The intricate world of automatic gear systems is essential for smooth and efficient vehicle operation. Each element plays a vital role in ensuring seamless transitions between gears, ultimately enhancing performance and drivability. A comprehensive exploration of these components reveals their individual functions and interconnections, shedding light on the overall mechanics at play.

For enthusiasts and professionals alike, visual aids can be invaluable in grasping the complex architecture of these mechanisms. By delving into detailed illustrations, one can better appreciate how each section contributes to the entire assembly. This understanding not only aids in maintenance and repairs but also enriches one’s knowledge of automotive engineering.

As we break down the specifics of this intricate system, we will highlight key components, their arrangements, and how they interact to facilitate movement. This journey through the mechanical intricacies promises to illuminate the essential features that keep vehicles operating smoothly and efficiently.

Understanding the TH400 Transmission

The subject at hand delves into a specific type of automatic gear-shifting mechanism widely used in various vehicles. This system is recognized for its robust performance and reliability, making it a popular choice among automotive enthusiasts and manufacturers alike. In this section, we will explore its fundamental components, functions, and maintenance tips to ensure optimal performance.

Key Components

This automatic gear-shifting unit comprises several essential elements that work in harmony to provide seamless operation. Understanding these components is crucial for both maintenance and troubleshooting. Below is a table highlighting the primary components and their functions:

| Component | Function |

|---|---|

| Torque Converter | Facilitates the transfer of power from the engine to the gearbox. |

| Planetary Gear Set | Enables different gear ratios for varying speeds and torque. |

| Hydraulic System | Controls the flow of fluid to engage and disengage gears. |

| Valve Body | Distributes hydraulic pressure to various components for gear selection. |

Maintenance Tips

Regular upkeep of this automatic gear-shifting unit is essential for longevity and performance. Here are some key maintenance practices:

- Regularly check and replace fluid to prevent overheating.

- Inspect filters for debris that could impede fluid flow.

- Monitor for any leaks or unusual noises during operation.

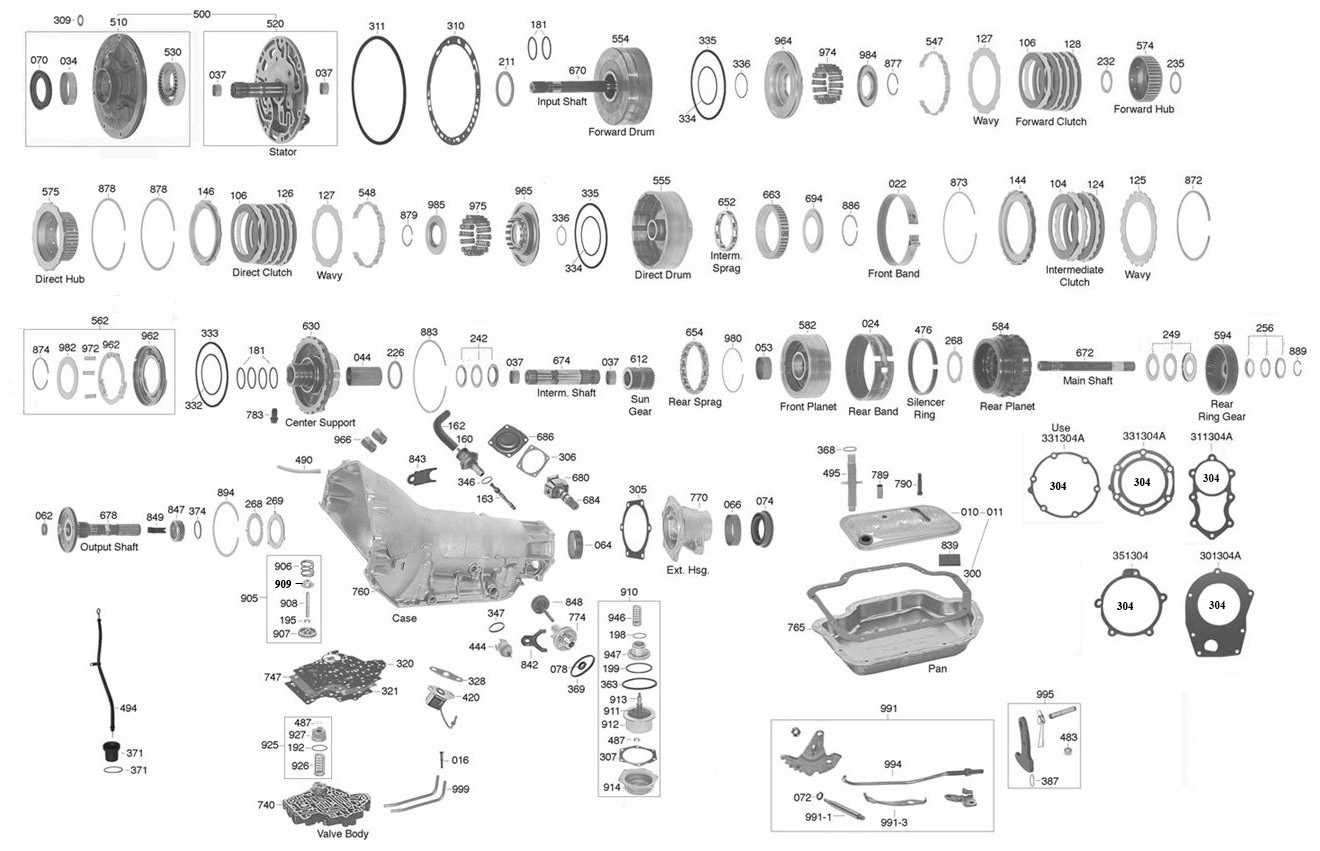

Key Components of TH400 Design

This section explores the essential elements that contribute to the functionality and efficiency of this robust automotive system. Understanding these components is crucial for those looking to enhance performance or conduct repairs, as each part plays a significant role in overall operation.

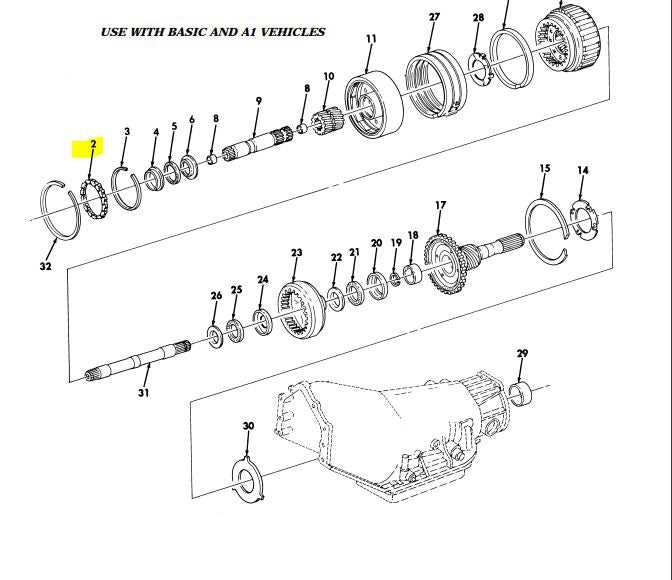

Gear Assembly

The gear assembly is a fundamental feature that enables various speed ratios, allowing the vehicle to adapt to different driving conditions. Its intricate design ensures smooth transitions and optimal power delivery, making it vital for performance.

Fluid Control Mechanism

This mechanism regulates the hydraulic fluid flow, which is essential for engaging and disengaging clutches within the system. Efficient fluid management is critical for maintaining temperature and preventing wear, ultimately influencing the longevity of the entire unit.

Functionality of Transmission Parts

Understanding the role of various components in a power transfer system is essential for maintaining optimal performance and reliability. Each element works cohesively to ensure smooth operation, enabling efficient energy conversion and control of vehicle dynamics. This section delves into the specific functions these components serve, highlighting their importance in the overall mechanism.

| Component | Function |

|---|---|

| Torque Converter | Facilitates smooth engagement and disengagement of power, allowing for increased torque multiplication. |

| Gear Sets | Provide different ratios to adapt engine output to varying speeds, optimizing performance under different conditions. |

| Clutch Packs | Engage and disengage the gears, allowing for seamless transitions between different operational states. |

| Valves | Control fluid flow and pressure, regulating how components interact and function together. |

| Planetary Gear Assembly | Enables compact design and multiple gear ratios within a smaller space, enhancing efficiency and versatility. |

Common Issues with TH400 Parts

When it comes to automatic gear systems, certain components often face recurring challenges that can affect performance and reliability. Understanding these common pitfalls can help in maintaining optimal function and extending the lifespan of the assembly.

Worn Seals and Gaskets

One prevalent issue is the deterioration of seals and gaskets, which can lead to fluid leaks. Over time, exposure to heat and pressure causes these materials to lose their integrity, resulting in insufficient lubrication and potential damage to the unit.

Valve Body Malfunctions

Another critical area is the valve body, where irregularities can impede fluid flow and shifting. Problems here can stem from debris buildup or wear, leading to erratic behavior and inefficiency in gear changes, ultimately affecting the overall driving experience.

Maintenance Tips for Longevity

Ensuring the durability and reliability of your vehicle’s components requires regular care and attention. Adopting a proactive approach to upkeep can significantly extend the lifespan of these crucial systems. Here are some essential practices to consider for optimal performance and longevity.

Regular Fluid Checks

Maintaining the proper levels and quality of essential fluids is vital. Inspect the fluid regularly for signs of contamination or degradation. Change the fluid at recommended intervals to keep everything functioning smoothly. Clean, fresh fluid helps reduce wear and ensures effective operation.

Routine Inspections and Adjustments

Conducting periodic inspections can help identify potential issues before they escalate. Look for leaks, unusual noises, or performance changes that may indicate underlying problems. Timely adjustments and repairs can prevent more significant damage, saving both time and money in the long run.

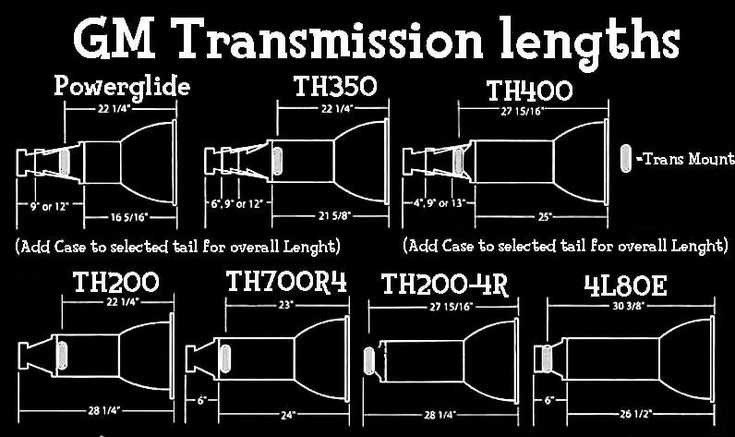

TH400 vs. Other Transmissions

This section explores the distinctions between various automotive gear-shifting mechanisms, highlighting their unique characteristics and performance metrics. Understanding these differences is crucial for enthusiasts and builders alike, as each design offers specific advantages suited to different driving needs.

| Feature | TH400 | Other Options |

|---|---|---|

| Weight | Heavy | Varies |

| Durability | High | Medium to High |

| Efficiency | Moderate | High |

| Common Applications | Heavy-Duty | Various |

Ultimately, each mechanism has its pros and cons, making the selection process highly dependent on the desired application and performance outcomes.

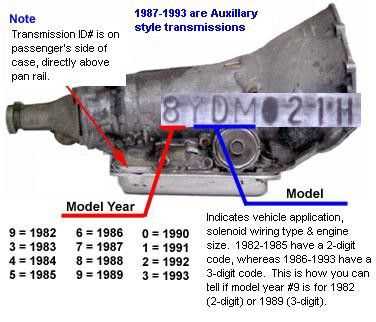

How to Identify TH400 Components

Recognizing the various elements within a specific gear mechanism is crucial for proper maintenance and repair. Each component plays a vital role in ensuring smooth operation and reliability. Familiarity with these parts enables effective troubleshooting and enhances overall performance.

Key Components to Recognize

- Case: The outer shell that houses all internal components.

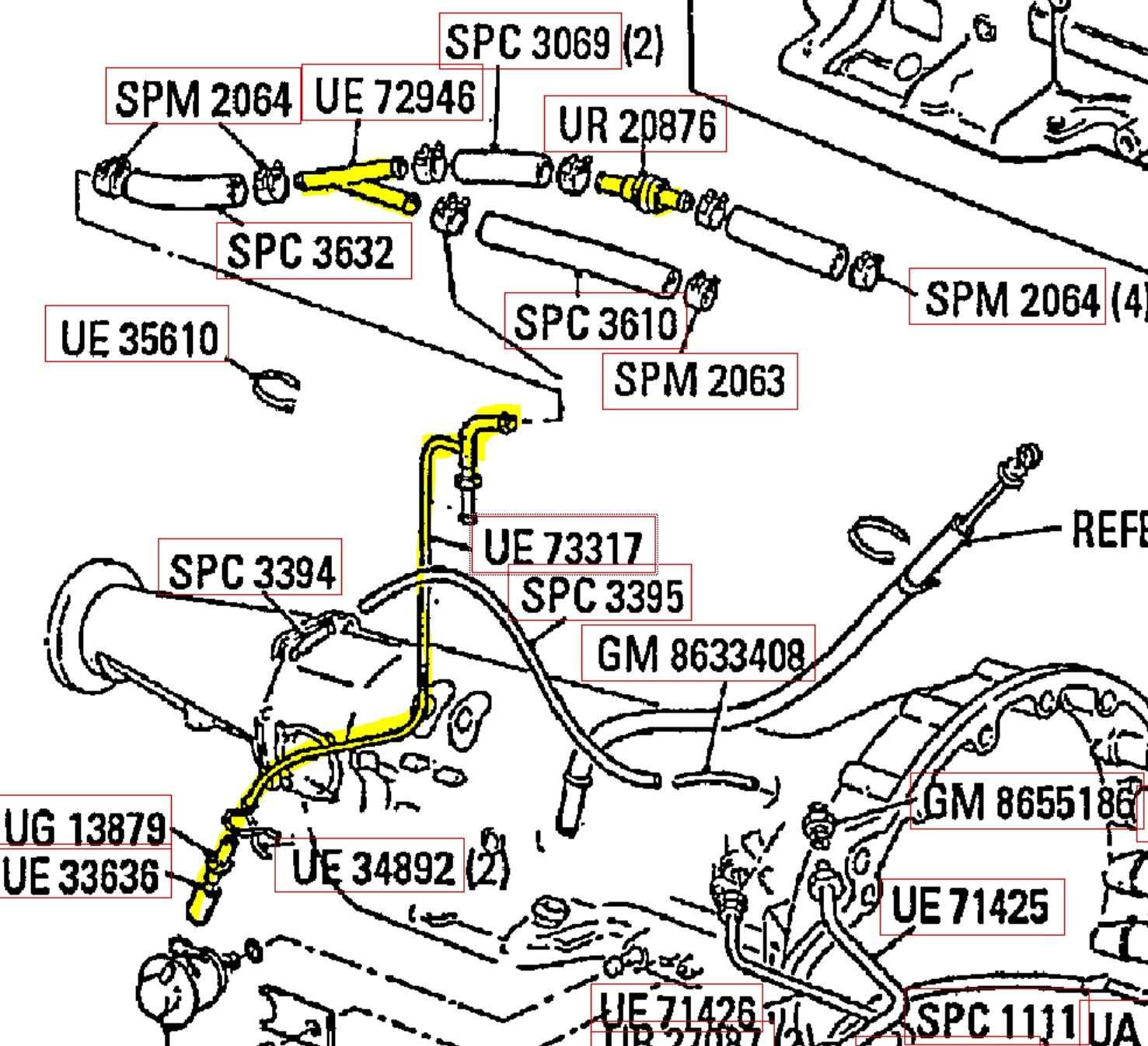

- Valve Body: Controls fluid flow and pressure, essential for gear shifts.

- Clutch Packs: Engages and disengages gears during operation.

- Planetary Gear Set: Responsible for gear ratios and torque multiplication.

- Oil Pump: Circulates fluid throughout the system, crucial for lubrication.

Identification Tips

- Check the manufacturer’s markings on each component for identification.

- Refer to repair manuals or online resources for visual references.

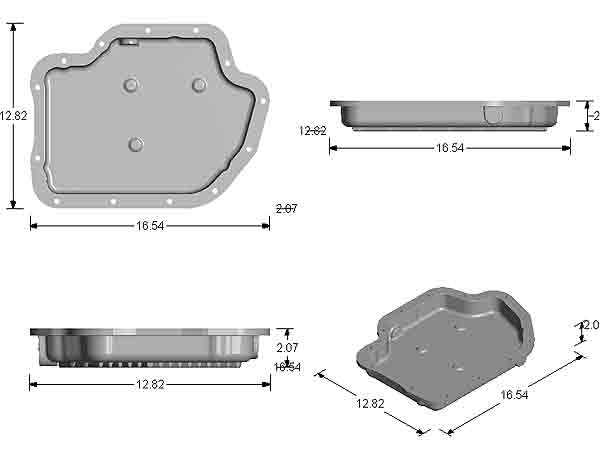

- Use a caliper to measure dimensions, ensuring compatibility with replacements.

- Look for wear signs, such as discoloration or uneven surfaces.

Understanding these critical elements will aid in maintaining the efficiency of your system and prolonging its lifespan.

Aftermarket Parts for TH400

Upgrading components for this well-known automatic gearbox can significantly enhance performance and reliability. Enthusiasts often seek alternative solutions that improve efficiency, durability, and overall driving experience. The market offers a variety of enhancements, catering to both everyday drivers and those looking for high-performance options.

Many opt for high-performance clutches and bands designed to withstand increased torque, ensuring smoother shifts and greater longevity. Additionally, improved valve bodies provide better fluid management, resulting in quicker response times and enhanced power delivery. Other common upgrades include heavy-duty servo kits that boost line pressure for firmer shifts, promoting a more engaging driving experience.

For those interested in tuning, modular kits allow for customizable setups that suit specific driving styles, whether it be for racing or off-road adventures. Cooling systems also play a crucial role in maintaining optimal operating temperatures, which can further increase the lifespan of the assembly under demanding conditions.

Ultimately, selecting quality alternatives from reputable manufacturers ensures not only better performance but also peace of mind, knowing that the chosen enhancements are built to last.

Installation Process Explained

Understanding the assembly procedure for your vehicle’s mechanical system is crucial for ensuring optimal performance. This segment will guide you through the essential steps involved in the setup, emphasizing precision and attention to detail.

First, gather all necessary components and tools to streamline the process. Having everything at hand minimizes interruptions and enhances efficiency. Ensure you follow safety protocols to protect yourself during the installation.

Next, carefully position the unit within the designated area of your vehicle. It’s important to align it properly to avoid future complications. Take your time here, as this step lays the groundwork for a successful assembly.

Once positioned, begin securing the unit with the appropriate fasteners, making sure to adhere to the specified torque settings. This ensures stability and prevents any potential leaks or failures. Regularly double-check your work to maintain accuracy throughout the process.

Finally, once everything is in place, perform a thorough inspection. Test the system to ensure all components are functioning seamlessly together. Proper testing is the ultimate way to confirm that your installation has been executed flawlessly, setting the stage for reliable performance on the road.

Upgrades for Enhanced Performance

Improving the functionality of your vehicle’s drivetrain can lead to significant gains in power, efficiency, and overall driving experience. Whether you’re looking to boost acceleration, improve shifting response, or enhance durability, several modifications can help you achieve your performance goals. Understanding the best components to upgrade is essential for maximizing the potential of your system.

Key Upgrades to Consider

When considering enhancements, it’s important to focus on components that contribute to better performance. Upgrades can range from improved fluid systems to high-quality internal mechanisms. Below is a table outlining some popular modifications and their benefits:

| Upgrade | Description | Benefits |

|---|---|---|

| High-Performance Clutch | A robust clutch designed to handle increased torque. | Improved engagement and reduced slippage. |

| Aftermarket Valve Body | An upgraded valve body that enhances fluid flow and shifting precision. | Faster, more responsive shifts and better control. |

| Cooling System Upgrade | Enhanced cooling components to maintain optimal temperatures. | Reduced overheating and increased longevity. |

| Performance Fluid | High-quality fluids designed for extreme conditions. | Better lubrication and heat dissipation. |

Choosing the Right Modifications

Selecting the appropriate upgrades requires careful consideration of your vehicle’s intended use and performance objectives. It’s crucial to balance enhancements with the overall setup to ensure compatibility and reliability. Consulting with professionals or experienced enthusiasts can provide valuable insights into making informed choices for your specific needs.

Resources for Further Learning

Understanding the intricate components of automotive mechanisms can greatly enhance both practical skills and theoretical knowledge. This section offers valuable resources to deepen your comprehension and expertise in this area, whether you are a novice enthusiast or a seasoned professional.

Books and Manuals

Exploring literature dedicated to automotive systems is essential for gaining foundational knowledge. Comprehensive guides and technical manuals provide insights into design, functionality, and repair techniques. Look for publications that focus on mechanical engineering and automotive repair for detailed information.

Online Forums and Communities

Engaging with online communities can be a rich source of information. Discussion platforms and forums allow enthusiasts to share experiences, ask questions, and obtain advice from knowledgeable peers. Participating in these groups can provide real-world insights and troubleshooting tips that are invaluable for hands-on learning.