The internal structure of various equipment models can sometimes seem overwhelming due to the wide array of elements involved. Whether you’re maintaining, repairing, or simply trying to understand how these elements work together, having a clear layout of each component’s position can simplify the task. By identifying the specific areas that each piece occupies, users can effectively address any issues or plan upgrades.

In this guide, we will focus on the arrangement of different sections, showing how each element connects and interacts with the others. This helps create a more organized approach to maintaining or replacing the individual elements, which can enhance both performance and longevity. With detailed insight into the spatial relationships between parts, you can ensure smooth operation and efficient troubleshooting.

Essential Components Overview

Understanding the key elements of this equipment is crucial for maintaining optimal performance. Each piece plays a vital role in ensuring smooth operation and durability. By recognizing the primary features and their functions, users can better manage the upkeep and repairs of the machine, leading to enhanced efficiency and longevity.

Engine System: The heart of the machine, this component drives all other systems. Its reliable function is critical for powering every task.

Cutting Deck: This part is responsible for the precision in cutting. It allows for adjustments to ensure an even and efficient cut, making it one of the most important features.

Transmission: Responsible for movement control, this mechanism ensures the smooth transition of power to the wheels, allowing for a seamless operation across different terrains.

Control Panel: The interface for the user, providing access to various settings and controls. A well-maintained interface enhances user experience and operational accuracy.

Understanding the Engine Assembly Layout

Comprehending the structure of the engine is crucial for ensuring its optimal performance and longevity. The engine is a complex system made up of various interconnected components that work in harmony to produce the necessary power. Each element has its role, and understanding how they are arranged can help in maintaining the unit effectively and diagnosing potential issues before they become major problems.

Key elements in the engine’s layout include the power-generating sections, cooling mechanisms, and the systems responsible for controlling air and fuel flow. These parts must be carefully aligned and maintained to function properly. Familiarizing yourself with this arrangement allows for easier identification of any issues that might arise during operation, as well as the proper way to handle routine upkeep tasks.

Exploring the Transmission System Structure

The transmission system is a key component responsible for efficiently transferring power, ensuring smooth operation across various terrains. Understanding its intricate structure allows for better maintenance and overall performance improvements. This section delves into the critical elements that make up the system, offering insights into how each part contributes to reliable power flow.

Main Components of the System

At the core of the system are various mechanical and hydraulic parts working together. These include gears, which handle speed adjustments, and a series of connecting elements that facilitate the transfer of energy from the engine to the wheels. Each of these components plays a crucial role in ensuring that the machine can handle different workloads and environmental conditions effectively.

Component Breakdown

The table below outlines the primary sections of the system and their corresponding functions. Understanding this breakdown can assist in identifying potential areas for upkeep or adjustment to optimize performance.

| Component | Function |

|---|---|

| Gears | Adjust speed and torque for varying terrains |

| Hydraulic system | Facilitates smooth shifting and power flow |

| Linkage | Connects the transmission to the wheels |

| Drive belts | Transfers power from the engine to the transmission |

Key Parts of the Drive Mechanism

The drive system is responsible for converting power into movement, ensuring efficient operation of the machine. It consists of various interconnected components that work together to control motion and provide stability. Understanding the main elements of this system can help ensure proper maintenance and performance.

Main Drive Assembly

The core element of the drive system, this assembly transfers energy from the engine to the wheels. It includes gears and belts that allow the machine to move smoothly and handle different terrains. Proper alignment and regular inspection of this part can prevent issues related to wear and tear.

Transmission and Control

This section regulates the speed and direction of movement. By shifting between different gears, it allows for smooth acceleration and deceleration. Keeping the transmission in good condition is essential for maintaining control and efficiency, especially during heavy workloads.

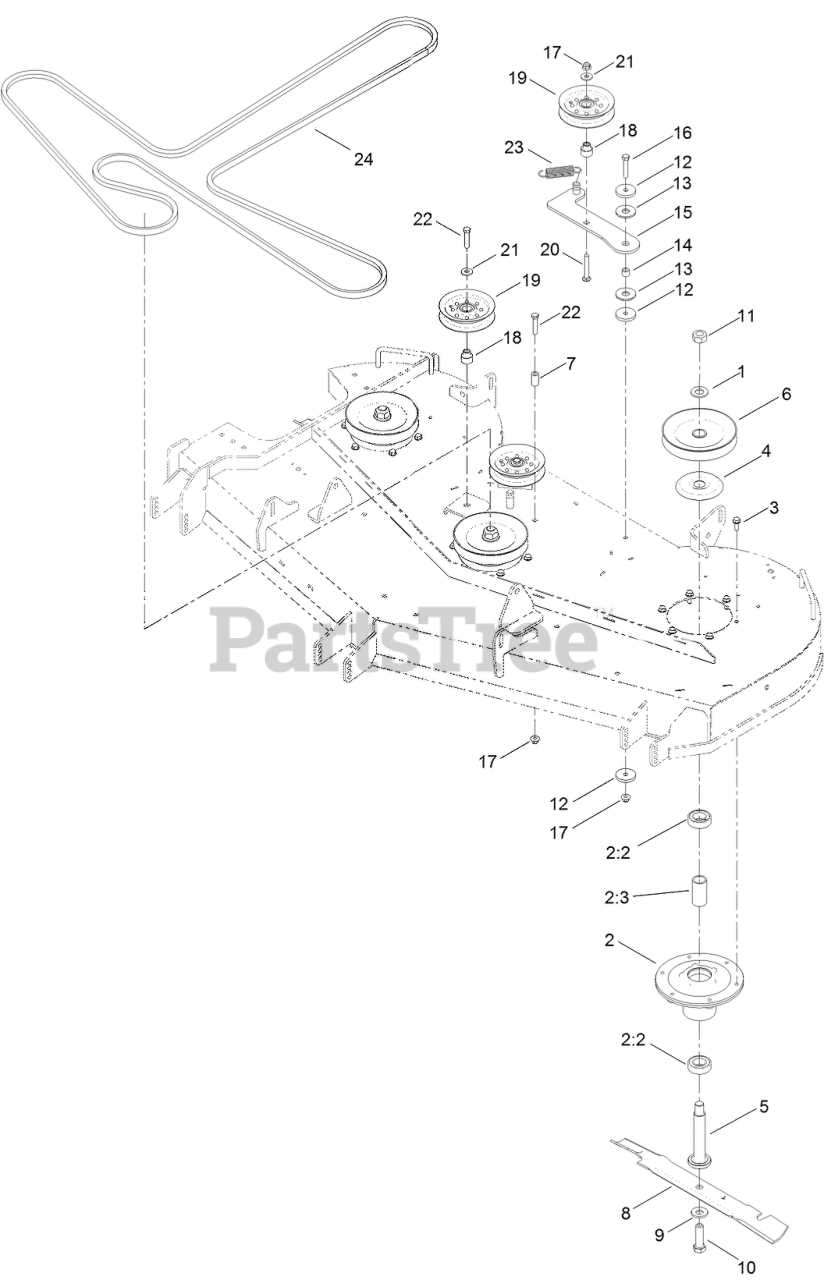

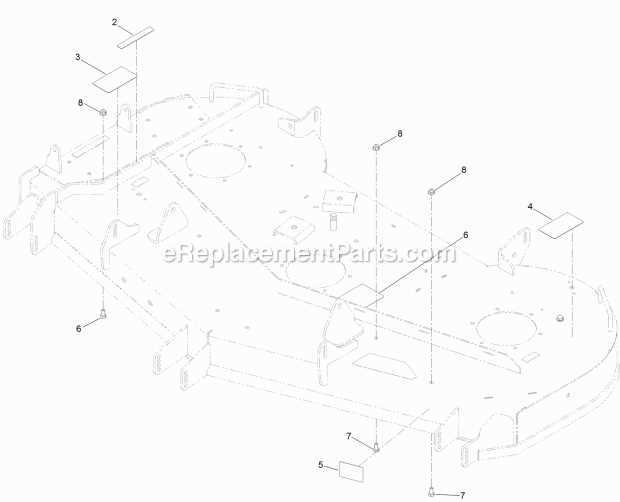

Detailed View of the Cutting Deck

The cutting mechanism is a crucial component in any lawn maintenance equipment. It is responsible for the efficient trimming of grass, providing a smooth and even cut. Understanding the structure and arrangement of this section helps in maintaining optimal performance and longevity.

At the core of the cutting deck are the blades, which are strategically placed to cover the maximum area during operation. These blades are driven by a reliable system that ensures consistent power distribution, allowing for a uniform result across different terrains. Each element in this setup plays a vital role in the overall functionality, from the drive belt to the spindles, contributing to the precise operation of the cutting process.

Proper care and periodic inspections of the cutting deck ensure that it continues to perform at its best. Attention to wear and tear on the blades, tension on the belt, and alignment of the spindles is essential for avoiding uneven cuts or damage to the underlying components. Regular maintenance guarantees a smooth and effective cutting experience.

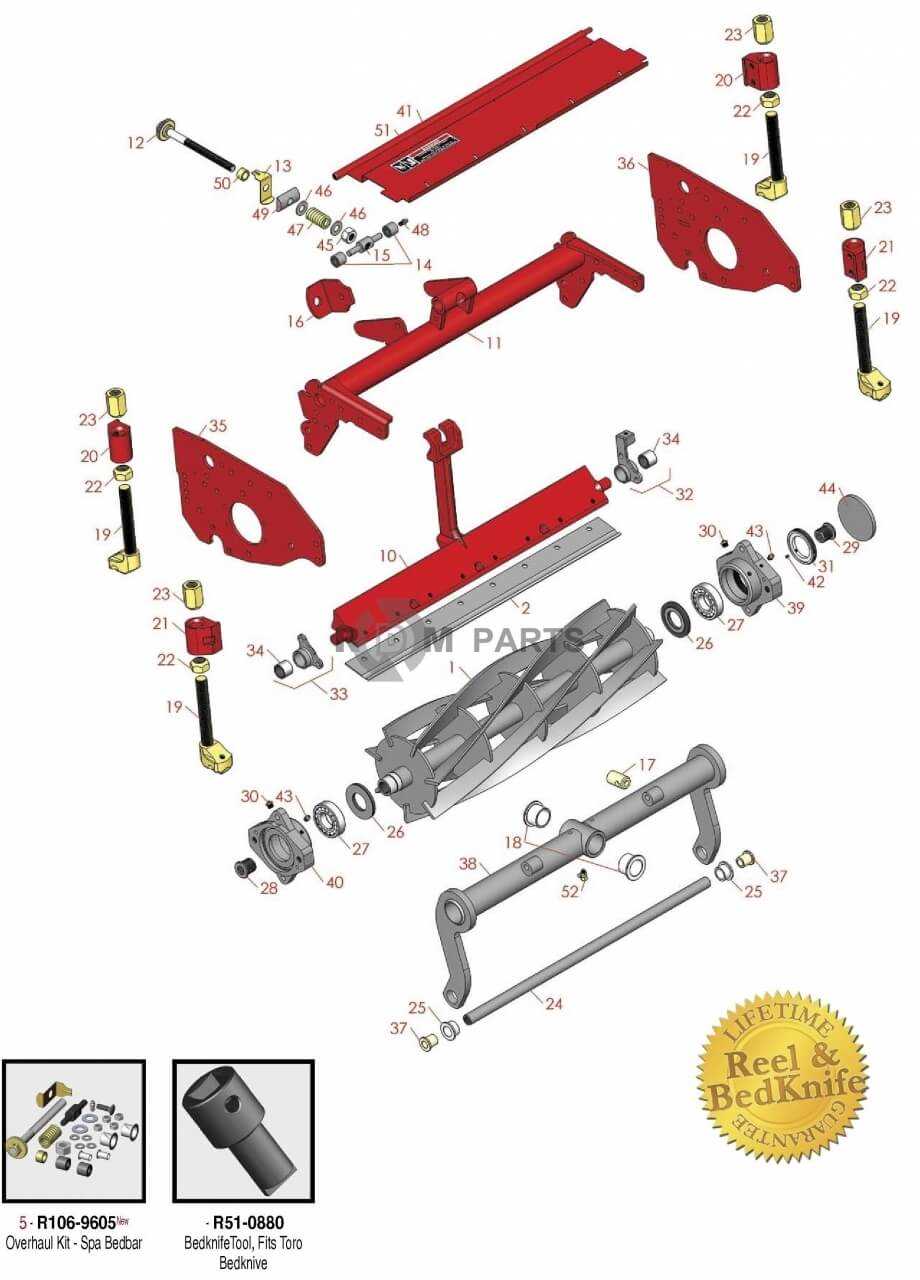

Blade Arrangement and Adjustment Components

The configuration and fine-tuning of cutting elements are crucial for achieving optimal performance in lawn maintenance equipment. Understanding how these components work together ensures effective operation and longevity of the machine.

Proper setup of the cutting elements not only enhances the efficiency of the task but also contributes to achieving a neat finish on the lawn. Key components involved in this process include:

- Cutting Blades: These are the primary elements responsible for trimming grass. Their arrangement influences the height and quality of the cut.

- Blade Holders: These components secure the blades in place, ensuring stability during operation. Proper installation is vital to prevent movement or misalignment.

- Adjustment Mechanisms: These allow for changes in the blade height, enabling users to customize the cutting level based on grass conditions.

- Washers and Nuts: Essential for securing the cutting blades and holders, these components ensure everything remains tightly fastened during use.

Regular inspection and adjustment of these elements are recommended to maintain peak performance. Ensuring that blades are correctly arranged and adjusted can significantly impact the efficiency and effectiveness of lawn care tasks.

Fuel System Components Breakdown

Understanding the various elements of a fuel delivery system is essential for optimal performance and maintenance. This system ensures that fuel is efficiently transported from the tank to the engine, allowing for smooth operation and reliable performance.

Key components of this system include:

- Fuel Tank: The reservoir that holds the fuel before it is sent to the engine.

- Fuel Pump: This vital part draws fuel from the tank and delivers it to the engine at the appropriate pressure.

- Fuel Filter: Designed to remove impurities and contaminants from the fuel, ensuring that only clean fuel reaches the engine.

- Fuel Lines: These pipes transport fuel from the tank to the engine and must be in good condition to prevent leaks.

- Fuel Injectors: Responsible for delivering precise amounts of fuel into the engine’s combustion chamber for efficient combustion.

- Pressure Regulator: Maintains consistent fuel pressure in the system, adjusting as necessary to ensure optimal performance.

Each of these elements plays a crucial role in maintaining a well-functioning fuel delivery system, and regular inspections can help prevent issues that may arise during operation.

Fuel Tank, Lines, and Related Elements

The efficient operation of any outdoor equipment relies heavily on the proper functioning of the fuel reservoir and its associated components. Understanding how these elements work together is crucial for maintaining optimal performance and longevity. The fuel storage unit plays a vital role in supplying the necessary energy, while the connected tubes and fittings ensure smooth transportation to the engine.

Fuel Reservoir: This component is designed to hold a specific quantity of liquid, providing a reliable source for combustion. It is essential that the tank is properly secured and free from leaks to avoid any operational issues or safety hazards.

Fuel Lines: These flexible conduits are responsible for transporting the liquid from the reservoir to the engine. They must be constructed of durable materials to withstand pressure and prevent deterioration over time. Regular inspection for wear and blockages is necessary to ensure uninterrupted fuel flow.

Fittings and Connectors: The connections between the tank, lines, and engine are critical for maintaining a sealed system. Any loose or damaged fittings can lead to leaks or air infiltration, affecting the overall efficiency of the equipment. It’s important to periodically check these components and replace them as needed.

In conclusion, maintaining the fuel reservoir and its associated lines is fundamental for the smooth operation of outdoor machinery. Regular maintenance and careful monitoring can help prevent potential issues and extend the life of the equipment.

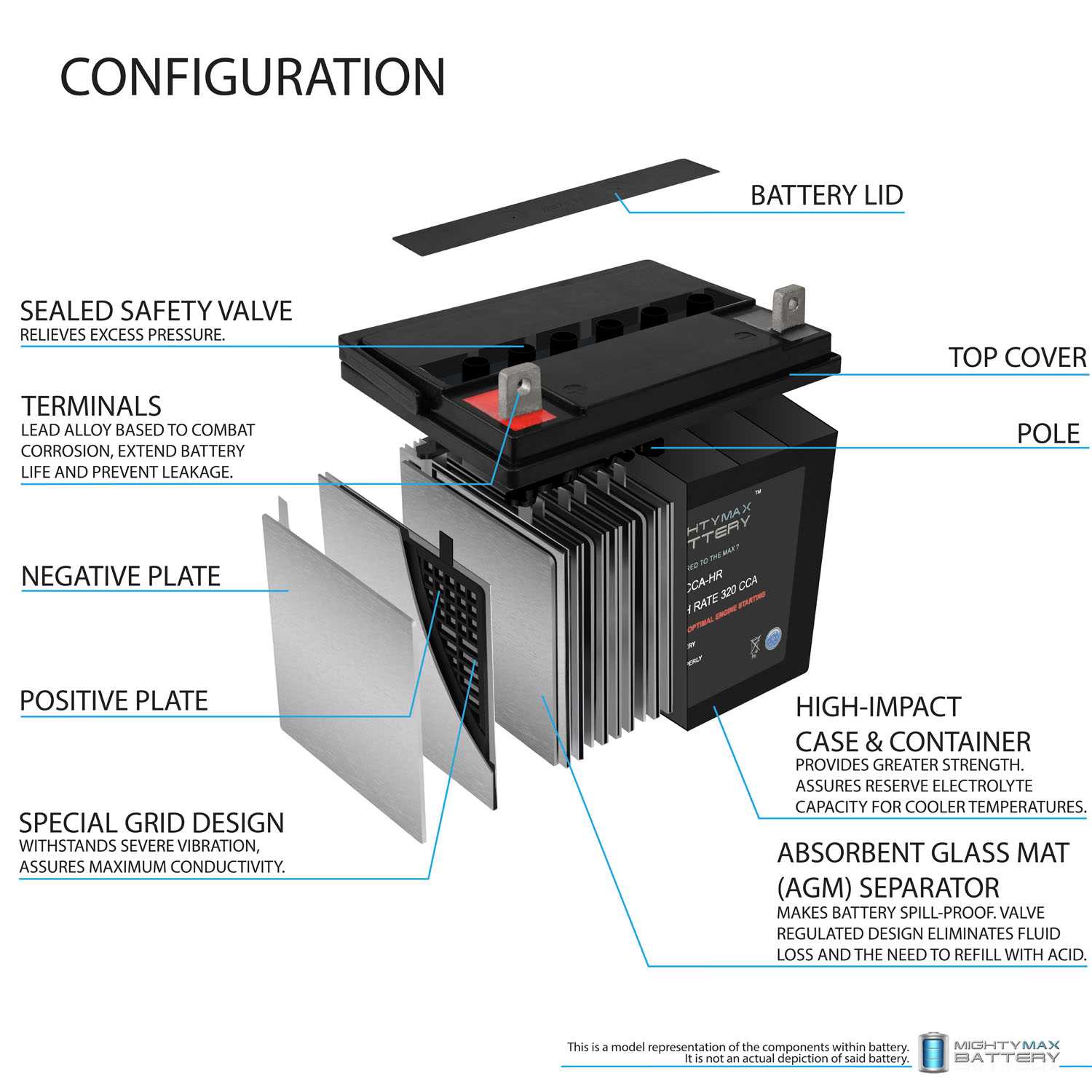

Electrical System Overview

The electrical framework of this equipment plays a crucial role in ensuring smooth operation and functionality. This network is responsible for powering various components, enabling efficient performance and reliable usage in diverse conditions. Understanding the intricacies of this system is essential for effective maintenance and troubleshooting.

Key components of the electrical setup include:

- Power source: Provides the necessary energy for operation.

- Wiring harness: Connects different elements, ensuring proper communication and power distribution.

- Control module: Manages and regulates the functions of the electrical system.

- Fuses and relays: Protect against overloads and ensure safe operation.

- Switches: Allow for user interaction, enabling the activation and deactivation of various features.

To maintain optimal performance, regular checks and maintenance of these elements are recommended. This includes:

- Inspecting connections for wear or corrosion.

- Testing the power source to ensure consistent voltage supply.

- Verifying the functionality of fuses and relays.

- Checking for any signs of damage in the wiring harness.

- Ensuring that switches operate smoothly without any obstruction.

By understanding and monitoring these components, users can enhance the reliability and efficiency of the electrical system.

Battery, Wiring, and Ignition Components

This section focuses on the essential elements related to the power supply, electrical connections, and starting mechanisms of a specific machine. Understanding these components is crucial for maintaining optimal functionality and ensuring reliable operation. Each part plays a vital role in the overall performance, influencing how efficiently the equipment runs.

Battery: The energy source is fundamental for powering various systems. It stores electrical energy and provides the necessary voltage to start the engine and operate electrical accessories. Regular checks on the battery’s condition, including terminals and charge levels, can prevent potential failures.

Wiring: The network of conductive paths facilitates the flow of electricity between components. Proper wiring is crucial for effective communication between the battery, ignition system, and other electrical devices. Ensuring connections are secure and free from wear is vital to prevent short circuits and maintain operational integrity.

Ignition Components: These elements initiate the combustion process, allowing the engine to start and run. They include the ignition switch, spark plugs, and coils, which work together to create the necessary spark for ignition. Regular maintenance and timely replacements of these parts can significantly enhance performance and reliability.

Hydraulic System Diagram

The hydraulic mechanism of this equipment plays a crucial role in its functionality, enabling effective operation through fluid power. Understanding the layout and interaction of the components within this system is essential for maintenance and troubleshooting. Each element works in unison to transmit force and control movement, highlighting the importance of hydraulic fluid in achieving optimal performance.

The system consists of various interconnected parts, including pumps, valves, and actuators, all designed to facilitate the efficient transfer of hydraulic fluid. The arrangement of these components determines the flow of fluid and the overall efficiency of the system. Familiarity with the configuration can assist operators and technicians in diagnosing issues and ensuring proper functioning.

Regular inspection and maintenance of the hydraulic elements are vital for preventing potential failures and extending the lifespan of the machinery. A thorough understanding of the setup allows for timely identification of wear or leaks, contributing to enhanced safety and reliability in operations.

Pumps, Hoses, and Control Valves

This section explores the essential components responsible for fluid movement and regulation within a mechanical system. Understanding these elements is crucial for ensuring optimal performance and reliability in various applications. Each component plays a significant role in the overall functionality, contributing to effective operation and control.

Fluid Transport Systems

Fluid transport systems are designed to facilitate the movement of liquids from one point to another. This involves a network of flexible tubes and specialized devices that create the necessary pressure for efficient delivery. By selecting appropriate materials and configurations, users can enhance the durability and effectiveness of the system, ensuring it meets the demands of its intended use.

Regulatory Mechanisms

Regulatory mechanisms are vital for maintaining the desired flow and pressure within the system. Control valves act as gatekeepers, allowing precise adjustments to the fluid flow based on specific requirements. The correct configuration and placement of these mechanisms are essential for achieving the desired operational efficiency and safety.

Understanding the Steering Mechanism

The steering system is a crucial component that enables operators to navigate their vehicles with precision and ease. It encompasses a variety of elements that work in unison to facilitate directional control, ensuring stability and responsiveness while maneuvering.

This mechanism typically consists of several key components, including a steering wheel, linkages, and the drive system. When the steering wheel is turned, it activates the linkages, which in turn manipulate the front wheels. This interplay allows for smooth transitions and accurate handling, making it essential for effective operation in various terrains.

Regular maintenance of the steering system is vital to ensure its longevity and performance. Operators should be aware of common issues, such as wear and tear of the linkages or misalignment, which can significantly affect the vehicle’s handling capabilities. By understanding the fundamentals of this mechanism, users can better appreciate its importance and maintain it effectively for optimal performance.