In the realm of agricultural machinery, comprehending the various elements that contribute to optimal performance is essential. Each piece of equipment is composed of intricate components that work in harmony to ensure efficiency and reliability in the field. Understanding these elements can significantly enhance maintenance practices and troubleshooting efforts.

Detailed representations of these components offer invaluable insights into their arrangement and function. By examining such illustrations, operators can gain a clearer understanding of how each segment interacts within the larger system. This knowledge is particularly beneficial for those involved in repairs and upgrades, allowing for more informed decisions when selecting replacements or enhancements.

Ultimately, familiarizing oneself with the assembly of these mechanical entities can lead to improved operational efficiency. This knowledge empowers users to make timely adjustments and optimizations, resulting in enhanced productivity and longevity of the equipment.

Overview of Ford 1520 Tractor Parts

This section provides a comprehensive examination of the essential components that contribute to the functionality of agricultural machinery. Understanding these elements is crucial for effective maintenance and repair, ensuring optimal performance during operation.

Key Components

Various vital elements play a significant role in the overall efficiency of the equipment. Each segment, from the engine to the transmission system, has been designed to work in harmony, enabling the machine to execute its tasks effectively. Regular inspection and timely replacement of worn-out components are necessary to prevent potential breakdowns and maintain productivity.

Maintenance Considerations

Routine upkeep is critical in prolonging the lifespan of the machinery. Proper care involves checking fluid levels, inspecting belts and hoses, and ensuring that all connections are secure. Neglecting these aspects can lead to severe complications, resulting in costly repairs and downtime. Therefore, a thorough understanding of each component’s function is essential for any operator.

Understanding the Parts Diagram

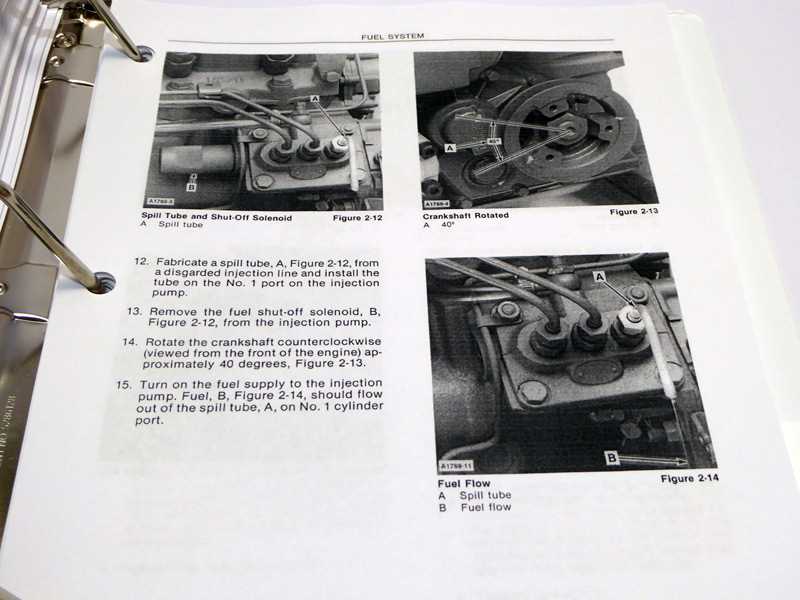

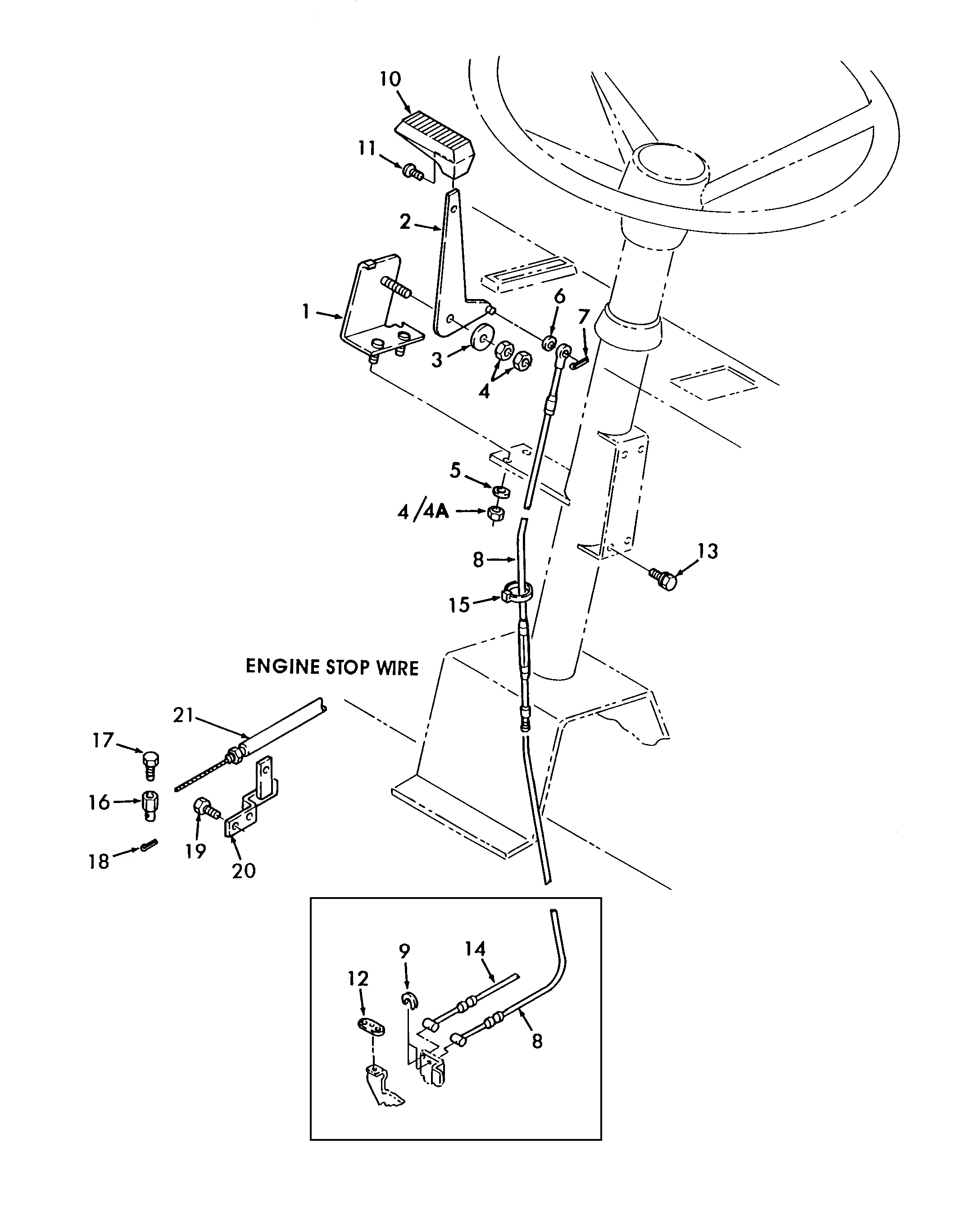

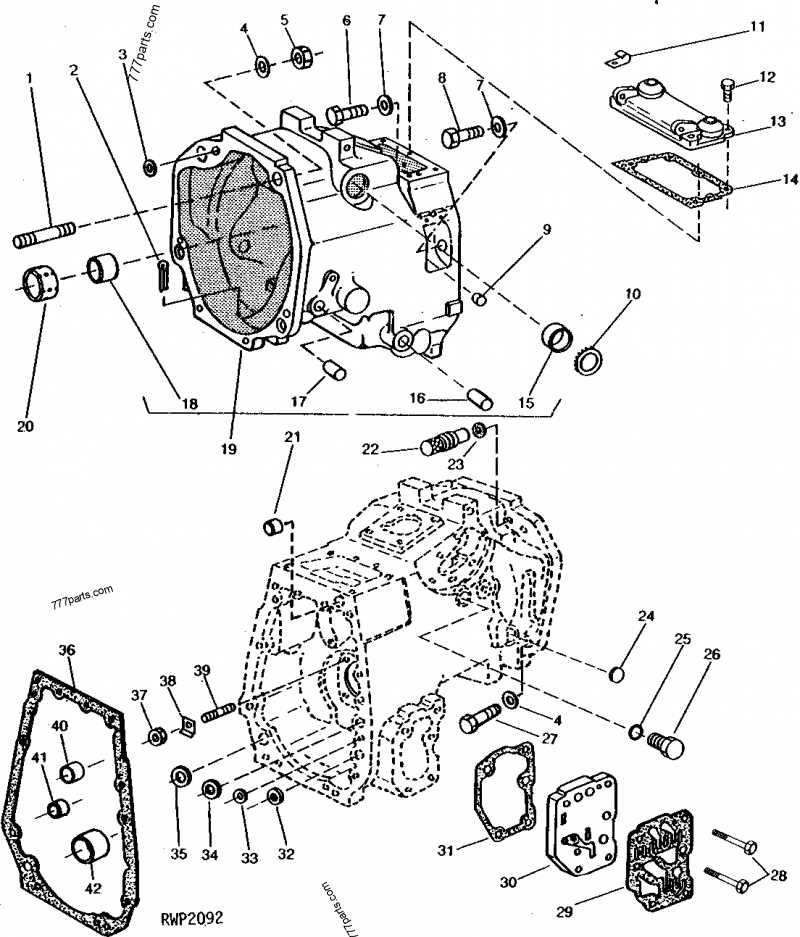

Comprehending the visual representation of components is essential for effective maintenance and repairs. These illustrations provide a clear overview of the various elements that comprise a machine, allowing users to identify, analyze, and locate specific parts efficiently. By familiarizing oneself with the layout and labeling, one can streamline the repair process and ensure proper functionality.

Typically, these visuals break down complex assemblies into manageable sections, illustrating how different components interact with one another. This organization helps both novices and experienced technicians navigate through the intricate systems found within machinery.

| Component Name | Description | Function |

|---|---|---|

| Engine | The power source of the equipment. | Converts fuel into mechanical energy. |

| Transmission | System that transmits power from the engine to the wheels. | Controls speed and torque. |

| Hydraulic System | A system utilizing fluid under pressure to perform work. | Operates lifting and moving mechanisms. |

| Chassis | The frame that supports all other components. | Provides structural integrity and support. |

Key Components of the Tractor

Understanding the essential elements of agricultural machinery is crucial for effective maintenance and operation. These components work together to ensure optimal performance and reliability in various farming tasks. Below is an overview of significant parts that contribute to the overall functionality of this heavy-duty equipment.

Major Elements

- Engine: The powerhouse that drives the vehicle, converting fuel into mechanical energy.

- Transmission: This system facilitates power transfer from the engine to the wheels, allowing for speed adjustments and direction changes.

- Hydraulic System: A vital component that operates various attachments and implements, providing the necessary force for lifting and lowering.

- Chassis: The framework that supports the machinery, providing stability and durability during operations.

Additional Features

- Steering Mechanism: Enables precise control and maneuverability.

- Electrical System: Powers lights, ignition, and other electronic components for enhanced functionality.

- Cooling System: Prevents overheating by regulating the engine temperature during operation.

These core elements are integral to the machinery’s effectiveness, ensuring it meets the demands of modern agricultural practices.

How to Read Parts Diagrams

Understanding technical illustrations is essential for anyone looking to maintain or repair machinery. These visual aids provide valuable information about the components involved, their arrangement, and how they interact with one another. Familiarizing yourself with these resources can greatly enhance your ability to troubleshoot issues effectively.

Here are some tips to help you interpret these illustrations:

- Identify the Sections: Begin by locating the different segments of the visual representation. Most images will be divided into sections that correspond to specific assemblies.

- Examine Labels: Look for annotations or labels that identify each component. These can provide insights into the function and location of various elements.

- Understand Symbols: Familiarize yourself with common symbols used in these illustrations. Recognizing these symbols will help you decode the meaning of different parts quickly.

- Follow the Flow: Trace the flow of connections and pathways shown in the illustration. This can help you understand how the components work together.

By applying these strategies, you can enhance your comprehension of technical illustrations and improve your overall repair and maintenance skills.

Importance of Regular Maintenance

Consistent upkeep is essential for ensuring the longevity and efficiency of any mechanical equipment. Routine checks and servicing not only enhance performance but also prevent unexpected breakdowns that can lead to costly repairs. Regular attention to machinery helps identify potential issues early, allowing for timely interventions and minimizing downtime.

Moreover, maintaining equipment in optimal condition contributes to safety during operation. Well-functioning machinery reduces the risk of accidents, protecting both the operator and surrounding personnel. Additionally, regular maintenance can improve fuel efficiency, leading to lower operational costs and a reduced environmental impact.

Ultimately, investing time and resources in the regular servicing of machinery fosters reliability and enhances overall productivity. By prioritizing maintenance, operators can ensure that their equipment remains in peak condition, ready to meet the demands of the job.

Common Issues with Ford 1520

Maintenance of agricultural machinery is essential for optimal performance and longevity. Various challenges may arise, impacting efficiency and operation. Understanding these common concerns can help in troubleshooting and timely repairs.

- Engine Performance:

Decreased power or rough idling can occur due to fuel quality issues, air filter blockages, or faulty injectors.

- Hydraulic System:

Leaks or sluggish operation in the hydraulic system may indicate worn seals, low fluid levels, or contaminated oil.

- Electrical Issues:

Problems such as starting difficulties or inconsistent lighting can often be traced back to battery faults, corroded connections, or wiring damage.

- Transmission Challenges:

Shifting difficulties or unusual noises can signal issues with the transmission fluid or internal components requiring inspection and maintenance.

- Cooling System:

Overheating can be a result of a clogged radiator, faulty thermostat, or low coolant levels. Regular checks are crucial to prevent serious damage.

Addressing these common issues promptly can ensure that machinery remains reliable and efficient, minimizing downtime and repair costs.

Where to Find Replacement Parts

Locating suitable components for your machinery can be a straightforward process if you know where to look. Several reliable sources offer a wide range of options, from new to refurbished items, ensuring that you can keep your equipment running smoothly. This section will guide you through various avenues to secure the essential elements needed for maintenance and repairs.

Authorized Dealers

One of the most dependable options is to consult authorized dealers. These establishments typically carry a complete inventory of genuine components, ensuring compatibility and quality. They often have trained staff who can assist you in identifying the right items for your specific model, making the purchasing process easier.

Online Marketplaces

The internet has transformed the way we shop for machinery components. Numerous online marketplaces feature an extensive selection of items, allowing you to compare prices and options conveniently. When using these platforms, make sure to read reviews and verify the credibility of sellers to ensure you receive high-quality merchandise.

Tips for Identifying Parts Quickly

When working on machinery, recognizing components swiftly can save valuable time and enhance efficiency. Knowing where to look and how to interpret identifiers can streamline the maintenance process. Here are some strategies to help you identify components effectively.

| Strategy | Description |

|---|---|

| Familiarize with the Manual | Consult the user manual to understand the layout and specifications of various components. |

| Use Visual Aids | Employ diagrams or images to visualize different elements and their connections within the machinery. |

| Labeling System | Implement a labeling system for easy reference during repairs and maintenance. |

| Take Photos | Capture images of components before disassembly to aid in reassembly. |

| Consult Online Resources | Utilize online forums and websites dedicated to machinery for additional insights and information. |

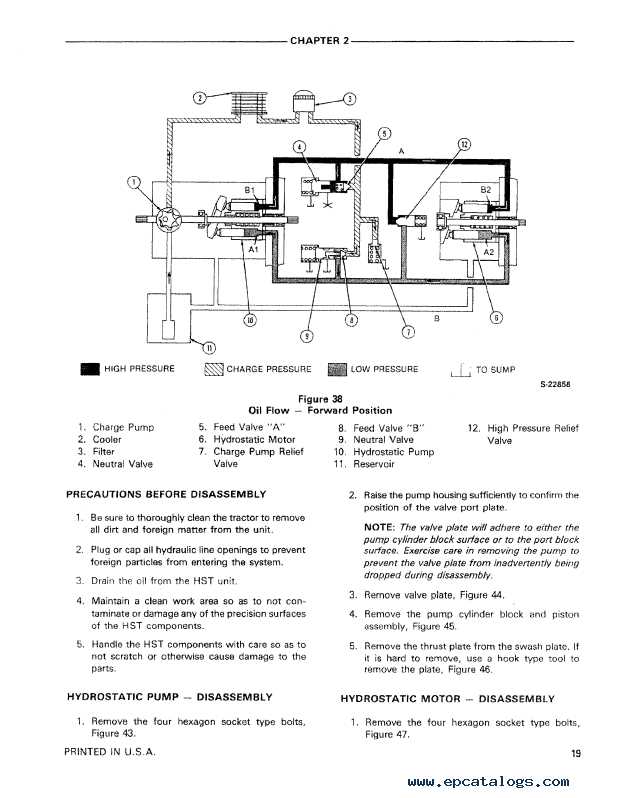

Understanding Hydraulic Systems

Hydraulic systems play a crucial role in modern machinery, providing powerful and efficient means of operation. These systems utilize fluid power to transmit force and motion, enabling various components to function seamlessly together. Understanding the mechanics behind hydraulic systems is essential for optimizing performance and ensuring longevity in machinery.

Key Components of Hydraulic Systems

A hydraulic system consists of several key elements that work in harmony. Each component has a specific role in maintaining the system’s efficiency and functionality. The primary components include:

- Hydraulic Fluid: The lifeblood of the system, facilitating the transfer of energy.

- Pumps: Devices that generate flow and pressure, moving fluid through the system.

- Actuators: Mechanisms that convert hydraulic energy into mechanical movement.

- Valves: Control the direction and flow of fluid, regulating system pressure.

Working Principles

The operation of hydraulic systems is based on fundamental principles of fluid mechanics. When pressure is applied to the hydraulic fluid, it is directed through pipes and hoses to the desired components, resulting in movement or force generation. This method allows for precise control and high power-to-weight ratios, making it ideal for various applications.

- Fluid is drawn from a reservoir by the pump.

- The pump creates pressure, pushing fluid into the system.

- Valves direct fluid to specific actuators, enabling movement.

- Actuators perform work by converting fluid energy into mechanical energy.

Understanding these systems is essential for troubleshooting and maintenance, ensuring machinery operates efficiently and reliably.

Electrical System Components Explained

The electrical system of a vehicle is essential for its operation, providing the necessary power for various functions. Understanding the key components that make up this system is crucial for diagnosing issues and ensuring optimal performance.

Key Elements of the Electrical System

- Battery: The power source that stores electrical energy and supplies it to the system.

- Alternator: A generator that converts mechanical energy into electrical energy, charging the battery while the engine runs.

- Starter Motor: A device that initiates the engine’s operation by converting electrical energy into mechanical energy.

- Wiring Harness: A network of wires that connects various components, allowing them to communicate and function together.

- Fuse Box: A protective element that houses fuses, preventing overloads and short circuits in the electrical system.

- Relay: An electrically operated switch that controls the flow of electricity to various components.

Understanding Each Component

- Battery: A rechargeable unit that provides power for starting the engine and running electrical systems when the engine is not operational.

- Alternator: Ensures the battery remains charged and powers the electrical accessories while the engine is running.

- Starter Motor: Engages the engine’s flywheel to start the combustion process, making it vital for ignition.

- Wiring Harness: Critical for safe and efficient electrical flow, it prevents shorts and maintains organization in the electrical layout.

- Fuse Box: Protects components from potential damage due to excess current, serving as a safety feature within the system.

- Relay: Used to control high-current devices like lights and motors, allowing for remote operation of these components.

By understanding these essential components, users can better troubleshoot issues and maintain the functionality of the electrical system, ensuring reliability and performance in their machinery.

Enhancing Performance with Quality Parts

Boosting the efficiency and longevity of machinery is crucial for optimal operation. Utilizing high-quality components can significantly enhance functionality, ensuring that equipment runs smoothly and effectively. Selecting superior replacements and upgrades allows for better performance and can prevent common issues associated with wear and tear.

Benefits of Quality Components

- Improved Reliability: High-grade materials offer greater durability, reducing the likelihood of breakdowns.

- Enhanced Efficiency: Quality replacements often lead to better fuel consumption and reduced operational costs.

- Increased Lifespan: Investing in premium components can extend the overall life of your machinery.

Choosing the Right Upgrades

- Research: Investigate various options available on the market to find components that meet your needs.

- Consult Experts: Seek advice from professionals or forums that specialize in machinery to gain insights on the best choices.

- Check Compatibility: Ensure that any selected upgrade is compatible with your specific model to avoid installation issues.

Ultimately, prioritizing quality in replacements and enhancements not only boosts performance but also contributes to a more reliable and efficient operation.