The intricacies of automotive engineering often require a comprehensive view of the various elements that contribute to a vehicle’s functionality. Exploring visual representations of manufacturer-specific components can greatly enhance one’s knowledge and assist in maintenance or upgrades. Such resources provide invaluable insight into the arrangement and purpose of each component within a vehicle.

Having access to detailed visuals allows enthusiasts and professionals alike to identify and understand the various assemblies involved in a car’s design. This understanding not only aids in effective repairs but also encourages informed decisions when selecting replacements or enhancements. By familiarizing oneself with these illustrations, individuals can navigate the complexities of automotive systems with confidence.

In the realm of vehicle maintenance, a clear depiction of each part is essential for effective troubleshooting. When faced with the challenge of addressing issues, these visual aids serve as crucial references, enabling users to pinpoint problems and streamline repair processes. Ultimately, embracing these resources paves the way for a more thorough appreciation of automotive craftsmanship.

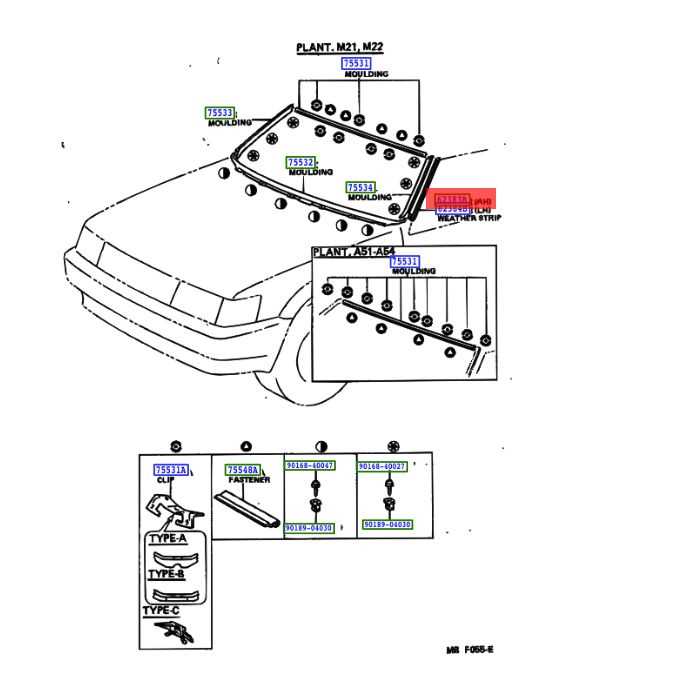

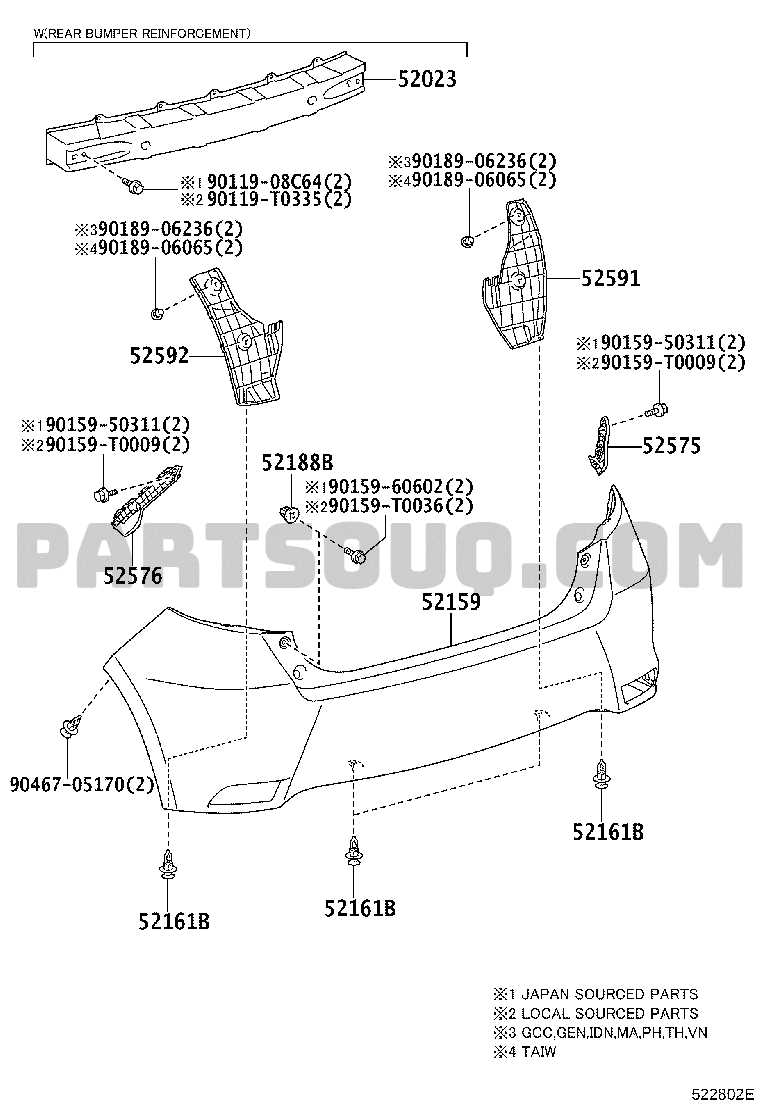

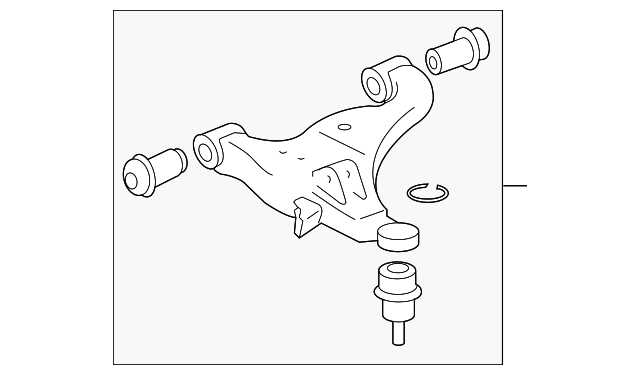

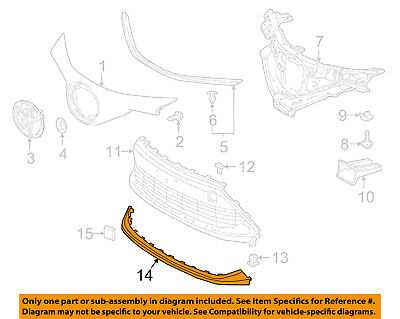

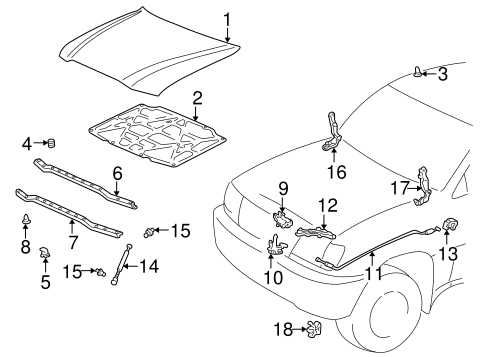

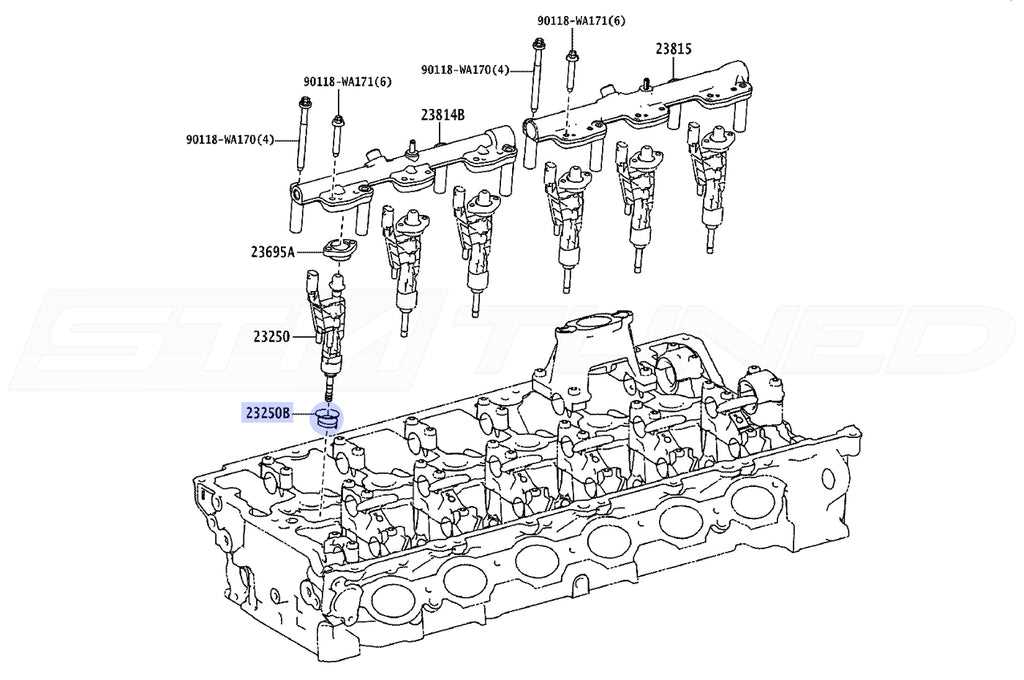

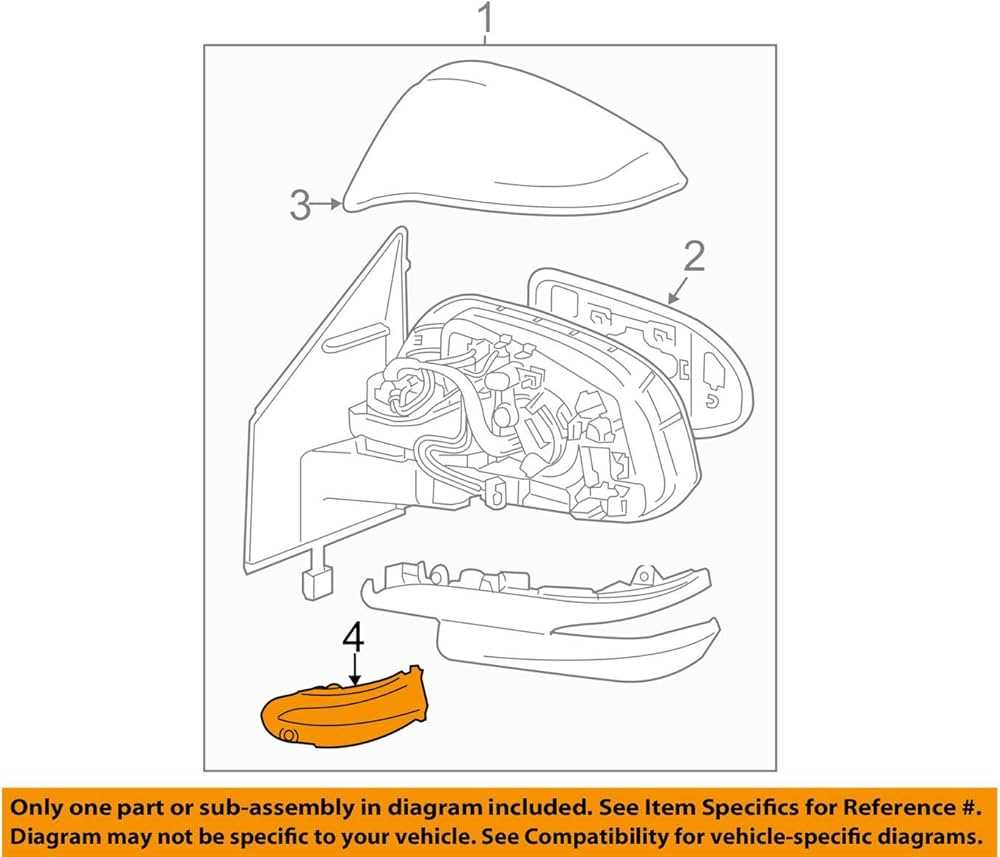

Understanding the layout of a component illustration is essential for effective maintenance and repair. This visual representation serves as a roadmap, helping you identify various elements and their interconnections. By grasping the key symbols and notations used, you can streamline your approach to restoring functionality.

Here are some steps to effectively interpret such illustrations:

- Familiarize Yourself with the Legend: Most illustrations come with a legend that explains the symbols used. Reviewing this section first will provide clarity on what each symbol represents.

- Identify the Main Components: Look for the primary elements highlighted in the illustration. These are often larger or more prominently displayed, making them easier to spot.

- Trace Connections: Follow the lines or arrows that connect different elements. This will help you understand how components interact with one another.

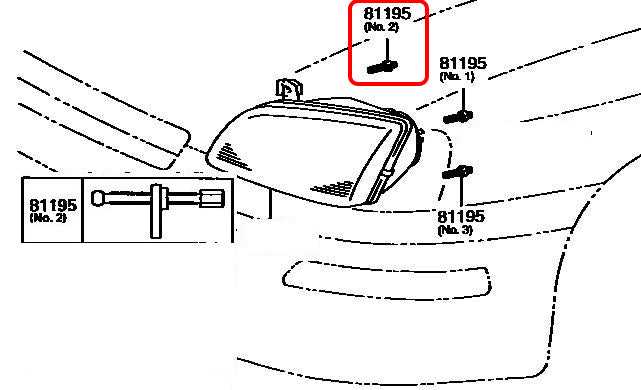

- Note Part Numbers: Often, illustrations include specific identifiers for each element. Take note of these as they can be crucial when ordering replacements.

- Use Color Codes: If the illustration employs color coding, use it to your advantage. Different colors may indicate varying functions or statuses.

By following these guidelines, you can enhance your ability to navigate and comprehend component illustrations, making your repair or maintenance tasks much more manageable.

Common Components in Toyota Diagrams

Understanding the intricacies of automotive schematics is crucial for effective maintenance and repair. These visual representations highlight essential elements that play significant roles in vehicle functionality. Familiarity with these components can greatly enhance one’s ability to troubleshoot and perform necessary adjustments.

- Electrical Connectors: Vital for establishing connections between various electrical systems, ensuring efficient operation.

- Sensors: Key elements that monitor different parameters, providing crucial data to the vehicle’s control unit.

- Relays: Act as switches that control high-current circuits, enabling safe operation of electrical systems.

- Fuses: Protect circuits from overload by breaking the connection when excessive current flows through.

- Actuators: Mechanical devices that execute commands from the control unit, affecting various systems like brakes and throttle.

Each component plays a unique role, contributing to the overall performance and safety of the vehicle. By analyzing these schematics, one can gain insights into the interplay between these elements, enhancing their understanding of automotive mechanics.

- Wiring Harness: A collection of wires that transmit signals and power throughout the vehicle.

- Control Modules: Central units that process information and manage functions of different systems.

- Mechanical Linkages: Connect various moving parts, allowing for smooth operation of mechanisms.

Comprehending the function of these components is essential for anyone looking to deepen their knowledge of vehicle systems and improve diagnostic skills.

Finding the Right Parts for Your Model

When it comes to maintaining and enhancing your vehicle, selecting the appropriate components is crucial. Whether you’re performing a routine upgrade or a necessary replacement, ensuring compatibility with your specific model can significantly affect performance and longevity. This section will guide you through the process of identifying and sourcing the ideal elements tailored to your needs.

Understanding Your Vehicle’s Requirements

Before embarking on your search, it’s essential to comprehend what your automobile demands. Consider the following:

- Identify the make and model of your vehicle.

- Understand the specific features and specifications relevant to your model year.

- Assess any modifications previously made that may influence compatibility.

Where to Look for Quality Components

Several resources can assist you in locating reliable replacements and upgrades:

- Authorized dealerships offer genuine selections, ensuring optimal fit and performance.

- Reputable online retailers provide a vast array of options, often with detailed specifications.

- Local automotive stores can be helpful for immediate needs and expert advice.

By following these guidelines, you can confidently navigate the selection process and find the right components to enhance your vehicle’s performance.

Using Diagrams for DIY Repairs

When tackling maintenance tasks on your vehicle, visual guides can serve as invaluable resources. They offer a clear representation of various components, helping enthusiasts understand the layout and function of each element. By utilizing these visuals, individuals can enhance their repair skills and increase their confidence in handling different projects.

Having access to these illustrations allows for easier identification of the necessary tools and techniques required for repairs. They can simplify complex processes, making them more manageable. Whether you are replacing a malfunctioning component or conducting routine inspections, these guides provide a roadmap for success.

Furthermore, visual aids can help prevent errors that might occur during the repair process. By clearly showing the arrangement and connections of different elements, you can avoid common pitfalls and ensure everything is assembled correctly. This attention to detail not only saves time but also enhances the overall safety and performance of the vehicle.

Benefits of Using OEM Over Aftermarket

When it comes to maintaining and repairing vehicles, choosing components from the original manufacturer can offer significant advantages. These elements are designed specifically for the make and model of the automobile, ensuring optimal performance and longevity. Unlike generic alternatives, which may vary in quality and compatibility, authentic components are produced to meet rigorous standards set by the manufacturer.

One of the primary benefits of selecting original components is the assurance of quality. These items undergo extensive testing and validation processes, ensuring they perform reliably under various conditions. This level of scrutiny can lead to fewer breakdowns and a lower likelihood of costly repairs in the future.

Additionally, opting for original components often means that they come with a warranty. This guarantee can provide peace of mind, knowing that if any issues arise, they will be addressed without incurring further expenses. In contrast, many aftermarket alternatives lack such coverage, leaving vehicle owners at risk for unexpected costs.

Furthermore, using original components helps maintain the vehicle’s resale value. Prospective buyers often prefer vehicles that have been maintained with authentic components, as this indicates a commitment to quality. By keeping the vehicle in its original condition, owners can enhance its appeal in the market, potentially leading to a higher resale price.

Identifying Parts by Diagram Codes

Understanding the reference codes associated with various components can significantly enhance the process of locating specific items for repair or replacement. Each identifier serves as a unique key, making it easier to pinpoint the exact element needed for maintenance or enhancement tasks.

How Reference Codes Work

These identifiers are typically alphanumeric sequences that correspond to individual elements within a comprehensive schematic. By recognizing these codes, one can efficiently navigate through extensive inventories and catalogues. Here’s how to effectively use these codes:

- Familiarize yourself with the coding system used in the references.

- Cross-check the code with the respective schematic to confirm the component’s details.

- Utilize online resources or manuals that provide detailed descriptions associated with each code.

Benefits of Using Reference Codes

Employing these identifiers brings several advantages:

- Streamlines the search process, saving time during repairs.

- Reduces the likelihood of errors when ordering replacements.

- Enhances communication with suppliers or service providers by providing precise information.

Accessing Toyota Parts Catalog Online

Locating components for vehicles has become more convenient with the availability of online resources. Accessing detailed catalogs can streamline the process of identifying necessary items for maintenance and repairs. This section explores how to navigate these resources effectively.

Many manufacturers provide digital access to their extensive collections, allowing users to browse through various selections. Here are some key steps to make the most of these online catalogs:

- Visit the official website or trusted third-party platforms specializing in automotive supplies.

- Utilize the search functionality to find specific components by entering relevant information such as model year, type, or serial number.

- Review the provided illustrations and descriptions to ensure accurate identification of the needed items.

Online catalogs often include valuable features that enhance the user experience:

- Detailed images to assist in recognizing components.

- Compatibility filters that help narrow down choices based on vehicle specifications.

- Information about pricing and availability for easy comparison shopping.

By leveraging these digital tools, vehicle owners and enthusiasts can efficiently locate and purchase essential components, ensuring optimal performance and longevity of their vehicles.

Role of Diagrams in Maintenance Planning

Visual representations are essential in the organization and execution of maintenance tasks. They provide a clear overview of components, facilitating a better understanding of complex systems. This clarity aids technicians in identifying and addressing issues efficiently, ultimately enhancing overall operational effectiveness.

Utilizing these visual tools significantly streamlines the workflow. By illustrating the interconnections and functions of various elements, they allow maintenance teams to prioritize actions and allocate resources effectively. Furthermore, they serve as a reference point, ensuring that all personnel are aligned in their approach to upkeep and repairs.

| Benefits of Visual Representations | Description |

|---|---|

| Enhanced Clarity | Provides a straightforward view of system layouts and functions. |

| Improved Communication | Facilitates discussion among team members by standardizing references. |

| Time Efficiency | Reduces troubleshooting time by quickly pinpointing areas of concern. |

| Resource Management | Helps in effective planning and allocation of tools and materials. |

Interpreting Electrical System Diagrams

Understanding the intricacies of electrical layouts is crucial for anyone engaged in vehicle maintenance or repair. These visual representations serve as guides, illustrating the connections and interactions between various components within the electrical framework of a vehicle. Mastery of these schematics enables technicians to troubleshoot issues more efficiently, ensuring optimal functionality.

Electrical layouts typically employ standardized symbols to denote different elements, such as switches, sensors, and power sources. Familiarizing oneself with these symbols is the first step toward deciphering the intricacies of the schematic. Each symbol represents a specific function, and recognizing them will significantly enhance the reader’s ability to navigate the complexities of the system.

Moreover, attention to detail is essential when analyzing these illustrations. Observing how different elements are interconnected can reveal potential problem areas and facilitate the identification of faults. Tracing circuits from one point to another helps in understanding the flow of electricity and diagnosing malfunctioning components effectively. This skill set is invaluable for ensuring reliability and safety in any vehicle.

Understanding Parts Warranty and Support

When acquiring components for vehicle maintenance or repair, it’s essential to recognize the significance of guarantees and assistance. These assurances not only offer peace of mind but also demonstrate the manufacturer’s confidence in the durability and reliability of their offerings. Knowing the specifics of these protections can aid consumers in making informed decisions and ensure a satisfactory ownership experience.

Importance of Warranties

Warranties serve as a safeguard for purchasers, covering potential defects and failures that may occur within a specified timeframe. They often outline the terms under which a replacement or repair will be provided, ensuring that customers receive adequate support if issues arise.

Support Options Available

In addition to warranties, various support services are offered to assist customers with their inquiries or concerns. These may include access to customer service representatives, online resources, and troubleshooting guides. Understanding the available support can enhance the overall experience and provide essential help when needed.

| Warranty Type | Coverage Duration | Details |

|---|---|---|

| Standard Warranty | 1 Year | Covers manufacturing defects under normal use. |

| Extended Warranty | Up to 3 Years | Additional coverage beyond the standard period for added peace of mind. |

| Limited Warranty | Varies | Specific coverage with exclusions for certain conditions. |