The functionality of any outdoor device relies heavily on its individual elements, each serving a specific purpose to ensure optimal performance. Understanding how these elements interconnect can greatly enhance maintenance and troubleshooting efforts, allowing users to keep their tools in top condition.

In this section, we will explore the various components essential for the operation of your device. By familiarizing yourself with these integral parts, you can better appreciate the mechanics behind their operation, which can lead to more informed decisions during repairs or upgrades.

Moreover, having a clear visualization of how these components fit together is invaluable. It enables users to pinpoint issues swiftly and effectively, ensuring that their equipment remains reliable and efficient throughout its lifespan. Knowledge of these elements is key to mastering the art of equipment care.

Understanding Stihl FS 35 Components

Familiarity with the various elements of a cutting tool can significantly enhance its maintenance and operational efficiency. Each component plays a crucial role in the overall functionality, contributing to the seamless performance of the equipment. Grasping the purpose and interrelation of these parts is essential for both troubleshooting and optimizing usage.

Key Elements of the Equipment

The central components include the engine, which serves as the powerhouse, delivering the necessary energy for operation. Additionally, the cutting attachment is vital for executing the intended tasks, ensuring precision and effectiveness. Other critical elements such as the handle, throttle control, and harness contribute to user comfort and control, enhancing the overall experience during operation.

Importance of Regular Inspection

Regular examination of these elements is paramount for sustained performance and longevity. Identifying wear and tear early can prevent unexpected breakdowns and costly repairs. Proper care ensures that each component functions harmoniously, enabling the tool to perform efficiently in various tasks.

Overview of Stihl FS 35 Parts

This section provides a comprehensive look at the various components that make up a specific model of a handheld garden tool. Understanding these elements is crucial for effective maintenance and repair, ensuring optimal performance and longevity. Each segment plays a vital role in the overall functionality, making it essential to be familiar with their arrangement and purpose.

Key Components

The assembly consists of multiple integral segments that work together seamlessly. Each component contributes to the device’s efficiency, enhancing its capabilities in cutting and trimming tasks.

Functionality and Maintenance

Proper upkeep of each element is vital for smooth operation. Regular inspection and replacement of worn-out pieces can significantly improve performance and extend the lifespan of the tool.

| Component | Description |

|---|---|

| Engine | The power source driving the entire mechanism. |

| Cutter Head | Houses the cutting line or blade, essential for trimming. |

| Handle | Provides grip and control for the user during operation. |

| Fuel Tank | Stores the necessary fuel for the engine’s operation. |

| Guard | Protects the user from debris and ensures safe usage. |

Common Issues with FS 35 Parts

The maintenance and repair of outdoor equipment can often present challenges that may arise from various components. Understanding these frequent complications can help ensure efficient operation and longevity. Identifying symptoms early allows for timely interventions, minimizing the impact on functionality.

Below is a summary of typical problems encountered with various components:

| Component | Common Issue | Possible Cause | Suggested Solution |

|---|---|---|---|

| Engine | Difficulty starting | Fuel blockage or stale fuel | Clean fuel lines and replace old fuel |

| Ignition System | Intermittent spark | Worn spark plug | Replace the spark plug |

| Trimmer Head | Line not feeding | Line jammed or worn | Clear jam and replace line if necessary |

| Fuel Tank | Leakage | Cracks or damaged seals | Inspect and replace damaged components |

| Air Filter | Reduced performance | Dirt accumulation | Clean or replace air filter |

Importance of Genuine Stihl Components

The utilization of authentic components in machinery maintenance and repair is essential for ensuring optimal performance and longevity. These original elements are specifically designed to fit seamlessly with the equipment, providing reliability and efficiency that counterfeit alternatives often lack.

Quality assurance is a primary benefit of choosing genuine components. They undergo rigorous testing and adhere to strict manufacturing standards, resulting in higher durability and effectiveness. By using these reliable pieces, operators can minimize the risk of malfunctions, which can lead to costly repairs and downtime.

Moreover, employing authentic items promotes consistent performance. Each component is engineered to work harmoniously with other elements, ensuring that the machinery operates at its best. This synergy is critical in maintaining the balance and functionality of the entire system.

Additionally, opting for original components can enhance warranty protection. Many manufacturers stipulate that the use of non-genuine parts can void warranties, leaving users vulnerable to unexpected repair costs. By investing in authentic components, operators can safeguard their warranties and receive comprehensive support from the manufacturer.

How to Identify Each Part

Understanding the components of a machine is crucial for effective maintenance and troubleshooting. Each element plays a significant role in the overall functionality, and recognizing them can enhance your ability to perform repairs or replacements. This section provides guidance on how to distinguish between various components and ensure proper identification for effective handling.

Visual Inspection Techniques

Begin with a thorough visual examination of the equipment. Familiarize yourself with the external features of each component. Look for unique shapes, colors, and markings that can aid in recognition. Pay attention to the arrangement of parts, as their positioning can also provide clues about their function and importance.

Consulting Reference Materials

Utilize manuals and online resources that provide detailed descriptions and images of the components. These references can serve as a valuable tool in cross-referencing the parts you observe. Many resources include exploded views and labeled images, which can simplify the identification process and clarify any uncertainties.

Replacement Parts and Maintenance Tips

Regular upkeep and timely substitutions are essential for ensuring optimal performance and longevity of your outdoor equipment. By following a few simple guidelines, you can maintain the efficiency of your device and avoid unnecessary downtime.

- Inspect components regularly for wear and damage.

- Keep the engine and air filter clean to promote better airflow.

- Sharpen or replace cutting blades as needed for effective operation.

- Check fuel lines and connectors for leaks or deterioration.

- Ensure spark plugs are in good condition for reliable starting.

When considering replacements, opt for high-quality alternatives that meet or exceed the specifications of the original components. Here are some tips for effective selection:

- Research compatible options that align with your device model.

- Consult user reviews and recommendations for reliability.

- Purchase from reputable suppliers to guarantee authenticity.

- Keep track of replacement schedules to prevent unexpected failures.

Implementing these practices will help you maximize the performance of your equipment while minimizing repair costs and time.

Diagram Interpretation for Repairs

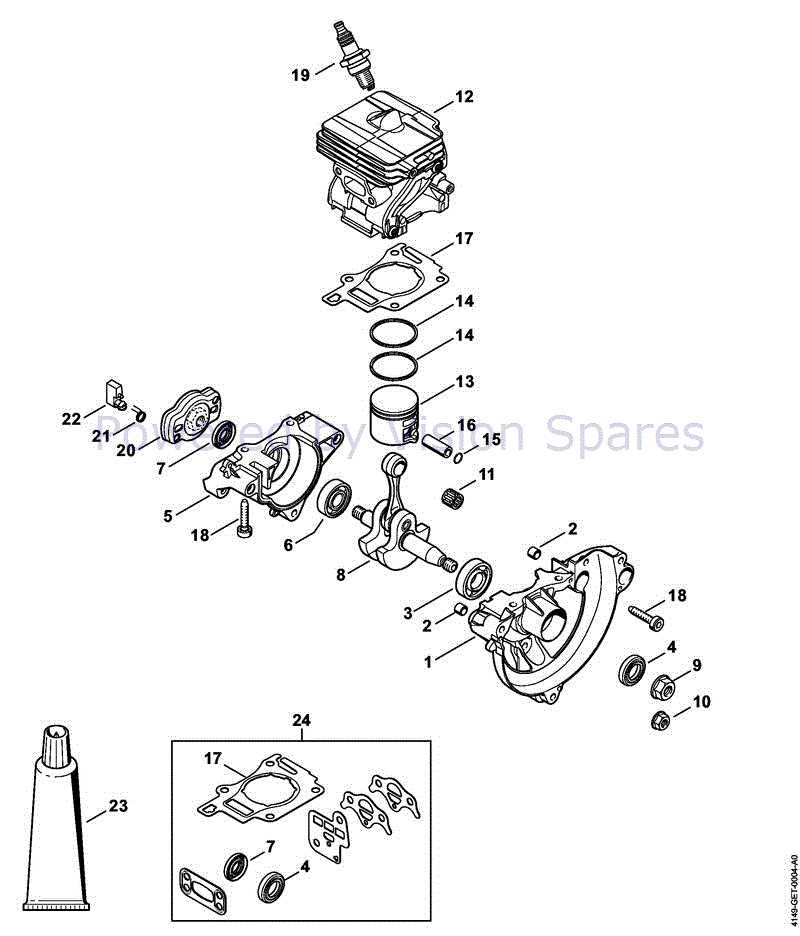

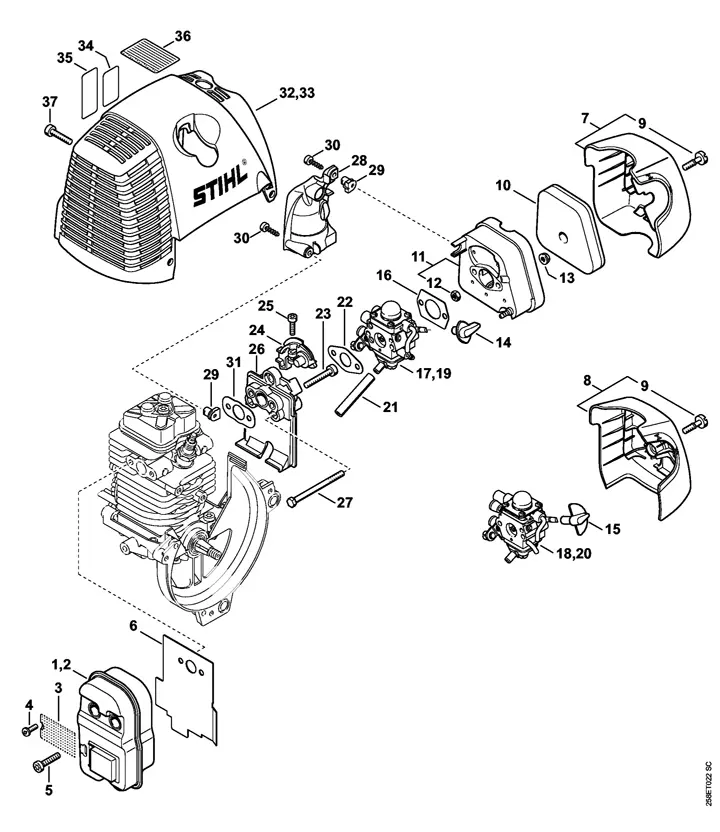

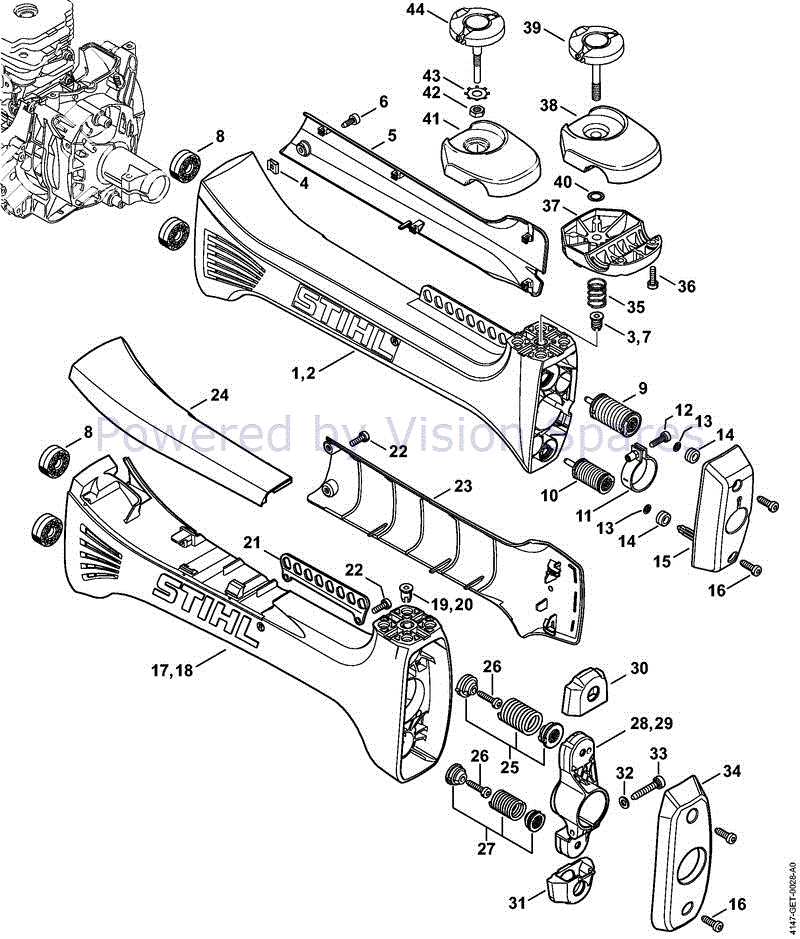

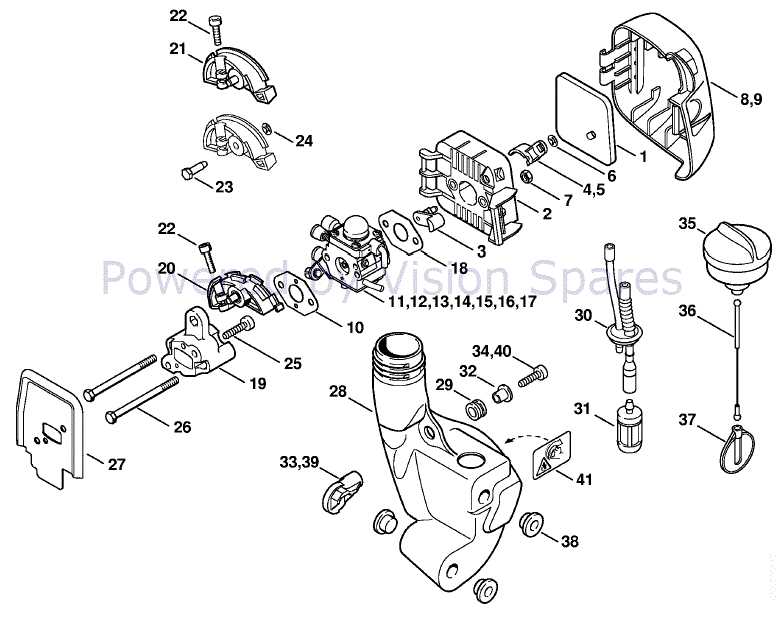

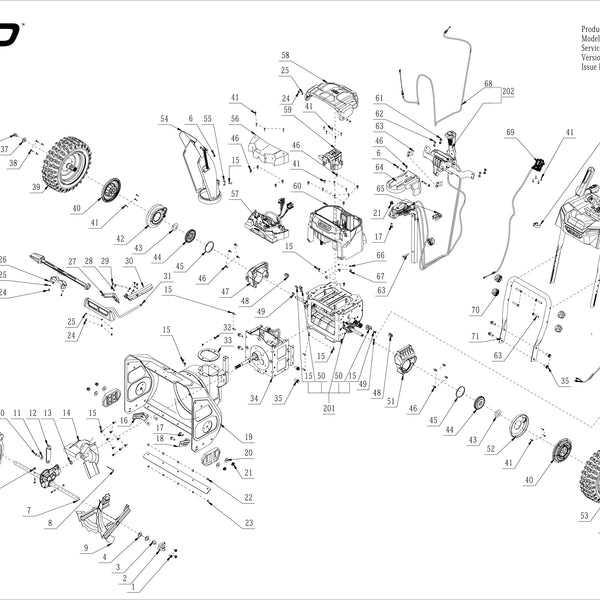

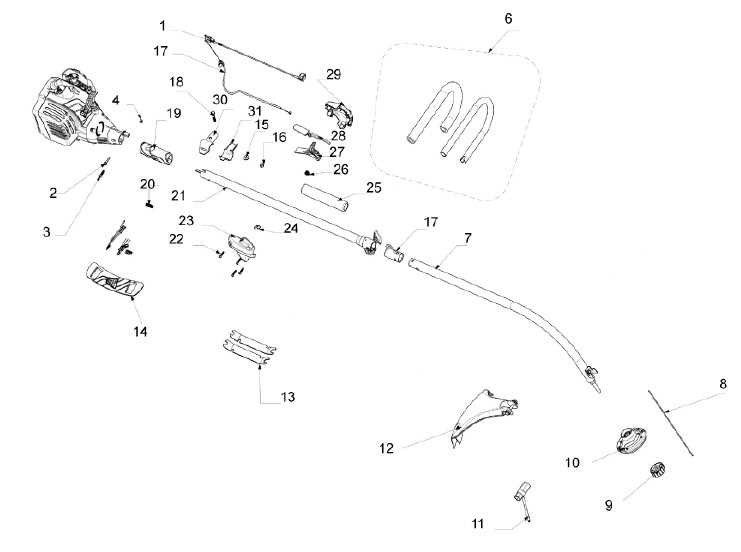

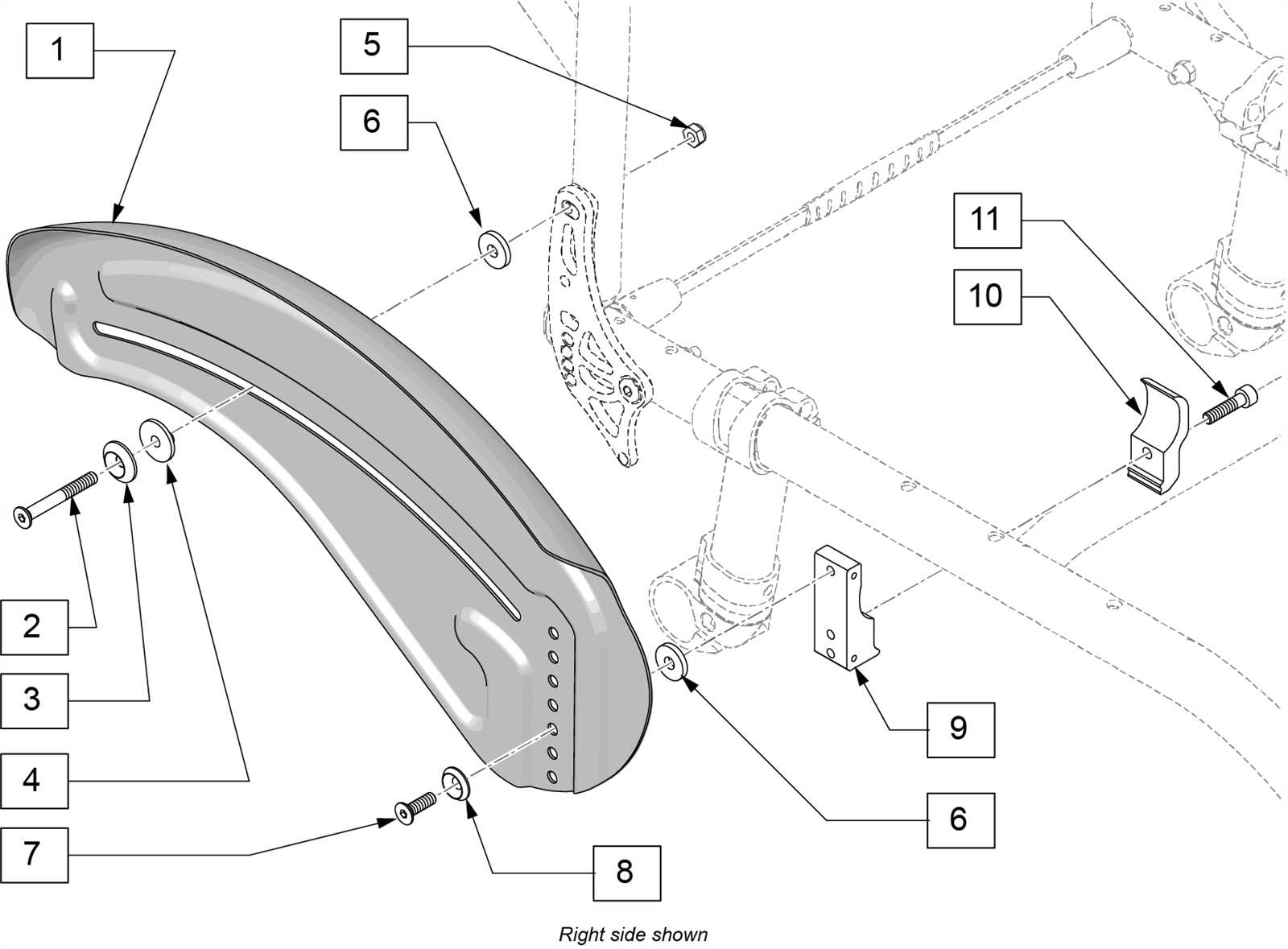

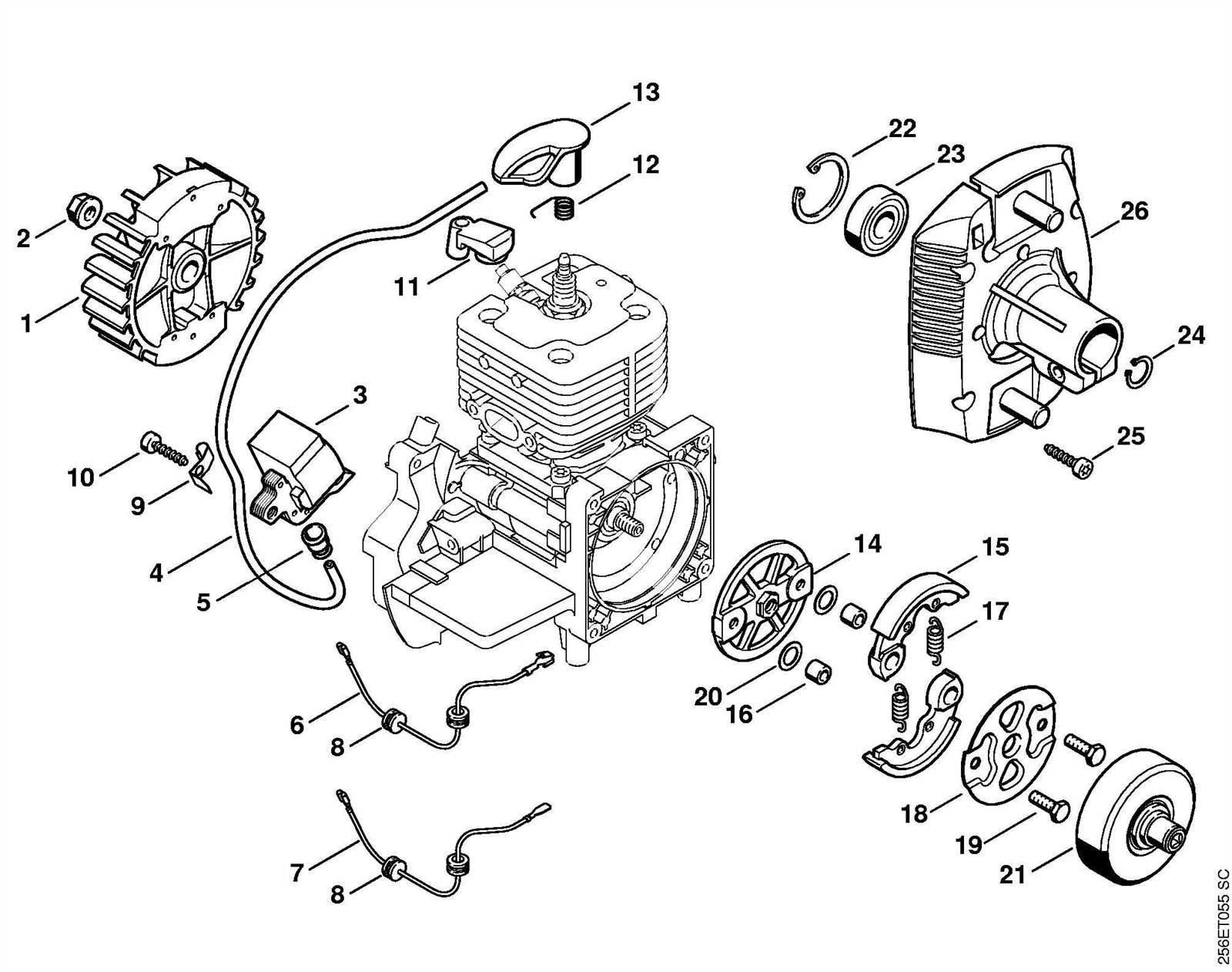

Understanding visual representations of components is essential for effective maintenance and restoration. By analyzing these illustrations, individuals can identify the arrangement and function of various elements within a device. This knowledge empowers users to approach repairs methodically, ensuring that each part is addressed accurately.

Identifying Key Elements

When reviewing illustrations, it’s crucial to focus on the labeling of each section. Components are typically marked with reference numbers or letters, which correspond to a list that outlines their specifications and functionalities. This reference can significantly streamline the repair process, making it easier to locate the necessary items and understand their roles.

Understanding Assembly and Disassembly

Another important aspect of interpreting visual representations is recognizing the sequence of assembly and disassembly. Many illustrations depict the order in which components should be removed or installed, which can prevent damage and ensure a smoother workflow. Following this guidance not only enhances efficiency but also reduces the likelihood of errors during repairs.

Finding Stihl FS 35 Manuals

For those looking to maintain or repair their outdoor power equipment, locating the appropriate documentation is essential. Manuals provide valuable insights, including operational guidelines, maintenance tips, and troubleshooting techniques that can enhance the longevity and performance of the equipment.

These resources can typically be found through various channels. One effective method is to visit the official website of the manufacturer, where downloadable manuals are often available in PDF format. Additionally, numerous online forums and communities dedicated to gardening and landscaping tools may offer links or copies of these important documents.

Another option is to explore local hardware stores or authorized dealers. Many of these establishments keep physical copies of manuals on hand or can assist in obtaining a copy from the manufacturer. Utilizing these avenues ensures access to reliable and detailed information for optimal equipment care.

Parts Compatibility with Other Models

Understanding the interchangeability of components across different models can significantly enhance the versatility and efficiency of equipment maintenance. This section highlights how various units can share specific elements, ensuring users can effectively source replacements or upgrades without compromising performance.

Cross-Model Element Sharing

Many models share common features, enabling the use of identical components in different devices. This not only simplifies repairs but also allows users to utilize a wider range of accessories. When considering replacements, it is beneficial to research and confirm compatibility to avoid operational disruptions.

Benefits of Component Interchangeability

Utilizing compatible components can lead to cost savings and improved functionality. Users can maintain their equipment more efficiently by sourcing affordable alternatives that fit seamlessly. Moreover, the ability to interchange elements fosters a deeper understanding of machinery and encourages resourcefulness in repairs.

Where to Purchase Replacement Parts

Finding reliable sources for acquiring components for your equipment is essential for maintaining its performance and longevity. Numerous avenues exist for obtaining quality replacements that ensure seamless operation. Here are some recommended options to consider.

Authorized Dealers

Visiting certified retailers offers a range of advantages, including:

- Access to genuine components that match your model’s specifications.

- Expert advice and assistance in selecting the right items.

- Potential warranty benefits for your purchases.

Online Retailers

The internet provides a vast marketplace for sourcing various items. Consider the following:

- Reputable e-commerce platforms known for reliable delivery.

- Specialized websites focusing on equipment accessories.

- User reviews and ratings to evaluate product quality and seller credibility.

By exploring these avenues, you can ensure that your equipment remains in optimal condition through the use of quality replacements.

DIY Repairs for Stihl FS 35

Undertaking repairs on your outdoor equipment can be a rewarding experience, allowing you to save money while gaining valuable skills. This section covers essential steps and tips for tackling common issues that may arise with your gardening tool. By understanding the components and how they function, you can perform effective maintenance and repairs without needing professional assistance.

Identifying Common Issues

Before starting any repairs, it’s crucial to diagnose the problem accurately. Common symptoms include difficulty starting, reduced power, or unusual noises during operation. Troubleshooting these issues often involves checking the fuel system, ignition components, and the cutting mechanism. By identifying the root cause, you can address the specific area that requires attention.

Basic Repair Techniques

Equipping yourself with the right tools and knowledge is key to successful repairs. For simple fixes, such as replacing a worn-out component, ensure you have the necessary tools like screwdrivers, wrenches, and safety gear. When disassembling parts, keep track of their arrangement to facilitate reassembly. Utilize online resources or user manuals for guidance on the assembly process, ensuring a smooth repair experience.

Remember: Regular maintenance not only extends the lifespan of your equipment but also enhances its performance. With patience and attention to detail, you can effectively manage minor repairs and keep your gardening tool in excellent condition.