In any mechanical system, grasping the intricate layout and components is essential for effective maintenance and repair. This section delves into the intricate network of elements that make up the equipment in question, providing valuable insights for both novice users and experienced technicians. Familiarity with the structure can greatly enhance the efficiency of troubleshooting processes.

By exploring the configuration of various components, users can develop a deeper understanding of how each part interacts within the larger mechanism. This knowledge is not only beneficial for routine upkeep but also for identifying potential issues before they escalate into significant problems. Engaging with this overview will empower users to navigate the complexities of the system with confidence and precision.

Additionally, having a clear reference for each component’s role within the assembly fosters a proactive approach to maintenance. Users equipped with this information are better prepared to make informed decisions regarding repairs, replacements, and upgrades, ultimately prolonging the lifespan of the equipment.

This section delves into the essential elements of a specific model, offering a comprehensive look at its key components. Understanding these parts is crucial for maintenance and troubleshooting, ensuring the machinery operates efficiently. The following headings will explore various aspects of the components, providing insights and practical information.

Essential Elements for Operation

Examining the fundamental elements necessary for the effective functioning of the equipment. These components work together to facilitate smooth performance.

Common Issues and Solutions

Identifying frequent problems associated with the components and presenting effective solutions to enhance the overall functionality.

| Component | Function | Common Issues | Solutions |

|---|---|---|---|

| Drive Belt | Transmits power from the engine | Worn or frayed | Replace with a new belt |

| Fuel Filter | Removes impurities from fuel | Clogged filter | Clean or replace the filter |

| Blades | Cuts grass and foliage | Dull edges | Sharpen or replace blades |

Maintenance Tips for Longevity

Providing practical maintenance advice to prolong the life of the equipment and its components. Regular care can prevent breakdowns and ensure optimal performance.

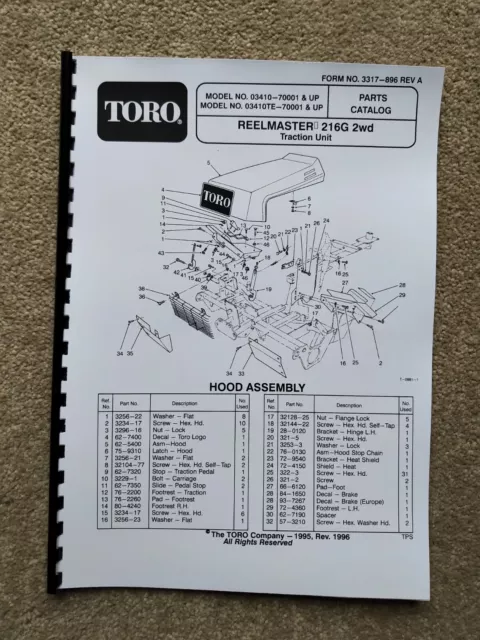

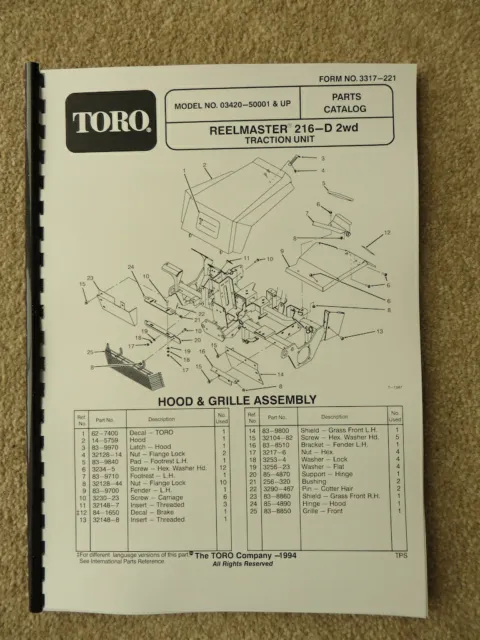

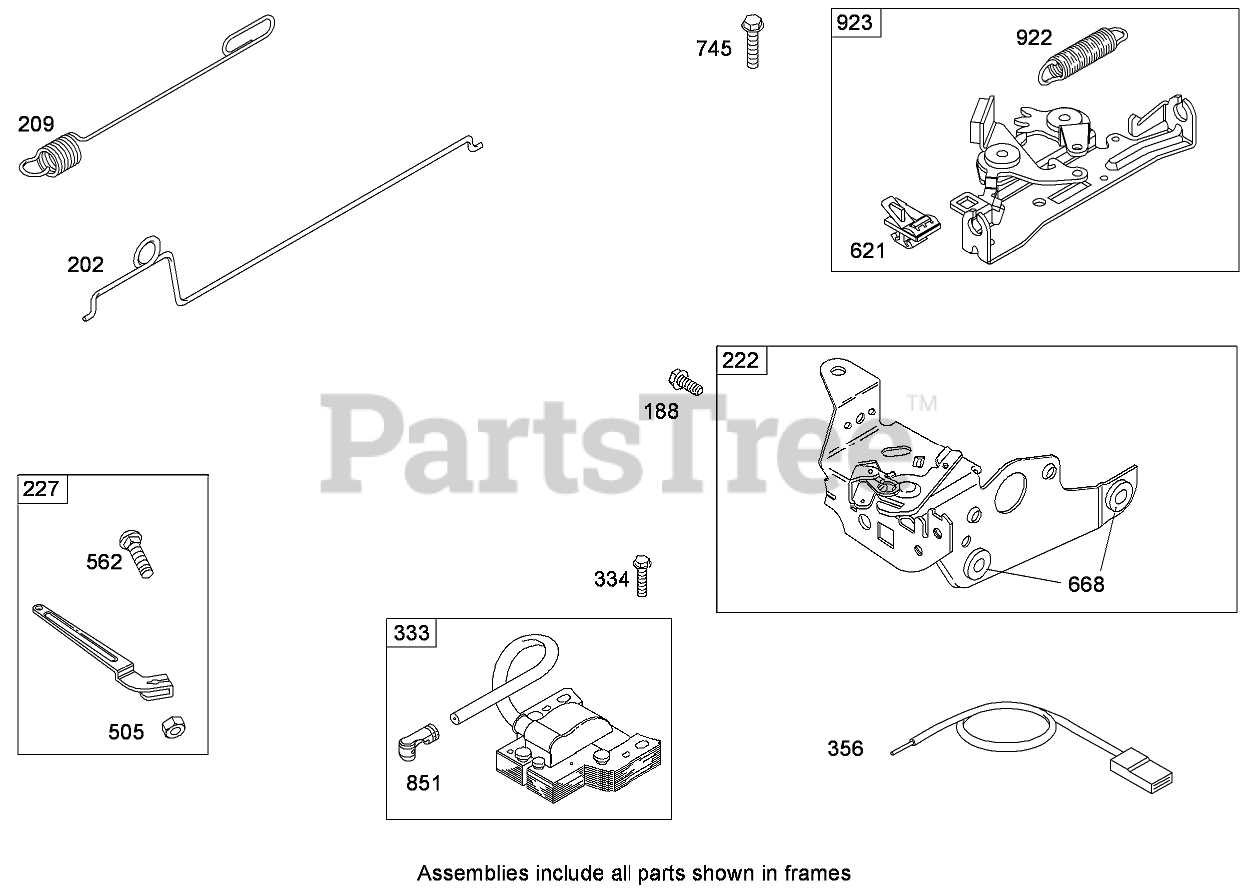

Understanding the Parts List

Grasping the components inventory is essential for effective maintenance and repair of machinery. It provides a comprehensive overview of the essential elements required for optimal functioning. A well-organized catalog enhances the user’s ability to identify, order, and replace parts efficiently.

The inventory typically includes various categories that facilitate easy navigation. Familiarizing yourself with these sections can streamline the process of locating specific items:

- Component Names: Each item is usually labeled with a descriptive title to clarify its function.

- Identification Numbers: Unique identifiers assist in accurately matching components with their specifications.

- Quantity: This indicates how many of each element are necessary for assembly or repair.

- Compatibility: Information about which models or systems the components are suited for is often included.

Reviewing the inventory thoroughly can prevent common errors during the ordering process and ensure that you have all necessary elements on hand before commencing work.

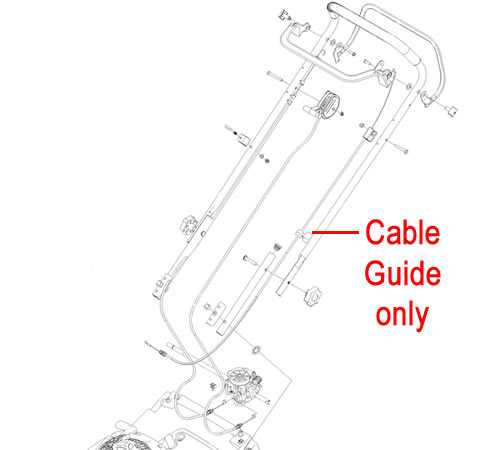

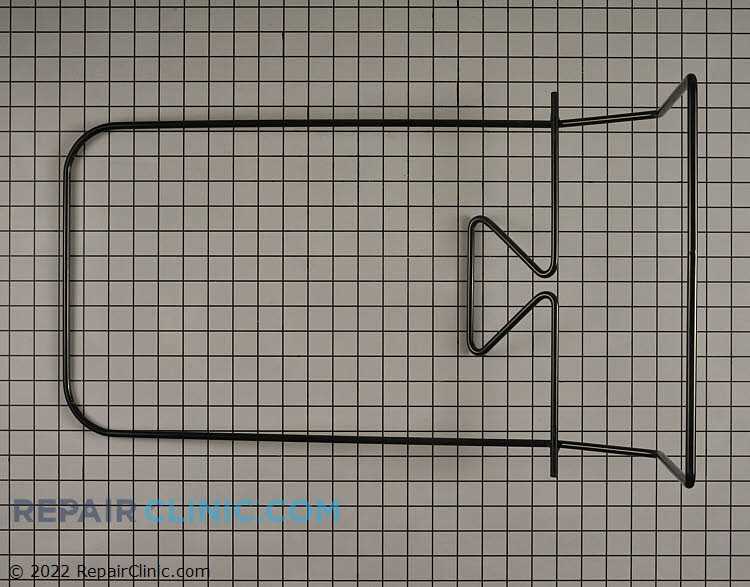

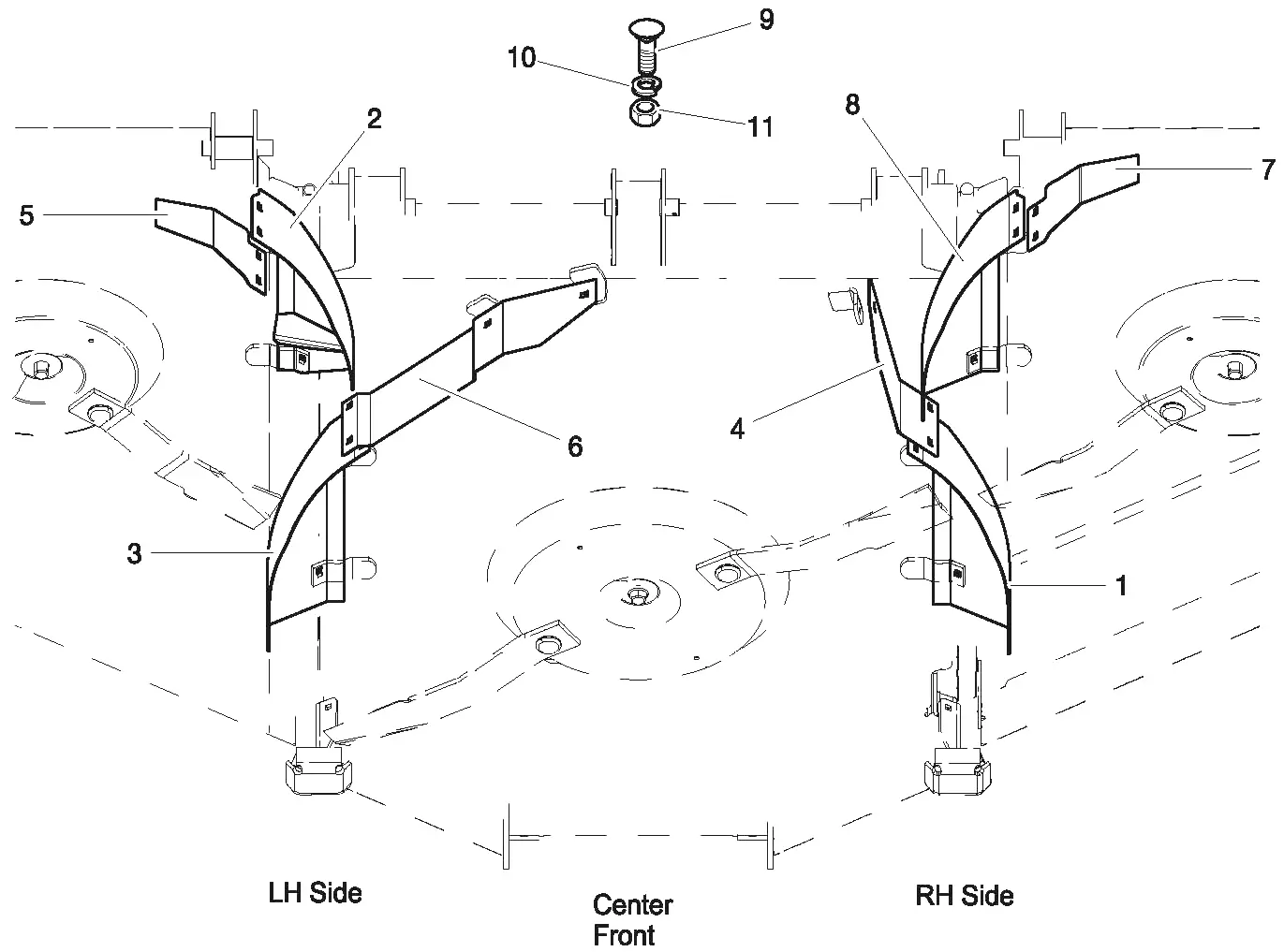

Visual Representation of Each Piece

This section aims to provide a comprehensive visual overview of the individual components involved in the assembly. Each element plays a crucial role in the overall functionality, and understanding their arrangement can enhance maintenance and repair processes.

Component Identification

Recognizing each part’s unique features is essential for efficient operation. Diagrams can clarify the role and location of each segment, allowing users to familiarize themselves with their respective functions and interconnections.

Benefits of Visual Aids

Utilizing visual representations simplifies the comprehension of complex assemblies. Clear illustrations help in identifying components quickly, aiding both novice and experienced users in navigating through the intricacies of assembly and maintenance tasks.

Importance of Accurate Diagrams

Precision in visual representations is crucial for understanding complex systems and ensuring effective maintenance. Clear illustrations not only facilitate proper assembly but also aid in troubleshooting by providing a reliable reference for users.

Enhancing Understanding

Visual clarity allows individuals to grasp the intricate relationships between various components. When users can easily identify elements, they are better equipped to navigate their functionality and interconnectivity, leading to more efficient operation.

Aiding Repair and Maintenance

Having an accurate illustration serves as a valuable resource during repair and upkeep. It enables technicians to locate specific elements quickly, minimizing downtime and streamlining the repair process. This results in a more effective resolution of issues and prolongs the lifespan of the equipment.

Common Issues with Toro 20339 Parts

When dealing with lawn maintenance equipment, users often encounter several challenges related to specific components. Understanding these common problems can enhance the efficiency and lifespan of the machinery.

Wear and Tear: Regular use of any mechanical device leads to gradual deterioration of its elements. Common signs include decreased performance and increased noise levels, which often indicate the need for replacement.

Compatibility Issues: When sourcing replacements, it is crucial to ensure compatibility with the existing system. Mismatched components can lead to malfunction and even cause damage to the equipment.

Improper Installation: Incorrect installation of new elements frequently results in operational failures. It is vital to follow the manufacturer’s guidelines to ensure proper setup and functionality.

Maintenance Neglect: Failure to perform routine maintenance can lead to preventable issues. Regular checks and servicing can help identify problems early, extending the life of the equipment.

By being aware of these common complications, users can take proactive steps to mitigate issues and maintain the performance of their machinery.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular attention and care. Implementing a consistent maintenance routine can significantly extend the lifespan of your machinery, leading to better performance and reduced need for replacements. Understanding the essential practices for upkeep will keep your tools in optimal condition.

Regular Inspections

Conducting periodic assessments of your machinery is crucial. Look for signs of wear and tear, loose components, or any irregularities that could indicate underlying issues. Addressing these problems early can prevent costly repairs and enhance operational safety.

Proper Cleaning Techniques

Maintaining cleanliness is essential for effective operation. Remove debris, dirt, and other contaminants from surfaces and moving parts to ensure smooth functioning. Utilize appropriate cleaning agents that will not harm the materials and follow the manufacturer’s guidelines for specific cleaning instructions.

How to Replace Specific Components

When it comes to maintaining your equipment, understanding how to effectively substitute certain elements is essential for optimal performance. This guide outlines the necessary steps to follow when replacing particular components, ensuring that you can keep your machine running smoothly and efficiently.

Before you begin, gather all required tools and new components to streamline the process. Always prioritize safety by disconnecting power sources and following manufacturer guidelines.

Below is a table detailing the common components, their functions, and suggested replacement procedures:

| Component | Function | Replacement Steps |

|---|---|---|

| Filter | Cleans the air intake | 1. Remove the cover 2. Take out the old filter 3. Insert the new filter 4. Replace the cover |

| Belt | Transfers power to moving parts | 1. Loosen tensioner 2. Remove the old belt 3. Fit the new belt 4. Adjust the tension |

| Blade | Cuts grass or material | 1. Detach the blade assembly 2. Replace with a new blade 3. Reattach the assembly securely |

| Battery | Powers the electrical system | 1. Disconnect battery terminals 2. Remove the old battery 3. Install the new battery 4. Reconnect terminals |

Following these guidelines will help ensure a smooth replacement process, allowing your machinery to function at its best.

Tools Required for Assembly

For a successful assembly process, it’s essential to have the right equipment at hand. This ensures that each component fits together seamlessly and minimizes the risk of damage during installation. Proper tools not only enhance efficiency but also contribute to a smoother workflow.

The following table lists the essential tools you will need to effectively assemble the components:

| Tool Type | Description |

|---|---|

| Wrench Set | Various sizes to fit different nuts and bolts. |

| Screwdriver Set | A variety of screwdrivers for different head types. |

| Pliers | For gripping, twisting, and cutting wires or small parts. |

| Socket Set | Used for tightening and loosening fasteners securely. |

| Measuring Tape | To ensure precise measurements of components and spaces. |

| Safety Glasses | To protect your eyes during the assembly process. |

Where to Purchase Replacement Parts

Finding quality components for your machinery can significantly enhance its performance and longevity. It is crucial to source these items from reliable suppliers to ensure compatibility and durability. Various options are available, each catering to different needs and preferences.

Authorized Dealers and Distributors

One of the most dependable avenues for acquiring components is through authorized retailers. These establishments often carry a wide range of genuine items specifically designed for your equipment, ensuring optimal functionality. Furthermore, purchasing from an authorized source provides access to knowledgeable staff who can assist with any inquiries regarding selection and installation.

Online Marketplaces

Numerous online platforms offer a convenient way to explore various options. Websites dedicated to selling components typically feature user-friendly interfaces that allow for easy searching and comparing. Additionally, many of these platforms provide customer reviews and ratings, helping you make informed decisions about your purchases. When using online sources, verify the credibility of the seller to avoid counterfeit products.

Compatibility with Other Models

This section explores the interchangeability of components among various equipment models, highlighting how certain features can be shared or adapted. Understanding these relationships can enhance maintenance efficiency and expand the usability of parts.

Many users seek to identify compatible options to optimize their machinery. Here are some key considerations:

- Check the specifications: Ensure that the technical details align with those of other models.

- Consult the manufacturer: Refer to official resources for compatibility information.

- Explore community forums: Engage with other users for insights on successful adaptations.

By exploring the compatibility of components, operators can enhance their equipment’s performance and longevity while minimizing downtime.