment’s features, ensuring optimal performance and longevity. By following the guidelines outlined in the document, users can achieve better results and avoid common pitfalls during usage.

Key Features and Components

This guide outlines various components and functionalities, helping users understand how each part contributes to the overall performance of the equipment. Users will find detailed explanations and insights into the essential features, enabling them to utilize the device effectively.

Maintenance and Safety Guidelines

Proper upkeep is vital for maintaining efficiency and safety while using the FS 38. The document emphasizes recommended practices, safety measures, and maintenance routines that every operator should follow. Adhering to these suggestions helps prevent accidents and prolongs the life of the equipment.

| Component | Description |

|---|---|

| Engine | Power source for optimal cutting performance. |

| Handle | Provides grip and control during operation. |

| Cutting Head | Equipped for various cutting tasks and grass types. |

| Safety Guard | Protects the user from debris during operation. |

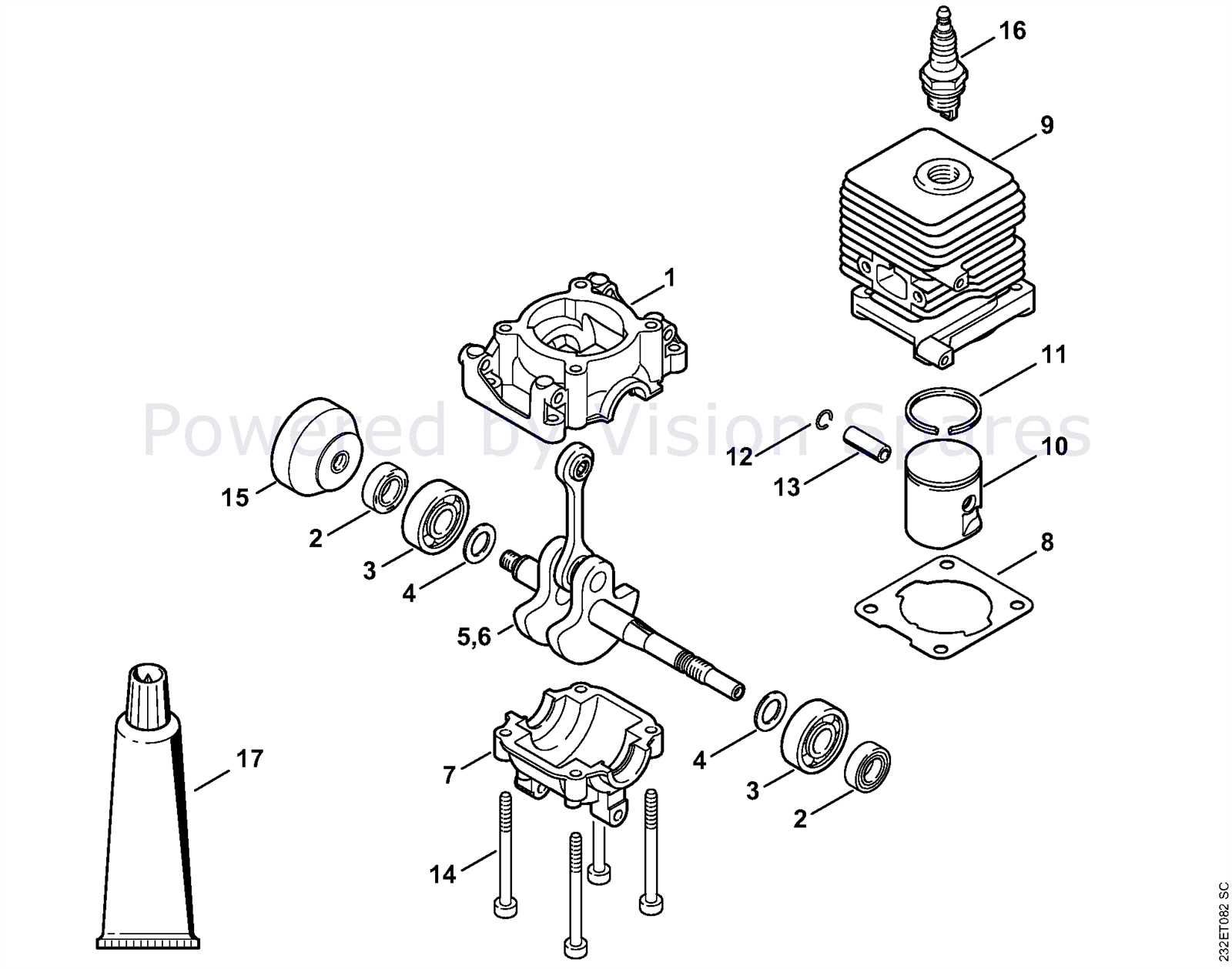

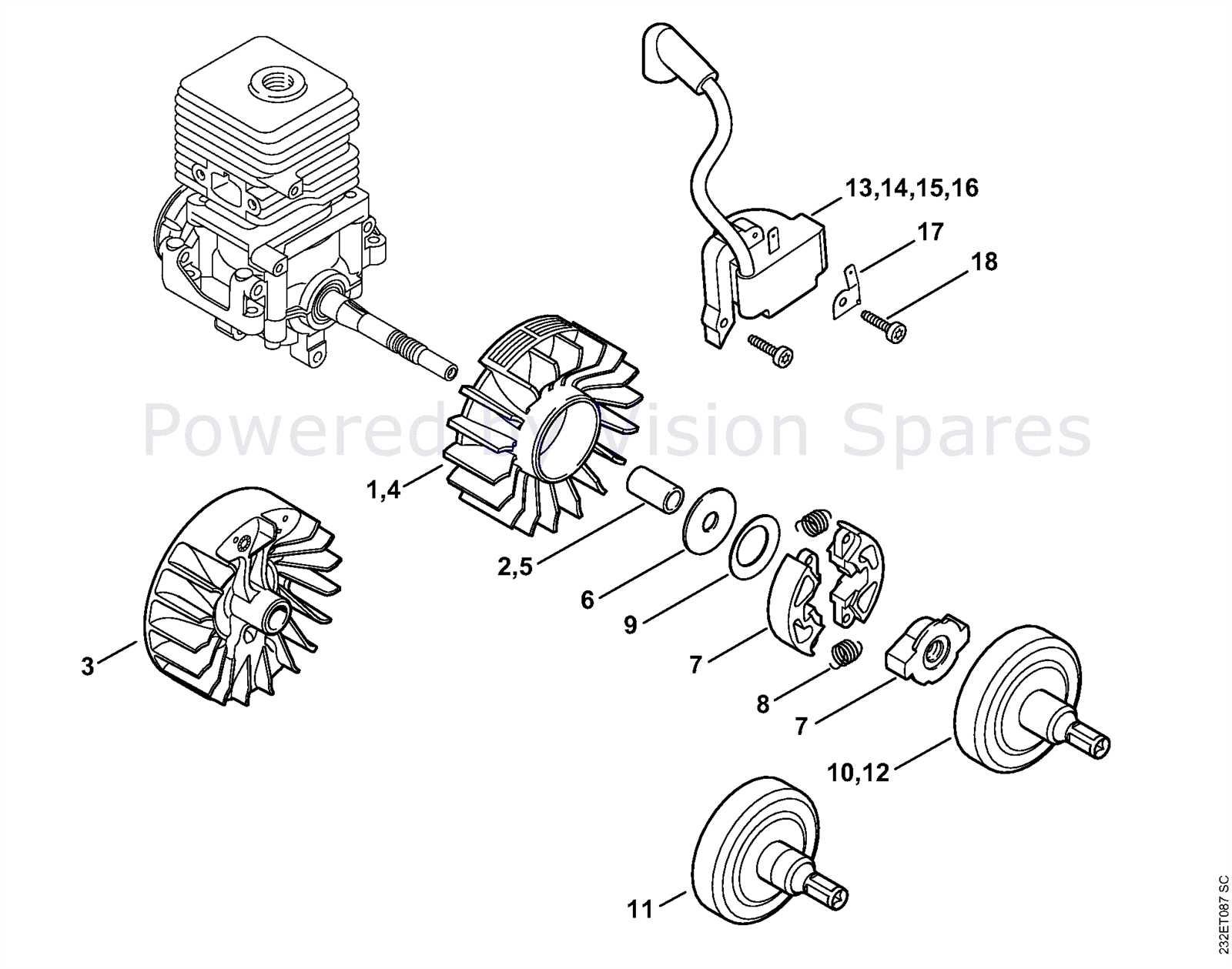

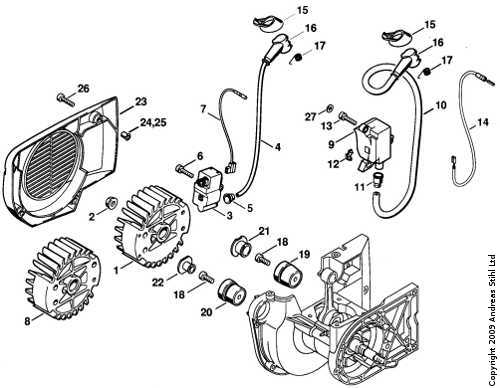

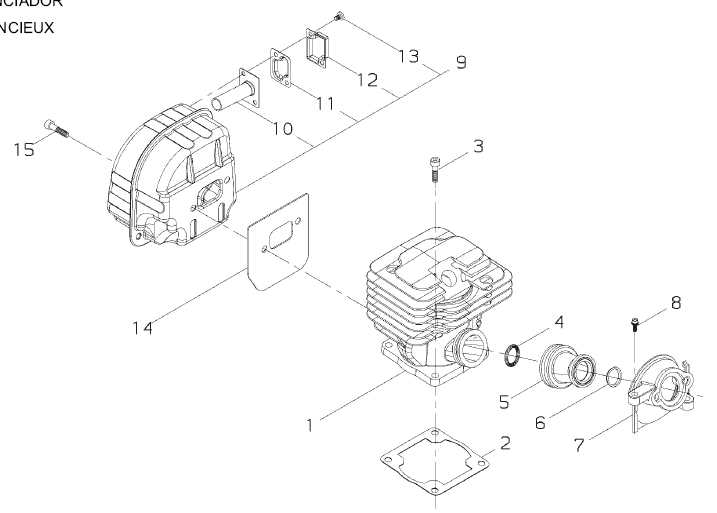

Importance of Parts Diagrams

Understanding the intricate structure of machinery is essential for effective maintenance and repair. Visual representations of components play a critical role in ensuring that users can navigate the complexities of their equipment with ease.

Here are several reasons why these visual guides are invaluable:

- Clarity: They provide a clear view of how different components fit together, making it easier to identify individual pieces.

- Efficiency: Quick reference to these illustrations can significantly reduce the time spent on repairs and adjustments.

- Accuracy: Detailed visuals help ensure that the correct components are selected for replacements or repairs, minimizing errors.

- Guidance: They serve as instructional aids for both novice and experienced users, offering step-by-step guidance in assembly or disassembly processes.

- Inventory Management: These illustrations assist in keeping track of necessary components, ensuring that users are aware of what is needed for maintenance or upgrades.

In conclusion, visual representations are not just helpful; they are a fundamental aspect of efficient equipment management, enabling users to maintain their machinery effectively and prolong its lifespan.

Common Issues with FS 38 Components

The FS 38 is a reliable tool, but like any mechanical device, it can experience various challenges over time. Understanding these common issues can help users maintain optimal performance and prolong the lifespan of their equipment. Below are some frequently encountered problems related to its components, along with potential causes and solutions.

1. Engine Performance Problems

- Hard Starting: This can occur due to stale fuel, clogged air filters, or faulty spark plugs. Regular maintenance, including fuel replacement and filter cleaning, can prevent this issue.

- Loss of Power: Insufficient power may stem from a dirty fuel filter or a malfunctioning carburetor. Cleaning or replacing these components is essential for restoring engine efficiency.

2. Cutting Head Malfunctions

- Inconsistent Cutting: This issue may arise from dull blades or improper line length. Regular sharpening and ensuring the correct line size can enhance cutting performance.

- Line Feed Problems: If the line does not advance properly, it may indicate a worn spool or debris blockage. Cleaning the spool and checking for wear are effective solutions.

How to Access the PDF Manual

Finding the appropriate guide for your equipment can greatly enhance your understanding and usage. This section will outline the steps to obtain the digital document that provides detailed information about your machine, ensuring you can effectively utilize its features and perform maintenance as needed.

Online Resources

The easiest way to find the desired document is to explore official websites or authorized retailers that offer comprehensive support for the equipment. Navigate to the support or resources section, where you can search by model number or specifications to locate the relevant digital file.

Direct Downloads

Many manufacturers provide a direct download option for their documentation. Look for links that allow you to download the file directly to your device. Ensure that you have the necessary software installed to view the document properly, such as a PDF reader, to access all the information without any issues.

Overview of Stihl FS 38 Parts

The Stihl FS 38 is a versatile and efficient tool designed for various gardening tasks. Understanding its components is essential for proper maintenance and optimal performance. Each element plays a crucial role in the overall functionality, ensuring that the equipment operates smoothly and effectively.

Here are some key components of the FS 38:

- Engine: The heart of the device, providing the necessary power for operation.

- Fuel System: Includes the fuel tank and lines, essential for delivering the mixture to the engine.

- Cutting Head: Designed to house the cutting tool, whether it’s a blade or line, for efficient trimming.

- Shaft: Connects the engine to the cutting head, transmitting power effectively.

- Handle: Provides control and maneuverability, allowing for comfortable operation during use.

- Guard: Safety feature that protects the user from debris during operation.

- Starter Mechanism: Enables the engine to start quickly and reliably.

Each of these components has a specific function and contributes to the overall efficiency of the machine. Regular inspection and maintenance of these elements are vital to extend the life of the equipment and ensure safety during operation.

Maintenance Tips for FS 38

Regular upkeep ensures your FS 38 remains reliable and efficient over time. By following essential care routines, you can extend its lifespan and avoid unnecessary breakdowns. Keeping the tool in top condition also improves performance and fuel efficiency.

Start by cleaning the air filter regularly. A clogged filter can reduce power and lead to engine issues. Ensure it is clean or replace it when necessary.

Inspect the spark plug for signs of wear. Over time, the plug may become dirty or damaged, affecting the engine’s ignition. Cleaning or replacing it will help maintain smooth operation.

Lubricate moving parts such as the throttle and control cables. This reduces friction and prevents unnecessary wear, keeping everything working smoothly.

Check the fuel system for leaks or deterioration. Using fresh, clean fuel with the appropriate mixture is critical for optimal engine performance.

Finally, store the tool in a dry, safe place when not in use, and perform periodic checks to ensure all components are

Identifying Replacement Parts Easily

Knowing which components need to be replaced and finding the right alternatives can save time and ensure efficient operation. Understanding the structure and function of various elements helps in recognizing when maintenance is required and how to address issues swiftly.

Steps to Locate the Right Component

- Examine the equipment thoroughly to identify any worn-out or damaged elements.

- Refer to the product’s model or serial number to ensure compatibility with available replacements.

- Compare the required dimensions and specifications to match with suitable options.

Best Practices for Maintenance

- Keep a regular check on all operational components to prevent unexpected malfunctions.

- Maintain a record of previous repairs and replacements for quick reference in future.

- Consult user reviews and feedback to find durable and cost-effective solutions

Tools Required for Stihl Repairs

When it comes to performing maintenance and fixes on outdoor equipment, having the correct tools is essential for ensuring smooth and effective repairs. The right set of instruments allows you to work efficiently and helps prevent damage to the equipment during the process.

Below is a list of the basic tools needed to complete various repair tasks:

- Screwdrivers: Both flathead and Phillips screwdrivers are crucial for loosening and tightening screws of different sizes.

- Socket Wrench Set: A set of socket wrenches with varying sizes will help with bolts and nuts in hard-to-reach areas.

- Pliers: Needle-nose and standard pliers can assist in gripping, cutting, and holding small parts

Safety Precautions During Maintenance

Proper upkeep of any equipment requires attention to safety to prevent accidents and ensure effective performance. Adhering to the right guidelines is critical, as even minor oversights during servicing can lead to serious harm or damage. Being mindful of potential hazards while working on machinery is essential for protecting both the user and the tool.

Wear Appropriate Protective Gear

Always wear safety gear, such as gloves and eye protection, to reduce the risk of injury. Gloves help prevent cuts and abrasions, while protective eyewear shields your eyes from flying debris. It’s crucial to avoid loose clothing or accessories that could get caught in the machine’s moving parts.

Ensure the Equipment is Powered Off

Before performing any maintenance, ensure the machine is completely turned off and disconnected from its power source. This includes removing any batteries or unplugging it from an electrical outlet. Double

Where to Purchase Stihl Parts

Finding the right components for your equipment is crucial to keeping it running smoothly. With a wide range of options available, it’s important to know where to source the necessary replacements, ensuring that you choose reliable and high-quality providers. Online platforms and local retailers offer various solutions, making it easier to maintain your tools with original and compatible alternatives.

One of the most convenient ways to acquire replacements is through certified dealers, both online and offline. Many authorized sellers offer a full range of choices, ensuring you get what you need with ease. Additionally, local repair shops and retailers often stock popular brands and components, allowing you to make a purchase in person.

When searching online, many dedicated platforms provide extensive catalogs where you can quickly find the necessary replacement options. Shopping on such platforms can offer competitive pricing, detailed product descriptions, and delivery straight to your door, adding convenience to your maintenance routine.

For those who prefer to see items before buying, physical stores remain

Comparing Stihl FS 38 to Other Models

When choosing a trimmer, it’s essential to understand how different models cater to varying needs. One model may be perfect for light trimming in smaller gardens, while others offer more power and additional features, making them suitable for larger spaces or tougher vegetation. By comparing several models, you can better assess which tool is the best fit for your specific requirements, considering factors like weight, engine efficiency, and overall versatility.

In terms of performance, some models are designed with higher power outputs, which can handle denser weeds and more extensive lawns. Meanwhile, others prioritize lightweight design, making them easier to maneuver in tight spots. Each tool serves a unique purpose, and understanding these distinctions helps in selecting a tool that aligns with your trimming tasks.

Ease of maintenance and fuel consumption also play a key role in comparison. Some tools

Frequently Asked Questions About FS 38

In this section, we will address the most common inquiries related to the FS 38 trimmer, providing clear and concise answers. Whether you’re a new user or have had it for a while, these answers will help you get the most out of your equipment.

How Do I Start the FS 38?

Starting the FS 38 requires following a few basic steps. Make sure the trimmer is placed on a flat surface, turn the switch to the “on” position, press the fuel pump several times, and pull the starter cord until the engine ignites. It’s important to always ensure safety measures are in place before starting.

What Maintenance Is Required?

Regular upkeep is essential to keep the FS 38 running smoothly. Common maintenance tasks include:

- Cleaning the air filter regularly to prevent blockages.