Understanding how various mechanical elements come together in a vehicle is essential for ensuring smooth operation and maintenance. Whether you’re an experienced technician or a novice enthusiast, having clarity on how different parts fit and function is key to successful repairs and adjustments. This guide will offer an insightful look into the assembly and connection of essential drivetrain elements in a straightforward and accessible manner.

Detailed exploration of the arrangement and relationships of individual components can significantly enhance your knowledge. From recognizing specific elements to identifying common troubleshooting areas, this section will provide a valuable resource for anyone looking to deepen their understanding of automotive mechanics. By paying close attention to the layout and positioning, you can confidently approach any task, big or small.

Overview of the Gearbox System

The discussed gearbox model is known for its durability and reliability, often found in various heavy-duty applications. It combines robust engineering with a design that supports long-term use under demanding conditions. This system is frequently chosen for its ability to handle significant power output while maintaining smooth operation.

Key Features of this unit include a highly efficient gear ratio that ensures optimal torque distribution. The internal components are designed to reduce wear, promoting a longer lifespan for the system. Additionally, its versatility makes it adaptable to various vehicles and mechanical configurations.

Another important aspect of this gearbox is its ease of maintenance. With a modular construction, techni

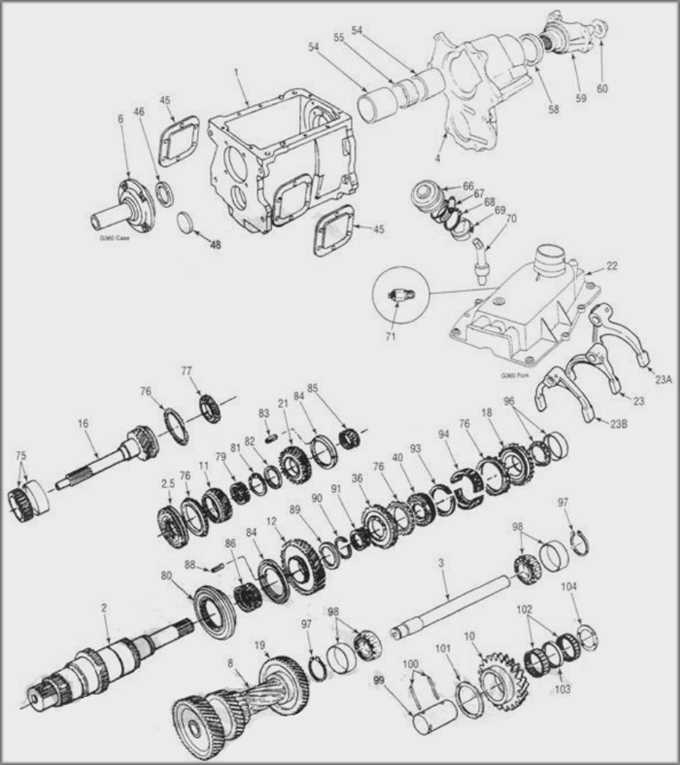

Key Components of the Nv4500 Gearbox

The core structure of this gearbox consists of various interconnected elements that ensure smooth power distribution and shifting capability. These components work together to optimize torque, control speed, and maintain durability under heavy load conditions. Understanding the main elements of this system is essential for both operation and maintenance.

Gearing System

The gearing system includes multiple cogs and shafts that manage the flow of power from the engine. The precision of gear alignment and spacing is critical to ensure efficient shifting and to reduce wear over time. Proper lubrication and regular checks are vital for the longevity of this system.

Synchronizer Assembly

The synchronizer assembly enables seamless gear shifts by aligning the speeds of different components before engagement. This assembly reduces friction and prevents potential damage during operation. It plays a key role in ensuring

Identifying the Main Gear Sections

Understanding the structure and key areas of a complex gear system is essential for efficient maintenance and repair. Each section has a distinct function, and recognizing them helps in diagnosing and addressing potential issues.

- Input section: This is where the initial force is applied, allowing the system to transfer power.

- Main shaft: The central axis that connects multiple components, ensuring the flow of power through the system.

- Synchronizers: Critical for smooth engagement between gears, preventing friction and wear.

- Output section: Responsible for channeling the energy to the connected mechanical components.

- Countershaft: A secondary

Functionality of the Synchro Assembly

The synchro assembly is a critical component that ensures smooth shifting by harmonizing gear rotations. It minimizes friction between moving elements, allowing seamless engagement between different gears without abrupt transitions. This system enhances efficiency and prolongs the lifespan of related mechanisms, making gear transitions feel fluid.

Main Components and Roles

The assembly is comprised of multiple key elements, each contributing to its operation. These include synchronizer rings, sliders, and hub assemblies. Each part works in unison to align rotational speeds and enable smooth transitions between gears. Below is a breakdown of these components and their functions:

Component Function Synchronizer Rings Help match the rotational speed of gears to prevent grin Clutch Mechanism and Its Role

The clutch system plays a fundamental role in the overall operation of a vehicle by allowing the driver to engage and disengage the engine from the rest of the drivetrain. This key component is essential for smooth transitions between gears and is responsible for transferring power from the engine to the wheels efficiently.

How the Clutch System Works

At its core, the clutch utilizes friction plates and a pressure plate to either connect or disconnect the engine’s power. When the pedal is pressed, the plates are separated, which interrupts the power flow. When released, the plates engage again, allowing the flow of power to continue.

Importance of Proper Maintenance

Regular maintenance of the clutch system ensures a longer lifespan and optimal performance. Issues such as slippage or grinding can indicate wear, and addressing these problems early helps to avoid more costly repairs.

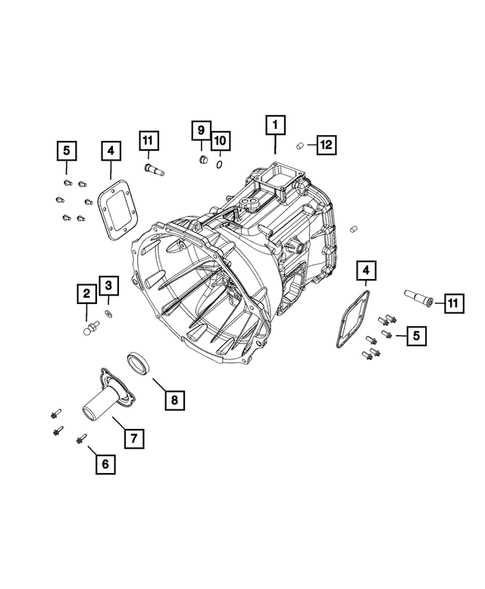

Exploded View of the Output Shaft

This section provides a detailed examination of the components related to the output shaft assembly, offering insights into its structure and functionality. Understanding the arrangement of these elements is crucial for effective maintenance and troubleshooting.

Components Overview

The output shaft consists of several key components that work together to facilitate power transfer. Each piece plays a significant role, ensuring smooth operation and enhancing the overall performance of the system.

Assembly Insights

In this assembly, careful attention to the interaction between components is essential. Proper alignment and fitting are necessary to avoid wear and ensure longevity, contributing to the reliable operation of the machinery.

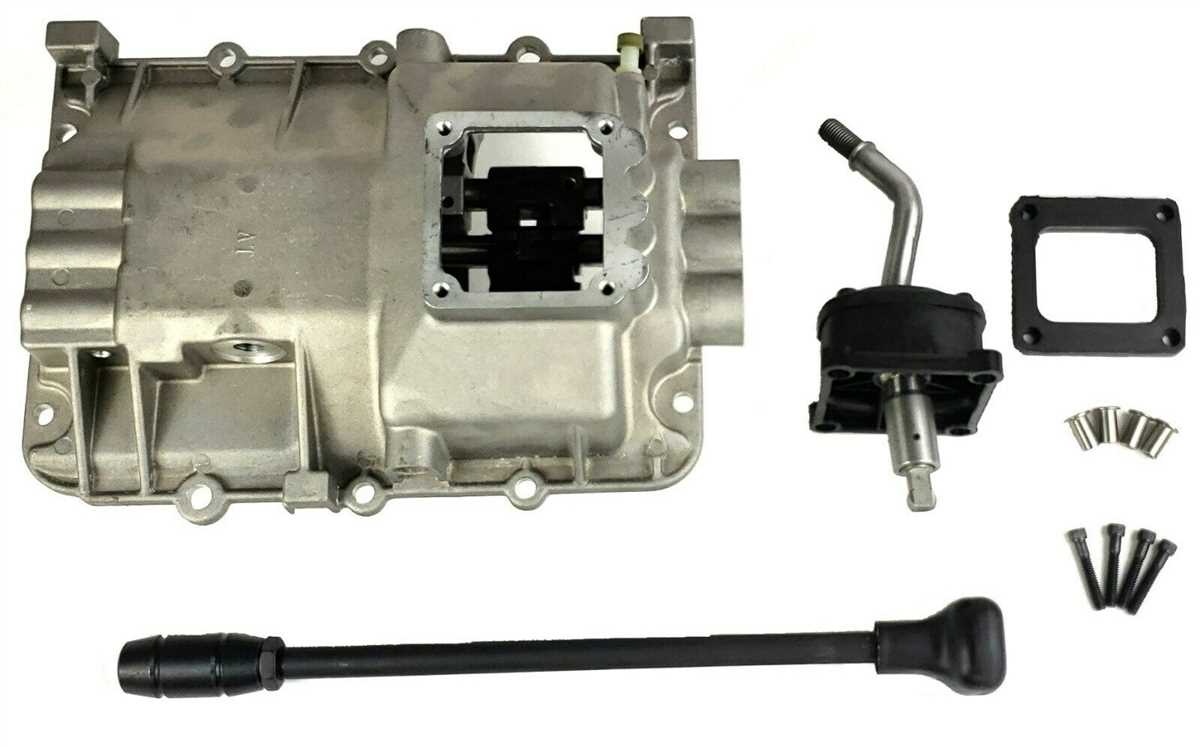

Shift Tower and Linkage Breakdown

The shift tower and its associated linkage system play a crucial role in the operation of a vehicle’s gear mechanism. This assembly facilitates the seamless engagement and disengagement of gears, allowing for smooth transitions while driving. Understanding its components and their functions is essential for maintenance and troubleshooting.

Key Components of the Shift Tower

The shift tower comprises several vital elements that work in harmony. These include:

- Shifter lever: The main handle used by the driver to change gears.

- Linkage rods: Connect the lever to the internal mechanisms, transmitting the driver’s input.

- Detent mechanism: Ensures that the lever remains in the selected position, providing a tactile response during gear changes.

Importance of Proper Alignment

Maintaining the correct alignment of the shift tower and linkage is essential for optimal performance. Misalignment can lead to difficulties in gear selection, increased wear on components, and potential operational failures. Regular inspections and adjustments can help prevent these issues, ensuring a reliable driving experience.

Bearing Assembly and Support Structure

The bearing assembly plays a crucial role in the overall functionality and stability of mechanical systems. Its design ensures the smooth operation of rotating elements while providing essential support to various components.

Key elements of the bearing assembly include:

- Bearing Components: Various elements such as races, rolling elements, and retainers work together to minimize friction and wear.

- Support Framework: The structure that holds the bearing in place, ensuring alignment and stability during operation.

- Lubrication Mechanism: A system to distribute lubricant, reducing friction and prolonging the lifespan of the assembly.

Understanding these components is vital for maintaining optimal performance in any mechanical application. Proper installation and regular maintenance of the bearing assembly and its support structure significantly enhance durability and efficiency.

Input Shaft Diagram and Details

The input shaft serves as a critical component in the assembly, playing a vital role in the overall functionality of the system. Its design and configuration significantly influence the efficiency of power transfer from the engine to the subsequent mechanisms.

Construction and Functionality

This shaft is typically constructed from durable materials to withstand the stresses of operation. It features a series of splines that enable a secure connection with other elements, facilitating smooth engagement and disengagement during operation. The precise alignment of the input shaft is essential for optimal performance.

Common Issues and Maintenance

Over time, wear and tear can affect the integrity of the input shaft. Common problems include scoring and excessive play, which can lead to inefficiencies or failures in the system. Regular inspection and maintenance are recommended to ensure longevity and reliable performance.

Inspection Points for Internal Gears

Evaluating the internal mechanisms of a gear system is crucial for ensuring optimal functionality and longevity. Key factors should be considered during the inspection process to detect potential issues that may affect performance.

Wear and Tear Assessment

One of the primary concerns is the wear patterns on the gear teeth. Inspecting for uneven surfaces or excessive wear can indicate misalignment or improper lubrication. Regular checks can prevent costly repairs and enhance the overall reliability of the system.

Clearance and Alignment Checks

Proper clearance between gears is essential for smooth operation. Measuring the spacing helps identify any deviations that may lead to operational failures. Ensuring correct alignment is equally important, as misalignment can cause undue stress on components, leading to premature failure.

Common Wear Areas in Nv4500 Transmission

Understanding the frequent areas of wear in a specific gear system is essential for maintaining its efficiency and longevity. Over time, certain components may experience deterioration due to the stresses of operation, which can lead to performance issues.

Key areas to monitor include:

- Bearings: These components often suffer from friction and inadequate lubrication, leading to premature failure.

- Synchronizers: Wear on these parts can result in difficult gear engagement and shifting problems.

- Seals: Deterioration in seals may cause fluid leaks, impacting overall performance.

- Gears: Teeth on gears may show signs of wear, which can lead to grinding noises and inefficient power transfer.

- Housing: Cracks or warping in the casing can affect alignment and structural integrity.

Regular inspection and timely replacement of these components can significantly enhance the reliability and functionality of the entire system.