Maintaining outdoor equipment requires a good understanding of how each individual piece functions. Whether you’re repairing or upgrading, knowing the layout and connections of various components is essential for efficient operation. This overview provides insights into how different elements of a landscaping tool fit together, helping ensure that everything works in harmony.

By exploring the configuration and placement of key elements, you can avoid potential malfunctions and extend the life of your machine. Recognizing the importance of each piece will not only aid in repairs but also enhance the performance of your equipment over time.

In this guide, we’ll look at how all the primary sections come together to form a complete system, focusing on clear explanations to

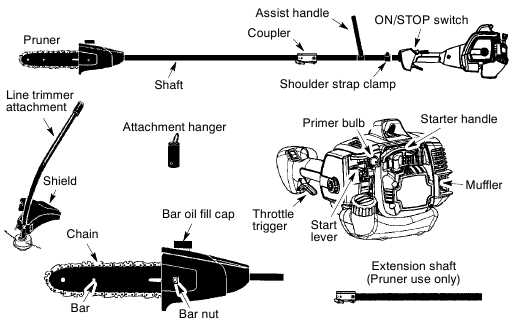

Poulan Pro Trimmer Overview

When it comes to efficient landscaping tools, few products stand out as much for their reliability and performance. This model is designed to handle a variety of tasks, from maintaining garden edges to managing overgrown areas. Its structure is built to deliver power while maintaining ease of use, making it a versatile option for both light and more demanding yard work.

Key features include an ergonomic design, allowing comfortable operation for extended periods, and a powerful engine capable of tackling tough jobs. The equipment is also engineered with durability in mind, ensuring long-term functionality even in challenging conditions. Its simplicity and adaptability make it a favorite among homeowners looking for practical outdoor

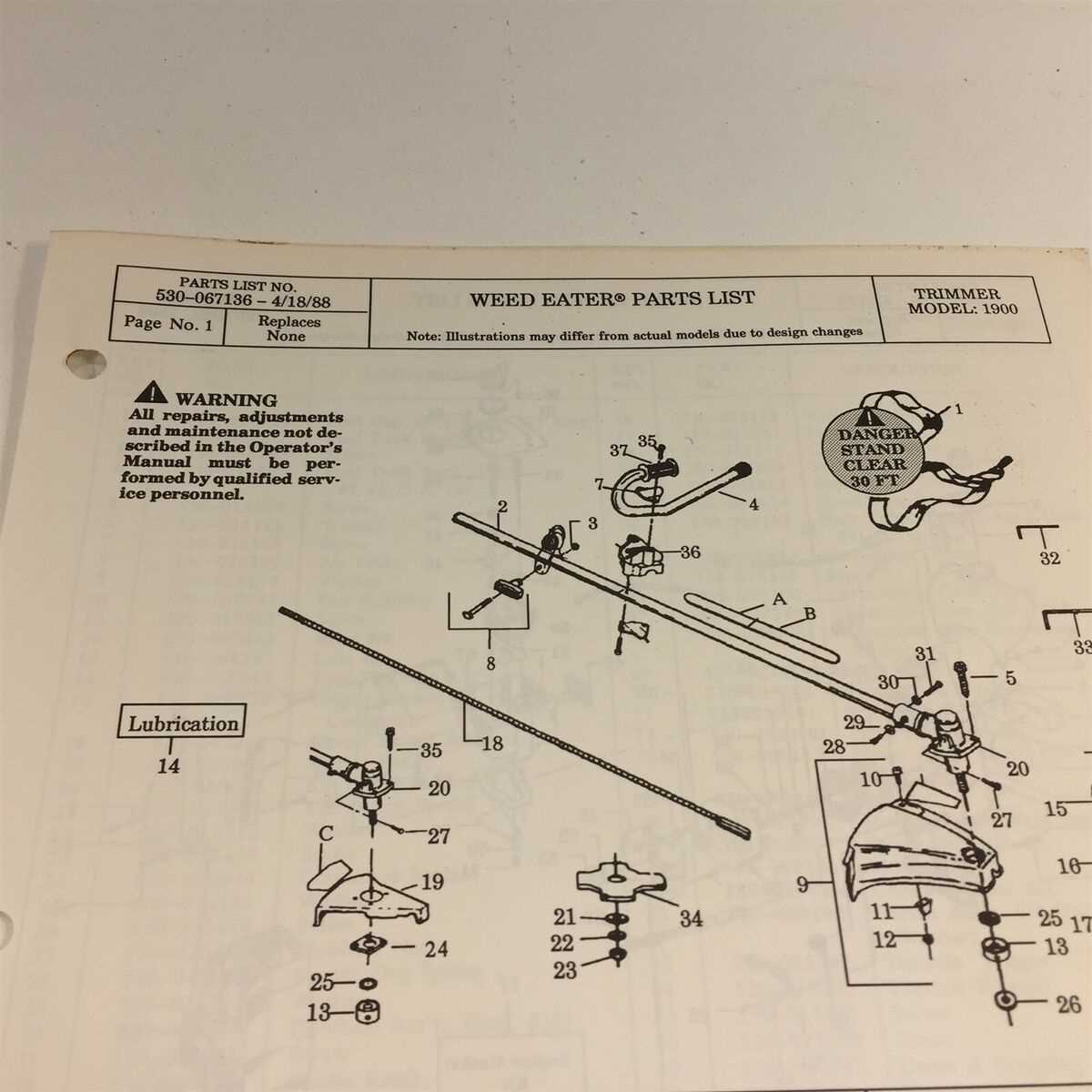

Key Components of the Trimmer

Understanding the fundamental parts of any handheld cutting device is essential for efficient use and maintenance. Each element plays a vital role in ensuring optimal performance, from power delivery to precision cutting. These elements are designed to work together seamlessly, contributing to a smooth and reliable operation.

Engine is the core that powers the entire tool, transforming energy into motion to drive the cutting head. It provides the necessary force to tackle various tasks, making sure the device runs smoothly.

Cutting Head is responsible for the actual trimming process, spinning rapidly to slice through unwanted vegetation. This is where the physical interaction with the material happens,

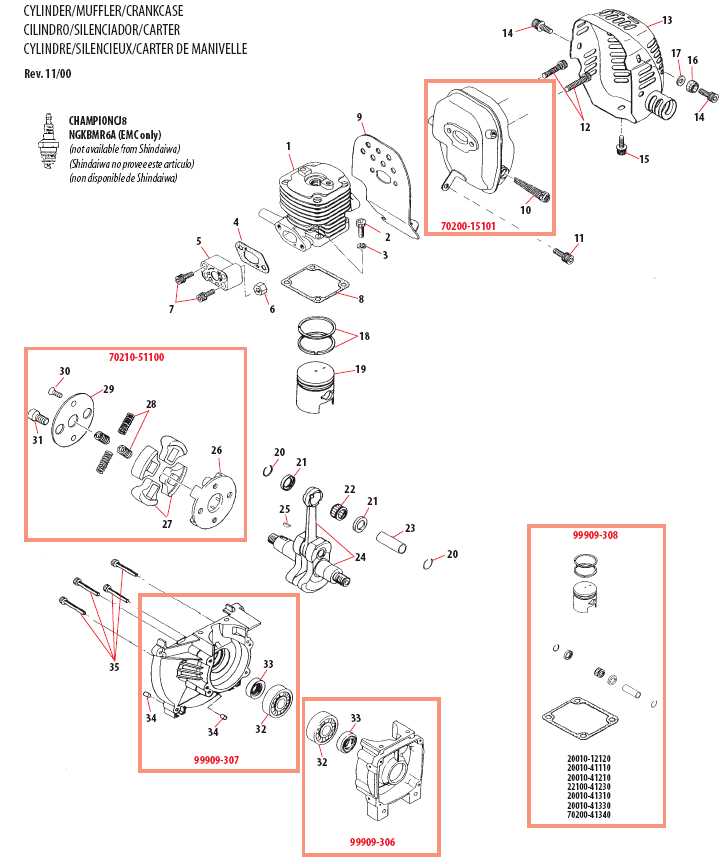

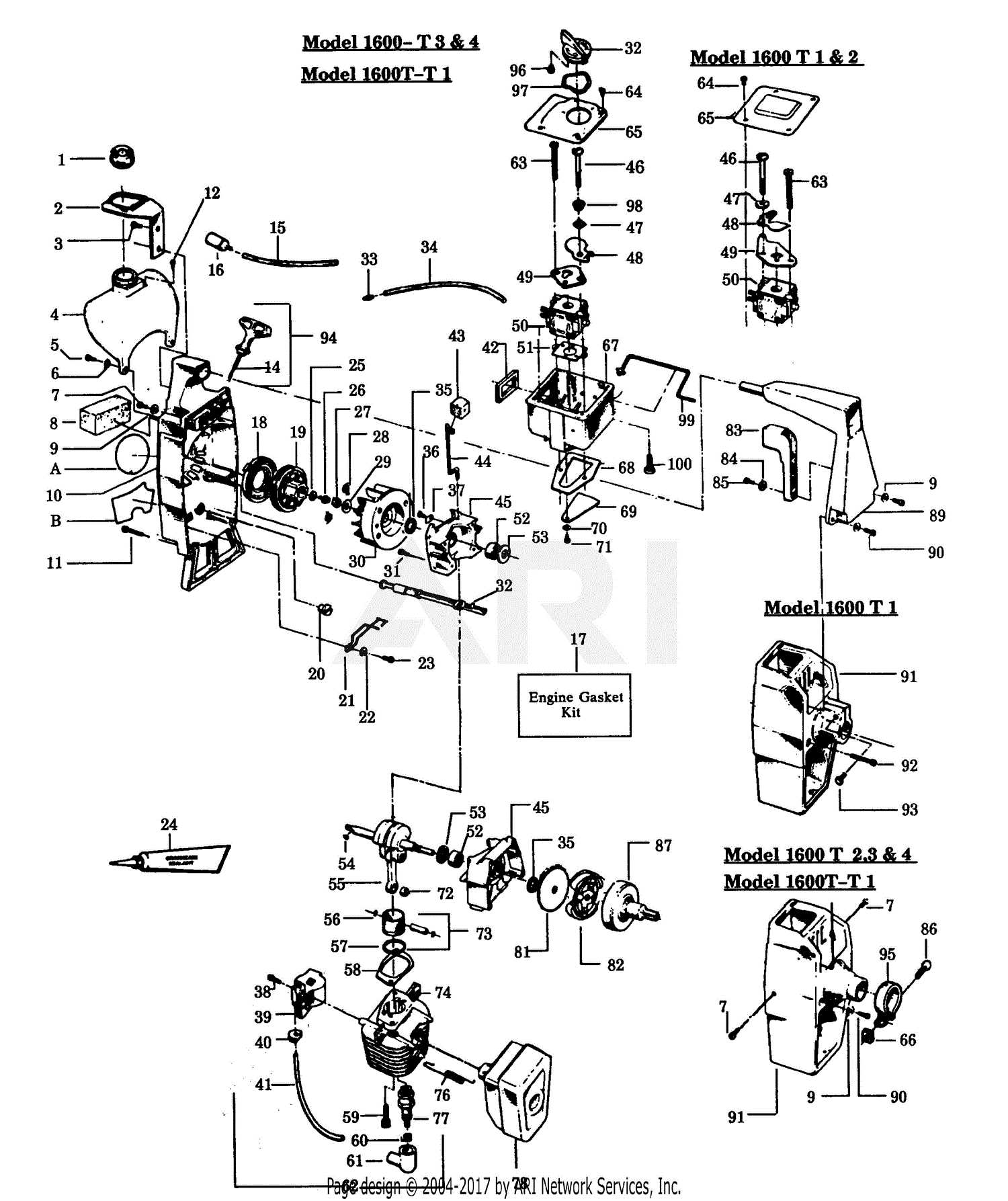

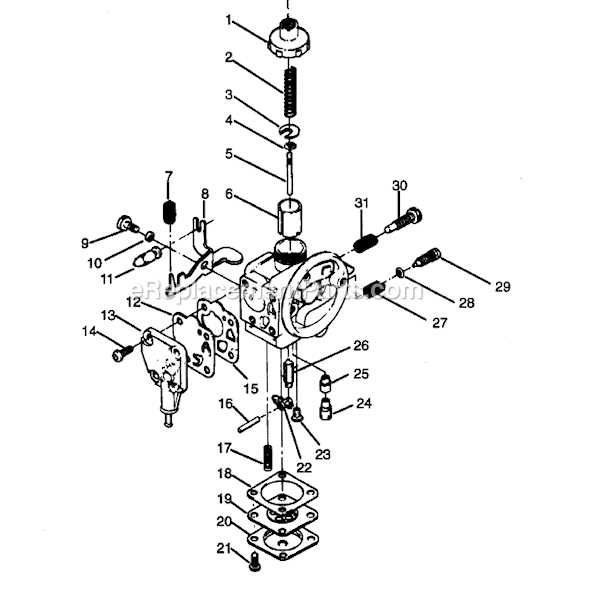

Understanding the Engine Assembly

When examining the core of any handheld equipment, it’s important to familiarize yourself with the main engine components. These elements work together to ensure the tool functions efficiently, powering the device and allowing for smooth operation. Understanding the structure of this key system is crucial for proper maintenance and potential troubleshooting.

Main Components of the Engine

The engine assembly typically consists of several integral parts, each contributing to the overall performance. These include the cylinder, piston, crankshaft, and other vital components that play a role in generating power. Knowing how these elements interact helps maintain the system’s durability.

Key Component Overview

| Component | Function |

|---|

| Component |

|---|

| Component | Function |

|---|---|

| Fuel Tank | Holds the fuel required for operation. |

| Fuel Lines | Transport fuel from the tank to the engine. |

| Filter | Cleans the fuel before it enters the engine, preventing debris from causing damage. |

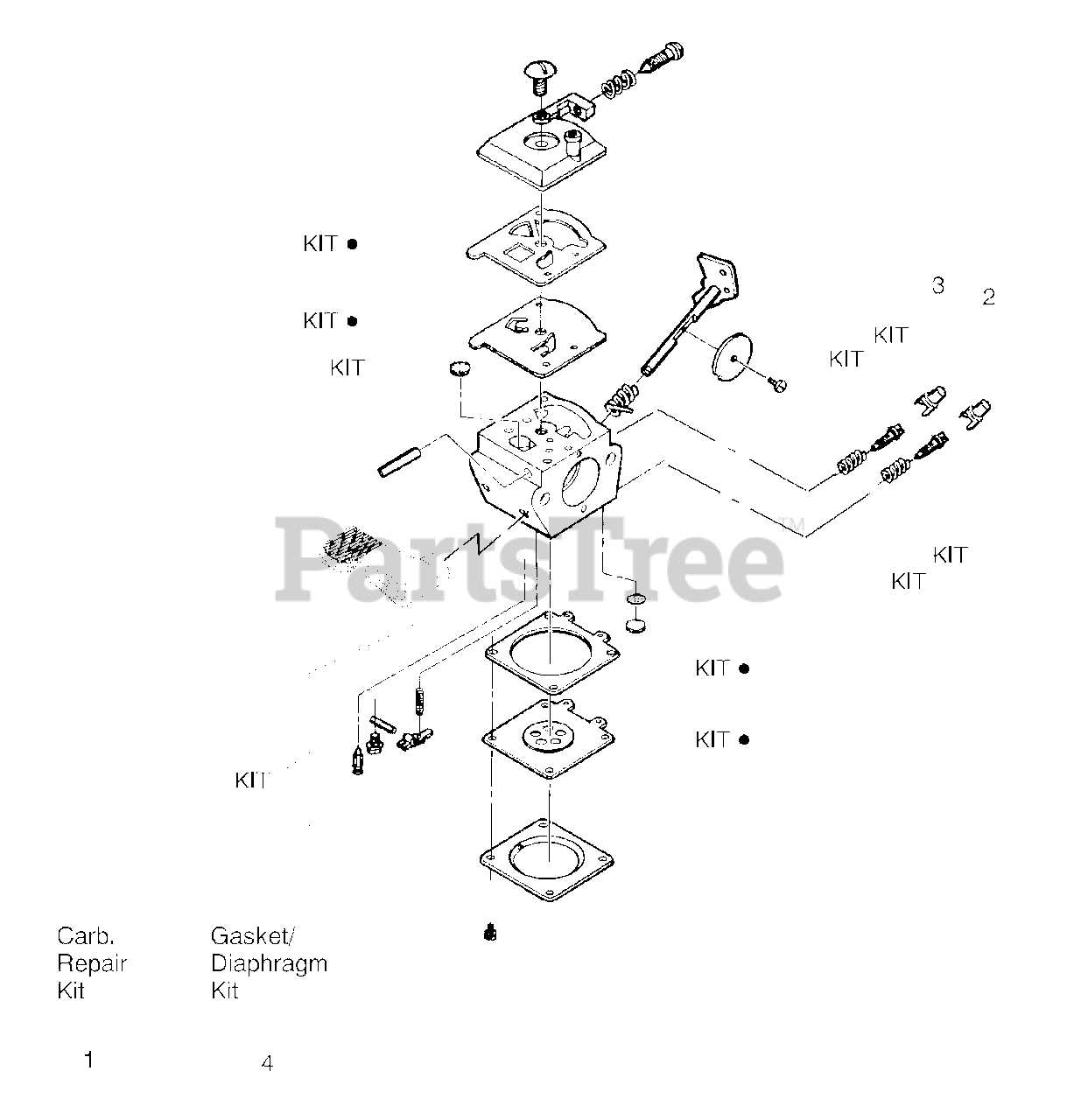

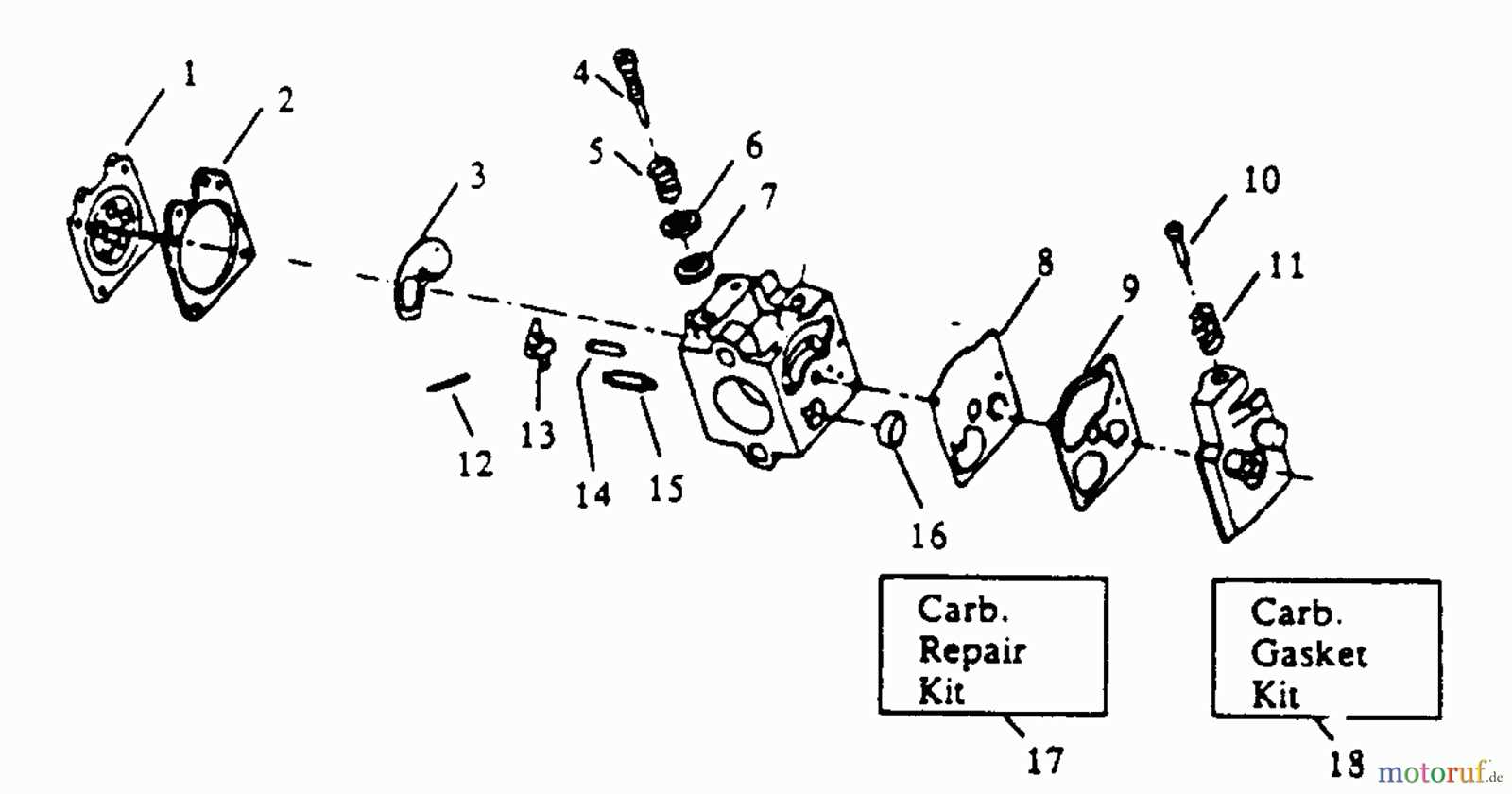

| Carburetor | Mixes fuel with air in the correct proportions for combustion. |

Exploring Fuel Line and Filter Setup

Understanding the configuration of the fuel delivery system is crucial for optimal performance and reliability of your equipment. This system plays a vital role in ensuring that the engine receives a consistent flow of fuel, which is essential for effective operation. Proper installation and maintenance of these components can significantly enhance the lifespan of your machine.

Components of the Fuel Delivery System

- Fuel Line: This conduit transports fuel from the tank to the engine.

- Fuel Filter: This element ensures that contaminants are removed from the fuel before it reaches the engine.

- Fuel Primer Bulb: Used to purge air from the fuel line and facilitate easy starting.

Installation Tips

- Ensure that the fuel line is correctly routed to prevent kinks or bends that could restrict flow.

- Regularly check and replace the fuel filter to maintain efficient fuel flow.

- Inspect the primer bulb for any signs of damage or wear; replace it if necessary to ensure proper fuel priming.

- Use appropriate clamps to secure the fuel line connections, preventing leaks and ensuring a tight seal.

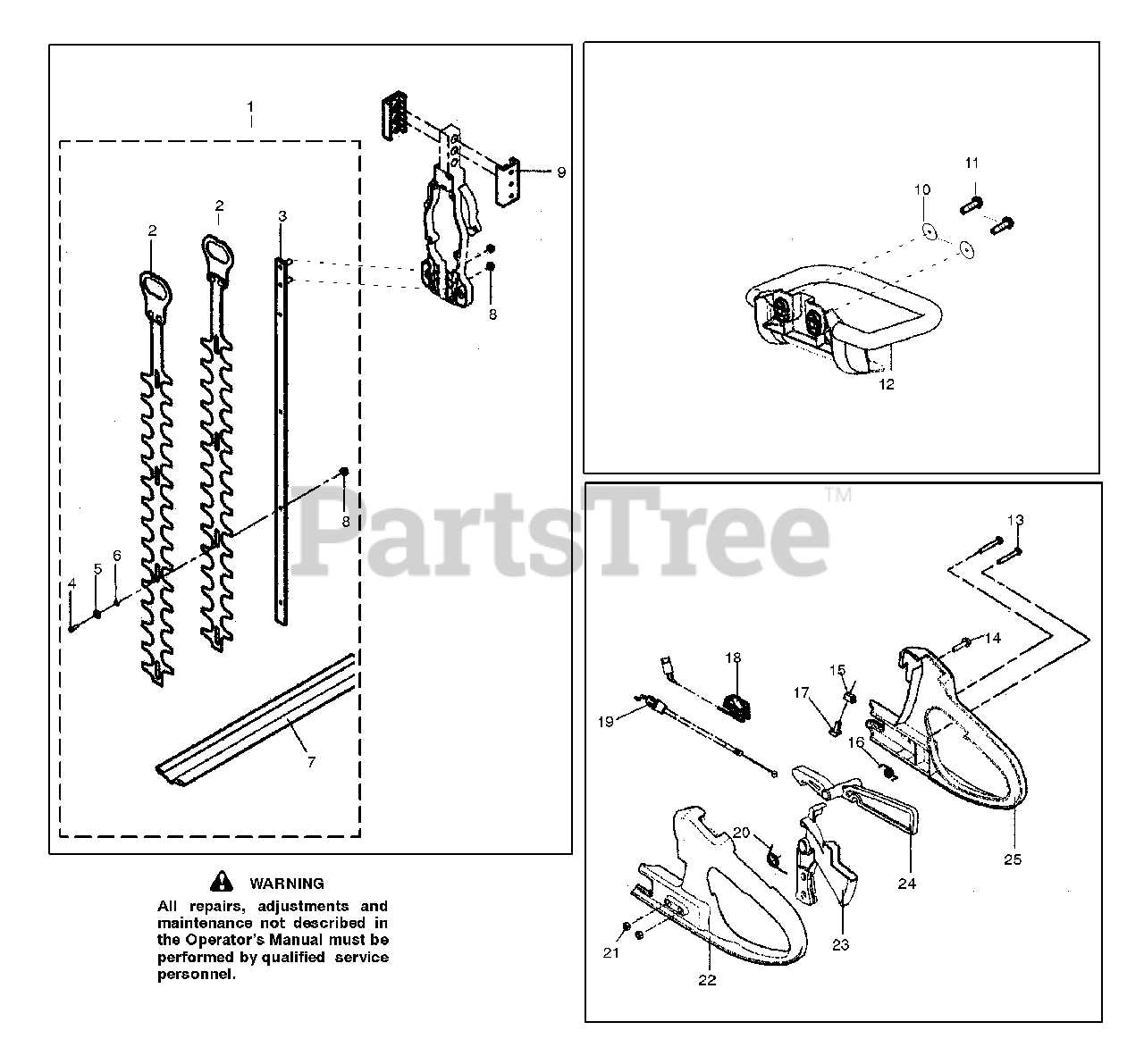

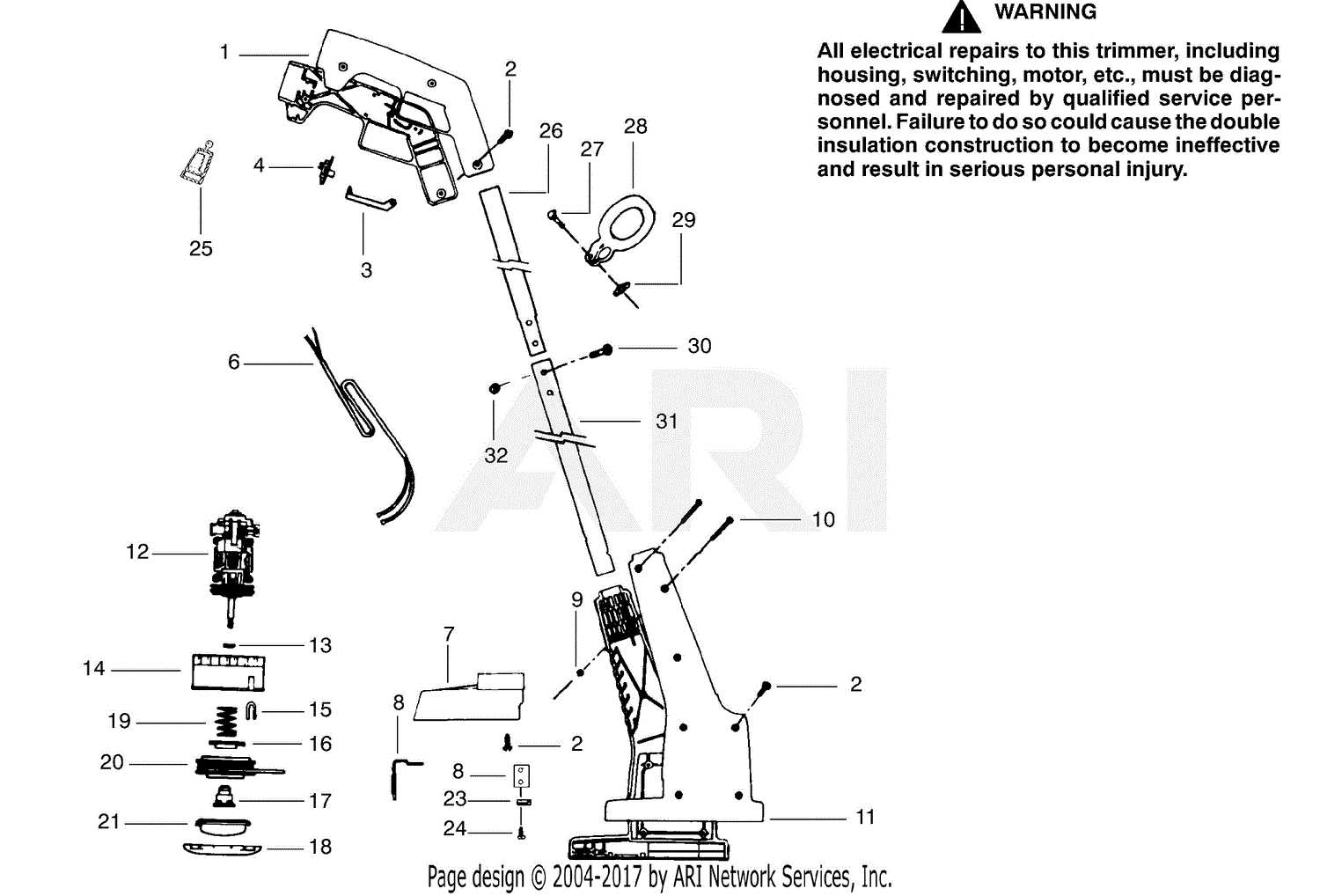

Handle and Trigger Mechanism

The handle and trigger assembly plays a crucial role in the operation of outdoor power equipment. This section will explore the functionality, design features, and maintenance tips associated with this vital component.

Functionality and Design

The handle and trigger mechanism allows users to control the operation of the equipment with ease. Key features include:

- Ergonomic design for comfortable handling

- Responsive trigger action for optimal control

- Integrated safety features to prevent accidental activation

Maintenance Tips

To ensure the longevity and efficiency of the handle and trigger assembly, consider the following maintenance practices:

- Regularly inspect for signs of wear or damage.

- Clean the handle and trigger area to prevent debris buildup.

- Lubricate moving parts to ensure smooth operation.

- Replace any broken or malfunctioning components promptly.

Details of Control and Operation

The effective management and functioning of lawn maintenance equipment depend on a variety of control mechanisms and operational components. Understanding these elements can significantly enhance performance and ensure smooth operation.

At the core of this equipment lies a sophisticated system designed to facilitate user interaction and manipulate various settings. Key components include the throttle control, which adjusts engine speed, and the on/off switch, which governs the overall operation. Familiarity with these elements is essential for achieving optimal performance and ensuring safe usage.

| Component | Function |

|---|---|

| Throttle Control | Regulates engine speed for varying tasks. |

| On/Off Switch | Controls the overall power supply to the equipment. |

| Choke Lever | Assists in starting the engine, particularly in cold conditions. |

| Trigger | Activates the cutting mechanism based on user input. |

| Safety Lock | Prevents accidental activation of the equipment. |

By mastering these control features, users can enhance their efficiency and achieve the best results while operating the equipment.

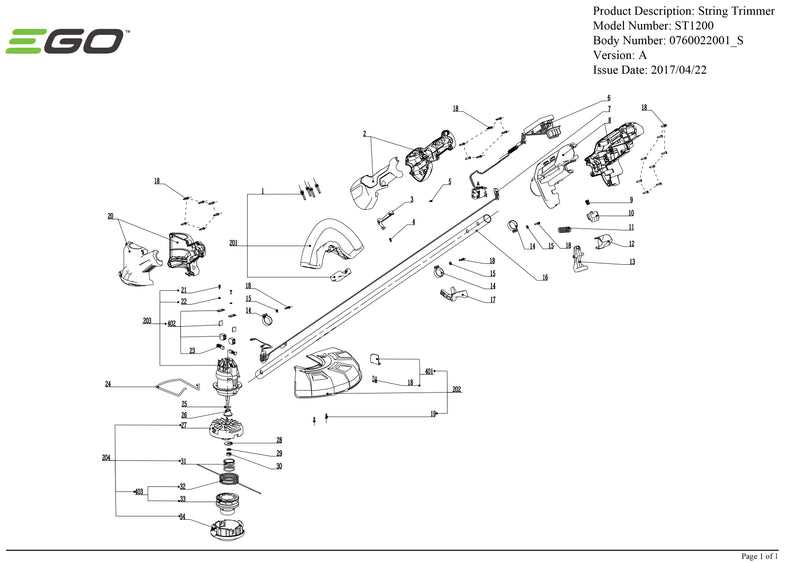

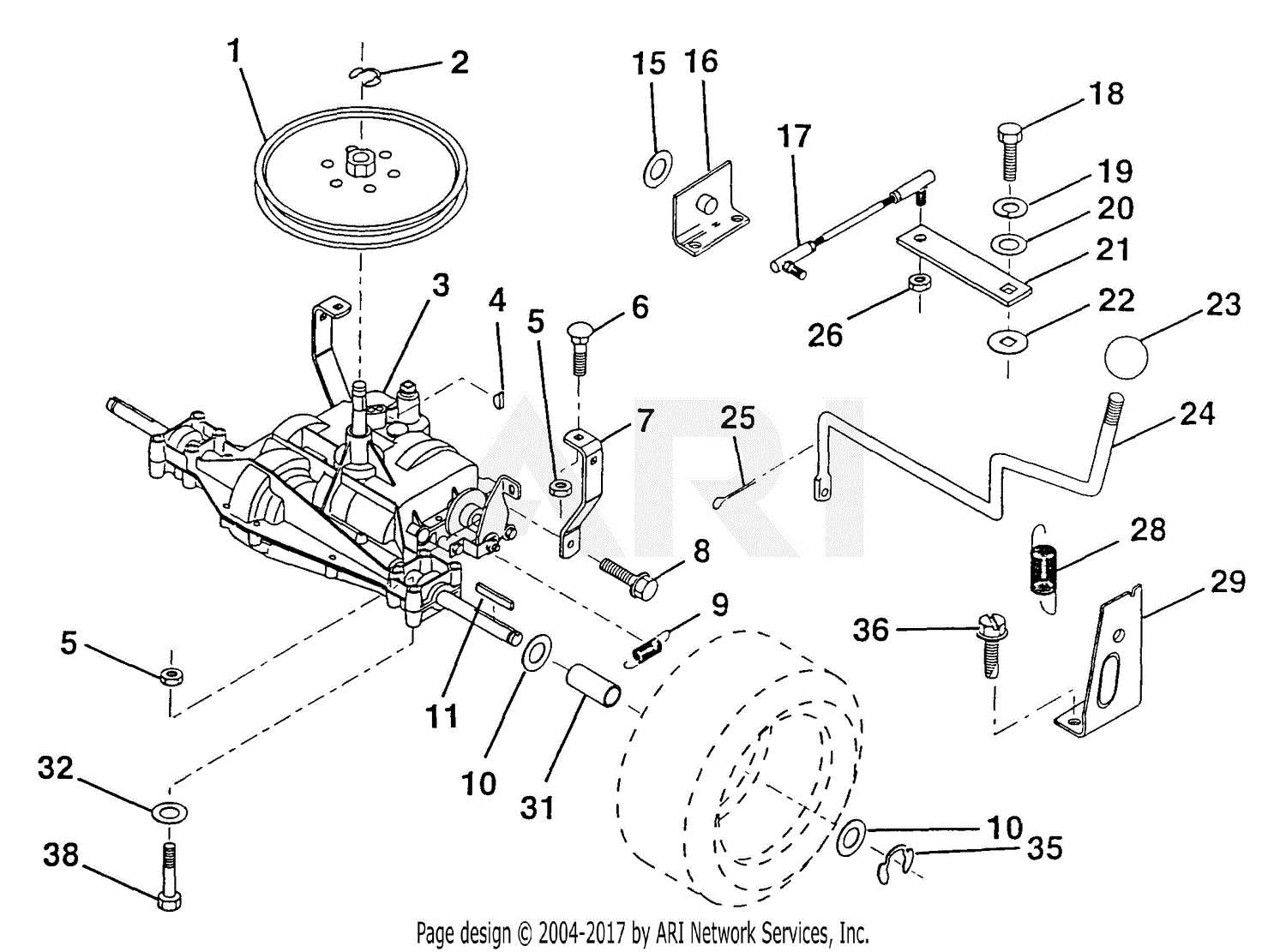

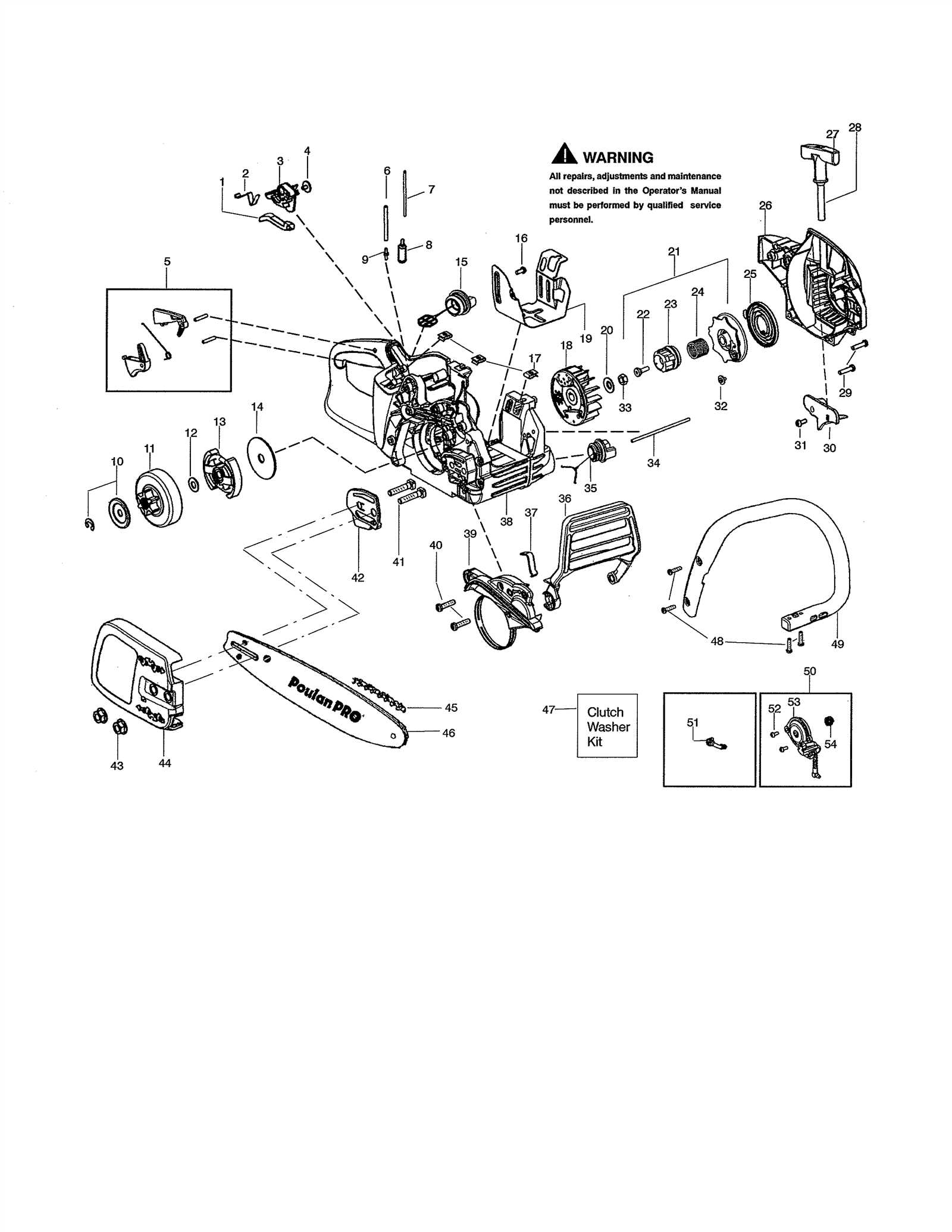

Drive Shaft and Transmission Assembly

The drive shaft and transmission assembly play a crucial role in the efficient functioning of outdoor power equipment. This assembly transmits rotational force from the engine to the cutting mechanism, ensuring that the device operates smoothly and effectively. Understanding the components and their arrangement within this assembly can aid in troubleshooting and maintenance, ultimately enhancing performance and longevity.

Key Components

The assembly comprises several essential components that work together to facilitate motion. These elements include the drive shaft, transmission casing, and associated gears, each contributing to the overall efficiency of the system.

| Component | Description |

|---|---|

| Drive Shaft | A cylindrical rod that transmits rotational power from the engine to the transmission. |

| Transmission Casing | The outer housing that protects internal gears and components from debris and damage. |

| Gears | Mechanical parts that alter the rotational speed and direction of the drive shaft’s movement. |

Maintenance Tips

Regular inspection and maintenance of the drive shaft and transmission assembly are vital for optimal performance. Ensure that all components are free from debris and properly lubricated. Replacing worn-out gears and checking for any misalignments can significantly improve the efficiency and lifespan of the equipment.

Connecting Power from Engine to Head

The transmission of energy from the motor to the cutting assembly is essential for the effective operation of gardening equipment. This process involves several components working in harmony to ensure smooth functionality, enabling the tool to perform its intended tasks efficiently.

Components Involved

- Engine: The primary source of power.

- Drive Shaft: A crucial element that transfers motion.

- Gearbox: Modulates the rotational speed and torque.

- Cutting Head: The part that interacts with the material being cut.

Steps for Proper Connection

- Ensure that the engine is securely mounted to avoid vibrations.

- Connect the drive shaft to the engine output, ensuring a snug fit.

- Attach the gearbox to the end of the drive shaft, aligning it properly.

- Securely fasten the cutting head to the gearbox, ensuring all connections are tight.

- Check for any misalignments or loose parts before operating.

Air Filter System

The air filtration system plays a crucial role in ensuring optimal performance and longevity of outdoor power equipment. It is designed to prevent dirt, debris, and contaminants from entering the engine, thereby maintaining its efficiency and reducing wear.

Maintaining the integrity of this system is essential for reliable operation. A clean and functional air filter allows for better airflow, enhancing combustion and overall performance. Neglecting this component can lead to reduced power output and potential engine damage.

- Function: The primary function of the air filtration system is to clean the incoming air before it reaches the engine.

- Components: Typical components include the air filter, housing, and often a pre-filter.

- Maintenance: Regular inspection and replacement of the air filter are vital for optimal performance.

- Signs of Issues: Reduced power, increased fuel consumption, and difficulty starting can indicate a problem with the air filter system.

In summary, the air filtration system is an integral part of outdoor equipment, directly influencing performance and durability. Ensuring its cleanliness and functionality is paramount for achieving the best results.