In this section, we will explore the essential elements of a powerful 18 HP engine, highlighting its structure and composition. Understanding the layout of its various components is crucial for anyone looking to maintain, repair, or optimize engine performance. By familiarizing yourself with the positioning and functions of each element, you can better identify and address any issues that may arise.

The engine’s robust design includes multiple interconnected elements that work together to deliver efficient and reliable performance. From the fuel system to the cooling mechanisms, each part has a specific role in ensuring the engine runs smoothly and efficiently. By diving into this detailed guide, you will gain insights into the precise arrangement of these elements and learn how they contribute to the overall functionality of the machine.

Whether you are a professional technician or an enthusiastic DIYer, understanding the engine’s layout will provide you with the knowledge needed to keep your machine in top shape. This guide aims to break down each section of the engine, offering a clear view of its structural components and their specific functions.

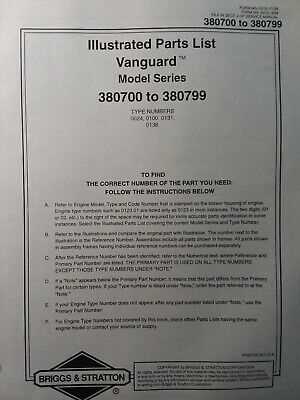

Understanding the Briggs and Stratton Vanguard Engine

This section provides an overview of a well-known small engine used in various machines. Known for its efficiency and durability, this engine powers many types of equipment, including outdoor power tools, commercial vehicles, and industrial machinery. By exploring its design and mechanics, users can gain insight into how it operates and maintains its performance over time.

Key Features of the Engine

The engine incorporates advanced technology to enhance power output and fuel efficiency. Its robust construction ensures longevity, while the cooling system is designed to regulate temperature effectively during prolonged use. The engine’s structure is optimized for both low emissions and reduced vibration, ensuring a smoother and quieter experience for operators.

Common Applications

This type of engine is versatile, often used in lawn maintenance tools, generators, and various types of construction machinery. Its adaptability and reliability make it a preferred choice for both residential and professional use. Understanding the mechanics and functionality of this engine can significantly aid in its maintenance and troubleshooting.

Exploring Engine Components and Their Roles

Understanding the various elements that make up an engine is crucial for recognizing how they work together to generate power. Each component has a distinct function that contributes to the overall efficiency and performance of the system.

- Cylinder: This is where the combustion process takes place. It houses the piston, which moves up and down, converting fuel into mechanical energy.

- Piston: A movable part within the cylinder that transfers the energy produced during combustion to the crankshaft.

- Crankshaft: Converts the vertical movement of the piston into rotational motion, ultimately powering other components.

- Camshaft: Manages the timing of the intake and exhaust valves, ensuring they open and close at the correct moments during the combustion cycle.

- Valves: Control the flow of air and fuel into the cylinder and the release of exhaust gases. Proper valve operation is essential for optimal performance.

- Carburetor: Mixes air and fuel in the correct ratio before it enters the cylinder, allowing efficient combustion.

- Cooling System: Helps regulate the engine’s temperature, preventing overheating and ensuring it runs smoothly over time.

These components work in harmony, each fulfilling a critical role in the engine’s operation, contributing to the overall function and durability of the machine.

Common Issues with Vanguard Engines

Engines of this series, known for their reliability and performance, may still encounter various operational challenges over time. Understanding these issues can help maintain functionality and extend the lifespan of the equipment.

Starting Problems: One of the most frequent issues is difficulty starting the engine. This can be due to fuel delivery interruptions, spark plug failures, or electrical system faults. Regular checks and proper maintenance can often prevent these troubles.

Overheating: Prolonged use or poor airflow can lead to overheating, causing reduced efficiency or damage to engine components. Ensuring the cooling system is clean and unobstructed is crucial for optimal operation.

Oil Leaks: Leaks are another common concern, typically caused by worn seals or gaskets. Monitoring oil levels and inspecting seals regularly can prevent further complications.

Power Loss: Engines may lose power if the air or fuel filter is clogged, or if the carburetor needs adjustment. Maintaining clean filters and tuning components ensures consistent power output.

Proper maintenance and timely troubleshooting are essential for preventing these common engine issues. Addressing problems early can extend the life and reliability of your equipment.

Maintenance Tips for Optimal Performance

Regular upkeep is essential to ensure that your engine continues to run smoothly and efficiently over time. By adhering to key maintenance practices, you can extend its lifespan and improve overall performance. Below are some essential tips and routines to follow for the best results.

1. Regular Oil Checks and Changes

To keep your engine running at its peak, always check the oil level before use and replace it according to the manufacturer’s guidelines. Fresh oil ensures proper lubrication, reducing friction and preventing wear.

2. Inspecting and Cleaning the Air Filter

The air filter plays a crucial role in keeping the engine clean. Ensure it is inspected regularly and replaced when necessary. A clean filter allows proper air intake, which is essential for optimal combustion.

| Maintenance Task | Frequency | Details |

|---|---|---|

| Oil Change | Every 50 hours | Use high-quality oil suitable for the engine type. |

| Air Filter Inspection | Every 25 hours | Clean or replace to ensure proper airflow. |

| Spark Plug Check | Annually | Inspect for damage and replace if necessary for reliable ignition. |

By following these essential maintenance tasks, you can maintain engine efficiency, reduce downtime, and prolong the equipment’s service life. Regular attention to these areas ensures that the engine operates smoothly and reliably.

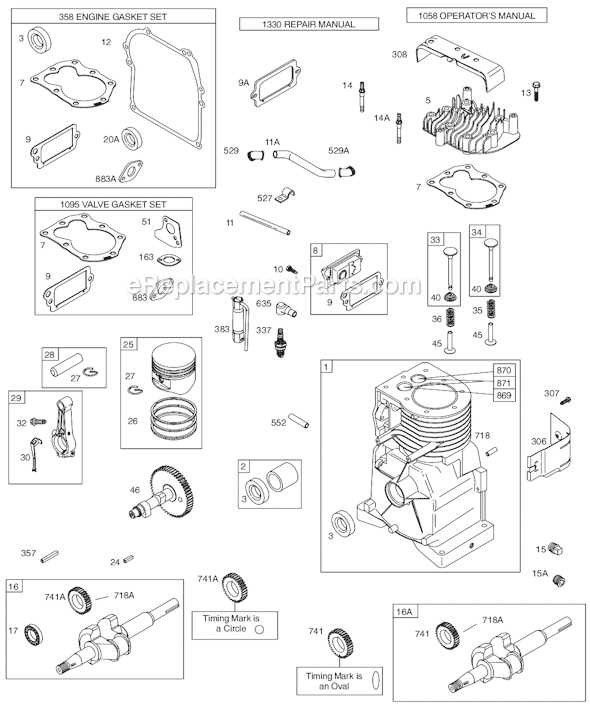

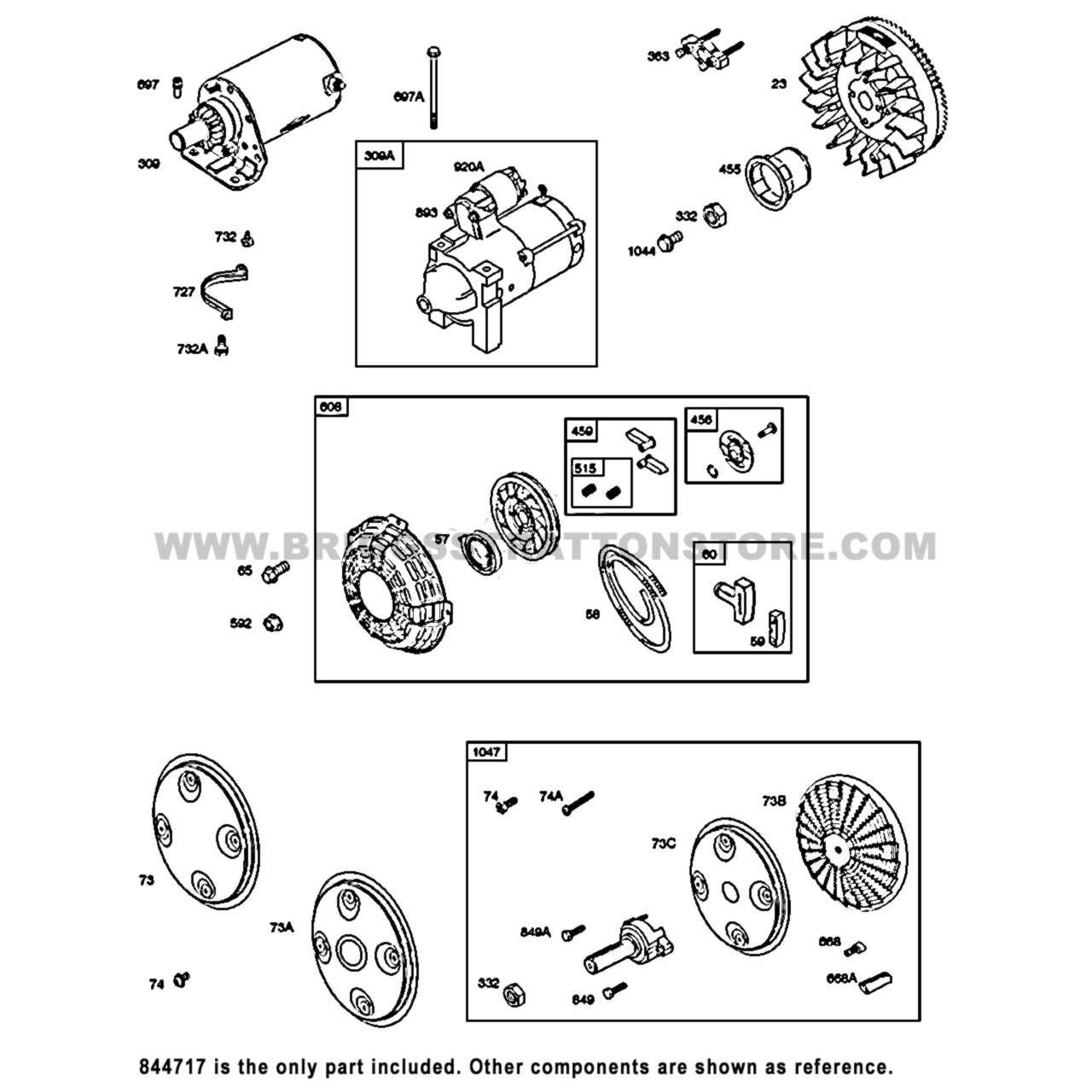

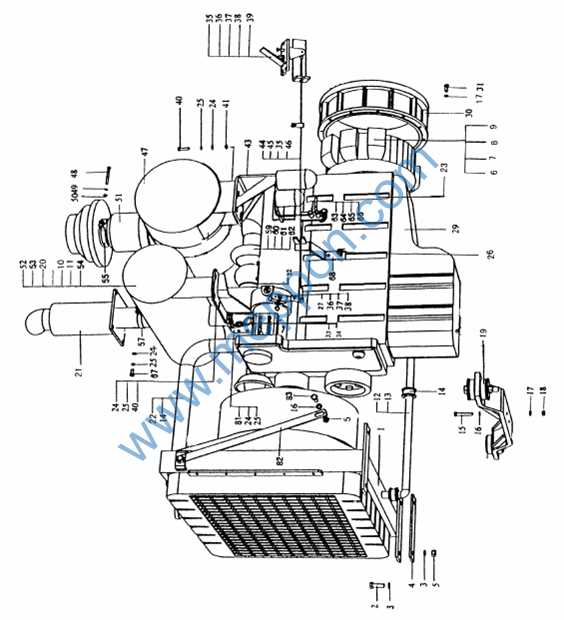

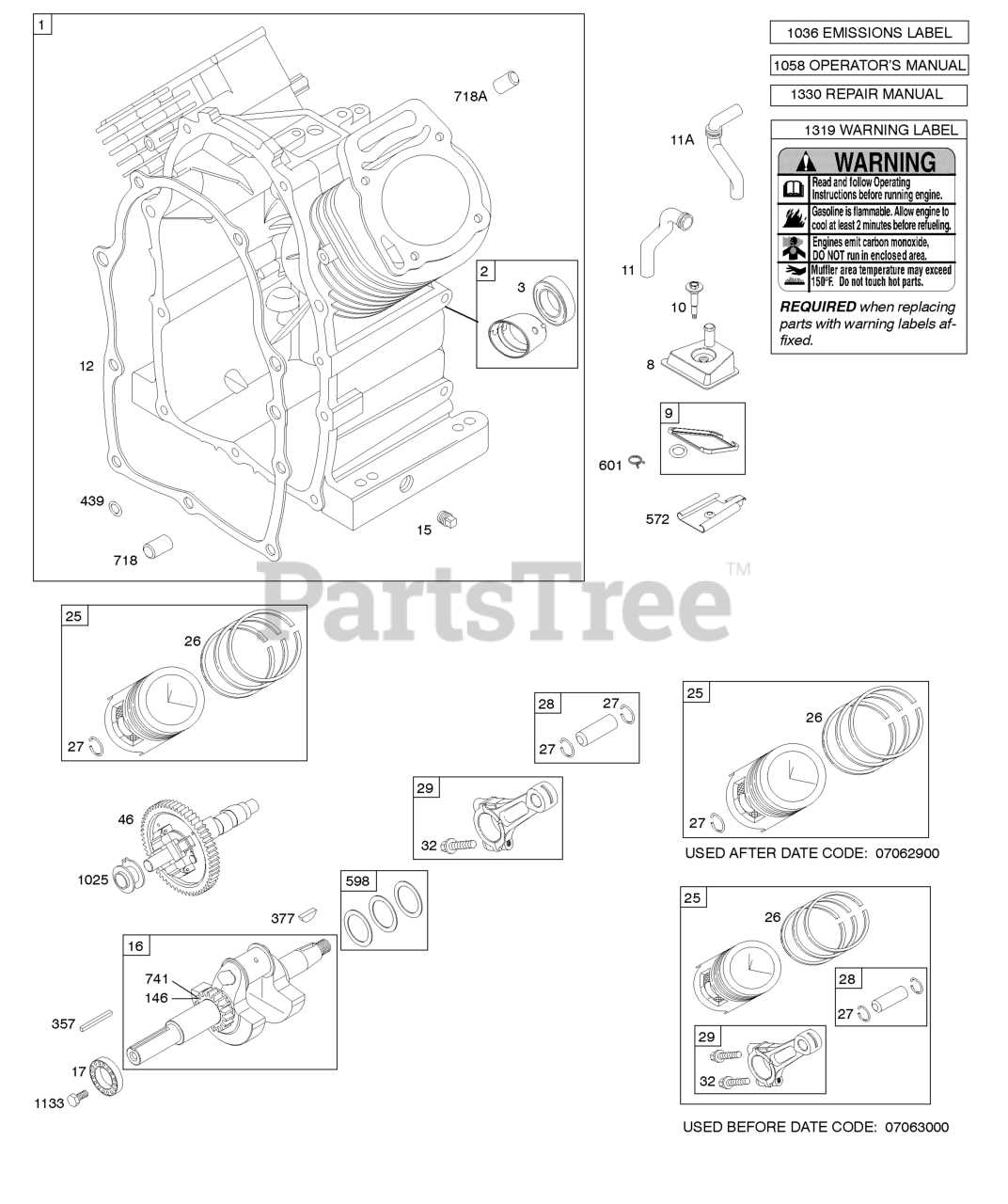

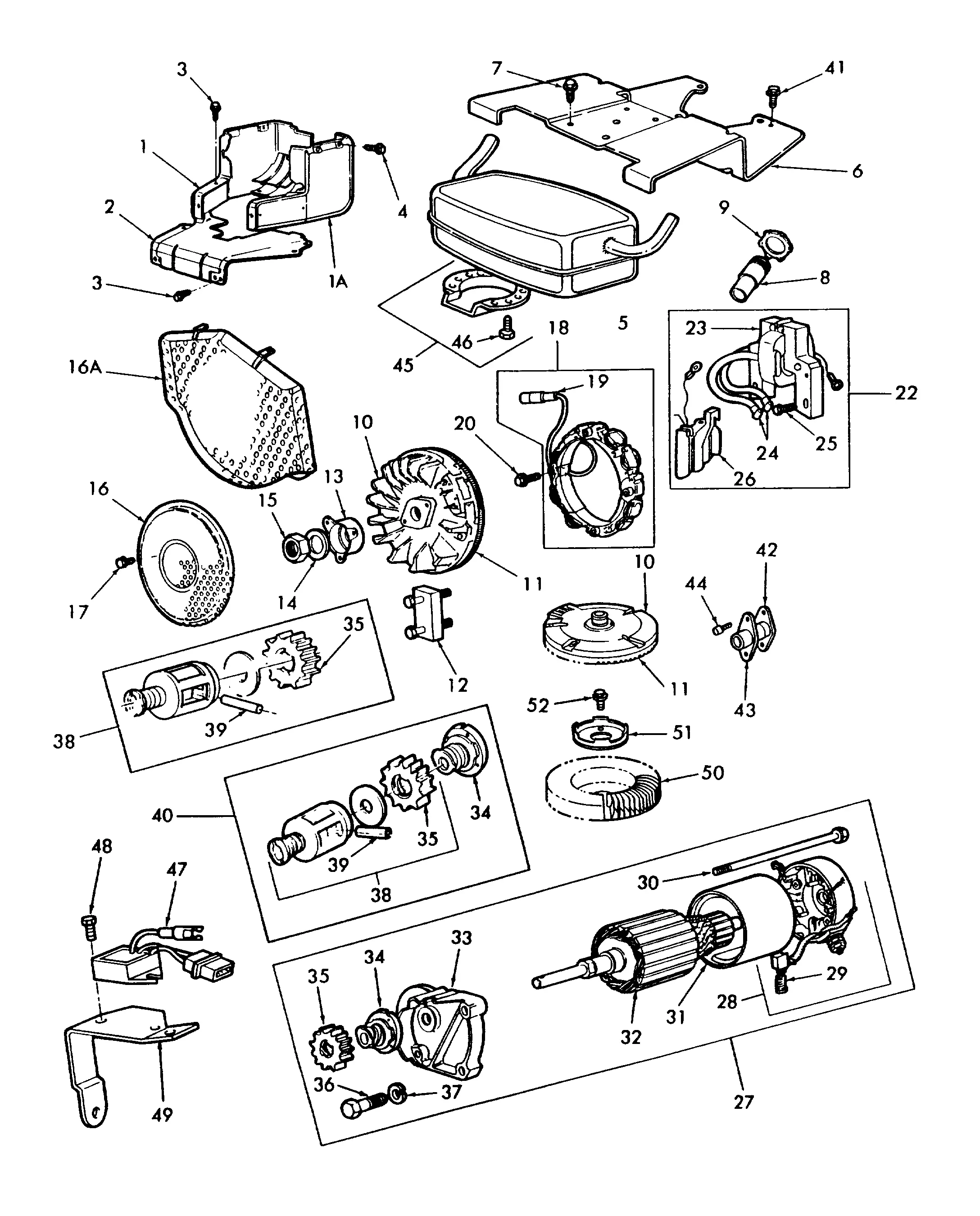

How to Read a Parts Diagram

Understanding a schematic illustration is essential for identifying the components of a machine and how they interact. These visual guides provide a detailed breakdown of each element and its placement, helping users understand assembly or maintenance procedures.

To navigate a schematic correctly, it’s important to recognize the different symbols and labels used. Follow these steps:

- Identify the Legend: Look for the key or legend. This will help you understand the symbols and notations used throughout the schematic.

- Locate Reference Numbers: Many illustrations use numbers to pinpoint specific items. Cross-reference these numbers with the list provided to identify each item.

- Check for Orientation: Notice the layout direction. Some images use arrows or labels to show how elements should be positioned.

- Examine Exploded Views: Often, an illustration will include expanded views to showcase how parts fit together or attach to other components.

- Follow Assembly Sequence: If available, check the recommended order of assembly. This sequence ensures that components are installed correctly and function properly.

By familiarizing yourself with these aspects, you can efficiently interpret a schematic, enabling precise maintenance or installation work.

Upgrading Parts for Better Efficiency

Enhancing components in your engine can significantly improve its performance and fuel economy. By replacing outdated or underperforming elements with high-quality alternatives, you can achieve smoother operation and increased power output. Such upgrades not only extend the lifespan of your machine but also reduce maintenance costs over time.

When considering enhancements, focus on areas such as the fuel delivery system, ignition components, and air filtration. Upgrading these systems can lead to a more efficient combustion process, resulting in better fuel utilization and lower emissions. Investing in advanced filtration can also help protect the engine from dirt and debris, ensuring longevity and optimal function.

Moreover, integrating modern technology, such as performance tuning and electronic controls, can lead to notable improvements in responsiveness and efficiency. These innovations allow for precise adjustments, ensuring that your engine runs at its best under varying conditions. By prioritizing component upgrades, you will not only elevate performance but also enjoy a more reliable and efficient operation.

Troubleshooting Guide for Engine Problems

This section provides guidance on diagnosing and resolving common issues encountered with small engines. By understanding potential problems and their causes, you can effectively restore functionality and ensure optimal performance. The following steps outline the typical symptoms and solutions that can assist in identifying the root cause of engine malfunctions.

Start by checking the fuel supply. Ensure that the fuel tank is filled with fresh, clean fuel. Stale or contaminated fuel can lead to starting difficulties and poor engine performance. If the fuel appears discolored or has a foul odor, it should be drained and replaced with new fuel.

Next, inspect the air filter. A clogged or dirty air filter can restrict airflow, causing the engine to run poorly or not start at all. If the filter is dirty, clean or replace it according to the manufacturer’s recommendations.

Examine the spark plug for wear or damage. A faulty spark plug can prevent the engine from starting or cause it to run unevenly. Remove the spark plug and inspect its condition; clean or replace it if necessary. Make sure the spark plug gap is set to the specifications outlined in the owner’s manual.

If the engine still fails to operate correctly, check the ignition system. Look for any loose connections or damaged wires. Ensure that the ignition coil is functioning properly, as a faulty coil can result in weak or no spark.

Lastly, inspect the oil level and condition. Low oil levels or dirty oil can lead to overheating and engine damage. Check the oil dipstick and add oil if necessary. If the oil appears dirty or has debris, perform an oil change following the recommended procedure.

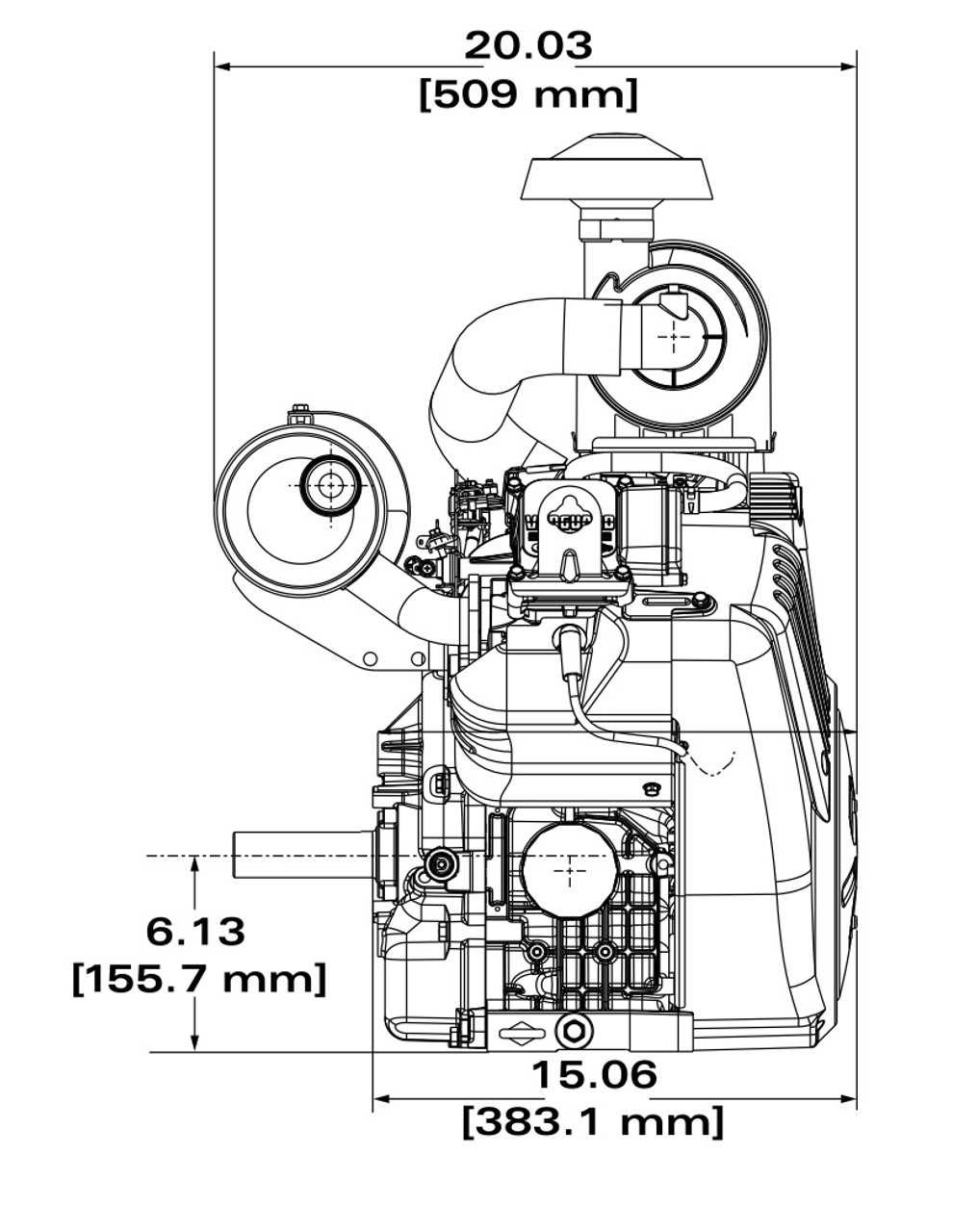

Identifying Essential Engine Parts

Understanding the key components of an engine is crucial for effective maintenance and repair. Each element plays a significant role in the overall function, contributing to the efficiency and performance of the machinery. Familiarizing oneself with these vital elements can enhance troubleshooting skills and ensure optimal operation.

Key Components Overview

Engines consist of various crucial parts that work together harmoniously. Here is a brief overview of some of the primary components:

| Component | Description |

|---|---|

| Cylinder | The chamber where the fuel-air mixture ignites, generating power. |

| Piston | A cylindrical component that moves up and down within the cylinder, converting energy from combustion into mechanical work. |

| Crankshaft | This part converts the linear motion of the piston into rotational motion, which drives the output shaft. |

| Fuel System | Includes components such as the fuel pump and carburetor that deliver and mix fuel with air for combustion. |

| Ignition System | Responsible for generating the spark that ignites the fuel-air mixture, ensuring efficient combustion. |

Importance of Regular Maintenance

Regular inspection and maintenance of these critical components are essential for prolonging the lifespan of the engine. Understanding how each part contributes to the engine’s performance can help identify potential issues before they escalate, ensuring reliability and efficiency in operation.

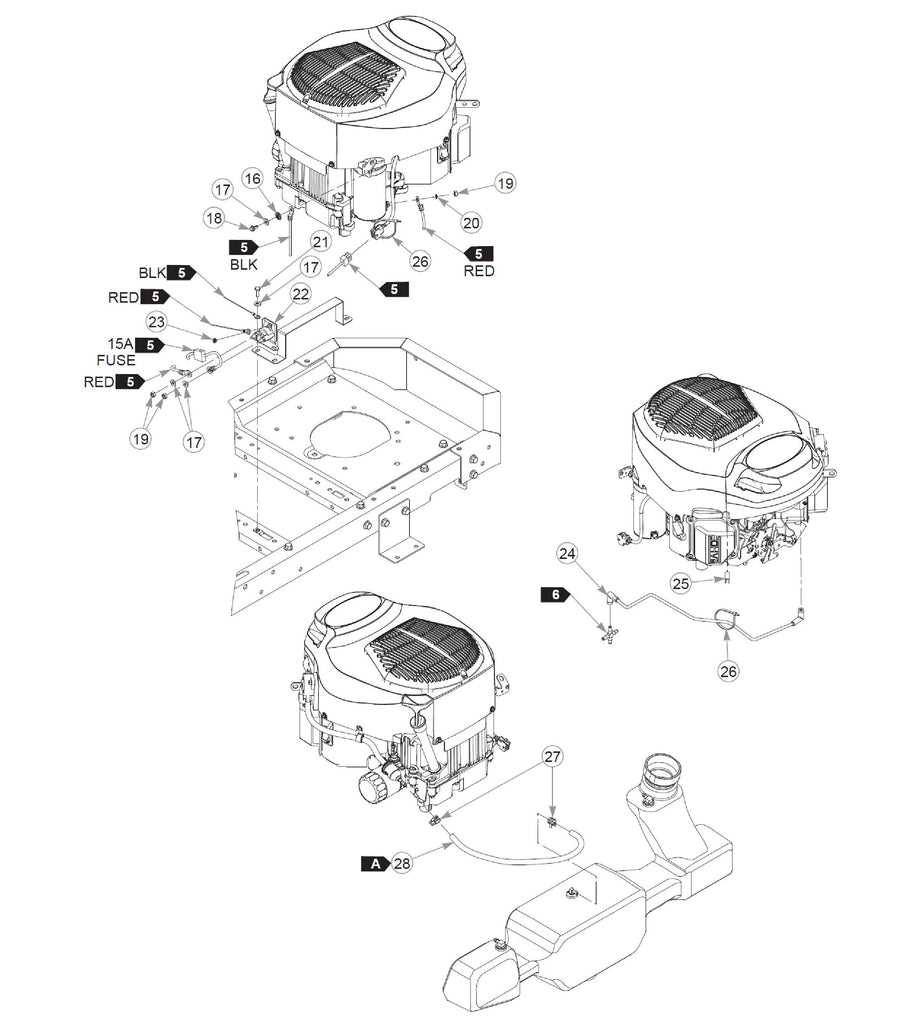

Vanguard Engine Compatibility with Accessories

Understanding the compatibility of engines with various attachments is crucial for ensuring optimal performance and functionality. This section explores how different accessories can enhance the capabilities of the engine, providing insights into suitable options for various applications.

Types of Accessories

There are several categories of accessories that can be paired with engines to improve their efficiency and versatility:

- Cooling systems: Essential for maintaining optimal operating temperatures.

- Fuel systems: Designed to enhance fuel delivery and efficiency.

- Exhaust components: Help in managing emissions and improving performance.

- Air filtration systems: Critical for ensuring clean air intake, which is vital for engine longevity.

Choosing the Right Accessories

When selecting accessories, consider the following factors to ensure compatibility:

- Specifications: Always refer to the manufacturer’s guidelines for compatible accessories.

- Installation: Ensure that the accessories can be easily installed without modifications.

- Performance: Look for accessories that enhance the engine’s capabilities based on your specific needs.

- Durability: Choose high-quality materials that can withstand the operational conditions.

By carefully considering these aspects, users can optimize their engine’s performance through appropriate accessories.

Choosing the Right Replacement Parts

When it comes to maintaining outdoor power equipment, selecting the appropriate components is crucial for optimal performance and longevity. Understanding the various options available can help ensure that your machinery operates smoothly and efficiently.

Quality Matters: Always prioritize high-quality components that meet or exceed manufacturer specifications. Inferior products may save money initially but can lead to more significant issues down the line.

Compatibility: Ensure that the components you choose are compatible with your specific equipment model. Checking the manufacturer’s recommendations can prevent installation problems and enhance performance.

Research Options: Take the time to research different brands and types of components. Reviews and testimonials can provide insight into the reliability and performance of the parts you are considering.

Consult Experts: If you are unsure about which components to select, consulting with knowledgeable professionals can provide valuable guidance. They can help identify the best options based on your specific needs and equipment.

By carefully considering these factors, you can make informed decisions that lead to successful maintenance and extended life for your outdoor machinery.

Cleaning and Caring for Engine Components

Maintaining the cleanliness and functionality of engine parts is essential for optimal performance and longevity. Regular cleaning not only prevents the buildup of dirt and grime but also enhances the overall efficiency of the machinery. This section outlines effective methods and best practices for ensuring that engine components remain in top condition.

Essential Cleaning Techniques

There are several effective techniques for cleaning engine parts, each tailored to specific components:

- Pressure Washing: Use a pressure washer to remove heavy debris and dirt from exterior surfaces.

- Degreasing: Apply a degreaser to oily components, allowing it to penetrate before scrubbing with a brush.

- Wiping: For delicate areas, use a clean cloth dampened with a suitable solvent to gently wipe surfaces.

Regular Maintenance Practices

In addition to cleaning, following routine maintenance practices is crucial for preserving engine health:

- Inspect components regularly for signs of wear or damage.

- Replace filters and fluids as recommended by the manufacturer.

- Keep fasteners and connections secure to prevent leaks and operational issues.

By adhering to these cleaning and maintenance practices, users can ensure that their engines operate smoothly and efficiently for years to come.

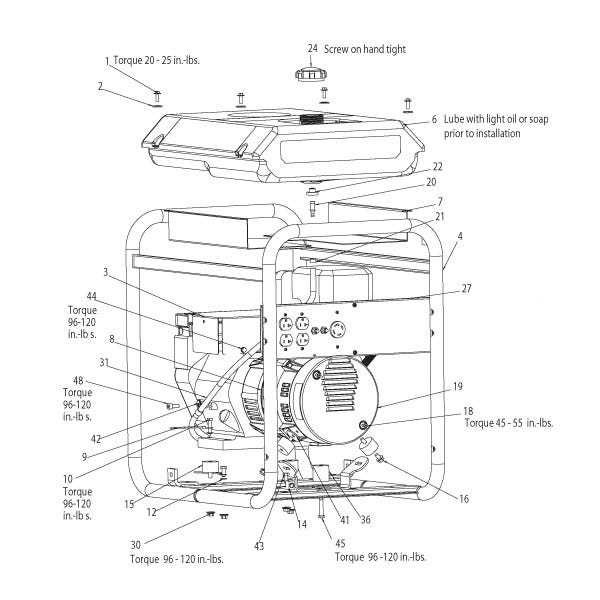

Installation Tips for New Engine Parts

Installing new components in an engine requires attention to detail and adherence to specific guidelines to ensure optimal performance and longevity. Proper installation can significantly affect the functionality of the engine and prevent premature wear or failure.

Preparation and Planning

Before beginning the installation process, it’s crucial to gather all necessary tools and components. Make sure to review the specifications for each part to understand the installation requirements. Familiarize yourself with the engine layout and the location of each component to streamline the process.

Step-by-Step Installation

When installing new components, always follow a step-by-step approach. Begin by securely fastening each piece according to the manufacturer’s instructions. Ensure that all connections are tight and free from any debris. Additionally, apply the recommended lubricants or sealants where necessary to prevent leaks and ensure smooth operation. Taking the time to double-check your work can save you from future complications.

Vanguard Engine Safety and Usage Guidelines

This section aims to provide essential recommendations for operating and maintaining small engines safely and effectively. Understanding these guidelines is crucial to ensure optimal performance and longevity while minimizing risks associated with engine operation.

General Safety Precautions

Before starting the engine, always take necessary precautions to protect yourself and others. Familiarize yourself with the equipment and its operational features. Ensure that you are wearing appropriate safety gear, including gloves, eye protection, and closed-toe shoes. Keep the work area clean and free of hazards.

Operating Procedures

Follow the manufacturer’s recommendations for starting and operating the engine. Regularly check fuel levels, inspect the engine for leaks, and ensure all components are secure before use. Be aware of your surroundings and avoid operating the engine in enclosed spaces where exhaust fumes can accumulate.

| Safety Tip | Description |

|---|---|

| Read Manual | Always read the user manual to understand the specific safety guidelines and operational instructions for your engine. |

| Fuel Handling | Use proper fuel storage methods and avoid overfilling to prevent spills and leaks. |

| Regular Maintenance | Schedule routine checks and servicing to keep the engine in optimal working condition. |

| Emergency Procedures | Know how to shut down the engine quickly and safely in case of an emergency. |