The efficiency and performance of a vehicle are heavily influenced by its emission pathway. This critical network plays a vital role in managing harmful gases and ensuring compliance with environmental standards. A well-designed configuration not only enhances engine function but also contributes to overall vehicle longevity.

Each element within this network serves a specific function, working harmoniously to direct gases away from the engine and reduce pollutants. From the initial stages of gas release to the final exit, every segment is essential for optimal performance and adherence to regulations.

Familiarity with the various elements allows for better maintenance and troubleshooting, empowering vehicle owners to ensure their transportation operates at its best. Understanding how these segments interact can lead to informed decisions regarding upgrades and repairs.

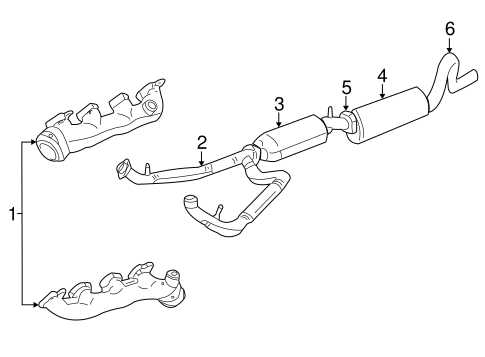

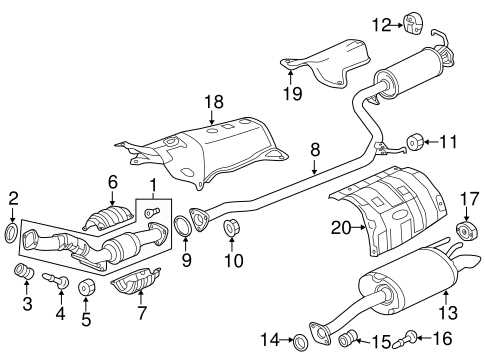

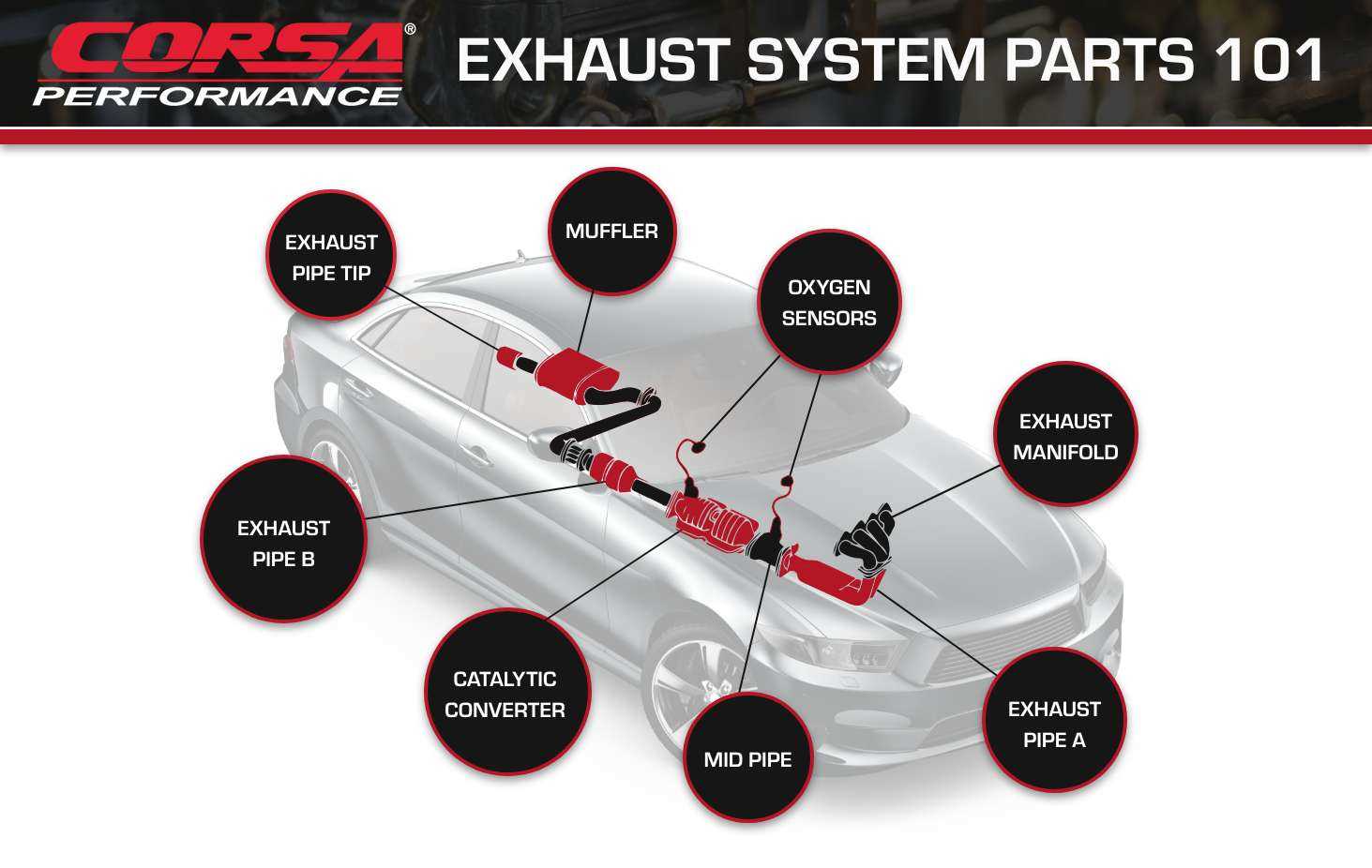

Overview of Exhaust System Components

This section delves into the essential elements that facilitate the effective management of emissions in vehicles. Understanding these components is crucial for comprehending how they work together to enhance performance and comply with regulations.

- Headers: These conduits channel gases from the engine to the subsequent sections, playing a vital role in minimizing backpressure.

- Catalytic Converter: This device transforms harmful pollutants into less harmful emissions, significantly reducing environmental impact.

- Muffler: Designed to decrease noise produced by the engine, this component also helps in managing gas flow.

- Pipes: Various tubes connect different elements, ensuring the smooth transition of gases from one part to another.

- Resonator: Often included to modify sound characteristics, this unit works alongside the muffler to enhance acoustic quality.

Each of these components plays a distinct role, contributing to the overall functionality and efficiency of the vehicle’s emission management framework. Understanding their individual contributions can aid in diagnosing issues and optimizing performance.

Function of Exhaust Headers

The primary role of these components is to facilitate the effective evacuation of gases generated during combustion. They play a crucial part in optimizing the flow and enhancing overall performance.

Efficient Gas Flow: By channeling emissions from multiple cylinders into a single path, these structures minimize backpressure. This allows for a smoother release of gases, promoting better engine efficiency.

Heat Dissipation: They are designed to withstand high temperatures and dissipate heat effectively. This characteristic helps prevent overheating and maintains optimal operating conditions.

Performance Enhancement: The shape and design contribute to improved airflow, which can lead to increased horsepower and torque. This modification is essential for those seeking enhanced performance from their vehicle.

Overall, these components are vital in maximizing engine efficiency, contributing to both performance and longevity.

Importance of Catalytic Converters

The role of specific components in modern vehicles is crucial for both performance and environmental impact. Among these, a certain device serves as a key player in reducing harmful emissions produced during fuel combustion. This technology not only aids in meeting regulatory standards but also contributes to cleaner air quality.

These devices operate by facilitating chemical reactions that transform toxic substances into less harmful emissions before they are released into the atmosphere. By converting pollutants such as carbon monoxide, hydrocarbons, and nitrogen oxides into benign gases, they significantly minimize the ecological footprint of automobiles.

Moreover, the efficiency of these components directly influences overall vehicle performance. A well-functioning device can enhance fuel efficiency and ensure optimal engine performance, leading to a smoother driving experience. Thus, their importance extends beyond environmental benefits, impacting the economy and functionality of vehicles as well.

Role of Mufflers in Sound Control

Mufflers play a crucial role in managing the auditory output of vehicles, ensuring a more pleasant driving experience. By altering the flow of gases, these components help minimize unwanted noise produced by the engine, making rides quieter and more enjoyable.

The primary function of these devices is to absorb sound waves generated during combustion. Through various internal designs, they create specific paths for gases to travel, effectively reducing the intensity of noise. This process not only contributes to comfort but also allows for compliance with regulatory noise standards.

Moreover, mufflers can enhance performance by allowing for a smoother gas flow, which indirectly supports optimal engine function. By balancing sound reduction with efficiency, they maintain a vehicle’s overall performance while catering to the driver’s preference for a quieter ride.

Exhaust Pipes: Materials and Types

Understanding the various components involved in vehicle emissions management is essential for both performance and environmental considerations. Different materials and configurations play a crucial role in how effectively gases are expelled from the engine, impacting durability, efficiency, and sound.

Commonly utilized materials include stainless steel, mild steel, and aluminized steel. Stainless steel is favored for its resistance to corrosion and heat, providing longevity even under harsh conditions. Mild steel, while more affordable, is prone to rust and may require replacement more frequently. Aluminized steel offers a middle ground, featuring a protective coating that enhances resistance to elements without the premium cost of stainless variants.

As for configurations, options range from straight pipes to curved designs, with considerations for diameter influencing flow rate and back pressure. Each type serves distinct purposes, from maximizing performance to ensuring compliance with regulatory standards. Understanding these choices allows for informed decisions when upgrading or maintaining vehicle components.

Understanding Oxygen Sensors

Oxygen sensors play a crucial role in monitoring and optimizing engine performance. These devices assess the concentration of oxygen in the gases exiting the engine, providing vital feedback for efficient operation.

The main functions of these sensors include:

- Enhancing fuel efficiency by adjusting the air-fuel mixture.

- Reducing harmful emissions by ensuring optimal combustion.

- Supporting engine management systems to improve overall performance.

There are two primary types of oxygen sensors:

- Lambda Sensors: Often used in modern vehicles to provide real-time data to the engine control unit.

- Wideband Sensors: Capable of delivering a broader range of readings for precise control of fuel mixtures.

Understanding these devices is essential for maintaining vehicle efficiency and minimizing environmental impact.

Performance Impact of Resonators

Resonators play a crucial role in modifying sound characteristics and enhancing overall efficiency within the vehicle’s airflow framework. By fine-tuning the frequencies produced during operation, these components help to achieve a balanced auditory experience while minimizing unwanted noise levels.

Moreover, their strategic placement can influence backpressure dynamics, which directly affects engine performance. Improved flow can lead to better throttle response and enhanced power output, making resonators an essential consideration for those seeking optimal performance. Additionally, the reduction of drone at cruising speeds contributes to a more comfortable driving experience.

Maintenance of Exhaust Manifolds

Proper upkeep of these components is essential for ensuring optimal engine performance and longevity. Regular inspections help identify wear and tear, preventing larger issues that can arise from neglect. Understanding key practices for care and maintenance can significantly enhance the overall functionality.

Inspection and Cleaning

Regularly check for cracks or corrosion that can hinder performance. Cleaning the surface helps prevent buildup of harmful deposits that may affect airflow. Utilizing appropriate solvents and tools can ensure a thorough job without damaging the material.

Sealing and Replacement

Inspecting seals for leaks is crucial, as any gaps can lead to reduced efficiency. If seals are worn or damaged, replacing them promptly is advisable. Consider the overall integrity of the assembly; if components are excessively degraded, full replacement may be necessary to restore functionality.

Effects of Backpressure on Efficiency

The resistance encountered in the flow of gases can significantly influence performance metrics. When this resistance is too high, it may lead to decreased power output and fuel efficiency, ultimately affecting the overall functionality of the vehicle.

Optimal performance relies on maintaining a balance in the pressure levels within the flow channels. When backpressure exceeds recommended levels, it can hinder the expulsion of gases, resulting in inefficient combustion processes. This imbalance may lead to several detrimental effects, outlined in the table below:

| Impact | Description |

|---|---|

| Reduced Power Output | Excessive resistance can decrease engine power, making acceleration sluggish. |

| Poor Fuel Economy | Increased fuel consumption may occur as the engine works harder to compensate for the resistance. |

| Increased Emissions | Incomplete combustion can result in higher levels of pollutants being emitted. |

| Overheating | Excessive pressure can lead to overheating of engine components, causing potential damage. |

In summary, managing backpressure is crucial for achieving optimal performance and efficiency. Understanding its effects helps in maintaining a well-functioning mechanism, leading to improved longevity and reliability of the vehicle.

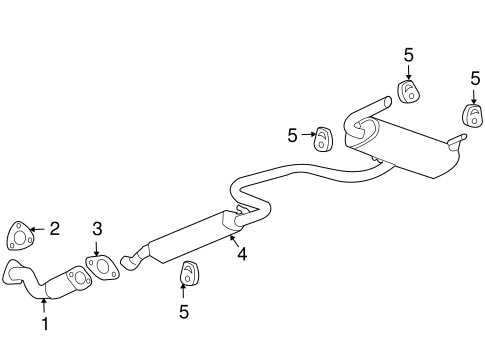

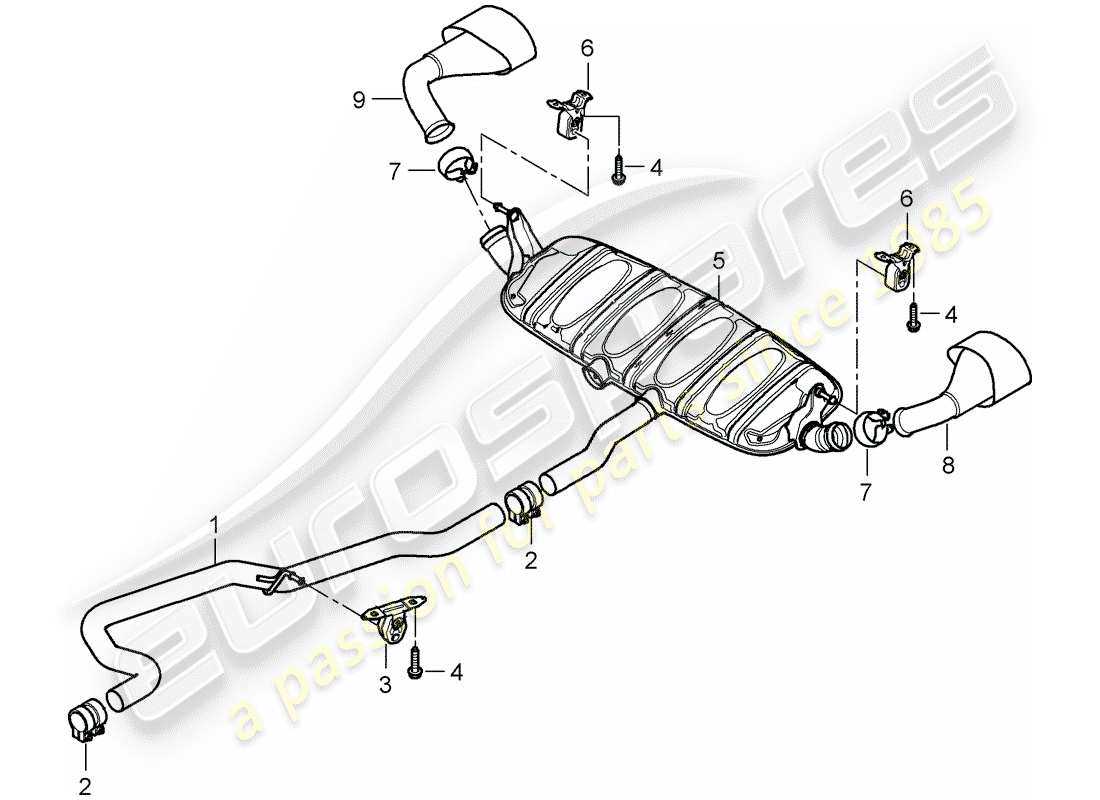

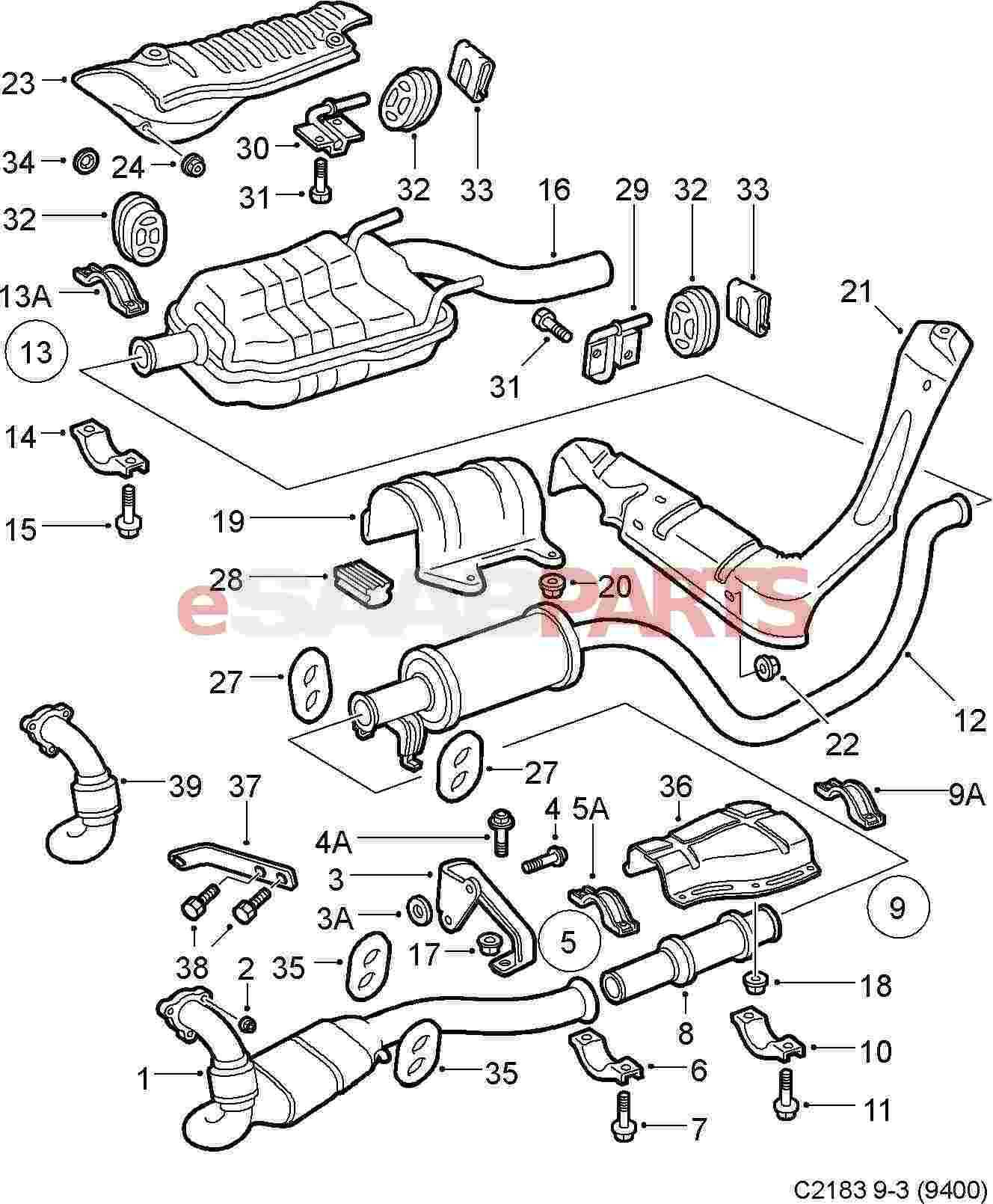

Exhaust System Layout Considerations

When designing the arrangement of components related to vehicle emissions, several key factors must be taken into account to ensure optimal performance and efficiency. The layout plays a crucial role in managing gases, reducing noise, and improving overall functionality.

One significant consideration is the routing of pipes, which should minimize bends and restrictions to enhance flow. Additionally, proper placement of silencers and catalytic converters is essential for effective noise reduction and emissions control. Adequate spacing between elements is necessary to prevent heat buildup and ensure longevity.

Moreover, the choice of materials affects durability and weight, impacting the vehicle’s overall efficiency. Balancing these factors while adhering to regulatory standards can lead to an effective configuration that meets both performance and environmental goals.

Common Exhaust System Issues

Various complications can arise in the assembly responsible for directing gases away from the engine, affecting performance and emissions. Recognizing these issues early can prevent further damage and ensure optimal functionality.

- Leaking Connections: Gaps or holes can lead to fumes escaping, causing noise and potential health hazards.

- Corrosion: Over time, exposure to heat and moisture can degrade materials, leading to failures in specific components.

- Clogged Components: Buildup of soot or debris can restrict airflow, diminishing efficiency and power.

- Improper Alignment: Misalignment can create additional stress on parts, increasing wear and leading to early breakdowns.

- Faulty Sensors: Malfunctioning sensors can affect the monitoring of emissions, leading to poor engine performance.

Addressing these common issues promptly can enhance vehicle longevity and maintain compliance with environmental standards.

Upgrades for Enhanced Performance

To maximize efficiency and boost overall output, various enhancements can be implemented in the components responsible for directing emissions. These modifications not only improve power delivery but also contribute to a smoother operation, ensuring an exhilarating driving experience.

High-Performance Catalytic Converters

Investing in advanced catalytic converters can significantly reduce back pressure, facilitating better flow. These units enhance the conversion of harmful gases, resulting in improved engine efficiency and compliance with emission standards.

Custom Mufflers

Choosing bespoke mufflers can dramatically alter sound and flow characteristics. Tailored designs allow for optimized gas expulsion, promoting a more aggressive tone while reducing turbulence, ultimately leading to an increase in horsepower and torque.

Environmental Regulations and Compliance

In today’s world, adherence to environmental standards is crucial for sustainable practices across various industries. Regulations aim to mitigate the impact of harmful emissions, ensuring cleaner air and a healthier ecosystem.

Key aspects of compliance include:

- Understanding local, national, and international laws

- Implementing best practices in manufacturing and installation

- Regular monitoring and reporting of emissions

- Utilizing technologies that minimize environmental footprints

Organizations must stay informed about evolving guidelines to maintain operational integrity and public trust. Fostering a culture of environmental responsibility can lead to innovative solutions and improved performance.

To ensure compliance, companies often engage in:

- Conducting regular audits and assessments

- Training staff on environmental policies

- Investing in research for cleaner alternatives

By prioritizing these elements, businesses can contribute positively to environmental stewardship while achieving regulatory compliance.