Exploring the intricate components of small power units can greatly enhance your maintenance skills and overall performance. These machines, often found in various outdoor tools, rely on a precise arrangement of elements to function effectively. Gaining insight into these vital parts not only aids in troubleshooting but also empowers users to undertake repairs and upgrades.

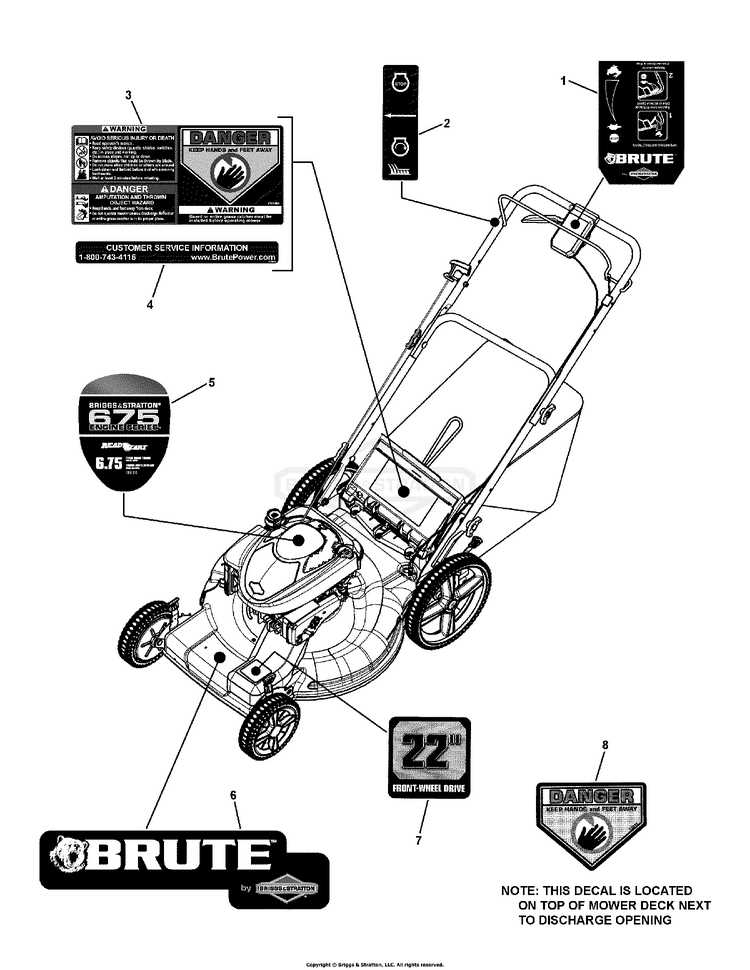

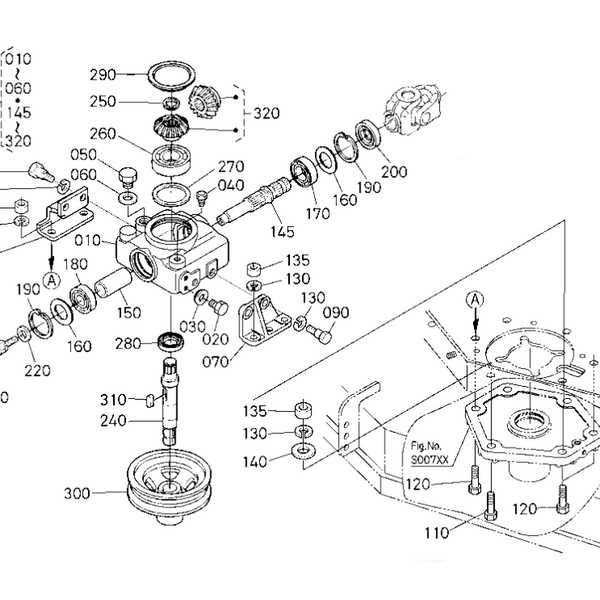

In this section, we will delve into the essential components of a specific model, illustrating how each piece contributes to the unit’s overall functionality. Visual aids will serve as a helpful reference, guiding you through the assembly and providing clarity on the interactions between different sections.

Understanding these components is crucial for anyone looking to optimize their machinery. Whether you’re a hobbyist or a professional, familiarizing yourself with the layout and function of these elements can lead to more informed decisions and improved operational efficiency.

Understanding Briggs and Stratton Engines

This section aims to provide insights into the workings and components of a well-known small motor brand. Recognized for reliability and efficiency, these power units have become a staple in various outdoor equipment. Understanding their structure and functionality can enhance maintenance and troubleshooting skills, leading to better performance and longevity.

The internal mechanisms of these machines consist of various crucial elements that work in harmony. Each component, from the ignition system to the fuel delivery, plays a significant role in ensuring optimal operation. Familiarity with these parts helps users identify potential issues and perform necessary repairs, ultimately maximizing the utility of the equipment.

Additionally, comprehending how these motors interact with different types of devices, such as lawnmowers and generators, allows users to select the right machine for their specific needs. The versatility of these powerhouses makes them suitable for a wide range of applications, thus enhancing their appeal among users seeking reliable solutions for their outdoor tasks.

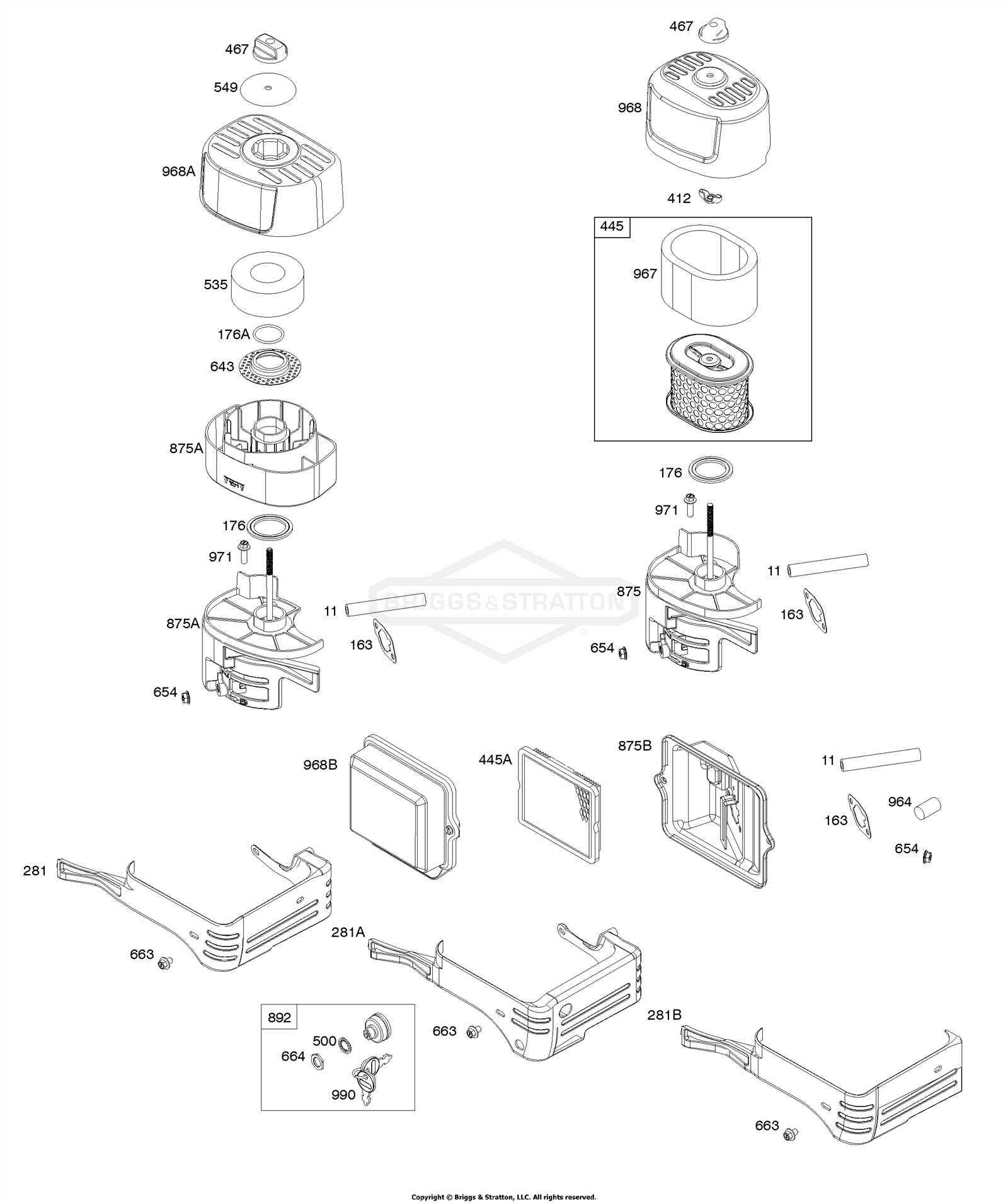

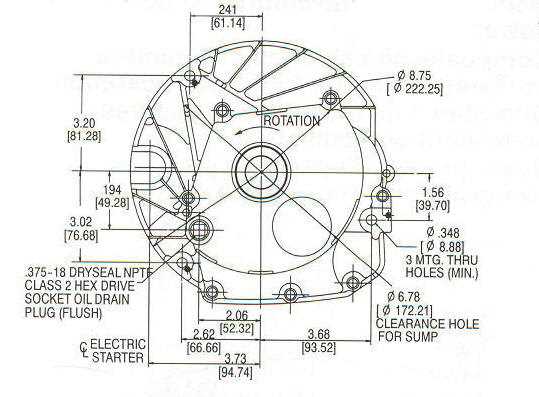

Key Components of the 6.75 Engine

This section explores essential elements that contribute to the performance and functionality of a specific power unit. Understanding these crucial parts allows for better maintenance and optimization of the overall operation.

Fuel Delivery System

The fuel delivery mechanism plays a vital role in ensuring that the combustion chamber receives the right mixture of fuel and air. Key elements include the carburetor, fuel lines, and filter, all working together to facilitate efficient energy production.

Ignition Mechanism

The ignition system is responsible for initiating the combustion process. Components such as the spark plug and ignition coil are pivotal, creating the necessary spark that ignites the fuel-air mixture, leading to effective power generation.

Common Issues with Engine Parts

Many individuals encounter frequent challenges when dealing with various mechanical components. Understanding these common difficulties can help in proper maintenance and enhance overall performance. Awareness of potential problems allows users to address them proactively.

Wear and Tear

Wear is an inevitable process affecting numerous components over time. Factors like friction, heat, and contaminants can lead to reduced efficiency and potential failure. Regular inspections are essential to catch signs of deterioration early.

Fuel-Related Problems

Fuel contamination and improper mixtures often result in operational issues. Stale fuel or the presence of debris can hinder performance and cause unnecessary strain on mechanical systems. Maintaining clean fuel and using the right mixtures is crucial for longevity.

How to Read Engine Diagrams

Understanding technical illustrations is crucial for effective maintenance and repair. These visual representations provide insights into the layout and functionality of various components, helping users identify specific areas for service. Mastering the art of reading these illustrations can enhance troubleshooting skills and facilitate informed decision-making.

Familiarize with Symbols

Each diagram utilizes standardized symbols to represent different elements. Learning these symbols allows for quick recognition and comprehension of the information presented. Referencing a legend or key can provide clarity and context to the visual representation.

Follow the Flow

Diagrams often depict the flow of processes or movement within the assembly. Tracking this flow helps in understanding how components interact and function together. Pay attention to arrows or lines indicating connections and directions to gain a deeper insight into operational mechanics.

Replacing Worn Parts Effectively

When components become aged or damaged, their performance can decline significantly, impacting overall functionality. Timely replacement of these elements is crucial to maintaining efficiency and prolonging the lifespan of machinery. Understanding the process of effectively substituting these elements can prevent further complications and ensure optimal operation.

Identifying Worn Components

Before initiating the replacement process, it’s essential to accurately identify which components are no longer functioning as intended. Look for signs such as unusual noises, decreased performance, or visible wear. Regular inspections can help pinpoint issues early, allowing for proactive measures.

Choosing Quality Replacements

Opt for high-quality substitutes that meet or exceed original specifications. Utilizing genuine parts or reputable aftermarket options ensures compatibility and reliability. Additionally, researching reviews and recommendations can guide you in selecting the best replacements, minimizing future problems.

Essential Maintenance Tips for Longevity

Proper upkeep is crucial for ensuring the durability and efficiency of your machinery. Regular maintenance not only enhances performance but also extends the lifespan of your equipment. By following a few essential practices, you can prevent costly repairs and keep your device running smoothly for years to come.

1. Regular Cleaning: Accumulated dirt and debris can hinder performance. Regularly inspect and clean the exterior and accessible interior components to maintain optimal function.

2. Oil Changes: Replacing the lubricant at recommended intervals is vital. Clean oil reduces friction and prevents overheating, which can lead to premature wear.

3. Air Filter Replacement: A clean air filter ensures efficient airflow, improving combustion and overall performance. Check and replace it periodically to avoid unnecessary strain on the system.

4. Spark Plug Inspection: Inspecting and replacing spark plugs as needed can significantly affect starting and efficiency. A well-functioning spark plug promotes better ignition and fuel consumption.

5. Fuel Quality: Using fresh, high-quality fuel is essential. Stale or contaminated fuel can lead to engine issues, so ensure your supply is clean and stored properly.

6. Seasonal Checks: Before and after seasonal use, conduct thorough inspections. Address any wear and tear promptly to avoid bigger problems later.

By adhering to these maintenance practices, you can ensure your equipment remains in prime condition, providing reliable service for many years.

Identifying Genuine Parts vs. Counterfeits

When it comes to maintaining machinery, recognizing authentic components is crucial for optimal performance and longevity. Counterfeit items can lead to various issues, including reduced efficiency and potential damage. Understanding the key differences can help users make informed decisions.

Quality of Materials: Genuine components are crafted from high-grade materials, ensuring durability and reliability. In contrast, replicas often use inferior substances, compromising performance.

Labeling and Packaging: Authentic products usually feature professional branding, clear labeling, and consistent packaging. Counterfeit versions may display inconsistencies or misspellings that raise red flags.

Price Point: If a deal seems too good to be true, it often is. Genuine components are priced fairly based on quality, whereas imitation products are typically cheaper but come with hidden costs.

Source Verification: Always purchase from reputable dealers or authorized retailers. This minimizes the risk of acquiring counterfeit goods that can ultimately harm your machinery.

Investing time in identifying authentic components ensures the longevity and efficiency of your equipment, safeguarding against the pitfalls of inferior alternatives.

Tools Needed for Engine Repair

When tackling the intricacies of motor maintenance, having the right equipment is essential for success. Proper tools not only facilitate the repair process but also ensure safety and efficiency. Understanding what instruments are necessary can make a significant difference in achieving optimal performance.

Essential Hand Tools

A variety of hand tools are indispensable for any repair task. Wrenches, screwdrivers, and pliers are among the basics that should be part of your toolkit. These allow for easy access to various components and enable adjustments or replacements as needed.

Power Tools and Equipment

In addition to hand tools, power tools can greatly enhance efficiency. A reliable drill, impact wrench, or grinder can expedite the repair process. Selecting high-quality tools ensures durability and reliability, ultimately contributing to the longevity of your machinery.

Common Upgrades for Performance Enhancement

Many enthusiasts seek to boost their machines’ efficiency and power output. Upgrading specific components can lead to significant improvements, enhancing both speed and reliability. Here are some popular modifications that can provide noticeable benefits.

Air Filter Replacement: Upgrading to a high-performance air intake system allows for better airflow, resulting in improved combustion and efficiency.

Exhaust System Upgrade: Installing a free-flowing exhaust can reduce back pressure, enabling the unit to expel gases more effectively, thus enhancing overall power.

Fuel System Modifications: Tweaking the fuel delivery with a performance carburetor can optimize the air-fuel mixture, providing better acceleration and responsiveness.

Ignition System Enhancements: A high-performance ignition coil can deliver a stronger spark, ensuring more efficient combustion and smoother operation.

Governed Speed Adjustment: Adjusting the governor allows the unit to reach higher RPMs, unlocking additional power for demanding tasks.

These upgrades not only enhance performance but also contribute to the longevity of the machine, making it more enjoyable to use.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is crucial to prevent accidents and injuries. Proper preparation and awareness of potential hazards can significantly reduce risks associated with repair work. It is essential to follow established guidelines to create a secure environment for oneself and others involved.

Essential Guidelines

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use gloves, goggles, and appropriate clothing to shield against debris and chemicals. |

| Disconnect Power Sources | Before starting any repairs, ensure that all power sources are turned off and disconnected. |

| Work in a Ventilated Area | Perform tasks in a space with adequate airflow to avoid inhaling harmful fumes. |

| Keep Tools Organized | Maintain a tidy workspace to prevent tripping hazards and misplacing tools. |

Emergency Preparedness

Having a first aid kit on hand and knowing emergency contact numbers can be lifesaving. Regularly reviewing safety protocols ensures that everyone is prepared for unexpected situations, allowing for swift action if needed.

Resources for Further Learning

Expanding your knowledge about small machinery can greatly enhance your maintenance skills and troubleshooting capabilities. Numerous resources are available to help enthusiasts and professionals alike understand the intricacies of these machines. From manuals to online forums, the following suggestions provide valuable information for anyone looking to deepen their expertise.

Online Communities

Engaging with online communities can offer insights from experienced users. Platforms such as forums and social media groups are excellent for sharing experiences, asking questions, and finding solutions to common problems. Connecting with others who share your interests can be an invaluable part of your learning journey.

Educational Resources

Consider exploring educational materials such as manuals, guides, and video tutorials. Many manufacturers provide detailed documentation that covers maintenance procedures and common repairs. Additionally, platforms like YouTube host countless tutorials that visually demonstrate techniques, making complex tasks more approachable for learners.

Utilizing these resources can significantly enhance your understanding and proficiency in maintaining small machinery.