Maintaining outdoor machinery requires a deep understanding of its components and how they function together. A well-organized reference can significantly simplify the process of identifying and replacing parts, ensuring your equipment runs smoothly and efficiently. This guide aims to provide clarity on the intricate details of your tool’s construction.

In this section, we will delve into the layout and functionality of various elements within the device. Recognizing each segment’s role can enhance your ability to troubleshoot issues effectively. Whether you are a novice or an experienced user, having a visual reference at your disposal will undoubtedly prove beneficial.

Additionally, knowing the specific configurations and connections among the different sections not only aids in repairs but also helps in understanding the overall operation. This foundational knowledge empowers users to tackle maintenance tasks with confidence and precision, ultimately extending the lifespan of their machinery.

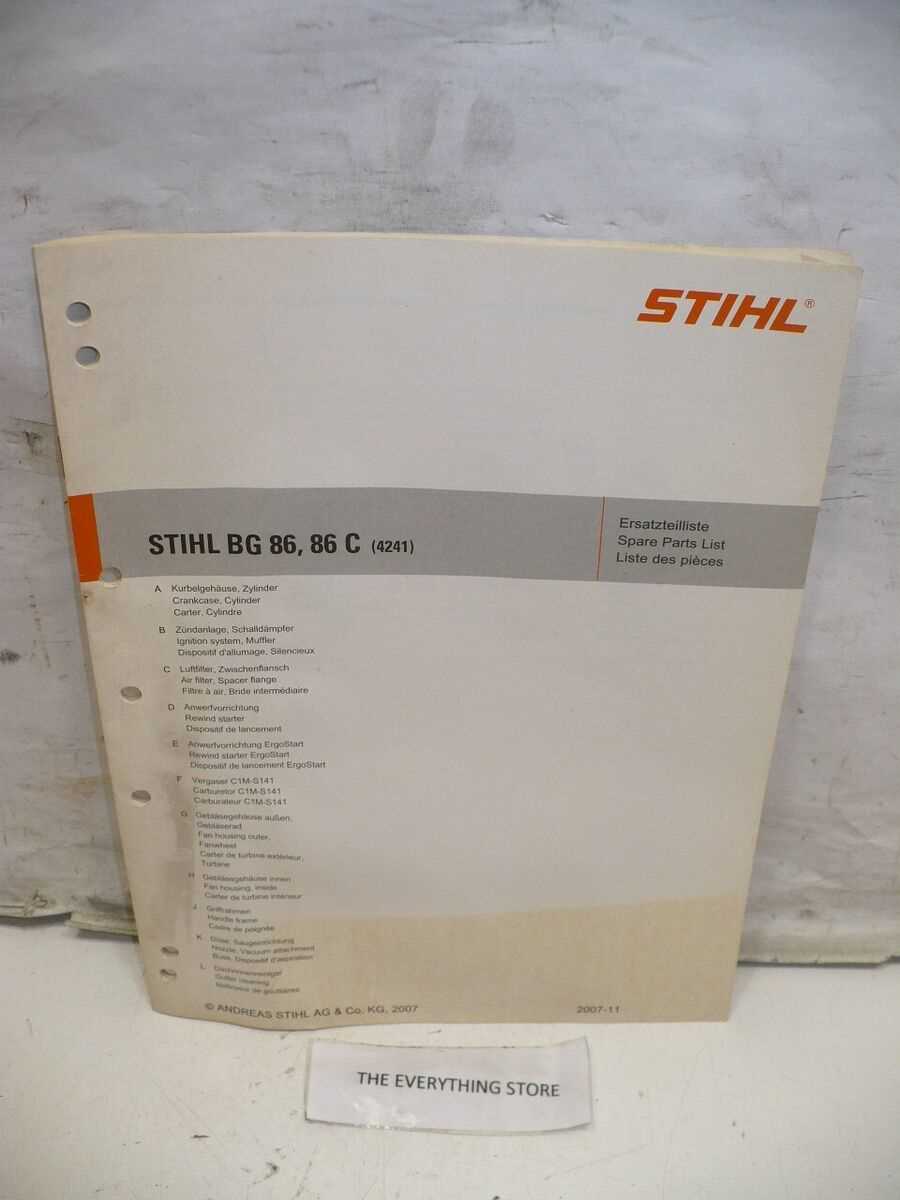

Understanding Stihl BG86C Components

In the realm of outdoor equipment, comprehending the various elements that constitute a powerful blower is essential for optimal performance. Each component plays a pivotal role in ensuring efficiency and functionality, contributing to the machine’s overall effectiveness in yard maintenance tasks.

Key Elements of the Equipment

The primary segments include the engine, air intake, and nozzle, which work in harmony to generate airflow. The engine serves as the powerhouse, while the air intake filters the environment, ensuring clean operation. Additionally, the nozzle design directly influences the airflow direction and intensity, making it crucial for targeted cleaning.

Maintenance and Functionality

Regular upkeep of these components is vital for longevity. Inspecting and replacing worn parts can prevent breakdowns, ensuring that the machine operates at its ultimate capacity. Understanding how each piece interacts will enhance your ability to troubleshoot and maintain your equipment effectively.

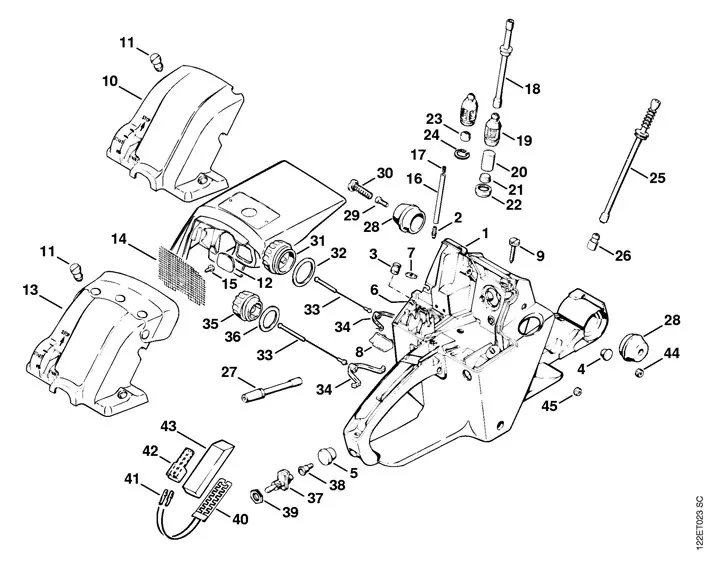

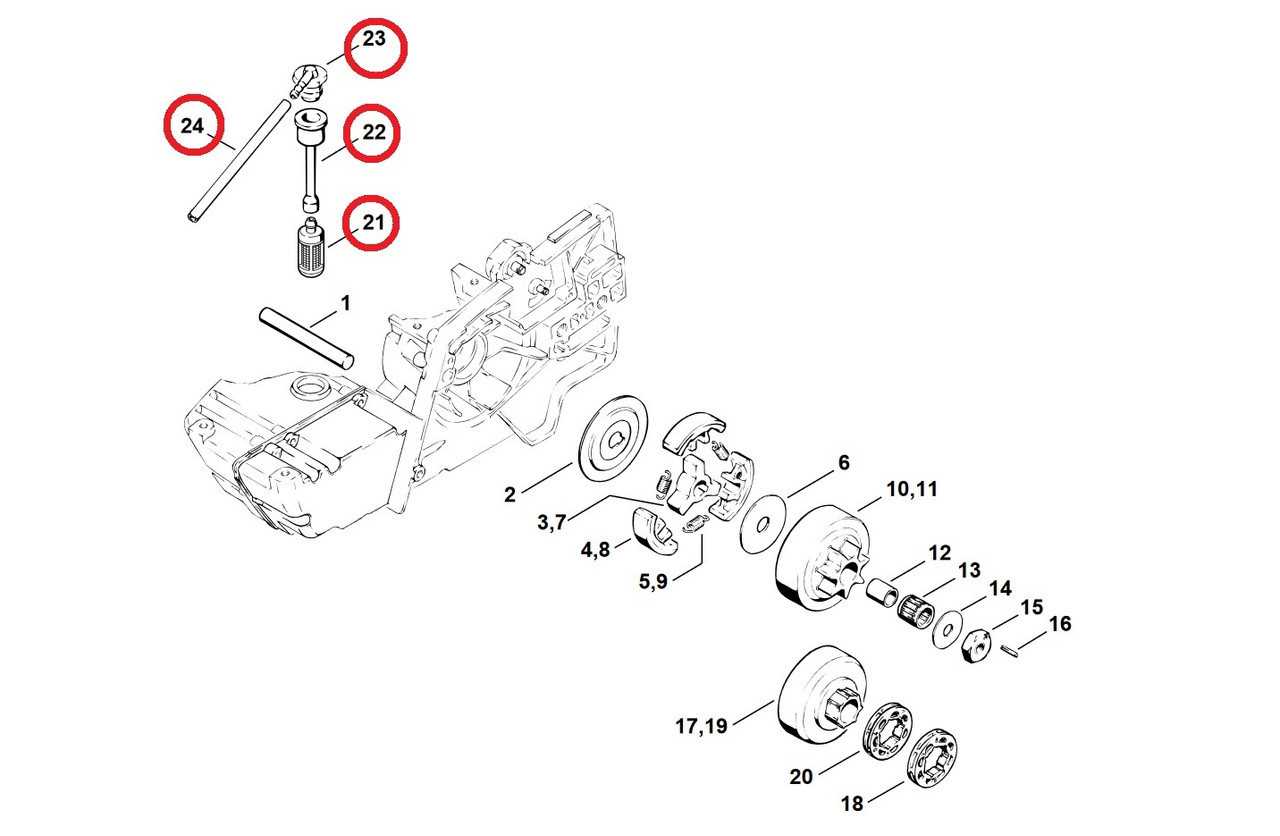

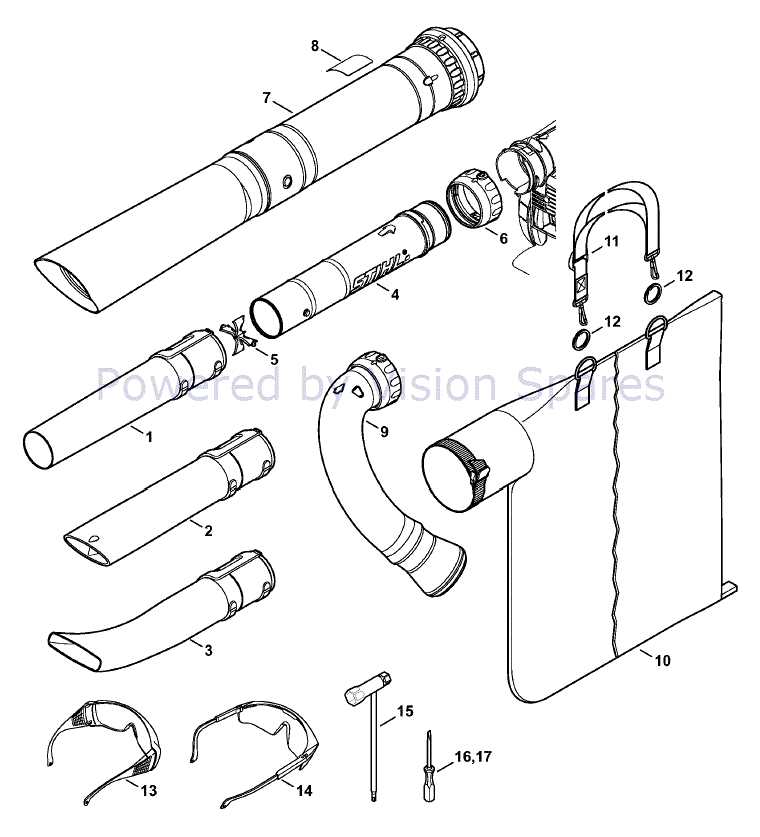

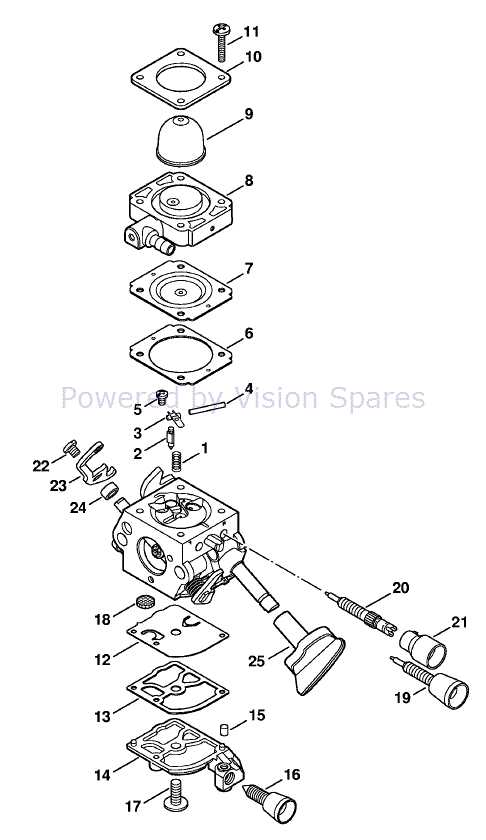

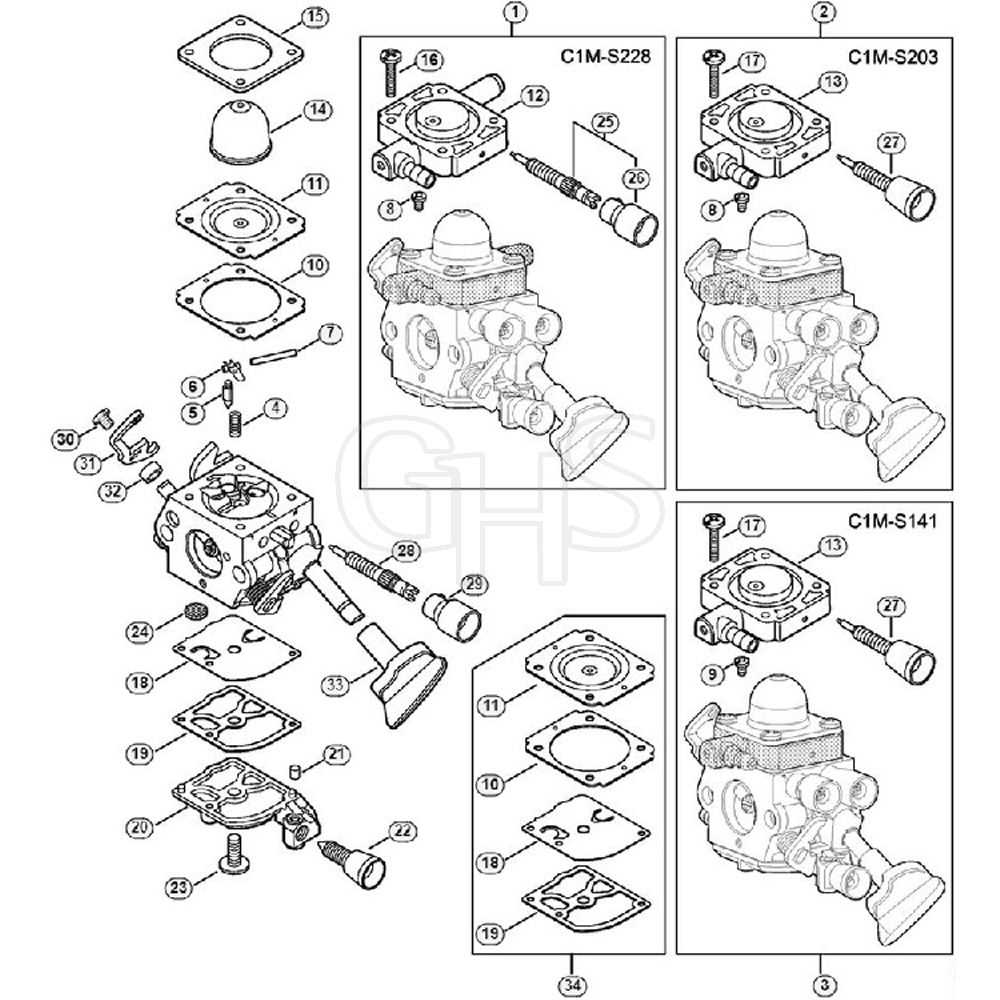

Overview of the Parts Diagram

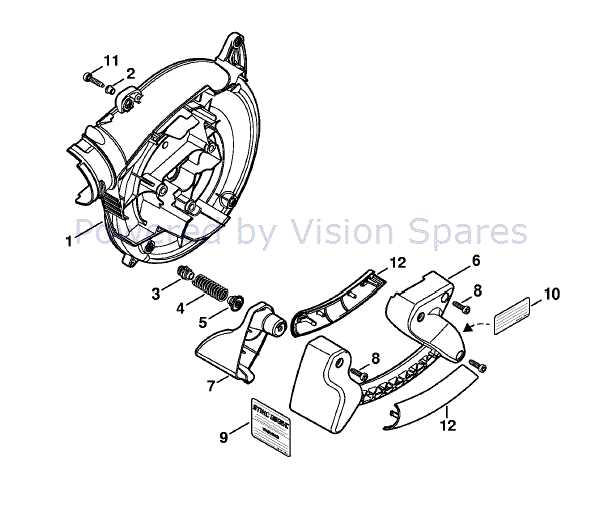

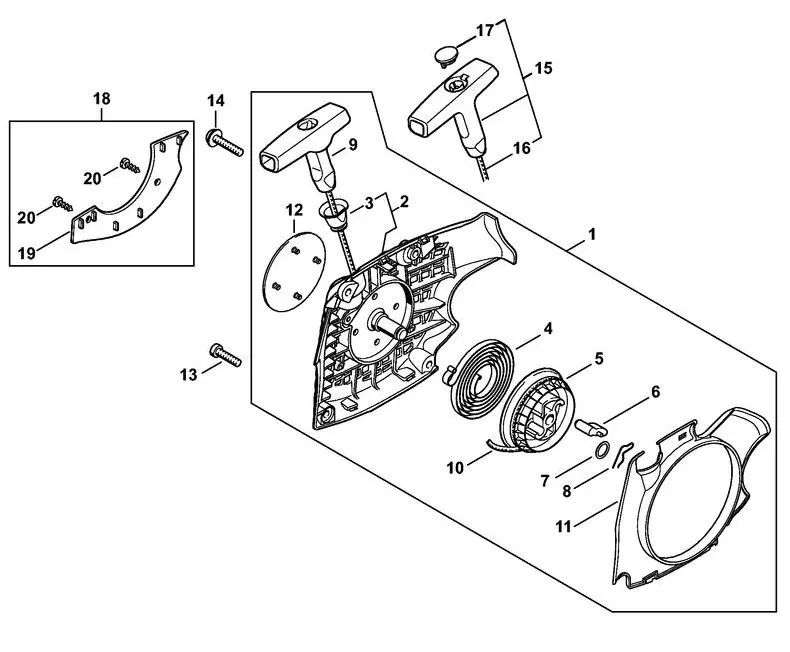

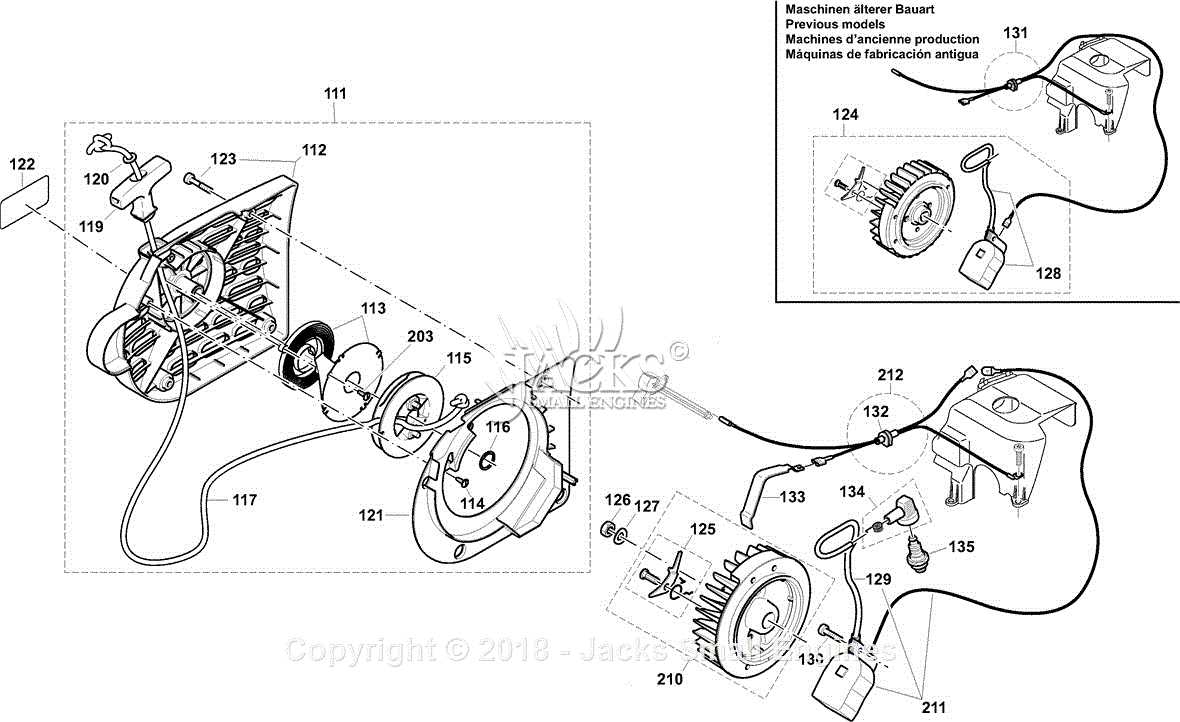

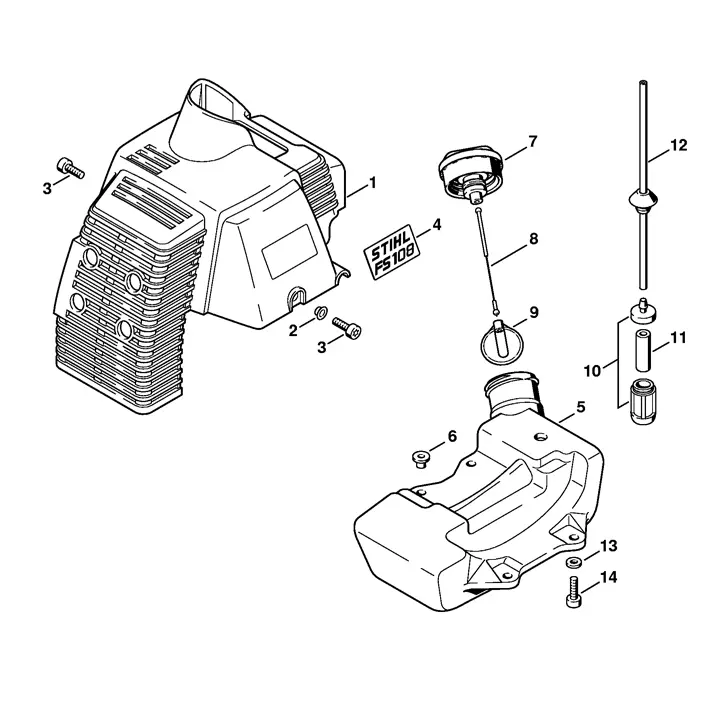

Understanding the assembly of a machine is crucial for maintenance and repairs. A visual representation of its components provides insight into how each element interacts within the overall system. This overview offers a comprehensive look at the various sections, helping users identify and locate specific pieces easily.

Each section of the visual guide serves a unique purpose, illustrating the relationship between different parts. From the engine to the outer casing, every component is depicted, allowing for a clearer understanding of functionality. By analyzing these illustrations, users can efficiently troubleshoot issues or plan for replacements when necessary.

Moreover, having access to this visual reference simplifies the process of reassembly after maintenance. It ensures that all parts are accounted for and correctly positioned, minimizing the risk of errors during repairs. Ultimately, this knowledge not only enhances the user’s proficiency but also extends the lifespan of the equipment.

Importance of Accurate Diagrams

Precise illustrations serve as essential tools in understanding complex machinery. They offer clarity and facilitate effective troubleshooting, ensuring users can navigate maintenance tasks with confidence.

- Enhances comprehension of assembly and disassembly processes.

- Minimizes the risk of errors during repairs.

- Streamlines inventory management for replacements.

- Provides a visual reference that aids in training and education.

Ultimately, having reliable visuals not only improves efficiency but also prolongs the lifespan of equipment.

Common Parts and Their Functions

This section explores essential components commonly found in handheld blowers, emphasizing their roles and importance in overall functionality. Understanding these elements can significantly enhance maintenance and operational efficiency.

Air Filter: The air filter is crucial for preventing dirt and debris from entering the engine, ensuring optimal performance and longevity.

Fuel Tank: This component stores the mixture of fuel and oil, providing the necessary power to the engine during operation.

Impeller: The impeller generates airflow by spinning rapidly, enabling the device to effectively move leaves and debris.

Throttle Trigger: This control allows the user to adjust engine speed, giving them the ability to manage power output based on task requirements.

Spark Plug: The spark plug ignites the fuel-air mixture in the combustion chamber, playing a vital role in starting and running the engine smoothly.

Exhaust System: This system directs harmful gases away from the engine, contributing to safety and environmental compliance during operation.

How to Read the Diagram

Understanding technical illustrations is crucial for effective maintenance and repairs. These visuals provide a detailed representation of components, allowing users to identify parts and their functions clearly. By familiarizing yourself with the layout, you can streamline your troubleshooting and assembly processes.

Identifying Key Elements

Begin by noting the symbols and labels associated with each component. Each item typically has a unique identifier, which corresponds to a list of specifications. This reference is essential for ordering replacements or understanding how parts interact.

Using the Reference Table

| Identifier | Description | Function |

|---|---|---|

| A1 | Fuel Tank | Holds fuel for operation |

| B2 | Air Filter | Prevents debris from entering the engine |

| C3 | Throttle Control | Regulates engine speed |

Identifying Wear and Tear

Understanding the signs of deterioration is crucial for maintaining optimal performance in any outdoor power equipment. Regular inspections can help you spot issues early, ensuring that your machine operates efficiently and safely. Knowing what to look for can save time and prevent costly repairs.

Common Indicators of Damage

Look for visible signs such as cracks, fraying, or excessive wear on components. Listen for unusual sounds during operation, which may indicate internal problems. Additionally, monitor for changes in performance, such as decreased power or erratic function, as these can signal underlying issues.

Preventive Measures

Regular maintenance is key to extending the life of your equipment. Lubrication, cleaning, and timely replacement of worn parts can significantly reduce the risk of serious damage. Keeping a maintenance log will also help track the condition of your machine over time, allowing for proactive care.

Replacement Parts Availability

When it comes to maintaining outdoor equipment, accessibility to components is crucial for ensuring longevity and optimal performance. Users often seek reliable sources for acquiring necessary elements that may wear out or become damaged over time. Understanding the market and knowing where to find these items can greatly enhance the user experience.

Availability of components can vary based on several factors, including the model and manufacturer. Many suppliers offer a wide selection of options, from original manufacturer items to aftermarket alternatives. This variety allows users to choose based on quality, price, and specific needs.

Moreover, online marketplaces and local dealers typically maintain an inventory of these essential components, making it easier for users to find what they need. It is advisable to check multiple sources to compare prices and availability, ensuring a more informed decision.

Additionally, seasonal demand can influence stock levels, so planning ahead for maintenance can prevent delays. Utilizing reliable sources not only aids in swift repairs but also contributes to the overall efficiency of equipment operation.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your outdoor equipment requires regular upkeep. By following a few essential practices, you can significantly extend the life of your tools and enhance their performance.

Regular Cleaning

Cleanliness is crucial for optimal functionality. After each use, remove debris and dirt from the exterior and air filters. This simple task prevents clogs and ensures proper airflow, which is essential for smooth operation.

Routine Inspections

Perform routine checks on all components to identify wear and tear. Pay attention to seals, hoses, and moving parts. Early detection of issues can prevent costly repairs and prolong the equipment’s lifespan. Always refer to the manual for specific maintenance guidelines.

Tools Required for Repairs

When undertaking maintenance or fixing equipment, having the right tools is essential for a successful outcome. Proper instruments not only facilitate efficient work but also ensure safety and precision during the repair process.

Essential Hand Tools

Basic hand tools include screwdrivers, wrenches, and pliers. These tools are crucial for loosening or tightening various components. A good set of these instruments can make tasks much simpler and more effective.

Power Tools and Equipment

For more complex repairs, power tools such as drills and saws may be necessary. These machines enable quicker and more efficient work, allowing for deeper exploration into mechanical issues and achieving the ultimate results with ease.

Step-by-Step Repair Guide

This guide provides a comprehensive approach to fixing common issues that may arise in outdoor power equipment. Following these steps will help ensure that your machinery operates efficiently and reliably. Each stage of the process is designed to simplify troubleshooting and repair, making it accessible even for those with minimal experience.

Identification of Problems

Begin by assessing the equipment to identify any visible signs of wear or malfunction. Look for leaks, unusual noises, or failure to start. Take notes on any specific symptoms you observe, as this information will be crucial in diagnosing the underlying issues.

Disassembly and Inspection

Once you have pinpointed the problem, proceed with disassembling the necessary components. Use appropriate tools to avoid damage. Carefully inspect each part for signs of wear, cracks, or other damage. Replace any components that do not meet operational standards, and clean all surfaces to ensure proper functioning during reassembly.

Common Issues and Solutions

In any equipment, operational challenges can arise that affect performance and efficiency. Identifying these common problems is crucial for maintaining functionality and ensuring longevity. Here, we explore prevalent issues along with effective strategies to resolve them.

One frequent concern is difficulty starting the machine. This can often be attributed to fuel quality or a clogged filter. Regularly checking and replacing the fuel can significantly improve starting reliability.

Another issue might be inconsistent power output during operation. This often indicates a need for maintenance on the air filter or spark plug. Cleaning or replacing these components can restore optimal performance.

Moreover, if the unit is emitting excessive vibrations, it may suggest that certain parts are loose or worn out. Conducting a thorough inspection and tightening or replacing any faulty elements can enhance stability during use.

Lastly, poor cutting performance can stem from dull blades or incorrect alignment. Sharpening or adjusting the blades ensures efficient operation and better results.

Upgrading Stihl BG86C Components

Enhancing the performance of your outdoor power equipment can significantly improve its efficiency and longevity. By carefully selecting and upgrading various components, you can achieve better results in your landscaping tasks, ensuring a more powerful and reliable experience. This section will explore the essential upgrades that can make a substantial difference in functionality and ease of use.

Performance Enhancements

Investing in high-quality air filters and fuel lines can lead to improved airflow and fuel delivery, which are crucial for optimal engine performance. Additionally, considering a more efficient ignition system can enhance starting reliability and responsiveness. Upgrading to a higher capacity spark plug can also contribute to smoother operation and increased power output.

Comfort and Usability

Upgrades don’t just focus on performance; enhancing user comfort is equally important. Ergonomic handles and vibration-dampening systems can make prolonged use much more enjoyable. Adding a shoulder strap can further alleviate strain, allowing for extended operation without discomfort. These modifications not only improve efficiency but also contribute to a better overall experience.

Resources for Further Assistance

When seeking help with equipment maintenance and repairs, there are numerous resources available to enhance your understanding and troubleshoot effectively. Utilizing these materials can ensure you achieve optimal performance and longevity for your tools.

Online Communities

- Reddit Forums – Engage with other enthusiasts and professionals for tips and advice.

- Tree Service Forum – A platform dedicated to discussions about various outdoor equipment.

- Facebook Groups – Connect with community members who share your interests and challenges.

Official Support Channels

- Manufacturer Support Page – Access manuals, troubleshooting guides, and customer service.

- Service Center Locator – Find authorized repair facilities near you for professional assistance.

- YouTube Channel – Watch instructional videos that demonstrate repair techniques and best practices.