When it comes to the smooth operation of a vehicle’s propulsion mechanism, one of the key components plays a crucial role in distributing power to the wheels. This element ensures that the engine’s force is effectively channeled to maintain stability and control, especially when navigating varied terrains. Without a proper grasp of how this system functions, identifying and resolving issues can be a significant challenge.

The assembly of this system consists of numerous interconnected units, each serving a specific function to facilitate torque distribution and overall vehicle movement. Knowing the layout and function of each element is essential for anyone looking to perform maintenance or upgrades on their vehicle’s powertrain setup. By delving into the specifics, it becomes easier to pinpoint inefficiencies and make informed adjustments.

In this guide, we’ll explore the intricate details of the components within this power distribution system. By breaking down each element, we aim to provide a comprehensive overview that enhances your understanding, enabling more effective troubleshooting and optimization. This knowledge not only aids in routine upkeep but also empowers you to make strategic improvements for better performance.

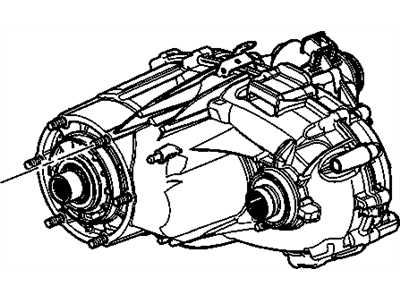

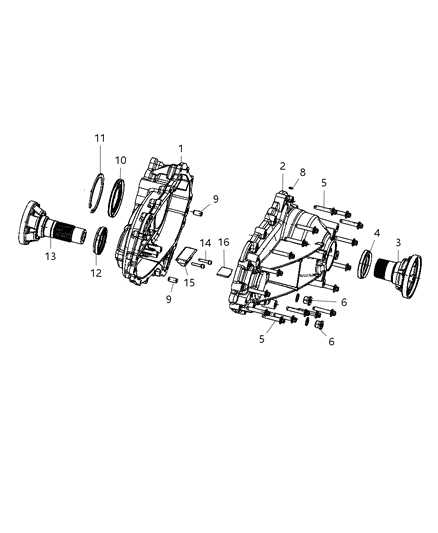

Overview of MP3023 Transfer Components

In modern drivetrain systems, a variety of crucial elements work together to ensure optimal functionality. Understanding these components is essential for anyone looking to maintain or upgrade their vehicle’s performance capabilities. This section focuses on the primary mechanisms that interact within the assembly, highlighting their roles and importance in the overall operation.

Core Mechanisms: Each of these elements is meticulously designed to handle specific tasks, ranging from power distribution to smooth control of torque. The precision of these mechanisms determines the efficiency of power delivery to the wheels, ensuring the vehicle adapts seamlessly to varying conditions.

Integrated Units: The integration of these units is engineered to achieve maximum reliability under different driving scenarios. Their collective performance directly impacts the vehicle’s stability and responsiveness, making it vital to understand their interaction within the system.

Identifying Key Mechanisms and Gears

Understanding the fundamental structures and gear systems within this setup requires a focus on each component’s role in achieving seamless operation. These elements work in unison to deliver balanced performance, ensuring the machinery operates smoothly under varying conditions. Identifying the core elements allows for better insight into how the system maintains its efficiency and stability during function.

Among the critical components are precision-engineered gears that facilitate movement and adjust to different speed ratios. Each gear interacts with the others to transfer motion effectively, adapting to changing demands while reducing mechanical strain. Recognizing these interactions is crucial for diagnosing issues and ensuring optimal performance.

Another essential mechanism includes rotational elements that synchronize movements between interconnected parts. These components are meticulously designed to handle torque variations and power transitions. By analyzing these systems, one gains a deeper understanding of the overall dynamics and can troubleshoot or enhance the machinery’s reliability.

Main Shaft and Support Structure

The central component and its surrounding framework play a crucial role in the efficient operation of mechanical assemblies. This section explores how these core elements interact within the broader system, ensuring seamless functionality under various conditions.

The main shaft serves as the pivotal element, transmitting rotational force throughout the setup. It is designed to handle significant torque and stress, maintaining stability even under heavy loads. The precision of its construction directly impacts the overall efficiency and durability of the machinery.

Surrounding the main shaft is a robust support structure that provides stability and alignment. This framework is engineered to absorb vibrations and distribute forces evenly, preventing undue wear on individual components. Its design aims to enhance the longevity of the assembly by maintaining optimal positioning of all interconnected elements.

Role in Torque Transmission

Torque distribution in mechanical systems plays a crucial role in ensuring that power is effectively directed to the necessary components. Understanding how energy is routed and managed is essential for maintaining stability and performance in a variety of vehicles.

| Component | Function |

|---|---|

| Drive Shaft | Transmits rotational force from the engine to the wheels. |

| Clutch Mechanism | Regulates the connection and disconnection of power flow to prevent slippage. |

| Gear Set | Adjusts torque levels based on driving conditions, enhancing control. |

Each of these elements works in unison to balance power delivery, ensuring that energy is channeled where it is most needed. This balance is fundamental to the operation of various propulsion setups, directly impacting vehicle handling and traction.

Understanding Clutch Assembly Details

The clutch assembly plays a crucial role in the system, ensuring smooth power distribution and reliable engagement between components. It is designed to handle various conditions, optimizing performance and reducing wear. Below, we delve into the essential elements that contribute to its operation and efficiency.

- Friction Discs: These components are responsible for transferring torque by creating the necessary friction when engaged. Their quality and material composition significantly impact the overall function and longevity.

- Pressure Plate: The pressure plate maintains the required force to keep the clutch disc firmly in place. It ensures consistent performance by applying uniform pressure across the disc surface.

- Release Mechanism: This part enables the disengagement of the clutch when needed, allowing for smooth transitions and gear shifts. It consists of springs and levers that work in unison to control the release process.

- Springs and Dampers: Springs and dampers help absorb shocks and vibrations during operation, minimizing stress on the connected components. They enhance durability and contribute to a quieter, more stable function.

A thorough understanding of these elements aids in diagnosing potential issues and performing effective maintenance. Regular inspection of the clutch assembly ensures its reliability and extends its operational lifespan.

Engagement and Disengagement Mechanism

The mechanism responsible for engaging and disengaging power is crucial for the proper operation of off-road vehicles. This system allows the driver to switch between different operational modes, optimizing performance for varying driving conditions. A well-designed engagement mechanism ensures seamless transitions, enhancing both control and stability on diverse terrains.

Key Components

Central to this mechanism are several essential components that work together to facilitate smooth operation. These include engagement levers, clutches, and locking devices. Each element plays a vital role in ensuring that the system responds accurately to the driver’s commands, thereby maintaining vehicle stability and safety.

Operational Process

The process of engaging and disengaging typically involves a series of mechanical actions initiated by the driver. When the driver activates the system, a series of gears and levers coordinate to lock or unlock the desired operational mode. This synchronization allows for efficient power distribution and optimal vehicle performance in various environments.

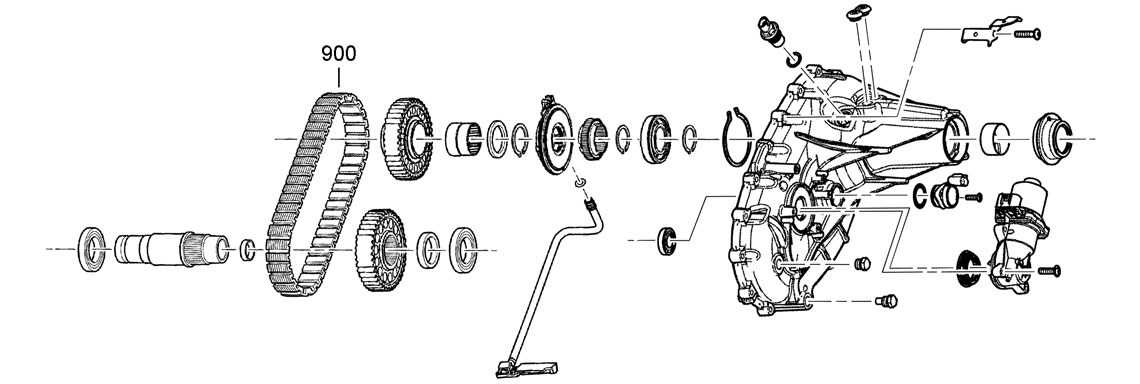

Chain Drive Layout Explanation

The configuration of the chain drive system plays a crucial role in the efficient operation of various mechanical assemblies. This arrangement facilitates the transfer of motion and power through interconnected components, ensuring smooth functionality within the overall system.

Components of the Chain Drive

At its core, the chain drive consists of several key elements, including the chain itself, sprockets, and supporting structures. The chain connects two or more sprockets, which are responsible for transmitting rotational motion. This interaction allows for precise control over the speed and torque delivered to different parts of the mechanism.

Functionality and Benefits

One of the primary advantages of utilizing a chain drive layout is its ability to handle significant loads while maintaining reliability. The system is designed to minimize slippage, ensuring consistent power delivery even under challenging conditions. Additionally, this configuration is relatively straightforward to maintain, making it a popular choice in various applications.

Impact on Power Distribution

The efficiency of energy distribution in vehicles is crucial for optimal performance and functionality. This aspect is significantly influenced by various mechanical components that work in harmony to manage the transfer of energy throughout the system. Understanding the mechanisms behind this process reveals how different elements contribute to the overall effectiveness of power distribution.

Mechanisms of Energy Flow

The flow of energy relies on several interconnected components that facilitate the transmission of power. These elements must be precisely calibrated to ensure seamless interaction, allowing for balanced energy distribution to different drivetrain sections. Any malfunction or inefficiency in these components can lead to imbalances, ultimately affecting vehicle performance.

Consequences of Inefficient Distribution

Ineffective management of energy distribution can lead to increased wear and tear on various components, reducing the overall lifespan of the system. Additionally, this inefficiency may manifest as reduced handling capabilities and compromised stability during operation. Addressing these issues requires careful analysis and maintenance of the involved elements to ensure they function optimally.

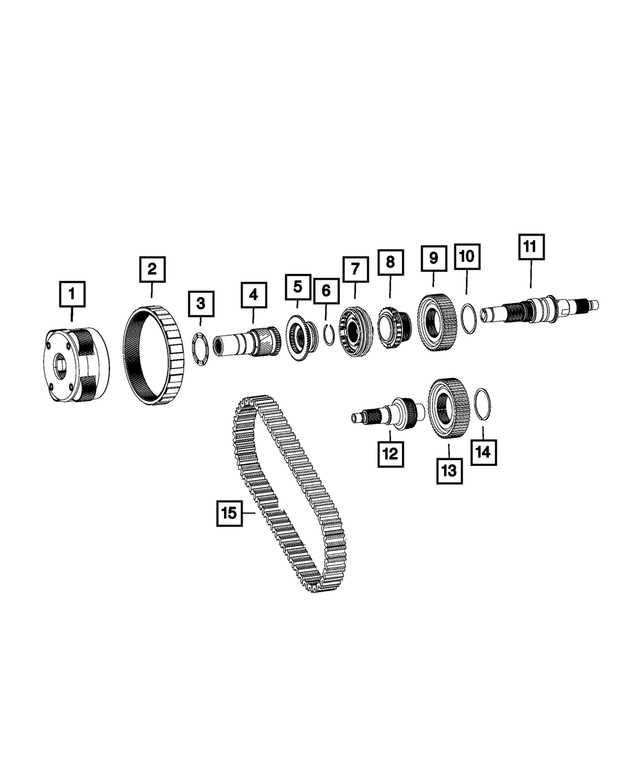

Planetary Gear Set Analysis

The examination of a specific gear arrangement reveals its critical role in enhancing mechanical efficiency and functionality within various systems. This intricate assembly comprises multiple gears that interact in a way that optimizes torque and speed. Understanding the dynamics and characteristics of this configuration is essential for effective design and maintenance.

In essence, the central gear, often referred to as the sun gear, serves as the focal point around which other gears revolve. The surrounding gears, known as planet gears, engage with both the sun gear and a stationary outer ring, contributing to the overall motion and power distribution. This setup allows for a compact design, making it ideal for applications requiring space efficiency without sacrificing performance.

Moreover, the arrangement’s ability to provide various gear ratios enables adaptability in different operational contexts. The smooth transfer of power and reduction of friction are further enhanced by the unique geometric relationships among the gears, which also play a pivotal role in minimizing wear and tear. Consequently, analyzing these elements is vital for anyone involved in engineering or mechanical maintenance.

Function in Speed Variations

The operation of a vehicle’s drivetrain is significantly influenced by its ability to adapt to different speed requirements. This flexibility ensures optimal performance under varying driving conditions, whether it be during acceleration, cruising, or navigating challenging terrains. Understanding how these mechanisms work together is essential for enhancing efficiency and responsiveness.

Adaptation to Driving Conditions

In diverse environments, the system must adjust to changes in momentum and traction. When the speed fluctuates, components engage or disengage to maintain stability and control. This adaptability allows the vehicle to seamlessly transition from high-speed travel on highways to lower speeds on rugged paths, ensuring safety and comfort for the occupants.

Impact on Fuel Efficiency

The ability to modulate power distribution not only enhances performance but also plays a crucial role in fuel consumption. By optimizing the energy used at different speeds, the overall efficiency of the vehicle is improved, leading to reduced emissions and operational costs. Thus, a well-designed drivetrain system is vital for achieving balance between power and sustainability.

Fluid Pump Operation Insights

The fluid pump is a crucial component in the system, responsible for circulating essential lubricants and fluids throughout the mechanism. Understanding its functionality can provide valuable insights into overall performance and longevity.

When the pump is activated, it generates pressure that moves the fluid from the reservoir to various parts of the assembly. This process not only lubricates moving components but also aids in cooling, reducing friction, and preventing wear. Maintaining optimal fluid levels is vital for ensuring that the pump operates efficiently and effectively.

Moreover, the design of the pump influences its capability to handle different fluid viscosities. A well-functioning pump will adapt to various operational demands, maintaining consistent flow rates under varying conditions. Regular inspections and maintenance of the pump can help identify potential issues before they lead to more significant problems.

Maintaining System Lubrication

Proper upkeep of lubrication within the system is essential for ensuring optimal functionality and longevity. Regular attention to lubrication not only enhances performance but also minimizes wear and tear on components, ultimately leading to a more reliable operation.

To maintain effective lubrication, consider the following practices:

- Regular Inspections: Periodically check lubrication levels and condition to prevent potential issues.

- Fluid Replacement: Change lubricants at recommended intervals to ensure their effectiveness and prevent contamination.

- Sealing Checks: Inspect seals and gaskets for leaks to avoid loss of lubricant and maintain pressure.

- Proper Application: Follow manufacturer guidelines for applying lubricants to ensure adequate coverage without overfilling.

By following these guidelines, you can significantly enhance the performance and lifespan of your system.

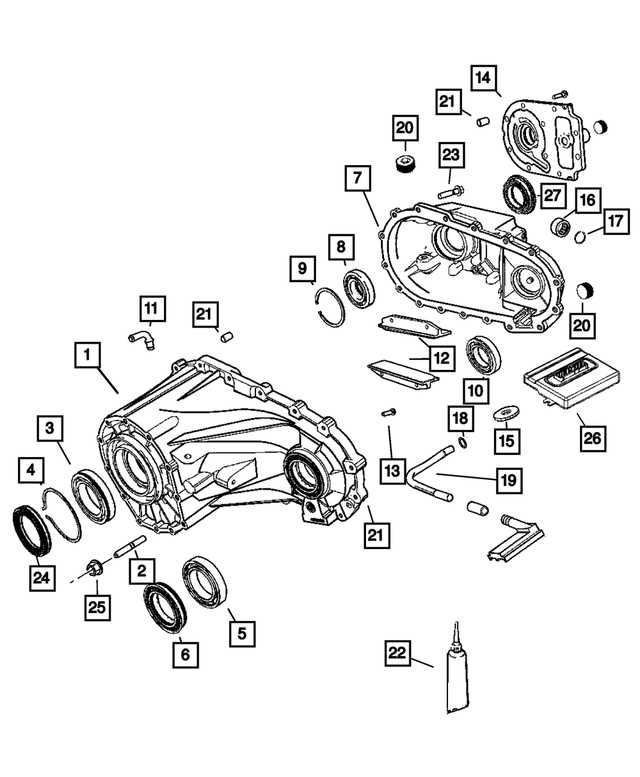

Housing and Casing Design

The construction of enclosures and shells plays a crucial role in the overall functionality and durability of mechanical assemblies. These elements must provide robust protection while facilitating seamless integration with other components. A well-designed housing not only supports structural integrity but also contributes to the efficient operation of the system.

Materials used in housing production significantly influence performance. Common choices include high-strength metals and durable polymers, each offering unique advantages such as weight reduction or enhanced resilience to environmental factors. Choosing the right material is essential for ensuring longevity and operational reliability.

Additionally, engineering techniques involved in the shaping of these structures are critical. Advanced manufacturing methods, including casting and machining, allow for precise tolerances and surface finishes. This precision is vital in achieving the necessary fit with internal components, which can impact the entire assembly’s effectiveness.

Furthermore, design considerations must account for factors like thermal expansion and potential wear. Integrating features such as cooling channels or wear-resistant linings can enhance performance and lifespan. An optimized housing design ensures that the assembly operates smoothly under various conditions, minimizing the risk of failure.