When it comes to winter maintenance, having a comprehensive grasp of your machinery is essential for optimal performance. Knowledge of each component ensures that you can troubleshoot effectively and maintain the equipment in peak condition.

Visual aids play a crucial role in this understanding, as they allow users to identify various elements quickly and accurately. These illustrations serve as a guide, helping to streamline repairs and replacements.

Whether you’re an experienced user or a newcomer, delving into the specifics of your equipment enhances your confidence and effectiveness in managing winter challenges. Familiarity with individual elements ultimately leads to better care and longer lifespan of your tools.

Toro Snow Thrower Parts Overview

This section provides a comprehensive look at the various components that make up a snow-clearing machine. Understanding each element is essential for effective maintenance and repair, ensuring optimal performance during winter operations. Each piece plays a critical role in the functionality and efficiency of the equipment.

| Component | Description |

|---|---|

| Auger | The rotating blade responsible for collecting and moving snow. |

| Chute | A funnel-like structure that directs the expelled snow to the desired location. |

| Engine | The power source that drives all operational functions of the equipment. |

| Drive Belt | Connects the engine to the auger and provides necessary power transfer. |

| Skids | Support the machine’s base, allowing for height adjustments on different surfaces. |

| Control Panel | The interface for operators to manage settings and operations efficiently. |

Familiarity with these essential elements will aid in troubleshooting and enhance the overall longevity of your equipment, ensuring it remains a reliable tool in harsh weather conditions.

Understanding Snow Thrower Components

Grasping the various elements of winter clearing equipment is essential for effective operation and maintenance. Each component plays a significant role in the overall functionality, ensuring efficient removal of frozen precipitation. Familiarity with these parts enables users to troubleshoot issues and perform necessary upkeep, ultimately prolonging the lifespan of the machine.

Key Elements of the Equipment

Every unit comprises several crucial components that work in harmony. Understanding their functions can enhance performance and facilitate repairs. Below is an overview of the primary elements commonly found in these machines.

| Component | Description |

|---|---|

| Engine | Powers the machinery and drives all operations. |

| Auger | Collects and directs the frozen material toward the discharge chute. |

| Chassis | Frame that supports all other components and provides stability. |

| Discharge Chute | Dispenses the cleared material away from the working area. |

| Control Panel | Interface for adjusting speed and direction of operation. |

Importance of Regular Maintenance

Routine inspection and care of these elements are vital for ensuring optimal functionality. Neglect can lead to performance issues, making it crucial to understand how each part contributes to the overall effectiveness of the equipment. Regular maintenance not only prevents breakdowns but also enhances the machine’s efficiency during the demanding winter months.

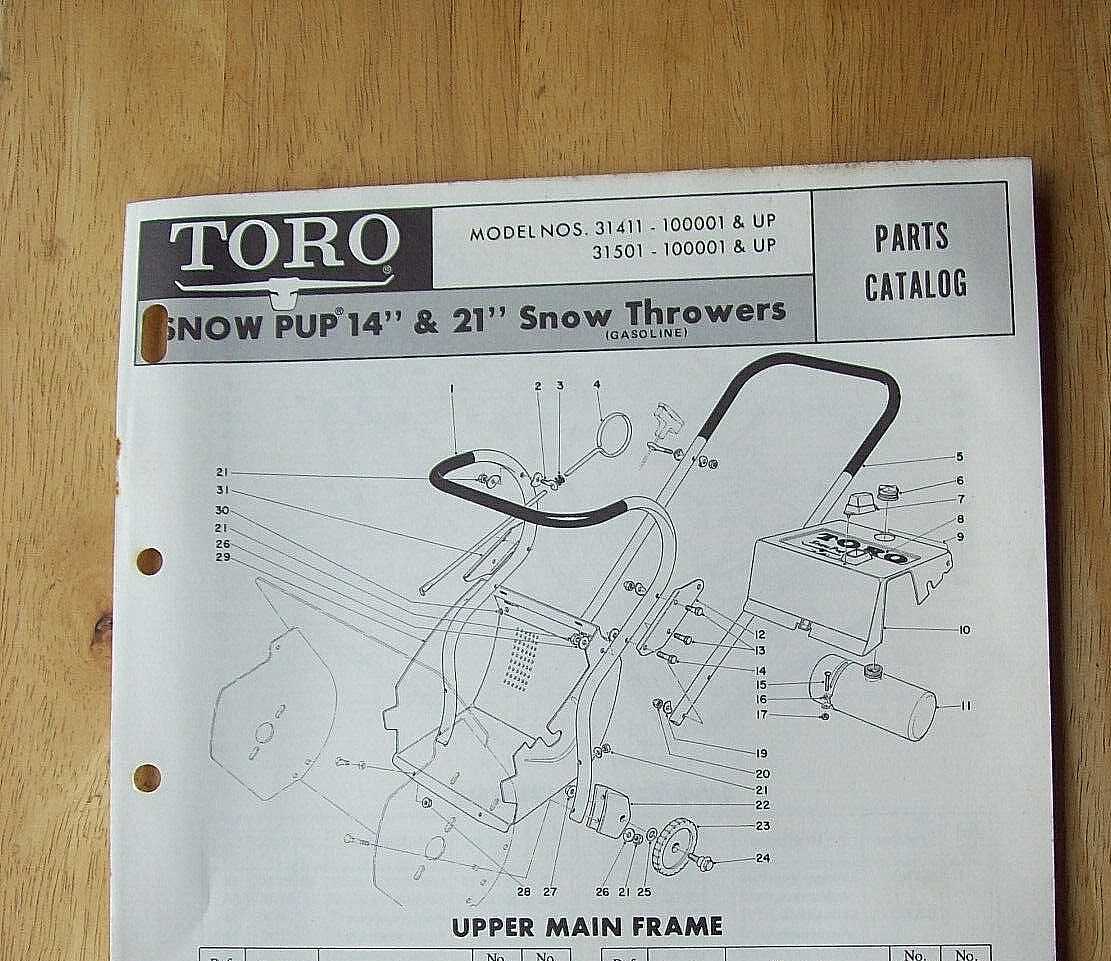

Common Toro Models and Their Parts

This section provides an overview of widely used models and their essential components, focusing on what makes each unit unique. Understanding these elements is crucial for effective maintenance and repair, ensuring optimal performance during harsh winter conditions.

Popular Models Overview

Each model boasts specific features tailored to various tasks. Below is a summary of some common variations and their key components:

| Model | Key Features | Common Components |

|---|---|---|

| Model A | Lightweight and easy to maneuver | Auger, impeller, chute |

| Model B | High-capacity for larger areas | Engine, fuel tank, control panel |

| Model C | Enhanced traction and stability | Tracks, skid shoes, gearbox |

Understanding Key Components

Familiarity with individual components is essential for troubleshooting and maintenance. The interaction between various elements affects overall functionality, allowing users to tackle diverse conditions efficiently.

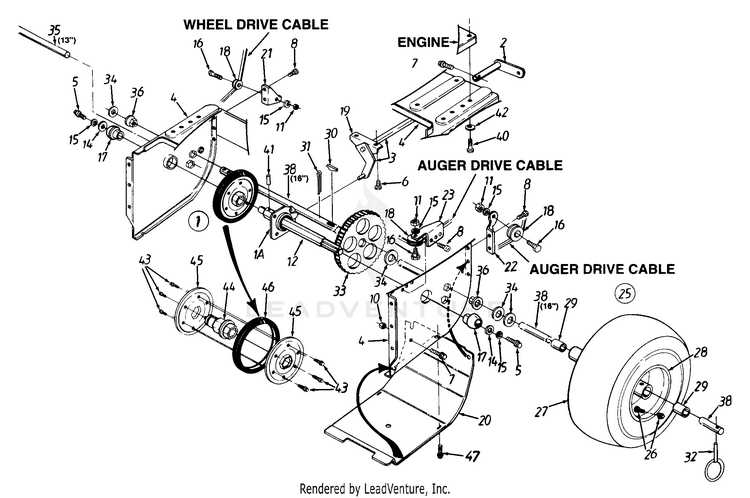

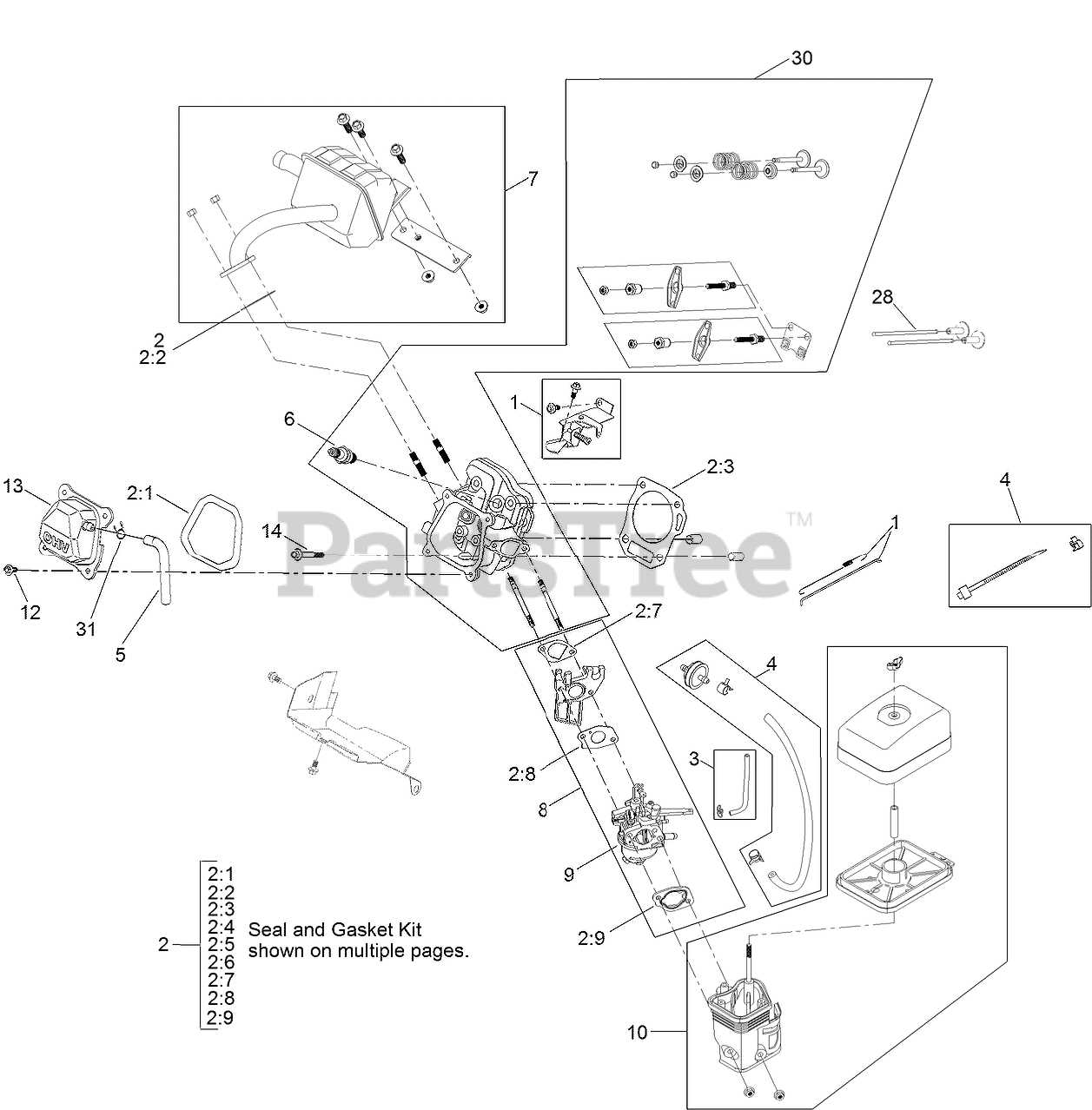

How to Read a Parts Diagram

Understanding the layout of components is essential for efficient maintenance and repair. By familiarizing yourself with the visual representation of elements, you can easily identify each section and its role in the overall system. This knowledge enhances your ability to perform tasks effectively.

| Element | Description |

|---|---|

| Key | Indicates the specific parts and their corresponding numbers or letters. |

| Labels | Provides names or designations for each component, facilitating easier identification. |

| Sections | Divides the overall structure into manageable parts for clearer understanding. |

| Connections | Shows how different elements interact or link with one another. |

By mastering these aspects, you’ll be well-equipped to delve deeper into repairs and upgrades, ensuring optimal performance and longevity of your equipment.

Essential Tools for Maintenance

Proper upkeep of outdoor equipment is crucial for optimal performance and longevity. Utilizing the right instruments not only simplifies the process but also enhances efficiency, allowing for timely repairs and adjustments. Here’s a guide to essential tools that will aid in maintaining your machinery effectively.

Basic Tools

- Wrenches

- Screwdrivers

- Pliers

- Socket Set

- Hammer

Specialized Equipment

- Oil Change Kit

- Fuel Stabilizer

- Cleaning Brush

- Safety Goggles

- Grease Gun

Having these tools on hand will ensure that you can perform necessary maintenance tasks promptly, helping to prolong the lifespan of your equipment.

Where to Find Replacement Parts

Locating suitable components for your equipment is essential for maintaining its performance and longevity. Whether you are facing wear and tear or need to upgrade certain elements, understanding where to source these items can save time and money. Here are some reliable options to consider when searching for the necessary replacements.

Authorized Dealers

One of the most dependable sources is an authorized dealer. These establishments often have a comprehensive selection of components specifically designed for your equipment. Additionally, purchasing from these vendors ensures that you receive genuine items, which are crucial for optimal functionality. Make sure to check the dealer locator on the manufacturer’s website for nearby options.

Online Retailers and Marketplaces

The internet offers a vast array of choices for sourcing components. Well-known online retailers often stock a wide variety of items, including aftermarket alternatives. Popular marketplaces provide a platform for both new and used options, giving you the flexibility to choose based on your budget. Always verify seller ratings and reviews to ensure a satisfactory purchase.

Identifying Worn Out Components

Recognizing deteriorated elements in machinery is essential for maintaining efficiency and performance. Timely identification can prevent further damage and ensure longevity. Here are key signs to look for when assessing the condition of various components.

Common Indicators of Wear

- Unusual Noises: Listen for grinding or rattling sounds that weren’t present before.

- Decreased Performance: Noticeable drops in efficiency or output may signal a problem.

- Visible Damage: Look for cracks, rust, or any physical deformities on components.

Steps for Assessment

- Conduct a visual inspection of all critical elements.

- Test functionality to determine any inconsistencies in operation.

- Consult the manufacturer’s guidelines for specific wear metrics.

Benefits of Regular Maintenance

Here are some key benefits of consistent maintenance:

| Benefit | Description |

|---|---|

| Increased Longevity | Routine care helps to extend the lifespan of your machinery by addressing wear and tear early on. |

| Improved Performance | Regular servicing ensures that all components are functioning optimally, leading to better overall efficiency. |

| Cost Savings | Preventive maintenance can reduce repair costs by identifying issues before they become significant problems. |

| Safety Assurance | Consistent checks help to identify potential hazards, ensuring safer operation for users. |

| Higher Resale Value | A well-maintained item retains its value better, making it more appealing to potential buyers. |

Tips for Proper Assembly

Assembling outdoor equipment can be a rewarding task when approached with care and attention to detail. Proper assembly ensures optimal performance and longevity of the machinery, minimizing the likelihood of issues down the line. Here are some key recommendations to guide you through the process effectively.

Preparation is Key

Before you start, take time to organize your workspace. Gather all necessary tools and components to prevent interruptions. Reviewing the instructions thoroughly will give you a clear understanding of the assembly sequence. Make sure to wear appropriate safety gear to protect yourself during the process.

Follow the Sequence

Adhering to the designated assembly order is crucial. Begin with larger components and gradually work your way to smaller parts, ensuring each piece is securely attached before moving on. Double-check all connections and tighten bolts to the manufacturer’s specifications to avoid future complications. If you encounter any resistance or difficulty, reassess your approach to prevent damage.

Exploring OEM vs. Aftermarket Parts

When it comes to maintaining machinery, the choice between original equipment manufacturer components and those produced by third-party companies can significantly impact performance and longevity. Understanding the differences between these two options is crucial for informed decision-making and ensuring optimal functionality of your equipment.

Benefits of OEM Components

Original manufacturer components are specifically designed for compatibility and reliability. They often come with warranties and assurances of quality, which can provide peace of mind for users. Additionally, these parts are typically subjected to rigorous testing and quality control, ensuring that they meet exact specifications and performance standards.

Advantages of Aftermarket Alternatives

Aftermarket components can offer a more budget-friendly option while still providing acceptable performance. These parts may also present innovative designs or enhancements that original parts do not. However, it’s essential to conduct thorough research to ensure that these alternatives are reputable and fit for purpose, as quality can vary widely across different manufacturers.

Customer Reviews on Toro Parts

When it comes to maintaining outdoor equipment, feedback from users plays a crucial role in guiding potential buyers. Reviews often provide insights into quality, durability, and overall performance, helping customers make informed decisions. A closer look at user experiences can reveal patterns regarding satisfaction and reliability of the components in question.

Positive Experiences: Many customers highlight the excellent functionality and longevity of the components. Users frequently praise the ease of installation and the compatibility with their equipment, noting that these items enhance performance significantly. For instance, individuals often mention how a particular item transformed their machine’s efficiency, allowing for smoother operation and reducing downtime.

Areas for Improvement: Despite numerous positive remarks, some users have pointed out areas that could benefit from enhancements. Common feedback includes concerns about availability and shipping times, which can be frustrating for those needing urgent replacements. Additionally, a few reviews mention occasional discrepancies in fit, urging prospective buyers to double-check compatibility before making a purchase.

Overall Impression: The consensus among users leans towards satisfaction, with many recommending these components for their reliability and effectiveness. By considering both the positive and constructive feedback, potential customers can better navigate their options and make choices that best suit their needs.

DIY Repairs for Snow Throwers

When the winter season approaches, ensuring your equipment operates efficiently can save time and hassle. Understanding how to perform basic repairs can empower users to tackle common issues without relying on professionals. This section explores essential steps and tips for maintaining your machinery.

Assessing Common Issues

Begin by identifying frequent problems that can arise during use. Common malfunctions include engine troubles, electrical failures, and performance drops. Knowing what to look for helps in diagnosing issues swiftly.

Gathering Tools and Resources

Having the right tools on hand is crucial. Basic hand tools, wrenches, and replacement components will facilitate most repairs. Additionally, consulting user manuals and online resources can provide valuable guidance.

Step-by-Step Repair Process

Once a problem is identified, proceed with a methodical approach. Start with disassembly if needed, cleaning parts, replacing worn components, and finally reassembling everything securely. Regular maintenance checks can prevent many issues before they escalate.

Safety First

Always prioritize safety. Ensure the machine is powered down and cool before starting any work. Wearing gloves and safety goggles can protect against accidents and injuries.

FAQs About Toro Parts Diagrams

This section addresses common inquiries regarding the visual representations of components used in outdoor equipment. Understanding these illustrations can significantly aid in maintenance and repairs, ensuring optimal performance.

What is the purpose of these illustrations? They serve as valuable tools for identifying and locating various elements within the machinery.

How can I access these resources? Most manufacturers provide these visuals online or within user manuals for easy reference.

Are these resources universally applicable? No, each model may have specific representations, so it’s essential to refer to the correct version for your equipment.

Can I use these visuals for troubleshooting? Absolutely, they can help pinpoint issues by showing where components are situated and how they connect.

What if I can’t find the right illustration? In such cases, contacting customer support or visiting authorized service centers can provide additional assistance.