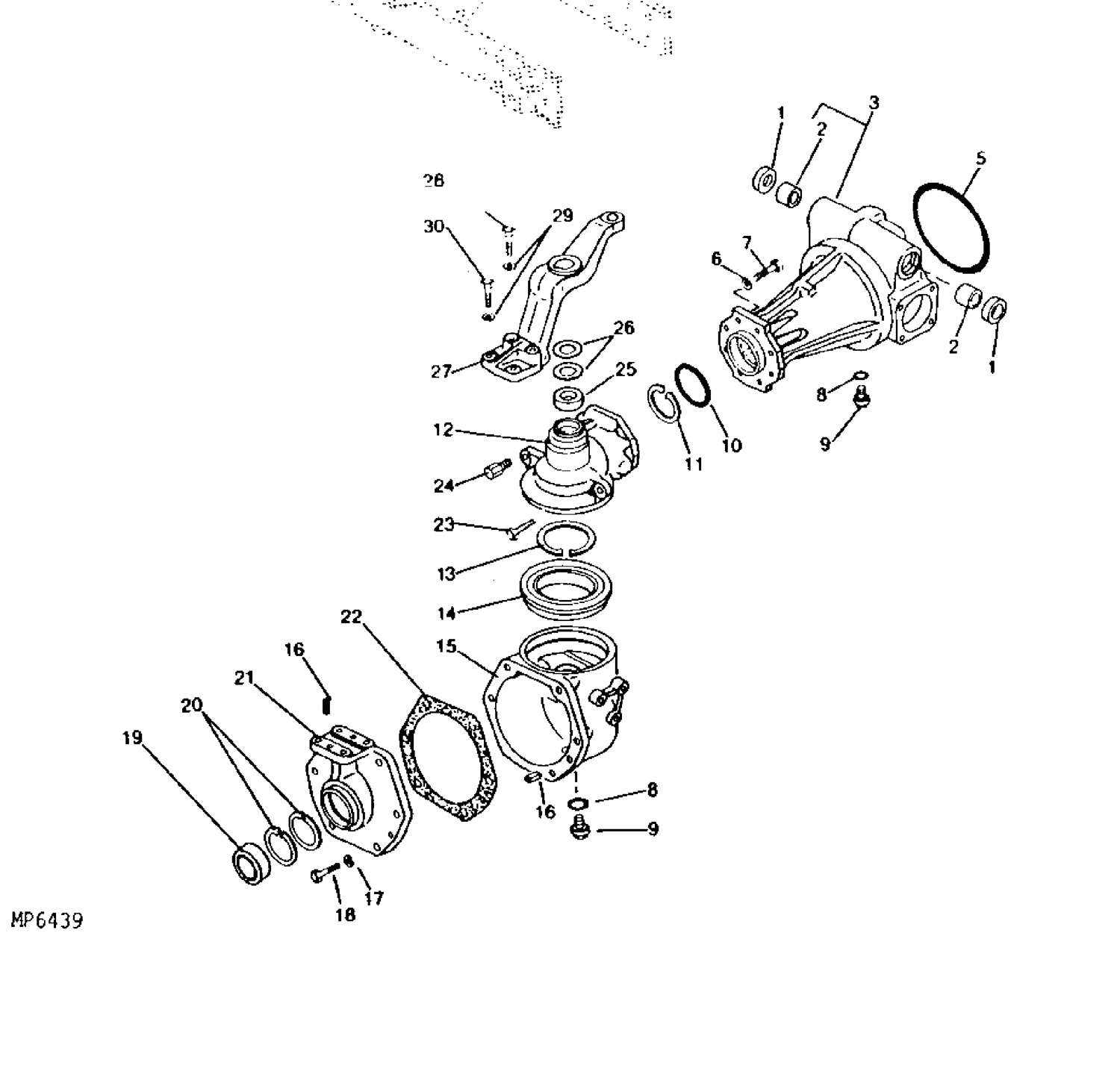

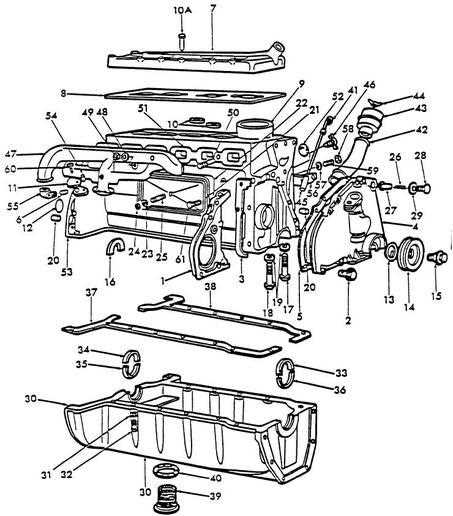

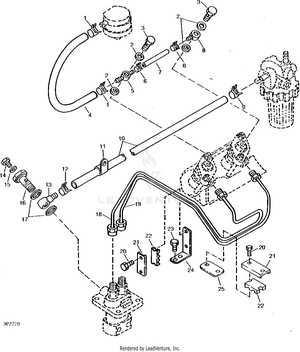

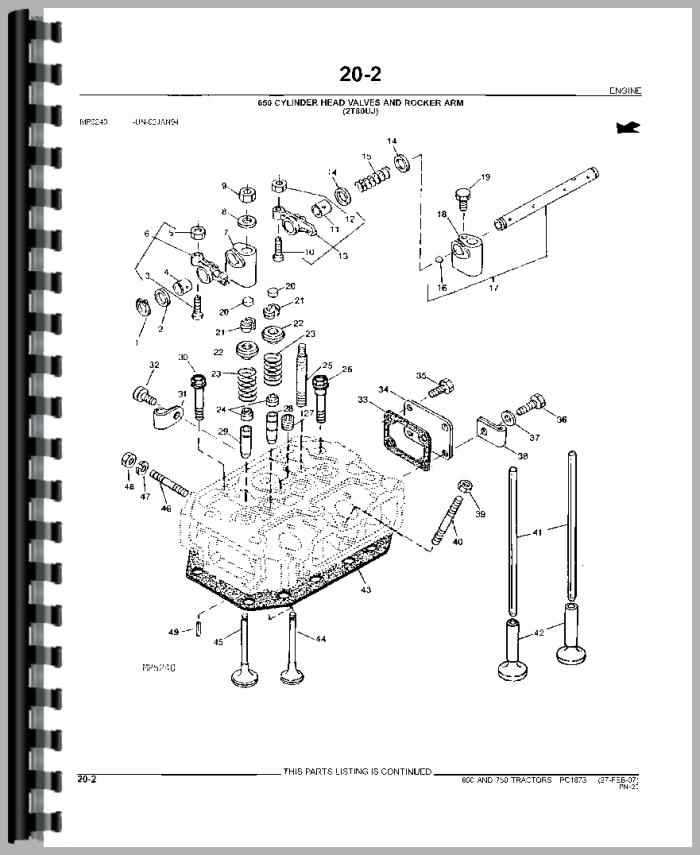

Understanding the intricate layout of machinery is essential for effective maintenance and optimal performance. This section focuses on the visual representation of essential elements within a specific agricultural machine, providing valuable insights into its operational mechanics.

Visual aids serve as an ultimate resource for both novice and experienced operators. They allow users to delve into the relationships between various sections, facilitating a deeper comprehension of functionality and assembly.

By examining these detailed representations, one can identify critical components and their respective roles. This knowledge not only enhances repair efficiency but also promotes longevity in the machinery’s use.

Understanding John Deere 750 Tractors

This section explores the essential components and functionalities of a popular agricultural machine known for its reliability and efficiency. Gaining insights into its construction can enhance performance and maintenance practices.

Key features include:

- Robust engine performance

- Durable transmission systems

- Versatile attachment compatibility

Understanding these attributes allows operators to maximize productivity. Regular inspections are vital for longevity and optimal operation.

- Check fluid levels frequently.

- Inspect belts and hoses for wear.

- Maintain tire pressure and condition.

By delving into the mechanics and upkeep, users can ensure their machinery remains at its best for years to come.

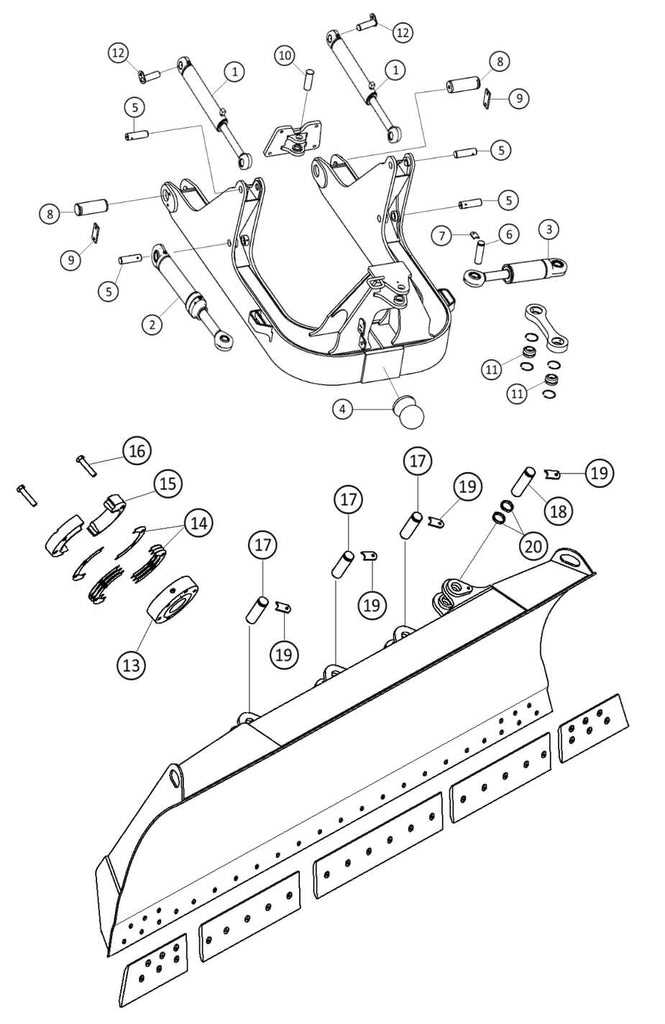

Key Components of the 750 Model

The 750 model features several essential elements that contribute to its efficiency and performance. Understanding these key components is crucial for optimal operation and maintenance, ensuring that users can effectively leverage the machine’s capabilities.

At the heart of this model lies the robust engine, which delivers the necessary power for various tasks. Coupled with a reliable transmission system, it allows for smooth operation across diverse terrains. The hydraulic system plays a vital role in enhancing functionality, enabling seamless attachment changes and providing lift support for implements.

Furthermore, the steering mechanism ensures precise control, making maneuverability effortless, even in tight spaces. The chassis is designed for durability, providing a stable foundation that can withstand demanding conditions. Finally, the electrical system powers all essential components, ensuring reliability and efficiency throughout use.

Importance of Accurate Parts Diagrams

Precision in visual representations of components is crucial for effective maintenance and repairs. These illustrations serve as a vital resource, guiding users through complex assemblies and ensuring that each element is correctly identified.

Understanding these visuals minimizes the risk of errors during reassembly, leading to enhanced performance and longevity of equipment. When individuals can delve into detailed schematics, they are empowered to make informed decisions regarding replacements and repairs.

Moreover, accuracy in these depictions can significantly reduce downtime, as operators are equipped with the ultimate knowledge to address issues swiftly. In a world where efficiency is paramount, reliable guides can be the difference between smooth operations and costly setbacks.

Where to Find OEM Parts

Locating original equipment manufacturer components is essential for ensuring optimal performance and longevity of your machinery. High-quality replacements not only enhance efficiency but also maintain the integrity of your equipment. This section provides insights into reliable sources for procuring genuine components.

Authorized dealers often serve as the most dependable source for authentic components. These establishments typically offer a comprehensive inventory, ensuring that you find exactly what you need. Additionally, they often have knowledgeable staff who can assist in identifying the correct parts and providing installation advice.

Online marketplaces have gained popularity for sourcing genuine components. Reputable websites dedicated to machinery often feature extensive catalogs with detailed descriptions and compatibility information. It’s crucial to verify the seller’s credibility and check customer reviews to avoid counterfeit products.

Another option is manufacturer websites, which frequently provide direct purchasing options or links to authorized retailers. These platforms often include valuable resources such as specifications and installation guides, helping you make informed decisions.

Finally, industry forums and communities can be excellent resources for recommendations. Experienced users often share insights about where to find authentic components, and you may discover trusted suppliers that you hadn’t previously considered.

Common Repairs for the 750 Tractor

Regular maintenance and timely repairs are essential for optimal performance and longevity of agricultural machinery. Various components may require attention due to wear and tear from frequent use in challenging conditions. Understanding common issues can help owners keep their equipment running smoothly.

One frequent concern is the hydraulic system, where leaks or pressure drops can impede functionality. Regular checks and replacements of seals and hoses are necessary to prevent downtime. Additionally, the engine may face problems such as overheating or oil leaks, necessitating inspections of the cooling system and gaskets.

Another area often needing repairs includes the drivetrain, particularly the transmission and differential. Ensuring proper fluid levels and addressing unusual noises promptly can avert more significant failures. Finally, maintaining the electrical system, including batteries and wiring, is crucial to avoid starting issues or electrical failures.

Step-by-Step Maintenance Guide

Regular upkeep of your machinery is essential for optimal performance and longevity. This guide outlines a systematic approach to maintaining your equipment, ensuring it operates efficiently and reliably.

-

Inspection:

- Check fluid levels, including oil and coolant.

- Examine belts and hoses for wear and tear.

- Look for any signs of leaks or corrosion.

-

Cleaning:

- Remove dirt and debris from exterior surfaces.

- Clean air filters to ensure proper airflow.

- Wash the undercarriage to prevent buildup.

-

Lubrication:

- Grease moving parts as recommended by the manufacturer.

- Lubricate joints and pivots to reduce friction.

-

Replacement:

- Change oil and oil filters at regular intervals.

- Replace worn or damaged components as needed.

-

Testing:

- Start the machinery to ensure all systems are functional.

- Monitor performance for any unusual noises or vibrations.

Following these steps will help maintain your equipment’s performance and extend its service life.

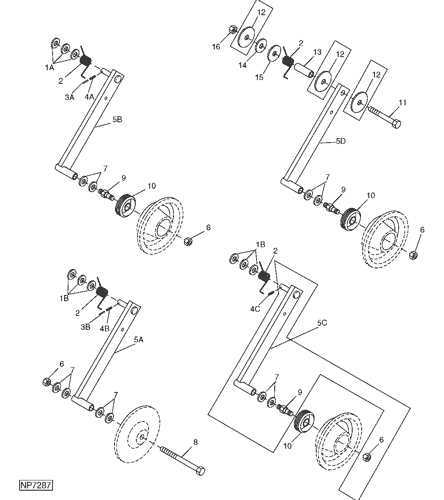

Identifying Compatible Replacement Parts

Understanding how to find suitable substitutes for machinery components is essential for maintaining optimal performance and longevity. It involves recognizing the specifications and compatibility requirements to ensure seamless integration and functionality.

| Component Type | Compatible Models | Part Number |

|---|---|---|

| Engine Assembly | Various Models | 123456 |

| Hydraulic Pump | Several Variants | 789012 |

| Transmission Unit | Compatible Series | 345678 |

By consulting reliable resources and databases, one can delve into the specifics of various components, ensuring the ultimate fit and functionality for your equipment.

Benefits of Using Genuine Parts

Utilizing authentic components for machinery maintenance offers numerous advantages that enhance both performance and longevity. By investing in quality, users ensure that their equipment operates at optimal efficiency, minimizing the risks of unexpected breakdowns and costly repairs.

Improved Performance

Authentic components are designed specifically for compatibility with your machinery, resulting in smoother operation. High-quality materials ensure that these parts can withstand the rigors of daily use, maintaining peak functionality over time. In contrast, inferior alternatives may lead to inefficiencies that compromise the overall output.

Long-Term Savings

While it may be tempting to choose cheaper options, genuine components often prove to be more cost-effective in the long run. Reduced maintenance costs and fewer repairs contribute to a better return on investment. Additionally, the durability of authentic parts means they are less likely to fail, saving both time and money on replacements.

Common Issues with the 750 Tractor

Many operators encounter various challenges when using this specific agricultural machinery. Understanding these common complications can help in effective troubleshooting and maintenance.

| Issue | Description |

|---|---|

| Engine Problems | Frequent starting issues and rough idling can arise from fuel system blockages or electrical malfunctions. |

| Hydraulic Failures | Low fluid levels or leaks can lead to insufficient power in the hydraulic system, affecting implement performance. |

| Transmission Difficulties | Shifting issues may occur due to worn gears or low transmission fluid, hindering operational efficiency. |

| Electrical System Issues | Faulty wiring or dead batteries can disrupt electronic components, leading to malfunctioning lights or gauges. |

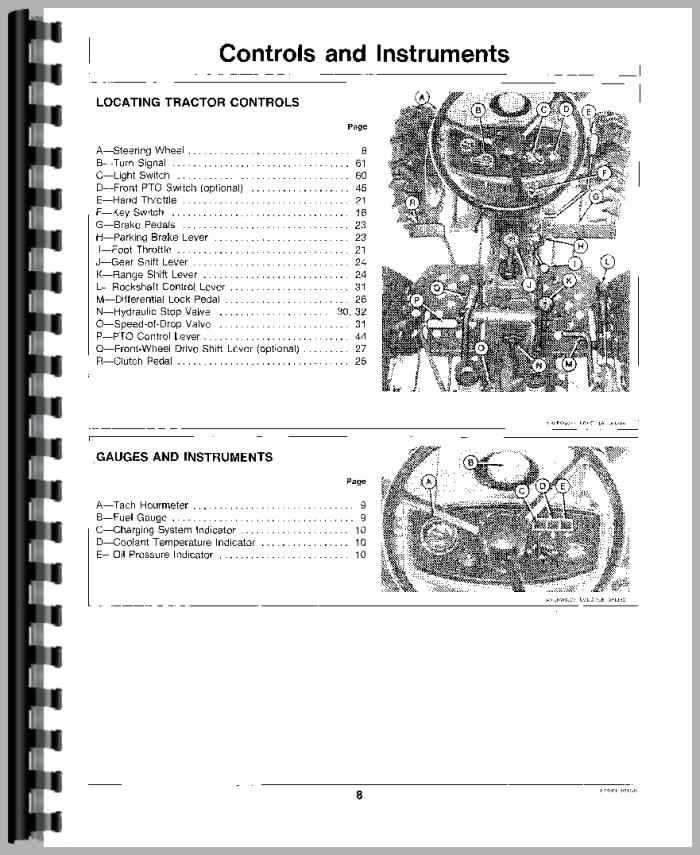

How to Read Parts Diagrams

Understanding visual representations of components is essential for efficient maintenance and repair tasks. These illustrations simplify the identification of various elements, helping users quickly locate what they need. Familiarity with these visuals enables smoother interactions with equipment and promotes effective troubleshooting.

To enhance comprehension, follow these steps:

| Step | Description |

|---|---|

| 1 | Start by identifying the key symbols used in the illustration. |

| 2 | Note the labels associated with each component for easy reference. |

| 3 | Cross-reference the visual with a parts list to confirm details. |

| 4 | Practice locating specific items to build confidence and familiarity. |

By mastering these techniques, you will ultimately enhance your ability to navigate component illustrations effectively.

Resources for Tractor Owners

Owning heavy machinery involves a commitment to understanding its components and maintaining optimal performance. Access to reliable resources can significantly enhance the experience, providing essential information and support for enthusiasts and professionals alike.

Helpful Online Platforms

Numerous websites offer valuable insights, ranging from instructional videos to comprehensive manuals. These platforms cater to a variety of needs, whether it’s troubleshooting or upgrading equipment.

Local Supply Stores

Local shops often provide personalized assistance and stock a range of items necessary for upkeep. Engaging with knowledgeable staff can lead to better decision-making and enhanced maintenance practices.

| Resource Type | Examples |

|---|---|

| Online Forums | Machinery Talk, TractorByNet |

| Video Tutorials | YouTube, Equipment World |

| Manuals and Guides | Manufacturer Websites, eBooks |

| Parts Suppliers | Local Dealerships, Online Retailers |

Upgrading Components for Better Performance

Enhancing machinery efficiency can significantly improve overall functionality and productivity. By focusing on key elements within the system, operators can achieve remarkable results that elevate performance standards. Upgrades not only increase power output but also contribute to longevity and reliability.

Identifying crucial areas for enhancement is essential. Components such as engines, transmissions, and hydraulic systems are prime candidates for upgrades. Investing in high-quality replacements can lead to smoother operations and better fuel efficiency.

Moreover, regular maintenance combined with strategic upgrades ensures optimal performance. By delving into the intricacies of each part, users can make informed decisions that align with their operational needs. The ultimate goal is to achieve a well-rounded and powerful system that meets demanding agricultural tasks.

Expert Tips for Troubleshooting

When encountering issues with heavy machinery, an effective approach is essential for identifying and resolving problems efficiently. Understanding common symptoms and potential causes can streamline the troubleshooting process, ultimately leading to quicker repairs and improved functionality.

Identify Symptoms

Begin by observing any unusual behavior or performance issues. Note specific signs such as noises, vibrations, or fluid leaks. Documenting these details can provide valuable insights when diagnosing the underlying problem.

Consult Resources

Utilize available manuals and online forums to gather information about common issues. Engaging with other operators can also offer unique perspectives and solutions that may not be immediately apparent.