In the intricate world of automotive mechanics, comprehending the various elements that make up a vehicle’s functionality is essential. Each segment plays a critical role in ensuring optimal performance, reliability, and efficiency. From the foundational structure to the sophisticated systems that drive innovation, every component is intricately linked.

For enthusiasts and professionals alike, a visual representation of these crucial elements can provide clarity and enhance understanding. Recognizing how each piece interacts and contributes to the overall operation can lead to better maintenance and informed decisions when modifications or repairs are necessary.

Delving into the specifics of these mechanical structures unveils a wealth of information. It empowers individuals to appreciate the craftsmanship behind their vehicles, fostering a deeper connection between driver and machine. By exploring these intricate designs, one can gain invaluable insights into the technology that powers modern transportation.

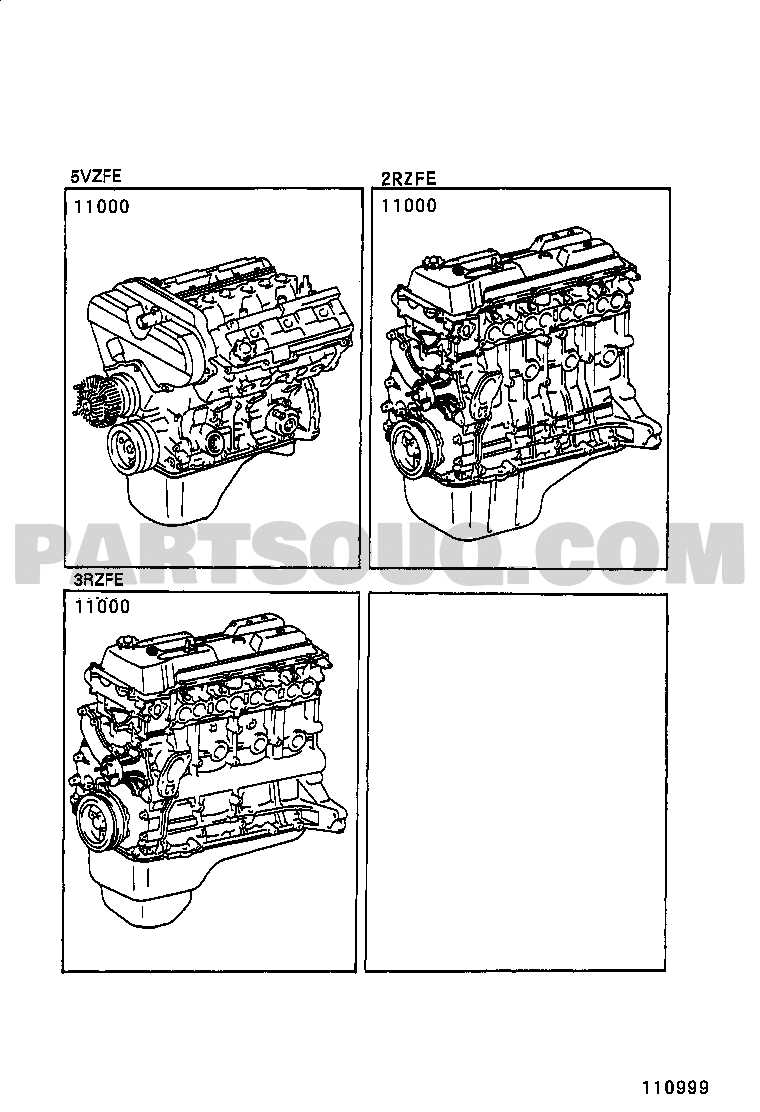

Toyota Tacoma Engine Overview

This section provides a comprehensive look at the powertrain components that drive performance and efficiency in a popular compact pickup. Understanding these elements is essential for enthusiasts and professionals alike, as they contribute significantly to overall functionality and reliability.

At the heart of this vehicle lies a robust assembly designed to deliver power and torque. Variations in displacement and configuration cater to diverse driving preferences, from daily commutes to off-road adventures. Enhanced fuel management systems further optimize consumption, ensuring that drivers can rely on both performance and efficiency.

Critical components such as the intake and exhaust systems play a pivotal role in facilitating airflow, which directly impacts the overall output. Additionally, advancements in technology have introduced features like variable valve timing, which enhances responsiveness and adaptability under various conditions.

Maintenance of these mechanical systems is crucial for longevity. Regular checks and servicing can prevent wear and tear, ensuring that each component operates at peak performance. Understanding the intricacies of these assemblies empowers owners to make informed decisions regarding upgrades or repairs.

In conclusion, a thorough grasp of the inner workings and innovations present in this powertrain offers valuable insights into its capabilities and the driving experience it provides. Familiarity with these elements not only enhances appreciation for engineering excellence but also aids in informed ownership and maintenance practices.

Key Components of Tacoma Engines

Understanding the essential elements that contribute to the performance and reliability of a vehicle’s power unit is crucial for maintenance and enhancement. These components work in unison to ensure optimal functionality and efficiency, making them vital for any enthusiast or technician.

Major Functional Elements

- Crankshaft: Converts linear motion into rotational motion.

- Pistons: Create the compression necessary for combustion.

- Cylinder Head: Houses valves and plays a key role in airflow.

- Fuel Injectors: Deliver the precise amount of fuel into the combustion chamber.

Supporting Systems

- Cooling System: Maintains optimal temperature to prevent overheating.

- Lubrication System: Reduces friction between moving parts.

- Intake and Exhaust: Regulates airflow in and out of the combustion chamber.

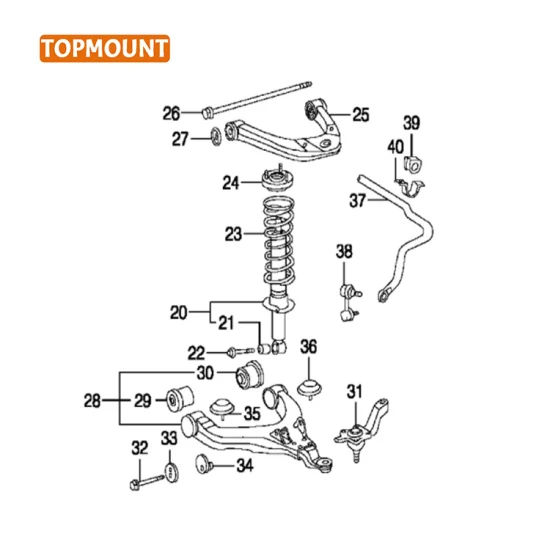

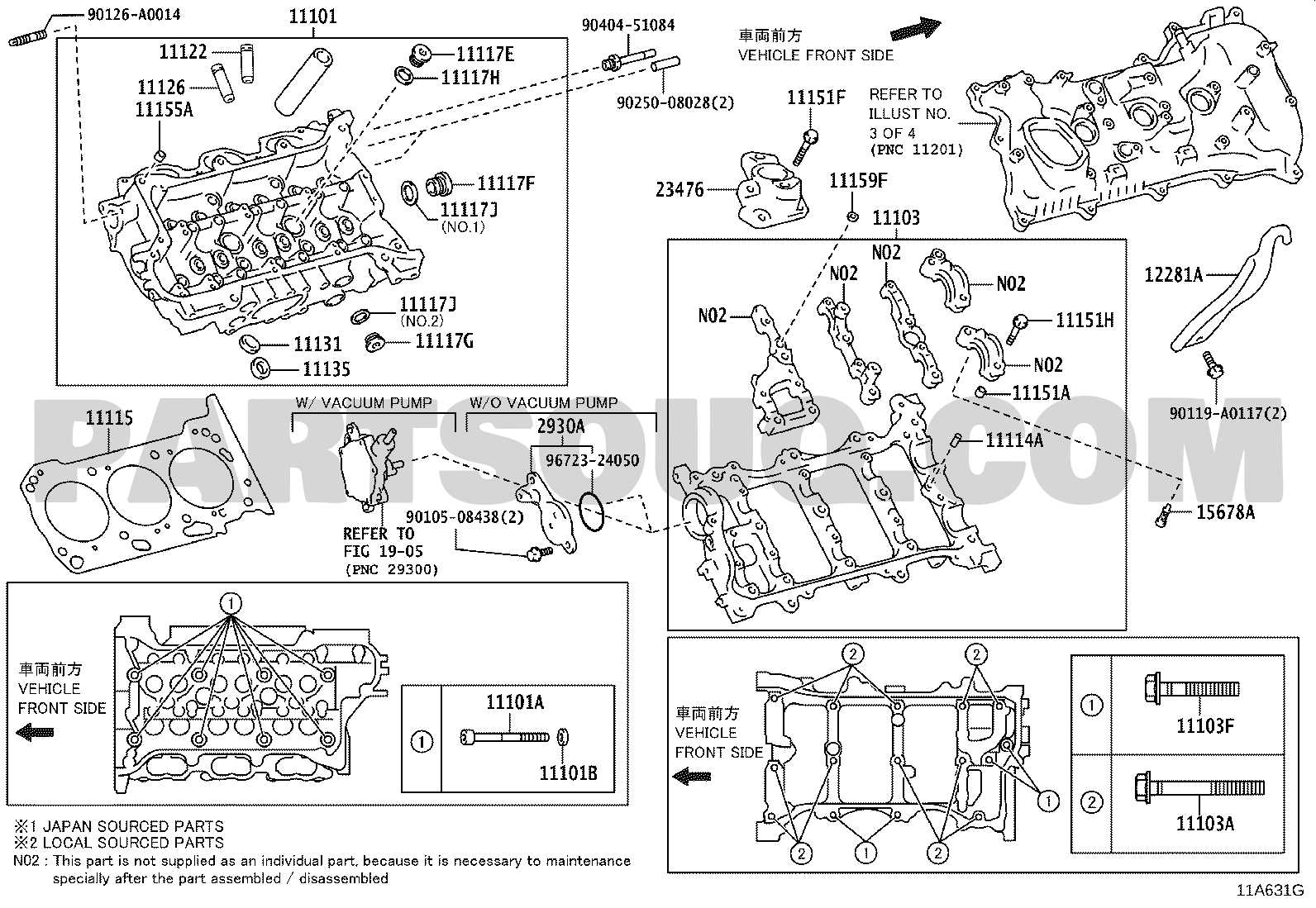

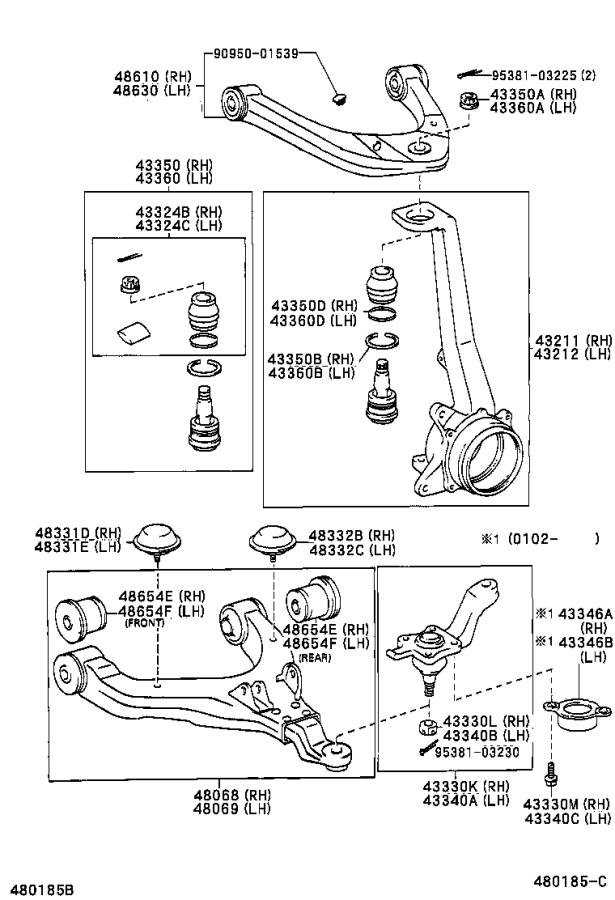

Understanding Engine Diagrams

Grasping the layout of mechanical systems is crucial for both enthusiasts and professionals. These visual representations serve as valuable tools, offering insights into the various components and their interconnections. By familiarizing oneself with these illustrations, one can enhance their comprehension of how these systems function.

Visual Learning plays a significant role in understanding complex machinery. Illustrations simplify intricate designs, making it easier to identify specific elements and their relationships. This clarity enables more effective troubleshooting and maintenance.

Additionally, familiarity with these visuals aids in recognizing wear patterns and potential issues before they escalate. By delving into the components illustrated, one can ultimately improve performance and longevity of the system.

Common Engine Parts Explained

This section aims to illuminate the essential components that contribute to the functioning of a power unit, enhancing performance and reliability. Understanding these elements can help in maintenance and repairs, ensuring longevity and efficiency.

Key Components

- Piston: Moves up and down within the cylinder, converting fuel energy into mechanical work.

- Cylinder Head: Houses the combustion chamber and contains valves and spark plugs.

- Crankshaft: Transforms linear motion from the pistons into rotational motion.

- Camshaft: Controls the timing of valve openings and closings.

Supporting Elements

- Oil Pump: Circulates lubricant to reduce friction and wear.

- Timing Belt: Ensures the crankshaft and camshaft operate in harmony.

- Exhaust Manifold: Directs gases away from the combustion area.

- Fuel Injector: Delivers the precise amount of fuel into the combustion chamber.

Importance of Regular Maintenance

Consistent upkeep is crucial for the longevity and efficiency of any vehicle. Regular check-ups not only enhance performance but also prevent costly repairs in the future. By dedicating time to maintenance, owners ensure their automobiles remain in optimal condition, providing a safe and enjoyable driving experience.

Benefits of Routine Care

- Improved performance and fuel efficiency

- Early detection of potential issues

- Increased resale value

- Enhanced safety for drivers and passengers

Key Maintenance Practices

- Regular oil changes

- Inspection of fluid levels

- Tire rotations and alignments

- Replacement of filters

How to Read Engine Diagrams

Understanding technical illustrations related to automotive components is essential for effective maintenance and repair. These visuals serve as guides that simplify complex information, enabling enthusiasts and professionals to visualize how various elements interact within a mechanical system.

Familiarize Yourself with Symbols

Every illustration uses specific symbols and notations to represent different components. Recognizing these symbols, such as connectors and fluid pathways, allows for quicker comprehension of the layout and functionality of the system. Take note of the legend or key, as it provides crucial context.

Follow the Flow of Operation

To grasp the overall mechanism, trace the flow of operation through the illustration. Identify how various parts connect and interact with one another. Understanding this sequence not only clarifies the workings of the system but also aids in troubleshooting potential issues that may arise during performance.

Differences Between Engine Models

The variety of mechanical systems available across different models can significantly affect performance and overall capabilities. Each system may vary in terms of size, functionality, and the types of materials used in construction. These differences cater to specific driving conditions, power outputs, and efficiency requirements, making it essential to understand the distinct characteristics of each version.

| Model | Displacement | Fuel Type | Power Output |

|---|---|---|---|

| Model A | 2.7L | Gasoline | 159 HP |

| Model B | 3.5L | Gasoline | 278 HP |

| Model C | 2.8L | Diesel | 201 HP |

These distinctions in specifications ensure that each variant meets the unique demands of various drivers, whether focused on power, fuel efficiency, or load capacity. Understanding the options allows for more informed choices when considering upgrades or maintenance.

Common Issues and Solutions

Many vehicles, regardless of their make or model, experience recurring problems that can affect performance and reliability over time. Understanding these issues and knowing how to address them can significantly extend the life of key components and improve overall functionality.

Overheating Problems

A frequent concern for drivers is overheating, which can result from a variety of causes. The most common culprits include a malfunctioning cooling mechanism, leaks, or a buildup of debris in key areas. Regular maintenance and timely replacements are crucial in preventing serious damage.

- Check fluid levels and ensure proper circulation.

- Inspect hoses and seals for any signs of wear or leaks.

- Clean or replace blocked parts to maintain optimal airflow.

Loss of Power

Another issue often faced is a noticeable reduction in power during operation. This can stem from a range of factors, including clogged filters, poor fuel supply, or improper adjustments in essential systems.

- Replace or clean filters regularly to ensure proper air and fuel intake.

- Inspect and maintain key control components to ensure they are functioning correctly.

- Consider tuning systems that affect performance for more efficient operation.

Addressing these common concerns with preventive care and regular

Replacement Parts Availability

When it comes to maintaining or repairing your vehicle, having access to the right components is crucial for its optimal performance. A wide range of essential elements can be found through various distributors and retailers, ensuring that any necessary replacements are readily available. This guarantees that your vehicle remains reliable and functional over time.

Reliable Distributors

Numerous suppliers provide high-quality components, making it easy to find exactly what you need. Many vendors specialize in providing original equipment manufacturer (OEM) products, while others offer more affordable alternatives that still meet industry standards. These options ensure that you can make informed choices based on both quality and budget.

Affordable Alternatives

If you are looking for cost-effective options, there are many aftermarket solutions available that can fit a variety of needs. These alternatives often offer a balance between affordability and reliability, making them a popular choice for those who wish to keep their vehicle in good condition without overspending.

Tools Needed for Engine Repairs

When it comes to addressing mechanical issues, having the right equipment is essential to ensure efficiency and precision. Without the proper set of instruments, even the simplest tasks can become overly complicated. Below is a guide to some of the most common tools used for maintenance and adjustments in mechanical systems.

Essential Hand Tools

Basic hand tools are crucial for any mechanical work. These include various sizes of wrenches, sockets, and screwdrivers that allow for the manipulation of different types of fasteners. Adjustable spanners and pliers are also necessary for tasks involving bolts, clamps, and wires. A torque wrench ensures that all connections are tightened to the correct specifications.

Specialized Instruments

In addition to hand tools, specialized instruments are often required for more specific tasks. A set of gauges is essential for checking pressure levels, while diagnostic tools are needed for electronic system assessments. Another vital piece of equipment is a multimeter, used to measure electrical current and ensure proper connectivity in circuits.

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening bolts and nuts |

| Torque Wrench | Ensures precise tightening of fasteners |

| Multimeter | Measures electrical voltage, current, and resistance |

| DIY Maintenance Tips for Tacoma

Regular upkeep of your vehicle ensures its longevity and smooth operation. Whether you’re a seasoned mechanic or a beginner, following a few simple maintenance practices can prevent issues before they arise, keeping your ride in top shape. By handling these tasks yourself, you can save money and time while gaining a deeper understanding of how your vehicle works. Fluid Checks and ReplacementsEnsuring that vital fluids are at optimal levels is crucial for a well-functioning vehicle. Regularly inspect and top up essential fluids such as oil, coolant, brake fluid, and transmission fluid. Periodic replacement is necessary to maintain performance, so follow recommended intervals to avoid potential problems. Tire MaintenanceTires play a pivotal role in safety and comfort. Regularly check tire pressure and inspect for wear. Uneven wear may indicate the need for alignment or rotation. Keeping your tires in good condition improves fuel efficiency and enhances overall handling, ensuring a safer driving experience. Upgrading Engine ComponentsEnhancing the performance of a vehicle’s power system often requires thoughtful modifications. Upgrades can range from replacing standard parts with high-efficiency alternatives to adding specialized components designed for better durability and output. By focusing on critical areas, it’s possible to significantly boost overall efficiency, fuel economy, and responsiveness. One of the most effective methods of improving performance is by upgrading key elements of the power unit. This might involve enhancing airflow systems, improving fuel delivery mechanisms, or strengthening certain internal parts for higher performance. Each change, while small in isolation, contributes to a more powerful and reliable system. When selecting upgrades, it’s essential to consider the compatibility of new parts with the existing setup, ensuring optimal functionality without unnecessary wear or damage. Proper planning and execution of these upgrades will not only increase power but also extend the overall lifespan of the vehicle’s key systems. Finding OEM vs. Aftermarket PartsWhen it comes to replacing essential components, the choice between factory originals and alternative options is crucial. Both types offer distinct advantages, and the decision depends largely on what you’re prioritizing in terms of performance, cost, and reliability. Understanding the key differences can help ensure you make the right decision for your vehicle’s needs. Advantages of Original Equipment Manufacturer (OEM)Factory-produced items are designed to match the exact specifications of your vehicle. They offer guaranteed compatibility and are often backed by warranties. These components are ideal for those who prefer a seamless fit and the peace of mind that comes with using products that meet the vehicle’s original standards. Benefits of Aftermarket Alternatives

Alternatives produced by third-party manufacturers are often more affordable and offer a wider range of choices. These options can sometimes provide better performance or customization, depending on the brand. However, it’s important to ensure that the chosen product meets quality standards to avoid potential issues in the long run. |