Maintaining optimal performance in Volkswagen automobiles often requires a comprehensive grasp of various components responsible for thermal regulation. Effective management of these elements is crucial for ensuring reliability and longevity of the vehicle. A detailed analysis helps enthusiasts and technicians identify potential issues and implement appropriate solutions.

Visual representations can be invaluable when studying the intricate connections and functions of these components. By examining the relationships between different elements, one can gain insights into their operations and the potential challenges they may face. This knowledge is essential for both regular maintenance and troubleshooting.

Through a thorough exploration of the relevant schematics, individuals can delve into the complexities of these systems. This understanding not only empowers car owners but also enhances the overall driving experience by addressing and mitigating any underlying concerns effectively.

Understanding VW 2.0 Engine Cooling System

The thermal management of automotive machinery plays a crucial role in maintaining optimal performance and longevity. A well-designed framework ensures that various components operate within their ideal temperature ranges, thereby enhancing efficiency and reducing wear over time. This discussion will explore the intricate network responsible for temperature regulation in a specific Volkswagen model.

Key Components of the Thermal Management Framework

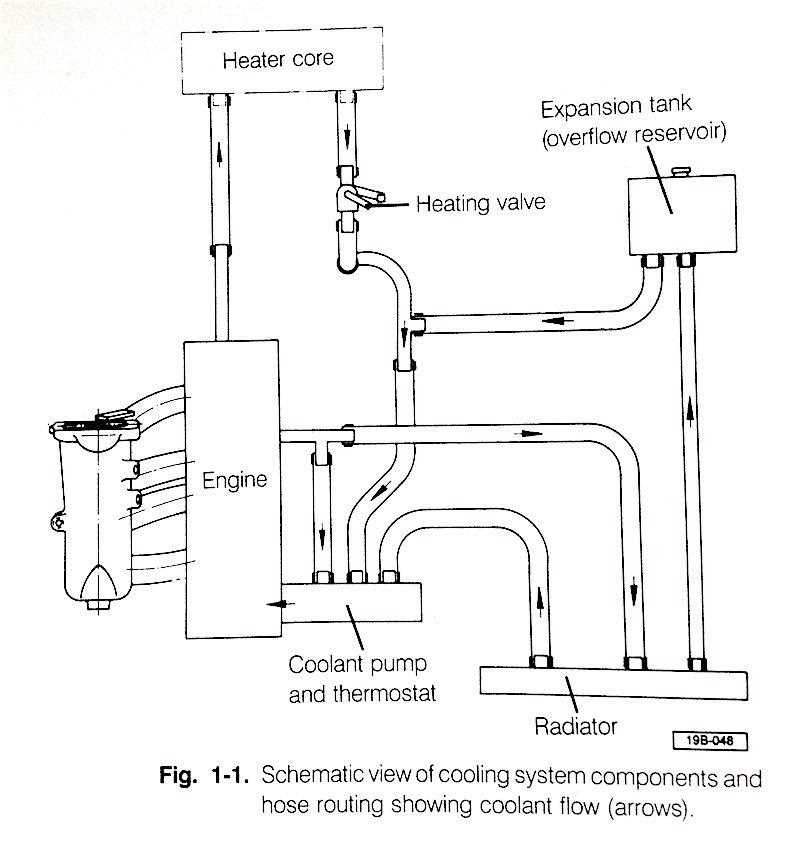

At the heart of this arrangement are several essential elements working in harmony. These include a heat exchanger that transfers excess warmth, a reservoir for the fluid, and a series of hoses that facilitate circulation. Each component is vital for ensuring that the unit remains within safe operational limits.

Importance of Regular Maintenance

Maintaining the integrity of the thermal management framework is critical. Routine checks and prompt repairs can prevent significant issues, such as overheating or inefficient operation. Drivers should be vigilant for any signs of malfunction, as early intervention can save time and resources in the long run.

Symptoms of Coolant Leaks

Identifying the signs of fluid loss is crucial for maintaining vehicle performance. Several indicators can help you recognize when there may be an issue that needs attention. Early detection can prevent more significant problems down the road and ensure the longevity of your vehicle.

Common Indicators

Various symptoms can suggest that there’s an unwanted escape of vital fluids within your automobile. Observing these signs can prompt timely intervention.

| Symptom | Description |

|---|---|

| Overheating | A rise in temperature gauge readings often indicates insufficient fluid levels. |

| Fluid Puddles | Spots of liquid under the vehicle can signal a problem with fluid retention. |

| Steam | Visible vapor from the hood can suggest that the engine is experiencing excessive heat. |

| Low Fluid Levels | Regular checks revealing diminished fluid levels may indicate an underlying issue. |

Visual Signs

In addition to functional indicators, visual cues can also be important. Observing the components of your vehicle can reveal cracks, stains, or discoloration that suggest the need for closer inspection.

Common Causes of Coolant Leakage

Understanding the typical reasons behind fluid loss in automotive machinery is essential for maintaining optimal performance. Several factors can contribute to the unwanted escape of vital liquids, impacting the overall functionality and longevity of the vehicle.

Worn Seals and Gaskets: Over time, seals and gaskets can degrade due to heat and pressure, leading to failures that allow fluids to escape. Regular inspections can help identify these issues before they escalate.

Damaged Hoses: Hoses that transport liquids can become brittle or develop cracks, particularly if exposed to extreme temperatures. Routine checks can catch early signs of wear, preventing more significant problems.

Corroded Components: Metal parts in the machinery can corrode over time, especially if exposed to moisture or harsh chemicals. This deterioration can create small openings where essential fluids can seep out.

Improper Installation: If components are not correctly installed, it can lead to misalignments and stress points that promote fluid loss. Ensuring proper installation during repairs is crucial for avoiding future issues.

Overheating: Excessive heat can cause materials to expand and contract, leading to cracks or separations. Maintaining the correct temperature range is vital for preventing this type of damage.

Essential Cooling System Components Explained

Understanding the key elements that maintain optimal temperatures within an automotive structure is crucial for efficient performance and longevity. Each component plays a significant role in regulating heat, ensuring the vehicle operates smoothly under various conditions.

The primary components involved in this process include:

- Radiator: This component dissipates excess heat by circulating fluid through its core, allowing air to cool it down as it passes through.

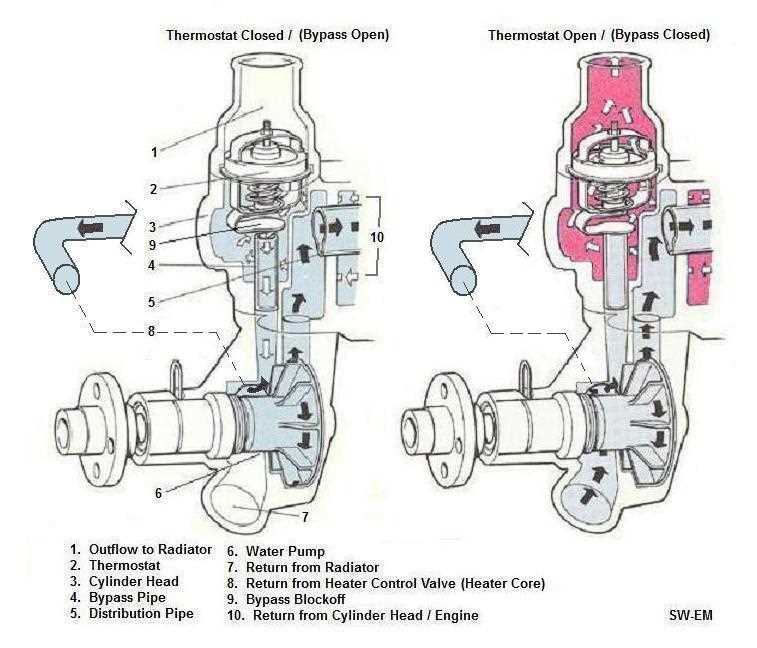

- Thermostat: A vital regulator, this device controls the flow of the fluid based on temperature, ensuring it remains within a safe range.

- Water Pump: Essential for circulating the fluid throughout the structure, this pump maintains a consistent flow to prevent overheating.

- Hoses: Flexible tubes that transport the fluid between components, ensuring an uninterrupted flow throughout the assembly.

- Cooling Fan: Often electric or belt-driven, this fan increases air circulation, enhancing the cooling effect on the radiator when necessary.

Each of these components works in harmony to prevent excessive heat build-up, ultimately preserving the overall functionality of the vehicle. Regular maintenance and checks of these elements are essential for optimal performance and durability.

How to Diagnose Coolant Issues

Identifying problems within the fluid distribution mechanism is crucial for optimal performance and longevity. Early detection can prevent significant damage and costly repairs. Here’s a guide to effectively assess potential issues.

- Visual Inspection:

- Check for puddles or stains under the vehicle.

- Inspect hoses and connections for wear or damage.

- Examine the reservoir for discoloration or debris.

- Temperature Monitoring:

- Observe the temperature gauge during operation.

- Look for fluctuations that indicate a malfunction.

- Pressure Testing:

- Use a pressure gauge to assess system integrity.

- Monitor for drops that suggest potential issues.

- Fluid Level Check:

- Ensure levels are within the recommended range.

- Add fluids if low, and determine the cause of depletion.

By following these steps, you can delve into the diagnostics of your vehicle’s fluid management, ensuring it operates at its ultimate potential.

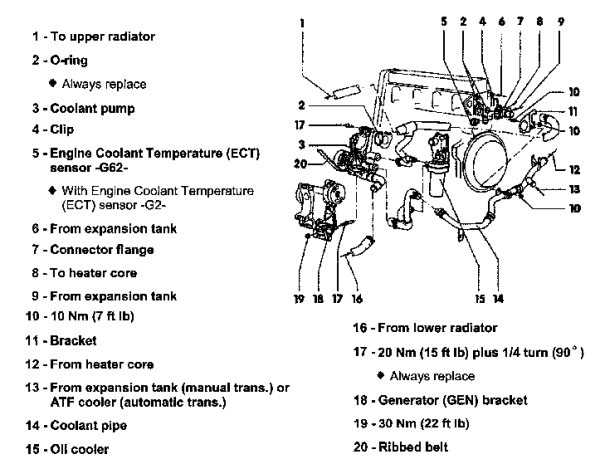

Parts Diagram Overview for VW 2.0

This section provides a comprehensive look into the various components that play a crucial role in the thermal management of VW vehicles. Understanding the arrangement and function of these elements is essential for effective maintenance and troubleshooting.

- Water Pump

- Thermostat

- Radiator

- Expansion Tank

- Hoses and Clamps

- Fans

Each component is vital for ensuring optimal performance and longevity. Regular inspection and timely replacements can prevent potential issues and enhance efficiency.

Coolant Types Suitable for VW Engines

Choosing the right liquid for temperature regulation is crucial for vehicle performance and longevity. Various formulations offer distinct benefits, ensuring optimal functionality and protection against wear.

Ethylene Glycol-Based Formulations are widely used due to their effective heat transfer properties and excellent protection against corrosion. They are often available in different colors, making it easier to identify compatibility.

Propylene Glycol Options are increasingly popular for their lower toxicity. These are suitable for those prioritizing environmental concerns without sacrificing protective qualities.

Hybrid Organic Acid Technology (HOAT) solutions combine the benefits of traditional and organic formulations, providing enhanced protection against rust and scale buildup while being gentle on seals and gaskets.

In addition to these, always check manufacturer recommendations to ensure compatibility and maximize the benefits of your chosen liquid.

Impact of Leaks on Engine Performance

Understanding how fluid escapes from various components is crucial for maintaining optimal vehicle functionality. These unintended discharges can significantly affect overall performance, leading to various complications that may compromise efficiency and longevity.

- Reduced thermal regulation

- Increased operational temperatures

- Potential for component damage

- Decreased fuel efficiency

As a result, monitoring and addressing these issues is essential for any vehicle owner aiming for the best possible performance. Regular inspections and prompt repairs can help mitigate the adverse effects of such occurrences.

Repairing Coolant Leaks: Step-by-Step

Addressing fluid issues in your vehicle requires careful attention and methodical action. This guide will help you navigate the necessary steps to identify and resolve any fluid escape effectively, ensuring your vehicle remains reliable and efficient.

Begin by inspecting the area around the reservoir and hoses for visible signs of moisture or staining. This initial assessment can help pinpoint potential sources of trouble.

Next, thoroughly clean the affected area to eliminate any grime or residue. A clean surface allows for a more accurate evaluation of the problem and helps in assessing the effectiveness of the repair.

Once you’ve located the source, decide whether a simple sealant will suffice or if you need to replace any damaged components. For minor issues, applying a suitable sealant may be an ultimate solution, while more severe cases might require part replacements.

After making the necessary repairs, refill the fluid to the appropriate level and run the vehicle to check for any remaining issues. Monitor for signs of return to ensure the fix is effective.

Lastly, perform regular inspections to prevent future occurrences. Staying proactive will help maintain your vehicle’s performance and longevity.

Preventive Maintenance for Cooling Systems

Regular upkeep is essential for the longevity and reliability of any vehicle’s temperature regulation apparatus. Neglecting routine checks can lead to significant issues that compromise performance and safety. By implementing a strategic maintenance plan, owners can ensure optimal functionality and avoid costly repairs.

Routine Inspections

Performing frequent examinations of various components is crucial. Look for any signs of wear or deterioration, as early detection can prevent severe complications. Focus on hoses, seals, and connections to ensure they are in good condition.

Fluid Quality and Levels

Maintaining the correct volume and quality of liquids is vital. Regularly check for contamination or degradation of the fluid. If necessary, replace it to maintain efficiency and protect components from damage.

Upgrading Parts for Enhanced Cooling

Enhancing thermal management in automotive applications can significantly improve performance and longevity. Upgrading various components can lead to more efficient temperature regulation, ensuring that the vehicle operates optimally under varying conditions. By selecting superior materials and advanced technologies, one can achieve better heat dissipation and overall reliability.

One effective approach is to consider high-performance radiators, which offer increased surface area for heat exchange. These upgraded units often feature lightweight designs that enhance airflow, contributing to lower operating temperatures. Additionally, using premium hoses and clamps ensures better fluid integrity, preventing failures during critical moments.

Another vital aspect involves the selection of thermostats with precise calibration, allowing for optimal fluid circulation. This helps maintain an ideal thermal environment, reducing the risk of overheating. Furthermore, incorporating aftermarket fans can provide additional airflow, particularly in demanding driving scenarios.

Lastly, exploring specialized fluids with enhanced thermal properties can also contribute to better management of heat. These fluids are formulated to provide superior heat transfer, ensuring efficient operation. Overall, investing in high-quality components tailored for performance can lead to a notable improvement in thermal efficiency and vehicle reliability.

Tools Needed for Coolant Repairs

When addressing issues within the liquid circulation apparatus of your vehicle, having the right instruments is essential for effective resolution. Proper preparation ensures a smoother process and reduces the risk of further complications.

Essential Tools

- Wrenches (various sizes)

- Screwdrivers (flathead and Phillips)

- Pliers

- Socket set

- Drain pan

Additional Equipment

- Funnel

- Hoses (if replacements are necessary)

- Rags for cleaning

- Pressure tester

- Torque wrench

FAQs About VW 2.0 Coolant Systems

This section aims to address common inquiries regarding the fluid management mechanisms in Volkswagen vehicles, focusing on the nuances that often perplex owners and enthusiasts alike.

- What are the signs of a malfunctioning fluid management mechanism?

Indicators include temperature gauge fluctuations, unusual puddles under the vehicle, and a visible reduction in fluid levels.

- How often should the fluid be checked?

It is advisable to inspect the levels every few months or during regular maintenance visits to ensure optimal performance.

- Can I use any type of fluid for my vehicle?

Using the manufacturer-recommended type is essential for maintaining efficiency and preventing damage.

- What should I do if I notice a drop in fluid levels?

Investigate for any signs of damage or wear in the hoses and connections, and consult a professional if necessary.

- Is it safe to drive with a suspected issue?

It’s best to avoid driving until the problem is diagnosed, as this could lead to more severe complications.