When it comes to maintaining and servicing your equipment, understanding the arrangement of its essential elements is crucial. This guide provides a clear and comprehensive view of how various mechanical parts interact and fit together, ensuring smooth operation and longevity of the machine.

The intricate connections between the components play a vital role in the overall performance. A well-organized structure not only enhances the ease of repairs but also simplifies regular maintenance tasks. With the right knowledge, you can easily identify each element’s location and function.

By gaining insights into the machine’s internal layout, you empower yourself to handle troubleshooting more effectively. This approach reduces downtime and helps keep your equipment running efficiently for years to come.

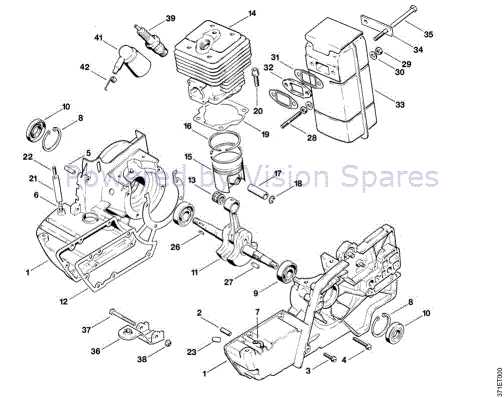

Overview of Stihl 08 Components

The internal structure of this model is comprised of various interconnected elements, each playing a crucial role in its operation. Understanding the key mechanisms and how they work together is essential for maintaining performance and longevity. Below is a detailed look at the major elements that contribute to the overall functionality of the device.

| Component | Description |

|---|---|

| Engine Assembly | The core power unit responsible for driving the machine, designed to provide reliable and efficient energy output. |

| Fuel System | A carefully designed network that ensures the proper mix and flow of fuel, enabling smooth and consistent operation. |

Cutting Mechanism

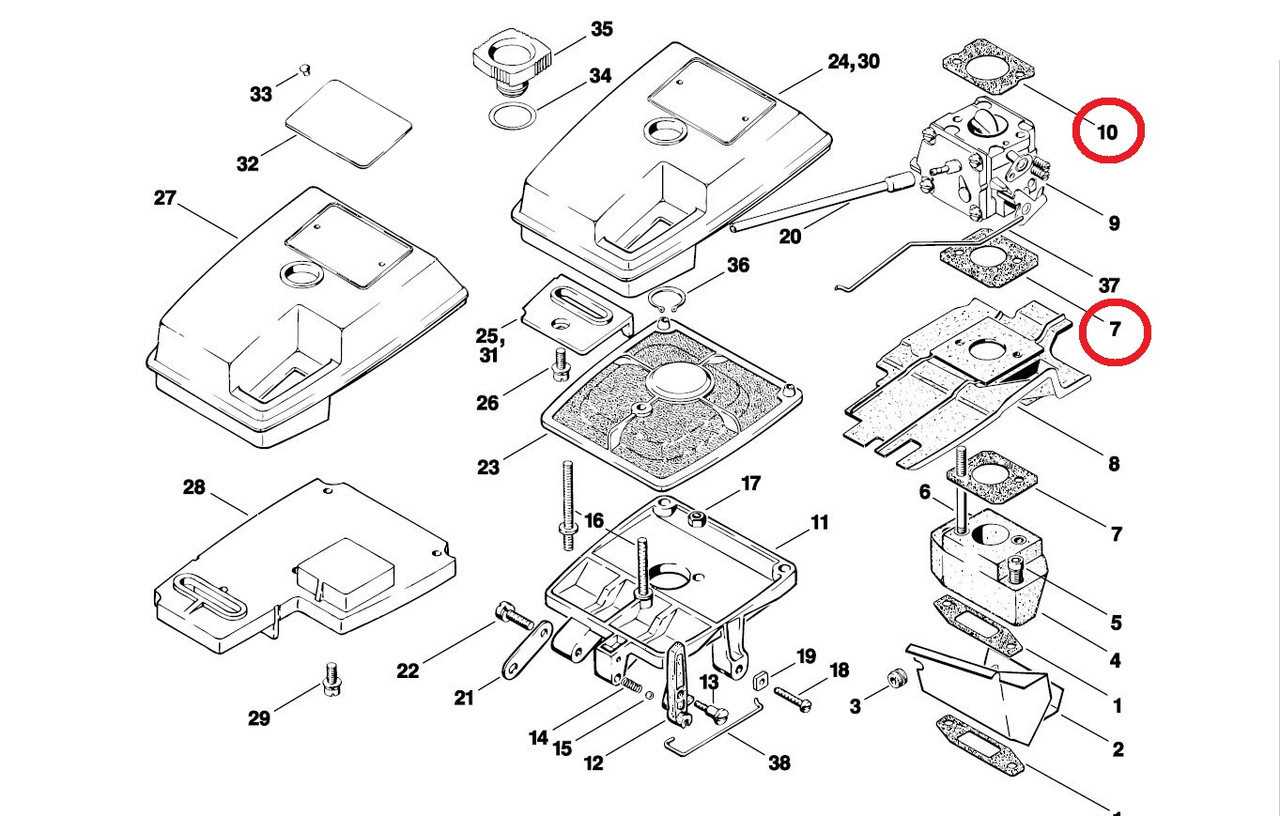

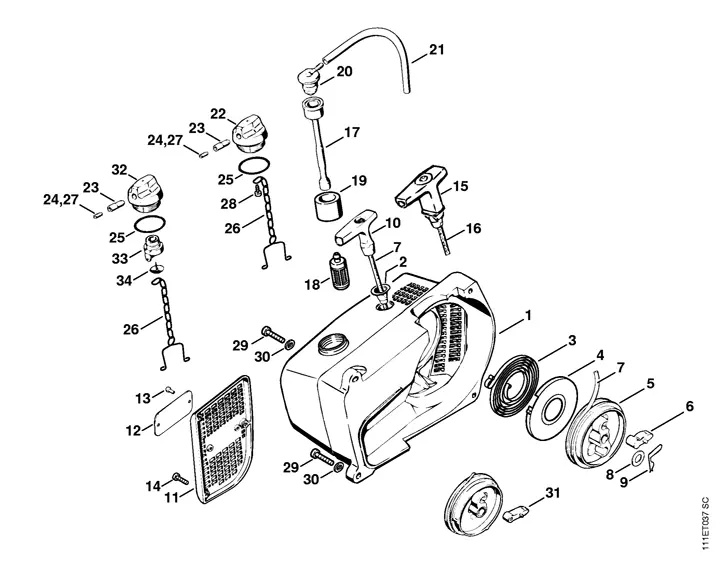

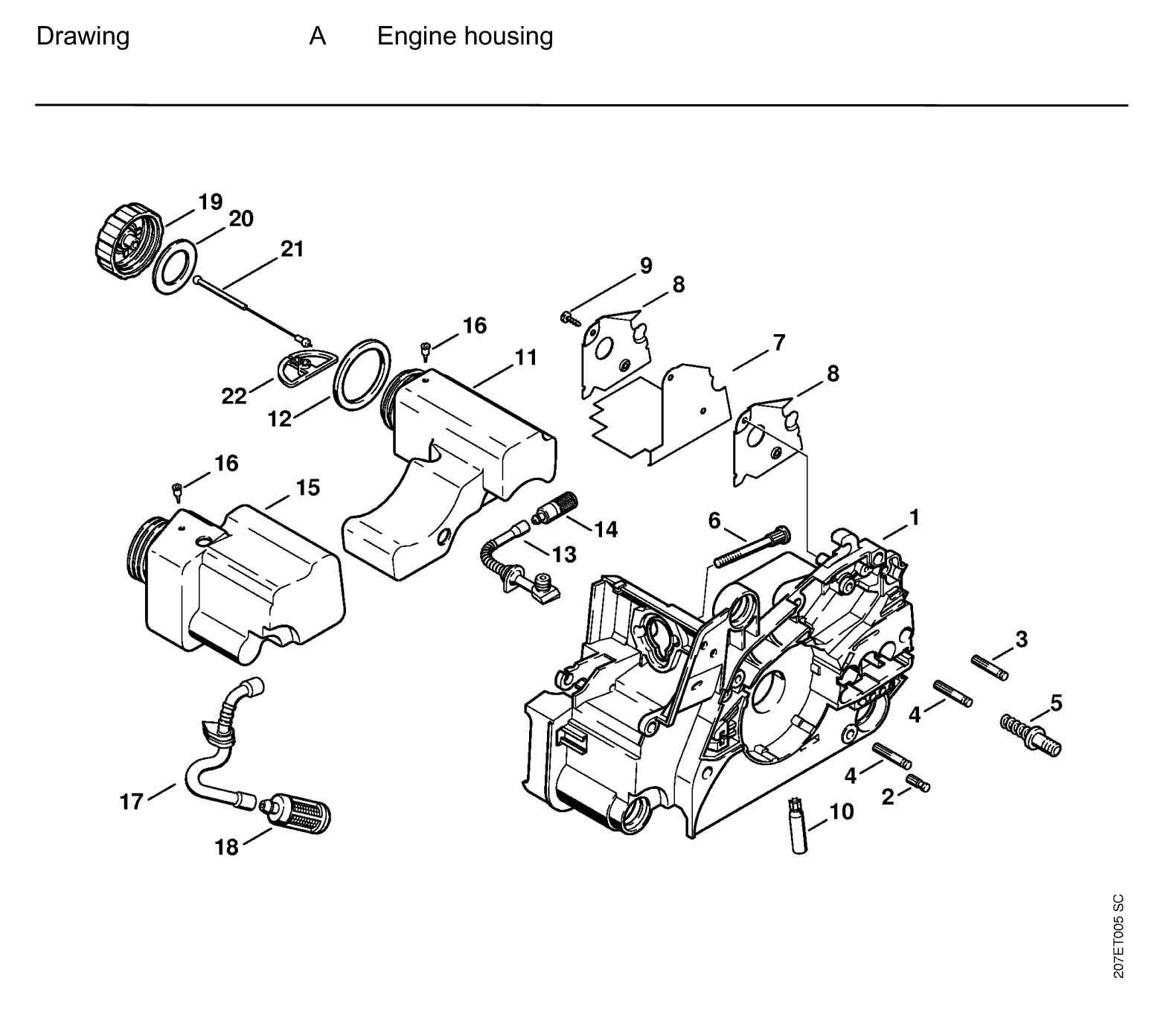

Understanding the Engine LayoutThe structure of the motor is essential for ensuring optimal performance and longevity. By familiarizing yourself with the arrangement of various internal components, you can gain a deeper appreciation for how the machine operates. This knowledge can be invaluable when it comes to maintaining or troubleshooting issues that may arise over time. At the core of the motor lies a well-organized system of elements that work in harmony to produce energy and ensure smooth functioning. The positioning of these elements is crucial for balancing power output and efficiency. Recognizing the significance of each component’s placement within the system can help in understanding its overall role and functionality. Additionally, being aware of the logical sequence of elements can aid in recognizing potential problems early on, allowing for timely adjustments or repairs. A clear understanding of the motor’s internal arrangement will ultimately contribute to a better overall operation. Guide to the Fuel System StructureThe fuel system is a crucial component in the operation of outdoor power equipment, ensuring that the engine receives the appropriate mixture of fuel and air for optimal performance. Understanding the layout and function of each element within this system can significantly enhance maintenance efforts and troubleshooting processes. Key Components of the Fuel SystemAt the heart of the fuel system are several vital elements, including the fuel tank, lines, pump, and carburetor. The fuel tank stores the fuel, while lines transport it to the engine. The pump plays a critical role in moving the fuel, ensuring it reaches the carburetor where the air-fuel mixture is prepared for combustion. Each of these parts must function harmoniously to maintain efficiency and reliability. Maintaining Fuel System Integrity

Regular inspection and maintenance of the fuel system are essential for preventing issues such as clogs or leaks. Checking for cracks in the lines, ensuring the filter is clean, and verifying that the tank is free from contaminants can prolong the lifespan of the equipment. By keeping the fuel system in optimal condition, users can enjoy consistent performance and avoid unnecessary repairs. Chain Assembly and Key ElementsThe chain mechanism is a critical component in ensuring smooth and efficient operation of cutting tools. Understanding its construction and the functions of various elements can enhance maintenance and performance. This section will delve into the essential parts of the chain assembly, highlighting their roles and importance. Key components of the chain mechanism include:

Proper maintenance of these elements is essential for longevity and effectiveness. Regular inspections and timely replacements can prevent operational failures and enhance the overall functionality of the tool. Understanding how each part works together will aid users in troubleshooting and performing repairs, ultimately leading to a more reliable cutting experience. Exploring the Ignition System Parts

The ignition system plays a critical role in the overall performance of any engine. Understanding its components can enhance maintenance and troubleshooting, ensuring optimal functionality and longevity. Key Components

Importance of Each Part

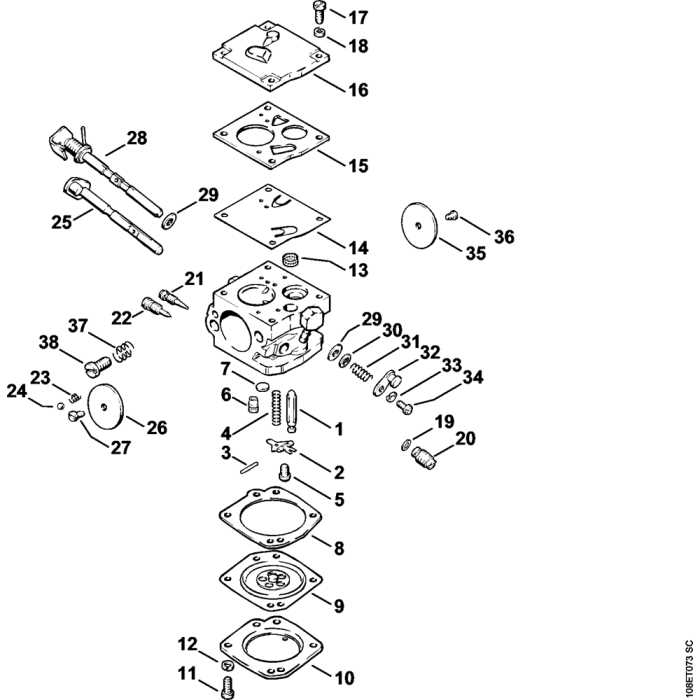

Each element in the ignition setup is vital for proper engine operation. A malfunction in any component can lead to performance issues, making it crucial to regularly inspect and replace worn-out pieces. Detailed Look at the Carburetor Setup

The carburetor is a crucial component that plays a vital role in the engine’s performance, blending fuel and air for optimal combustion. Understanding its configuration and functionality can significantly enhance maintenance and troubleshooting efforts. Components: The assembly typically includes a float chamber, venturi, and adjustment screws, each serving specific purposes. The float chamber regulates fuel levels, while the venturi creates a vacuum that draws fuel into the air stream. Adjustment: Proper calibration of the adjustment screws is essential for achieving the ideal air-fuel mixture. Rich or lean settings can lead to performance issues, making regular checks imperative for maintaining efficiency. Maintenance: Regular cleaning of the carburetor helps prevent clogs and ensures smooth operation. It’s advisable to inspect gaskets and seals for wear, as any leaks can disrupt performance. Examining the Clutch and Drive MechanismThe engagement and disengagement of the rotational force in power tools are vital for efficient operation. This section explores the intricacies of the system responsible for transferring energy from the motor to the cutting components, highlighting the significance of each element in ensuring smooth functionality. Clutch: The clutch acts as a critical interface, allowing for controlled engagement and disengagement. When activated, it ensures that the tool operates only when necessary, preventing unnecessary wear and enhancing safety. Drive System: The drive system is composed of various gears and linkages that convert the motor’s rotational movement into usable power. This mechanism must be precisely engineered to withstand high torque while maintaining efficiency and durability. Understanding these components provides insights into the overall performance of the tool, allowing users to maintain optimal functionality and prolong the lifespan of their equipment. Air Filter and Exhaust System ConfigurationThe configuration of the air filtration and exhaust systems is crucial for optimal engine performance and longevity. Proper airflow not only enhances combustion efficiency but also minimizes harmful emissions. Understanding the relationship between these components can significantly impact overall machine functionality. Air Filter FunctionalityThe air filter plays a vital role in maintaining clean airflow to the engine. A well-functioning filter prevents dust and debris from entering the combustion chamber, ensuring efficient operation. Key aspects include:

Exhaust System DesignThe exhaust system directs harmful gases away from the engine and operator while also influencing engine sound and efficiency. Important design elements include:

Handlebar and Control Features Explained

The handlebar and control mechanisms are vital components that significantly influence the usability and comfort of outdoor power equipment. These features not only enhance maneuverability but also ensure operator safety during operation. Understanding the layout and functionality of these elements is essential for achieving optimal performance and efficiency. At the forefront, the design of the handlebar often incorporates ergonomic principles, allowing for a natural grip that minimizes fatigue. Controls are strategically placed to ensure easy access, facilitating seamless adjustments while in use. This arrangement promotes a more intuitive handling experience, allowing users to focus on their tasks without unnecessary distractions. Moreover, certain models may include additional features such as vibration dampening systems and adjustable handle heights. These enhancements contribute to greater control and comfort, making it easier for operators to manage different terrains and conditions. A comprehensive grasp of these aspects ultimately leads to a more enjoyable and effective operational experience. Maintenance of the Oil Pump SystemThe oil pump system is essential for ensuring optimal performance and longevity of the equipment. Regular upkeep is necessary to prevent wear and ensure proper lubrication, which can enhance efficiency and minimize potential issues. Inspection and CleaningRegularly inspecting the pump for any signs of wear or damage is crucial. Cleaning the system to remove debris and residue helps maintain proper function. Pay attention to the intake screen and passages to prevent blockages that could impede oil flow. Oil Quality and LevelsUsing the correct type of lubricant and maintaining proper levels is vital. Frequent checks can help identify any leaks or deficiencies early on. Always replace the oil according to the manufacturer’s recommendations to ensure smooth operation. Troubleshooting Common Wear and Tear PartsUnderstanding the signs of wear in various components can significantly enhance the longevity and efficiency of your equipment. By recognizing the common issues, you can effectively address them before they escalate into more serious problems. Identifying Common Issues

Maintenance Tips

|